A Guide to Concentration Alternating Frequency Response Analysis of Fuel Cells

Summary

We present a protocol for concentration alternating frequency response analysis of fuel cells, a promising new method of studying fuel cell dynamics.

Abstract

An experimental setup capable of generating a periodic concentration input perturbation of oxygen was used to perform concentration-alternating frequency response analysis (cFRA) on proton-exchange membrane (PEM) fuel cells. During cFRA experiments, the modulated concentration feed was sent to the cathode of the cell at different frequencies. The electric response, which can be cell potential or current depending on the control applied on the cell, was registered in order to formulate a frequency response transfer function. Unlike traditional electrochemical impedance spectroscopy (EIS), the novel cFRA methodology makes it possible to separate the contribution of different mass transport phenomena from the kinetic charge transfer processes in the frequency response spectra of the cell. Moreover, cFRA is able to differentiate between varying humidification states of the cathode. In this protocol, the focus is on the detailed description of the procedure to perform cFRA experiments. The most critical steps of the measurements and future improvements to the technique are discussed.

Introduction

Characterizing the dynamic behavior of a PEM fuel cell is important in order to understand which mechanisms dominate the transient operational states lowering the performance of the cell. Electrochemical impedance spectroscopy (EIS) is the most commonly used methodology for studying PEM fuel cell dynamics, due to its ability to separate different process contributions to the overall dynamic performance1,2. However, transient processes with similar time constants are often coupled in the EIS spectra, making it difficult to interpret them. For this reason, in the past transient diagnostic tools based on the application of non-electrical inputs with the aim of detecting the impact of a few or individual dynamics have been developed and proposed3,4,5,6,7.

A novel frequency response technique based on concentration perturbation input and electrical outputs named concentration-alternating frequency response analysis (cFRA) has been developed in our group. The potential of cFRA as a selective diagnostic tool has been investigated theoretically and experimentally6,7. It was found that cFRA can separate different kinds of mass transport phenomena and discriminate between the different states of operation of the cell. In this protocol, we focus on the step-by-step description of the procedure for performing cFRA experiments. The assembling of the cell, its conditioning and the experimental setup for creating a feed with periodic concentration perturbation, as well as the data analysis will be shown and discussed in detail. Finally, the most critical points of the procedure will be highlighted and several strategies for improving the quality and selectivity of cFRA spectra will be pinpointed.

Protocol

1. Material preparation

- Cut and perforate two rectangular pieces of Teflon of the same size as the end plates by using a cutting press; take care and ensure that the holes are in the exact position where the bolts should be placed.

- Using the same procedure cut Teflon gaskets considering the outer and inner dimensions of the flow field, and the position of the holes where the screws should be placed.

- Cut the gas diffusion layers using a metal frame fitting the size of the gaskets.

- Cut the excess Nafion from the catalyst coated membrane (CCM) in order to adjust it to the size of the bipolar plates. Make holes in the membrane at the positions where the screws should go through with the help of the metal frame used previously. Take care to center the frame before making the holes.

2. Fuel cell assembly

- Place the cathode bipolar plate on a smooth and sturdy surface with the flow field side up.

- Place the gasket on top. Make sure it aligns with the screw holes.

- Place the cathode GDL in the middle of the gasket and put the CCM on top. Make sure the CCM is aligned with the screw holes.

- Place the anode GDL and gasket on top. Make sure the gasket aligns with the screw holes and the GDL is placed in the middle.

- Place the anode bipolar plate on top (flow field side down) and use screws to clamp the parts together.

NOTE: The bipolar plates must not be strongly tightened. The purpose of the screws is just to keep aligned the different parts. - Place the cathode stainless steel end plate on a smooth and sturdy surface.

- Place the rectangular Teflon piece and the copper current collector on top. Make sure they align with the bolt holes.

- Slot the cathode side of the cell unit assembled in step 2.1 on the cathode current collector taking into account the notches in the flow fields.

- Slot the anode side of the unit on the anode current collector, position the Teflon gaskets and finish with the anode stainless steel end plate on top.

