Construction of Microdrive Arrays for Chronic Neural Recordings in Awake Behaving Mice

Summary

The design and assembly of microdrives for in vivo electrophysiological recordings of brain signals from the mouse is described. By attaching microelectrode bundles to sturdy driveable carriers, these techniques allow for long-term and stable neural recordings. The lightweight design allows for unrestricted behavioral performance by the animal following drive implantation.

Abstract

State-of-the-art electrophysiological recordings from the brains of freely behaving animals allow researchers to simultaneously examine local field potentials (LFPs) from populations of neurons and action potentials from individual cells, as the animal engages in experimentally relevant tasks. Chronically implanted microdrives allow for brain recordings to last over periods of several weeks. Miniaturized drives and lightweight components allow for these long-term recordings to occur in small mammals, such as mice. By using tetrodes, which consist of tightly braided bundles of four electrodes in which each wire has a diameter of 12.5 μm, it is possible to isolate physiologically active neurons in superficial brain regions such as the cerebral cortex, dorsal hippocampus, and subiculum, as well as deeper regions such as the striatum and the amygdala. Moreover, this technique insures stable, high-fidelity neural recordings as the animal is challenged with a variety of behavioral tasks. This manuscript describes several techniques that have been optimized to record from the mouse brain. First, we show how to fabricate tetrodes, load them into driveable tubes, and gold-plate their tips in order to reduce their impedance from MΩ to KΩ range. Second, we show how to construct a custom microdrive assembly for carrying and moving the tetrodes vertically, with the use of inexpensive materials. Third, we show the steps for assembling a commercially available microdrive (Neuralynx VersaDrive) that is designed to carry independently movable tetrodes. Finally, we present representative results of local field potentials and single-unit signals obtained in the dorsal subiculum of mice. These techniques can be easily modified to accommodate different types of electrode arrays and recording schemes in the mouse brain.

Introduction

The use of the microelectrode technique for recording extracellular neural signals in vivo has a long and valued tradition in neuroscience 1, 2. The ability to record electrical activity from many brain regions in freely behaving animals is, however, a more recent technology that is becoming increasingly common as the software packages for the acquisition, analysis and discrimination of neural signals becomes more sophisticated and user-friendly 3, 4. The technological advances on the software side have also been accompanied by reductions in the weight and bulk of the implantable devices, which have been scaled down sufficiently for recording in small mammals, such as mice. By using lightweight (mostly plastic) components, researchers are able to construct microdrives that allow for independent positioning of electrodes or tetrodes to target a wide variety of brain regions 5-7. Even deep brain structures, such as the amygdala 6 and the striatum 5, can be routinely targeted with the selection of an appropriately long drive screw. These recording techniques allow researchers to obtain high-fidelity neural signals and are in register with the electrical activity of single neurons recorded intracellularly 8, 9. Using these types of microdrives, we have successfully recorded single-units from mice for up to two months after implantation 10. In addition, the lightweight nature of the devices (approximately 1.5-2.0 g) has resulted in behavioral performance that is comparable to non-implanted mice in many behavioral tasks. In particular, we have demonstrated that implanted mice exhibit normal performance in the novel object recognition task 10 and the object place task (unpublished data).

The use of microdrives coupled to multiple tetrodes allows researchers to monitor and analyze neural activity at the network level while also recording from multiple single-units within the brain. Recording with these tetrodes has several major advantages for unit identification purposes and enables the high accuracy acquisition and discrimination of multiple single-units 11. We describe how to fabricate and gold-plate tetrode bundles and then subsequently load them into driveable electrode carriers. One type of drive carrier we describe is commercially available and the other is a simple, but easily expandable, drive design that can accommodate multiple carriers and tetrode arrangements without a significant investment of resources.

Protocol

1. Tetrode Fabrication

- Start by using insulated 12.5 μm (0.0005″) diameter core platinum-iridium wire from California Fine Wire. The length of the wire should be cut to the appropriate length for the target structure. For example, cut the wire to at least 30 cm long for targeting the dorsal subiculum or hippocampus.

- Fold the wire over at the center so that there are two parallel wires which will be 15 cm in length. Drape the midpoint of this wire over a horizontal arm to form four parallel wires of 7.5 cm in length. Next attach the rubber-coated clip near the bottom of the draped wire, creating a bundle of four wires.