- Place the insulating sleeves, the O-ring and the bolts in the holes of the anode end plates; insert the bolts in the holes.

- Position the insulation sleeves and the O-ring; finish by placing the nuts on the bolts on the cathode side.

- Tighten the bolts crosswise using a torque-wrench until you reach the recommended torque value of 5 N·m. 5 crosswise cycles are suggested; start by low torque value (1 N·m) and increase by 1 N·m in each subsequent cycle.

3. Integration of a fuel cell with the periphery

- Place the fuel cell in the heating box and connect the inlets and outlets to the periphery. Use snoop liquid to check for leakages.

- Insert the thermocouple in the cathode end plate.

- Interface the fuel cell with the potentiostat; choose 2 electrode-configuration. Connect the cables marked as RE and CE to the anode side and the ones marked as WE and SE to the cathode side.

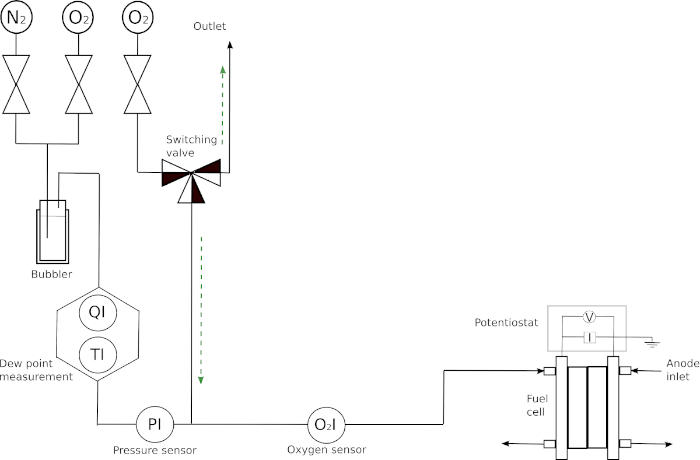

- Start the software used to control the cell periphery; a scheme of the experimental setup is visualized (see schematic in Figure 1). Choose the values of the anode and cathode inlet gas flow rates and open the valves. In the experiments shown in this protocol, flow rates of 850, 300 and 300 mL/min were used for hydrogen (anode side), nitrogen and oxygen (cathode side) respectively.

- Choose the temperature of the inlet gases and turn on the heating tapes. Wait until the set point temperature is reached. In all experiments in this protocol, the set point temperature of the inlet gases at the anode and cathode side was 68 °C.

- Set the temperatures of the thermostats to define the desired dew point temperature of the inlet gases; turn the thermostats on.

- Set the chosen temperature of the fuel cell on the control panel of the heating box. Then, turn the heating on. In the experiments described in this protocol a fuel cell temperature of 80 °C was set.

- Wait until the set point temperature of the fuel cell is reached; check the humidification state of the inlet gases; check the fuel cell open circuit cell potential. The open circuit cell potential value on the display of the potentiostat should be between 1 and 1.2 V.

4. Fuel cell start up procedure

NOTE: The procedure described in the following section uses a specific software program and potentiostat (Autolab N104, NOVA 2.0 software). However, it can be also performed using other software and potentiostats without changing the main outcomes. The start-up procedure must be performed if a new CCM is used.

- Start the Autolab NOVA 2.0 software.

- Select New Procedure in the Action section of the software; the procedure editing page opens.

- In Command, click on the Autolab Control icon ; drag the Autolab Control icon to the workspace section. Then, in Properties, select Mode On Potentiostatic.

NOTE: The Autolab NOVA 2.0 software does not differentiate between the terms potentiostatic and voltastatic. - In Command, select the Cell icon and place it next to the Autolab Control icon. Then, in Properties choose Cell On. Add the Apply icon and in Properties set 0.9 V as Cell Potential with respect to the reference electrode.

- Add the Wait command and set Duration to 1800 s.