- Place the rubber clip into the motorized Tetrode Spinner, making sure that the wire is taut, but not too taut or bearing weight as it will break during the spinning process.

- Switch the Tetrode Spinner to “Manual” mode and push the joystick to “Right” to spin the wire in a clockwise direction. The spinner will rotate at approximately 2 Hz, creating a tight bundle of four wires to form the tetrode.

- Apply 80 clockwise rotations then stop by pushing “Up” on the joystick. This will pause the motorized spinner. Next, apply 20 counter-clockwise (“Left”) rotations in order to release tension on the tetrode. The final number of rotations per length of wire should be 8 rotations per micron.

- Use the heating gun on the lower setting 1, which reaches a maximum of 400 degrees, in order to fuse the wires together by melting the VG bond coat. Hold the heat gun ~2 cm from the wire and run the gun up and down the straight length of the wire for about 5 sec from several different angles. Make sure to constantly sweep the heat gun and not hold it any single location as this will melt the HML insulation and cause the wires to fuse together within the bundle.

- Make a cut at the top of the tetrode (near the horizontal arm) and then release the tetrode from the clip at the bottom. Cut the single loop so that there are four separate wires on one end of the tetrode, these wires will be electrically connected to gold pins or a circuit board at a later step.

- Place the completed tetrode in a dust-free holding box for storage until the drive has been completed.

2. Custom Microdrive Assembly

- First construct the base that will hold the microdrive(s). The base of the implanted microdrive is generally most stable if it is secured and positioned along the midline of the skull. This protocol describes steps to build a base with a single microdrive to hold four polyamide tube carriers. Additional microdrives and tubes can be easily added as needed.

- Start with an approximately 20 mm square piece of Plexiglas acrylic (5 mm thick) and sand the acrylic into a shape that will allow the mouse to move freely with the drive after it is implanted on the head.

- Next, assemble the drive unit. Use customized 3.3 x 6.3 mm brass guides that will carry the drive screw. First, solder two brass guides together perpendicularly. The vertical brass guide will hold the drive screw and electrodes, while the horizontal piece will be glued into the acrylic base.

- After soldering the brass pieces together, begin assembly of the drive itself by passing a fillister head brass screw through the top of the guide and into a Delrin plastic block. The square block is designed so that the thread hole is slightly off center (by 0.2 mm), resulting in one face of the block protruding very slightly from the guide. This is the side where the polyamide tubes carrying the electrodes will sit.

- With the Delrin block inside the guide, and the screw all the way through, thread a hex brass nut until the nut is nearly touching the bottom of the guide. Do not tighten the nut fully; instead melt a small amount of solder onto the end in order to join the nut and the screw but being careful not to solder anything to the guide. Now, rotating the screw should move the Delrin block up (clockwise) and down (counterclockwise) vertically along the screw thread. Cut off thread that protrudes past the soldered nut.

- Once the drive has been assembled, go back to the acrylic base and cut a 3 mm wide slot where the electrode drive will be. Pass the horizontal brass guide through the slot and then use cryanoacrylate glue to secure the piece to the base.

- Place the acrylic base in a vise to secure it in place. Place a electronic interface board (EIB) on top of the base and mark the locations of the two screw holes. EIBs are microchips that provide a signal connection between the electrode wires and a pre-amplifier headstage. Using a 1.5 mm tip drill bit, carefully drill holes at the marks for screws that will hold the EIB in place on top of the base. Place the EIB and thread two brass screws into the holes.

- Use micro dissecting scissors to cut four 7 mm long pieces of polyamide tubing. Line the four tubes next to each other on a piece of folded laboratory tape. Apply cyanoacrylate to the center to join them together but take caution not to get glue within the tubes themselves. Allow the joined tubes to dry fully.

- Rotate the drive base 90 degrees so that the EIB chip is vertical and the drive is positioned horizontally with the protruding Delrin block facing upward. Looking through a dissecting microscope, carefully dab a small amount of cyanoacrylate on the Delrin face then place the four joined tubes on the glue. Allow the glue to set completely before attempting to move the drive.

- Test that the polyamide tubes are securely attached and that the entire assembly moves smoothly without touching the guide or meeting any resistance.