- Add the LSV Staircase command from Measurement Cyclic and Linear Sweep Voltammetry. Set the Start Potential to 0.9 V, the Stop Potential to 0.6 V, the Scan Rate to 0.4 mV/s and Step to 0.244 mV.

- Add the Wait command and set Duration to 1800 s.

- Add the LSV Staircase command from Measurement Cyclic and Linear Sweep Voltammetry. Set the Start Potential to 0.6 V, the Stop Potential to 0.9 V, the Scan Rate to 0.4 mV/s and the Step to 0.244 mV.

- Add the Repeat command. In the workspace select the commands from step 4.1.4 (the first Wait command) to step 4.1.7 (the last LSV Staircase command); drag and drop the icons into the Repeat box. In Properties asset the number of repetitions to 20.

- Start the cell start up procedure by clicking the Play button.

- After 2 h, if the current is stable at 0.6 V stop the program by pressing on the Stop button. If the current is still changing, let the program run until it terminates.

5. Galvanostatic electrochemical impedance spectroscopy experiment

- Start the Autolab NOVA 2.0 software.

- Select New Procedure in the Action section of the software; the procedure editing page opens.

- In Command click on the Autolab Control icon ; drag and drop the Autolab Control icon to the workspace section. Then, in Properties select Mode On Galvanostatic.

- Add the Cell On command.

- Add the LSV Staircase command. In Properties set the Start Current to 0 A, the chosen steady state current to Stop Current, the Scan Rate to 0.005 A/s and Step to 0.01 A.

- Insert the Record Signal command; in Properties set the Duration to 7200 s and the Interval Sampling Time to 0.1 s.

- Insert the FRA measurement command window. In Properties set the First applied frequency to 1000 Hz, the Last applied frequency to 0.01 Hz and the Number of frequencies per decade to 5. Set the Amplitude to 5% of the steady state current.

- Add the Cell Off command.

- Start the cell galvanostatic EIS program by pressing the Play button.

- Wait until the cell potential value stabilizes by observing the change in the recording window. Then click on the Forward button to start the EIS experiment.

- Check the stability of the system during the experiment and wait until the program is terminated.

6. Concentration-alternating frequency response experiment

NOTE: The following instructions describe the procedure for performing cFRA experiments under galvanostatic conditions. However, the procedure would not differ if performing cFRA experiments under voltastatic conditions, apart from setting the galvanostatic to potentiostatic control in the software and fixing a certain cell potential as a steady state instead of current.

- Set up the Pyro fiber oxygen sensor for fast dynamic measurements.

- Push gently down on the plunger in the upper part of the Pyro fiber oxygen sensor in order to remove the sensitive part of the fiber from the protective needle and place it in the center of the tubing at the cell inlet.

- Open the Pyro software.

- Click on Options | Advance and choose Enable Fast Sampling.

- Set the Sampling Interval to 0.15 s.

- Edit the cFRA procedure by using Autolab NOVA 2.0 software.

- Open the NOVA software and select New Procedure in the Action section ; the software editing page opens.

- In Commands select the Control icon and insert it in the workspace. In Properties select Mode On Galvanostatic. Then select the Cell On command and place it next to the Control icon.

- Add the LSV Staircase command from the Measurement Cyclic and Linear Sweep Voltammetry. In Properties set the Start Current to 0.0 A; set as Stop current the steady state current value at which the cFRA experiment should be performed. Then use 0.005 A/s as the Scan Rate and 0.01 A as the Step.

- Insert two Record Signal commands; in Properties set Duration to 7200 s and Interval Sampling Time to 0.05 s. Repeat the same step 20 times by adding a Repetition command. The number of repetitions must be equivalent to the number of signal frequencies that need to be measured.

NOTE: Two recording signal windows are convenient for the following reasons: one recording window is used to monitor the transient part of the periodic output signal, while the second one is used to register the steady state part of the periodic output signal. The steady state part of the signal is used for transfer function determinations.

- Press the Play button to start the cFRA program.

- In the first set of repetitions, check if the cell potential reaches the steady state value by observing the recording window.

- Open the additional oxygen valve and set the mass flow controller to 5% of the value of the total flow rate of the main feed in order to ensure a linear response (example: set 30 mL/min with 600 mL/min of total flow rate). Then set the switching time of the valve to an initial value of 0.5 s. Press the switching control Start button.

- Monitor the recording window and wait until the cell potential achieves a periodic steady state; then click on the Next button.

- Register the periodic steady state signal in the new recording window for 60 s. Then, click again on the Next button.

- Simultaneously with the previous step 6.7, register the periodic oxygen input. Select the Start button in the sensor software, insert a name which recalls the frequency input (example: 1 Hz), and click on OK. Register the signal for 60 s as in the current output case and press the Stop button.

- Repeat the previous steps 6.6-6.8 at increasing switching time values in order to measure periodic input/output correlations for a frequency range from 8-1000 mHz by taking 8 frequency points per decade. For experiments at a frequency higher than 100 mHz, register input and output for 60 s. At lower frequencies, sample the signals for a range of time equivalent to 5 periods.

7. Analysis of cFRA data

- Export measured cell potential responses from the Autolab NOVA 2.0 software.

- In the recording window click on the diagram with the measured periodic steady state cell potential output.

- Click on the Show Data | Key | Export buttons. Insert a file name which recalls the frequency of the input (Example: 1 Hz) and click on Save.

- Repeat steps 7.1.1-7.1.2 for each measured cell potential output at each frequency.

- Open the Matlab scripts FFT_input.mat and FFT_output.mat. In the Address Folder section insert the specifications of the location of the folder where the measured oxygen pressure and current data files are stored.

NOTE: The script was written with the aim of performing the windowing of the collected inputs in order to have an integer number of periodic cycles to analyze, and calculate their Fourier transforms accurately and quickly. Any other procedure which performs the same task does not change the results. - Run the FFT_PO2.mat and FFT_Pot.mat scripts; check in the plotted diagrams if the computed algorithm works properly (in the time domain, an integer number of input and output cycles should be extracted from the original input and output samples).

CAUTION: A Fourier transform based on a non-integer number of periodic cycles could result in misleading analysis of the inputs and outputs resulting in inaccurate cFRA spectra. - Open the Matlab script cFRA_spectra.mat and run it. Magnitude, phase angle and Nyquist spectra of the cFRA transfer function under galvanostatic conditions are plotted.

NOTE: The script calculates the cFRA transfer function by using the Fourier transform values at the fundamental frequency of the oxygen pressure (inputs) and cell potential (outputs) signal using the following equation.

Representative Results

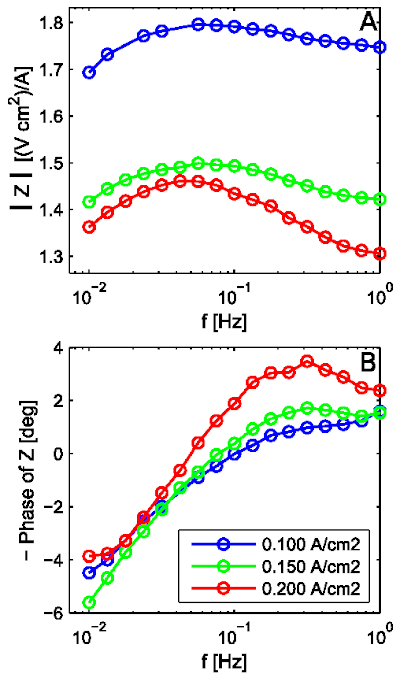

The preliminary analysis of the fuel cell dynamics based on EIS spectra is shown in Figure 2. EIS magnitude (Figure 2A) and phase Bode plots (Figure 2B) spectra are measured at three different steady state current densities under galvanostatic control. As expected, all main transient processes are observed: the double layer charging/discharging in the high frequency range, mass transport dynamics in the range between 1 Hz and 100 mHz, and membrane hydration dynamics in the low frequency range1,2,8. In order to avoid the data scattering often observed at frequencies below 100 mHz the following conditions must be fulfilled: (i) the EIS experiment should start only after the steady state current density is achieved (quasi steady state condition is characterized by a negligible constant drift), (ii) the input amplitude is set at 5% of the steady state current value in order to ensure a linear response whilst simultaneously reducing the influence of noise in the harmonic analysis, (iii) at least 4 periods for each frequency are sampled in order to further minimize the noise effects.