- Next, prepare the ground screw and connect the ground wire to the EIB. Make a ground screw by taking a brass screw (3/32″) and sanding down the threads until only 1-2 threads remain. This should be ~1 mm as this screw will sit within the skull and is not intended to penetrate brain tissue.

- Cut a 30 mm length of copper wire (the exact length will depend on where on the skull to place the animal ground). The copper wire should be 100 – 500 μM (0.004-0.02″) in diameter, this is roughly equivalent to 38 AWG thru 24 AWG wire. Apply solder flux to both ends of the copper wire. On one end, solder the ground screw to the wire. On the other end, solder an EIB gold pin. This ground wire can be set aside and connected to the EIB later during the implantation surgery.

- The next step is to guide the electrodes through the polyamide tubes and connect them to the channel holes on the EIB chip. Turn the drive screw fully clockwise so that the tubes are at their top position.

- For single electrodes, cut a 50 mm length of Stableohm 50 μM wire and guide it through one polyamide tube, allowing it to extend at least 2.0 mm past the tube end (for targeting subiculum or hippocampus). Apply a small drop of cyanoacrylate at the top of the tube, affixing the wire to the tube and preventing any wire movement. Next, connect the loose end of the wire to an EIB channel hole using a gold pin. Trim off any excess wire with fine scissors. Repeat for other microelectrodes.

- For connecting tetrodes, take one completed tetrode out of the storage box. Guide the fused end of the tetrode through one polyamide tube and allow it to extend at least 2.0 mm past the tube end (for subiculum or hippocampus). Apply a small drop of cyanoacrylate at the top of the tube, affixing the tetrode to the tube and preventing any movement. Take the four loose wires at the other end of the tetrode and connect each wire to an EIB channel hole using a gold pin. Trim off any excess wire. Repeat for the other tetrodes.

3. VersaDrive Assembly

- Begin constructing a four tetrode VersaDrive; this consists of a base, enclosure, and cap pieces.

- Cut one polyamide tubing to 10 mm and guide it through the smallest hole on a tetrode carrier. Allow the tube to extend past the carrier very slightly (0.5 mm). Use 5-min epoxy to glue the polyamide tube in place, being careful not to allow the epoxy to go into the tube itself. Repeat this for three other tubes and carriers.

- After the epoxy has fully set, guide each polyamide tube through one of the four holes on the VersaDrive base. Once all four tubes are through their holes, push an insect pin through the outer hole; this will hold the tetrode carrier in line and serve as a rail for the carrier to travel on. Repeat this for the three other carriers.

- Take a cap and line it up with the four insect pins so that the cap covers the base and the tetrode carriers reside within the cap. Thread a 1 mm x 5 mm machine screw through the appropriate hole in the cap and into the tetrode carrier. This will be the drive screw for moving the carrier up and down. Repeat this for the other three screws.

- Turn all screws clockwise until tetrode carriers are at their top position and the polyamide tubes are visible through the cap opening. Using fine micro dissecting scissors, cut the tubing just below (1 mm) the base so that all four polyamide tubes are of the same length.

- Using a dissecting microscope, carefully thread one tetrode through a polyamide tube. It is important to keep the tetrode wire perfectly straight as it advances through the tube as any kinks or bends will make it very difficult to fully thread the tetrode through. Repeat for three other tetrodes.

- Once all the tetrodes are in their tubes, carefully apply a small drop of cyanoacrylate to the top of each tube, securing the tetrodes within their respective tubes. Take caution not to get any cyanoacrylate between the carriers or on the loose tetrode wires that are protruding through the cap.

- Cut the tetrodes so that they only extend past the tubes 2.0 mm (for subiculum or hippocampus). Then place the drive base (with the four insect pins inserted) into the VersaDrive jig. The other half of the jig will hold the VersaDrive cap that has all the receptacle holes for making the channel connections.

- Turn the drive screw completely counterclockwise so that the tetrodes are in their lowest position.

- Before connecting the tetrode wires to the gold receptacles, first connect the ground wires to the cap. The VersaDrive cap has two pin holes for ground connections at the center position of the two rows of holes. Cut a copper wire of at least 30 mm (depends where on the skull to place the ground) and guide it through one of these center holes. The copper wire should be 100 – 500 μM (0.004-0.02″) in diameter, this is roughly equivalent to 38 AWG thru 24 AWG wire. Push a gold receptacle through the hole to catch the copper wire in place and trim any excess wire. On the other end of the copper wire, apply flux and solder this wire end to a ground screw (see 2.11.). Repeat for the second ground wire.

- Next, guide all the loose tetrode wires (there should be sixteen in total) through their respective receptacle holes on the cap. It’s best to start with one tetrode and thread the individual wires to the appropriate four holes that will end up directly above it. The individual tetrode wires should be handled with light pressure as they are fragile and can crimp easily if gripped too firmly. Install the cap by lining up the insect pins holes and press fitting to the base.

- With the tetrode wires protruding through the cap, press fit the gold receptacles to capture the tetrode wires in place and make the electrical connections. Approximately 50% of the wires will be clipped off (above the cap) once the gold receptacle is pushed down. Trim any excess wire that remains protruding from the top of the cap. In rare instances (less than 5%), pushing the down gold receptacle will crush the wire and break it below receptacle, resulting in a disconnected channel. This disconnection may not be realized until the impedance testing and electroplating steps (see 4.7).

- Repeat the press-fitting process for the three other tetrodes. Turn the drive screws clockwise to move them back to the top and ensure that the drive movement is smooth.

4. Gold-plating of Electrode Tips

- Regardless of what type of microelectrodes being used, the tips of the electrodes should be gold-plated in order to reduce tip impedance. This will maximize the ability to reliably record and discriminate single-unit action potentials. Test the electrode impedance using the Neuralynx nanoZ device. The nanoZ is a computer-based device that measures impedance and allows for automated electroplating.

- First turn the microdrive screws down (counter-clockwise) to their lowest position. Then securely mount the microdrive on a clamp that will allow lowering of the electrode tips into the gold plating solution.

- Fill one Delrin tower with SIFCO Gold solution and the other tower with distilled water. Lower the electrode tips into the gold solution.

- Plug the nanoZ USB cable into a Windows-based computer and then open the nanoZ program. This program will give impedance readings and perform gold-plating on each connected channel of the microdrive.

- Go to the Device drop-down and select the nanoZ, after which it will show “Connection established” at the bottom of the window. Next, select the appropriate adaptor for testing in the drop-down menu. Click on “Test impedances” and set the test frequency to 1004 Hz (40 cycles, 0 msec pause). Click on “Test probe”, which will open the “Probe Report” window that shows all the available channels with their MΩ readings. Save these impedance values by clicking on the disk icon or by selecting “File”, then “Save report”.

- Next, click on “DC Electroplate” and assign the following values: Mode = match impedances, Plating current = -1.0 μA, Target = 350 kΩ at 1,004 Hz, 5 runs, 5 sec interval, 2 sec pause.

- Click “Autoplate”. The program will first read the impedance of each channel, then apply the specified current to that channel, re-test the impedance and apply current as needed until the Target impedance (or a lower value) is reached. While the goal is to reduce electrode impedance, it is possible that channels will electroplate below values of 100 kΩ. In such cases, it is possible that neighboring wires on the tetrode have been shorted together. If this happens, reverse the current polarity (+ 1.0 μA) to remove excess gold particles, re-test the impedance of that channel, and then repeat the electroplating. Typical final impedance values on a bundle of four 12.5 μM wires range from 150 – 325 kΩ.

- If there is any single channel that has not plated below 350 kΩ, repeat the electroplating process. The program will skip over channels that have already reached the Target and will only plate channels which have not.

- Once all channels have been plated to an acceptable impedance, close the nanoZ program and disconnect the device. Raise the electrodes out of the plating solution and lower the tips into the distilled water Delrin tower in order to rinse off excess gold particles.

- Turn the drive screws clockwise until the electrodes are raised to their top position. Now the microdrive and electrodes are ready for implantation.