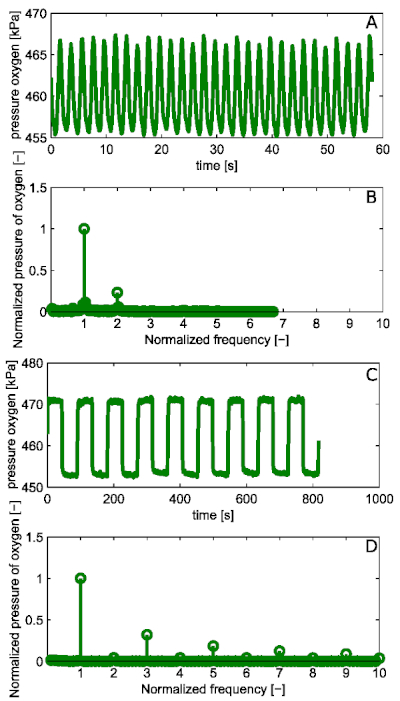

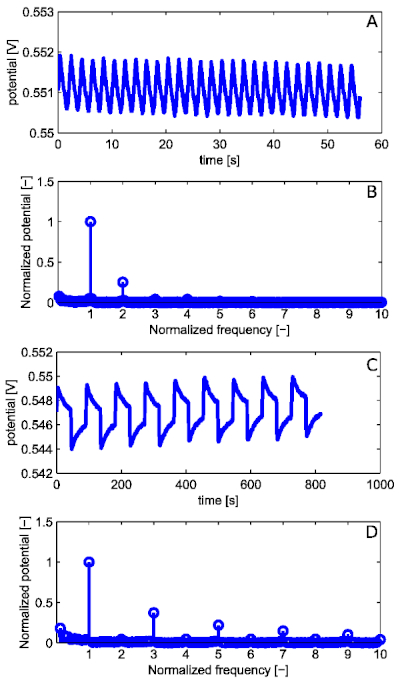

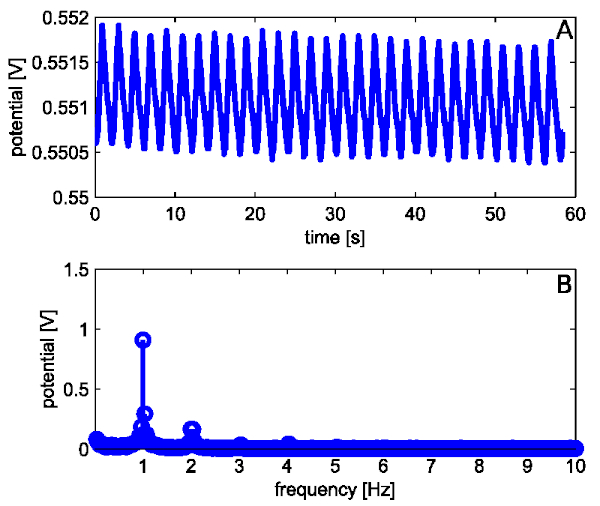

Figure 3 depicts exemplary periodic oxygen pressure inputs at two different frequencies and their Fourier transforms. The magnitudes of harmonics in Figure 3B are normalized with respect to the fundamental harmonic. As already stated in the protocol, all signals were sampled after quasi steady state conditions were reached. The pressure input at a frequency of 49 mHz (Figure 3A) is characterized by a sinusoidal shape. Its Fourier transform (Figure 3B) displays a harmonic at the fundamental frequency and an additional higher harmonic at a frequency which is the double of the fundamental one, indicating a small deviation from a pure sinusoidal signal. The pressure input at lower frequency resembles a periodic square wave shape (Figure 3C). The related normalized Fourier transform (Figure 3D) reflects perfectly that of a square wave signal, presenting descending harmonic components at multiple odd integer frequencies with respect to the fundamental one. The cell potential responses present identical features (Figure 4A-D). The different signal shapes at different frequencies are caused by the way the perturbation is produced. The switching valve passes quickly from the open/closed state resulting in a sharp change in oxygen pressure. However, at higher switching frequencies the pressure profile has no time to achieve a new stable value before the valve changes its state again. For this reason, at high frequencies the input perturbation, as well as the output response, follow a sinusoidal shape. On the other hand, a low switching frequency allows oxygen pressure to achieve a constant value between the switches, resulting in a square wave input. In order to minimize the noise effects, only the values of the inputs and outputs at the fundamental frequency are considered for determining the transfer function while the higher harmonics are not taken into account (please see eq. 1). For the same reason, at frequencies higher than 100 mHz the signals were simultaneously registered for at least 60 s. At lower frequencies the sampling time corresponded to an equivalent of at least 5 periods.