Representative Results

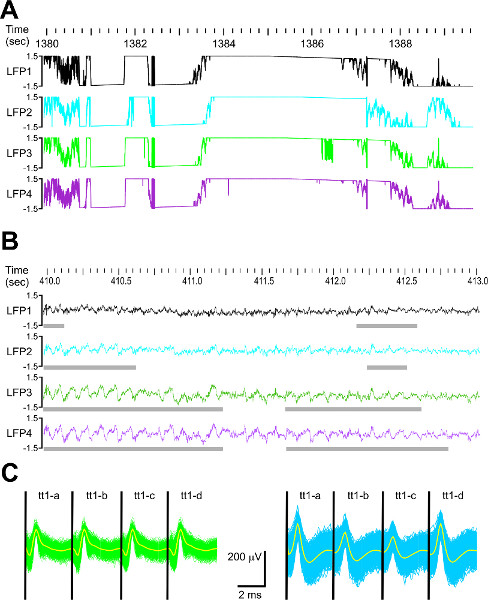

After implanting the microdrive and lowering the electrodes to the intended brain targets, an amplified data acquisition system, such as a Neuralynx Lynx-8, is needed for recording neural signals. Representative neural recordings of local field potentials (LFPs) and single-unit action potentials (often termed “spikes”) from the mouse dorsal subiculum are shown in Figure 2. LFP signals were sampled at 3 kHz and band-pass filtered between 0.1-500 Hz (Figure 2A and 2B). Figure 2A shows four continuously sampled LFP channels with a poorly grounded signal. These signals appear extremely noisy and easily saturate within the given amplitude range. Figure 2B shows an example of four channels from well-grounded LFP signals, with clearly visible network oscillations in the theta range (4-12 Hz). LFP signals were visualized in the “1D Data Viewer” using NeuroExplorer (version 4.0) data analysis software.

Single-unit spike channels were sampled at 30 kHz and band-pass filtered between 0.5-9 kHz. The main advantage of using tetrodes is that they allow signals from putative individual neurons to be triangulated between several recording points for improved unit discrimination. The left panel of Figure 2C shows an example of a poor tetrode recording because the four electrode wires have registered essentially identical spike waveforms throughout the recording session. Over a thousand individual spike waveforms (n = 1458) were overlaid on top of each other for each channel of the tetrodes, with the averaged waveform shown in yellow. This pattern was likely due to the fusing of the wires together during tetrode fabrication (during the insulation melting step), causing the bundle of wires to effectively act as a single recording electrode. It is also possible that this pattern was due to a referencing artifact or that a source that is equidistant from all four electrodes was responsible for the signal. These possibilities cannot be excluded but they can be minimized. Typically within the amplifier system, a recording channel can be user-assigned to be a reference channel. This helps to troubleshoot problematic ground connections and references and allows flexibility in obtained low-noise recordings. The right panel of Figure 2C shows an example of a good tetrode recording showing overlaid spike waveforms (n = 1939) from a putative unit with different amplitudes across the four tetrode wires. This type of spike recording pattern allows for improved unit discrimination during subsequent offline clustering and separation. Spike waveforms were visualized using Plexon Offline Sorter (version 2.8.8).

| Name of Reagent/Material | Company | Catalog Number | Comments |

| 0.0005″ (12.5 μM) diameter Platinum-Iridium wire | California Fine Wire | CFW#100-167 | HML VG insulated www.calfinewire.com |

| 0.002″ (50 μM) diameter Stableohm 675 wire | California Fine Wire | CFW# 100-188 | HML insulated Ni-Cr |

| polyamide tubing | Polymicro Technologies | 1068150020 | 99 micron I.D., 166 micron O.D. www.polymicro.com |

| brass guides | World Plastics Inc | 3.3 x 6.6 mm | |

| Delrin blocks | World Plastics Inc | 3.13 x 2.5 mm | |

| Fillister head brass screws | J.I. Morris Co. | 00-90 x 1/2 | drive screw www.jimorrisco.com |

| hex brass nuts | J.I. Morris Co. | 00-90 | |

| Fillister head brass screws | J.I. Morris Co. | 000-120 x 3/32 | EIB mount and ground screw |

| plexiglass acrylic | Canal Street Plastics | 5 mm thick, clear, www.cpcnyc.com | |

| cyanoacrylate | Krazy Glue | 2 g tube | |

| electronic interface board | Neuralynx | EIB-18 | www.neuralynx.com |

| non-cyanide gold solution | SIFCO | SIFCO 5355 | www.sifcoasc.com |

| VersaDrive 4 | Neuralynx | four tetrode model | |

| tetrode assembly station | Neuralynx | ||

| motorized tetrode spinner | Neuralynx | tetrode spinner 2.0 | |

| VersaDrive jig | Neuralynx | ||

| soldering iron | Radio Shack | 64-2802B | www.radioshack.com |

| nanoZ | Neuralynx | ||

| small bit drill/driver | Ram Products | Rampower 35 | with footpedal controller, www.ramprodinc.com |

| drill bits | Small Parts, Inc. | 3/32″ bits, www.smallpartsinc.com | |

| dissecting microscope | Olympus | SZ-60 | www.olympusamerica.com |

| heat gun | Alphawire | Fit gun 3 | use setting “1” only, www.alphawire.com |

| 26 AWG copper wire | Arcor Electronics | F26 | for ground wires, www.arcorelectronics.com |

| soldering flux | Eagle | 2 oz, #205 | |

| 0.02″ diameter solder | Kester | 24-6337-0010 | www.kester.com |

| benchtop vise | Vacu-Vise | Model 300 | |

| fiber optic light | Nikon | MKII | dual light arms, www.nikon.com |

| 5-min epoxy | Allied Electronics | 25 ml, www.alliedelec.com | |

| fine tweezers | Roboz Surgical Instrument Co. | RS-4907, RS-5010 | INOX material, www.roboz.com |

| micro dissecting scissors | Roboz Surgical Instrument Co. | RS-5880 |

Table 1. Materials and reagents used for constructing tetrodes and microdrives.

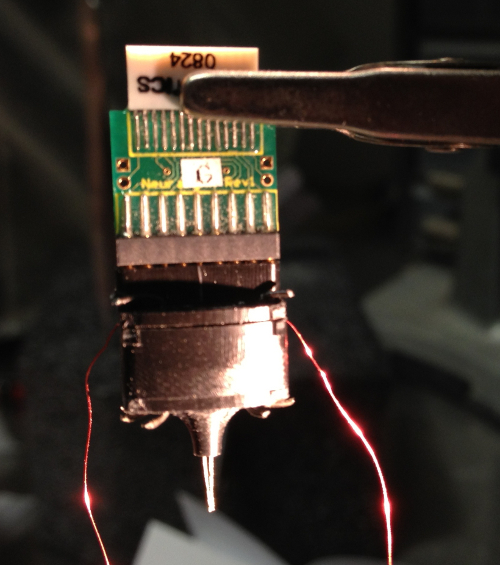

Figure 1. Completed VersaDrive 4 assembly. This picture shows a completed VersaDrive with four tetrodes extending from the bottom and two ground wires protruding from the sides. The green chip on top is an Omnetics adapter that plugs directly into the VersaDrive and is used to connect with a Neuralynx amplifier system.

Figure 2. Representative local field potentials and single-unit spike waveforms. Local field potentials (LFP) and single-unit recordings obtained from electrodes implanted in the dorsal subiculum of a mouse. A. The traces represent 10 sec of LFP signals shown from four continuously sampled channels with a poor electrical ground. B. The traces represent 3 sec of LFP signals from four continuously sampled channels with a proper electrical ground, which show a stable, continuous baseline with visible network oscillations in the theta range (4-12 Hz). Episodes of theta activity are marked by grey bars. C. The left panel shows an example of a poor tetrode spike pattern, with all four channels displaying comparable spike waveforms from a putative individual unit. The right panel shows an example of good tetrode spike waveforms with a range of waveforms across the four channels. The average waveforms for each tetrode channel are shown in yellow; scale bars, 2 msec (x axis), 200 μV (y axis). Click here to view larger figure.

Discussion

We have described a set of techniques for constructing light and compact microdrives for the recording of extracellular unit and field potential activity in mice. By building custom microdrives with bases fashioned from acrylic glass (methyl methacrylate), the core system can be easily adapted for multiple drives and for the targeting of a wide array of neural regions. We have successfully modified the system for recording from multiple brain targets and with larger arrays for recordings in mice. With further modification, motorized drive elements can be incorporated to allow for remote, and potentially more precise, electrode placement 7.

We would like to stress that these recording devices give the researcher flexibility in utilizing either single microwires or wire bundles, such as tetrodes. Larger diameter single microwires are more robust and better suited for the recording of LFPs within brain tissue. While tetrodes can also be used to record LFPs, they are optimized for the isolation of single-unit action potentials 8, 11. In our laboratory, stable recordings of single-units have been obtained for up to 8 weeks following implantation. However, these recordings are not of the same putative units over that entire time. In our hands, a single-unit can be followed over several recording sessions (30 min each) that span a period of 3 days, reflecting an inter-session stability 10. On the other hand, robust LFPs and network oscillations can be recorded throughout the entire post-implantation period, especially with the use of larger diameter wire such as 50 μm (0.002″) wire. Note that the methods described here apply to unilateral recording of brain structures, but they can be easily modified for bilateral recordings. For example, when building custom microdrives, the appropriate distance between the drives must be determined beforehand in order to properly target brain structures bilaterally.

As microdrive components become more lightweight and the software to analyze neural signals improves, the library of potential brain targets and testable hypotheses within neuroscience continues to expand. It is clear that, since their inception 1, 12, brain recordings from awake behaving animals have greatly advanced our understanding of how neurons and networks of neurons encode behaviorally relevant events 3, 4,13,14. In particular, brain recordings from genetically modified mice have allowed the identification of molecular cascades that are crucially involved in neural encoding 15-17. Importantly, the technique has only recently been applied to clinically oriented issues 17, 18.

Advances in the fabrication of tetrodes and the increased availability of manufactured solutions will further facilitate the movement of this technology into addressing human diseases and ailments 19, 20. And while the penetration of electrodes into brain tissue is invasive in nature, these recordings offer invaluable information from individual neurons that cannot be obtained with technologies such as functional imaging. Thus, in both animal models and humans, awake behaving recordings using moveable microdrives will continue to provide indispensable information about neural ensembles, neural coding, topographic specificity, and network oscillations within the brain.

Disclosures

The authors have nothing to disclose.

Acknowledgements

We thank Daniel Carpi for his help and early contributions to this project. We also thank Lucrecia Novoa for her assistance with artwork and images. This work was supported by NIH/NIAID program grant 5P01AI073693-03.

Materials

| Name of Reagent/Material | Company | Catalog Number | Comments |

| 0.0005″ (12.5 μM) diameter Platinum-Iridium wire | California Fine Wire | CFW#100-167 | HML VG insulated www.calfinewire.com |

| 0.002″ (50 μM) diameter Stableohm 675 wire | California Fine Wire | CFW# 100-188 | HML insulated Ni-Cr |

| polyamide tubing | Polymicro Technologies | 1068150020 | 99 micron I.D., 166 micron O.D. www.polymicro.com |

| brass guides | World Plastics Inc | 3.3 x 6.6 mm | |

| Delrin blocks | World Plastics Inc | 3.13 x 2.5 mm | |

| Fillister head brass screws | J.I. Morris Co. | 00-90 x 1/2 | drive screw www.jimorrisco.com |

| hex brass nuts | J.I. Morris Co. | 00-90 | |

| Fillister head brass screws | J.I. Morris Co. | 000-120 x 3/32 | EIB mount and ground screw |

| plexiglass acrylic | Canal Street Plastics | 5 mm thick, clear, www.cpcnyc.com | |

| cyanoacrylate | Krazy Glue | 2 g tube | |

| electronic interface board | Neuralynx | EIB-18 | www.neuralynx.com |

| non-cyanide gold solution | SIFCO | SIFCO 5355 | www.sifcoasc.com |

| VersaDrive 4 | Neuralynx | four tetrode model | |

| tetrode assembly station | Neuralynx | ||

| motorized tetrode spinner | Neuralynx | tetrode spinner 2.0 | |

| VersaDrive jig | Neuralynx | ||

| soldering iron | Radio Shack | 64-2802B | www.radioshack.com |

| nanoZ | Neuralynx | ||

| small bit drill/driver | Ram Products | Rampower 35 | with footpedal controller, www.ramprodinc.com |

| drill bits | Small Parts, Inc. | 3/32″ bits, www.smallpartsinc.com | |

| dissecting microscope | Olympus | SZ-60 | www.olympusamerica.com |

| heat gun | Alphawire | Fit gun 3 | use setting “1” only, www.alphawire.com |

| 26 AWG copper wire | Arcor Electronics | F26 | for ground wires, www.arcorelectronics.com |

| soldering flux | Eagle | 2 oz, #205 | |

| 0.02″ diameter solder | Kester | 24-6337-0010 | www.kester.com |

| benchtop vise | Vacu-Vise | Model 300 | |

| fiber optic light | Nikon | MKII | dual light arms, www.nikon.com |

| 5-min epoxy | Allied Electronics | 25 ml, www.alliedelec.com | |

| fine tweezers | Roboz Surgical Instrument Co. | RS-4907, RS-5010 | INOX material, www.roboz.com |

| micro dissecting scissors | Roboz Surgical Instrument Co. | RS-5880 |

Table 1. Materials and reagents used for constructing tetrodes and microdrives.

References

- Recce, M. L., O’Keefe, J. The tetrode: a new technique for multi-unit extracellular recording. Soc. Neurosci. Abstr. 15, 1250 (1989).

- O’Keefe, J., Recce, M. Phase relationship between hippocampal place units and the EEG theta rhythm. Hippocampus. 3, 317-330 (1993).

- Chen, G., Wang, L. P., Tsien, J. Z. Neural population-level memory traces in the mouse hippocampus. PLoS ONE. 4 (12), e8256 (2009).

- Buzsáki, G., Anastassiou, C. A., Koch, C. The origin of extracellular fields and currents — EEG, ECoG, LFP, and spikes. Nat. Rev. Neurosci. 13 (6), 407-420 (2012).

- Tort, A. B., Kramer, M. A., et al. Dynamic cross-frequency coupling of local field potential oscillations in rat striatum and hippocampus during performance of a T-maze task. Proc. Nat. Acad. Sci. U.S.A. 105 (51), 20517-20522 (2008).

- Seidenbecher, T., Laxmi, R., et al. Amygdalar and hippocampal theta rhythm synchronization during fear memory retrieval. Science. 301 (5634), 846-850 (2003).

- Yamamoto, J., Wilson, M. A. Large-scale chronically implantable precision motorized microdrive array for freely behaving animals. J. Neurophysiol. 100 (4), 2430-2440 (2008).

- Harris, K. D., Henze, D. A., et al. Accuracy of tetrode spike separation as determined by simultaneous intracellular and extracellular measurements. J. Neurophysiol. 84 (1), 401-414 (2000).

- Henze, D. A., Borhegyi, Z., et al. Intracellular features predicted by extracellular recordings in the hippocampus in vivo. J. Neurophysiol. 84 (1), 390-400 (2000).

- Chang, E. H., Huerta, P. T. Neurophysiological correlates of object recognition in the dorsal subiculum. Front. Behav. Neurosci. 6, 46 (2012).

- Gray, C. M., Maldonado, P. E., et al. Tetrodes markedly improve the reliability and yield of multiple single-unit isolation from multi-unit recordings in cat striate cortex. J. Neurosci. Methods. 63 (1-2), 43-54 (1995).

- O’Keefe, J., Dostrovsky, J. The hippocampus as a spatial map. Preliminary evidence from unit activity in the freely-moving rat. Brain Res. 34 (1), 171-175 (1971).

- Wilson, M. A., McNaughton, B. L. Dynamics of the hippocampal ensemble code for space. Science. 261 (5124), 1055-1058 (1993).

- Buzsáki, G. . Rhythms of the Brain. , (2006).

- McHugh, T. J., Blum, K. I., et al. Impaired hippocampal representation of space in CA1-specific NMDAR1 knockout mice. Cell. 87 (7), 1339-1349 (1996).

- Resnik, E., McFarland, J. M., et al. The effects of GluA1 deletion on the hippocampal population code for position. J. Neurosci. 32 (26), 8952-8968 (2012).

- Cacucci, F., Yi, M., et al. Place cell firing correlates with memory deficits and amyloid plaque burden in Tg2576 Alzheimer mouse model. Proc. Natl. Acad. Sci. U.S.A. 105 (22), 7863-7868 (2008).

- Sigurdsson, T., Stark, K. L., et al. Impaired hippocampal-prefrontal synchrony in a genetic mouse model of schizophrenia. Nature. 464 (7289), 763-767 (2010).

- Engel, A. K., Moll, C. K., et al. Invasive recordings from the human brain: clinical insights and beyond. Nat. Rev. Neurosci. 6 (1), 35-47 (2005).

- Cash, S. S., Halgren, E., et al. The human K-complex represents an isolated cortical down-state. Science. 324 (5930), 1084-1087 (2009).