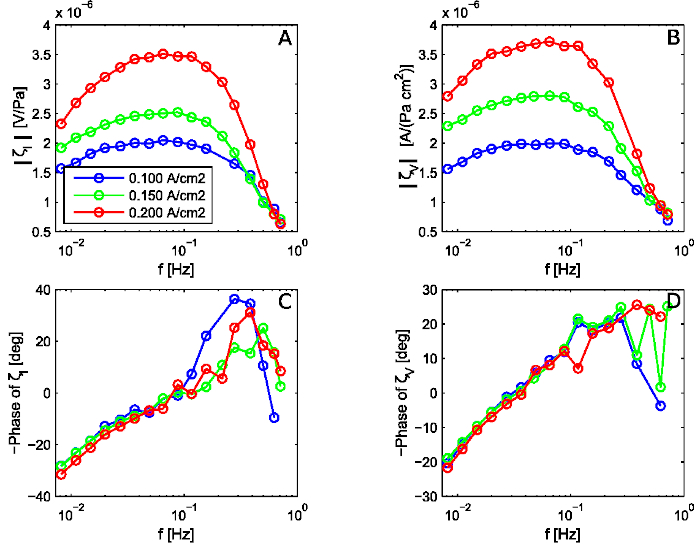

In order to avoid the effect of the spectral leakage, which can cause misleading results, the spectral analysis of the input and output data was performed on an integer number of periodic cycles. Since the sampling procedure starts and stops manually, an exact integer number of periods was not always sampled. For this reason, prior to any other analysis, the data were subjected to a windowing procedure. Figure 5 illustrates the effect of spectral leakage due to incorrectly sampled signals. The current response without the application of the windowing procedure and its normalized Fourier transform are displayed in Figure 5A and Figure 5B respectively. For comparison purposes, the correctly processed signal is shown in Figure 4B. As can be seen, the Fourier transform of the improperly processed signal (Figure 5B), is characterized by the more expressed noise bandwidth at fundamental frequency as well as the lower magnitude of the first harmonic. The magnitude of the improperly processed signal (Figure 5B) is approx. 90% of the properly processed signal (Figure 4B). It can be easily comprehended that the windowing process is crucial for obtaining reliable results. Figure 6 displays cFRA spectra measured under voltastatic and galvanostatic conditions under the same steady state conditions as in the EIS spectra. As can be seen, in the high frequency region, both voltastatic and galvanostatic cFRA spectra show no sensitivity to the steady state conditions. Since the high frequency region is mainly influenced by fast transients like double layer charging/discharging dynamics, the cFRA results indicate low sensitivity of the cFRA method to fast transients. On the other hand, mass transport and membrane hydration dynamics can be detected in the same frequency range as verified by EIS. Therefore, cFRA can be considered as an experimental technique for selectively studying transport dynamics in PEM fuel cells. The data at higher frequencies are usually more scattered due to the greater effect of the noise. This can be avoided by extending the sampling time or by resampling the data more frequently and averaging them.

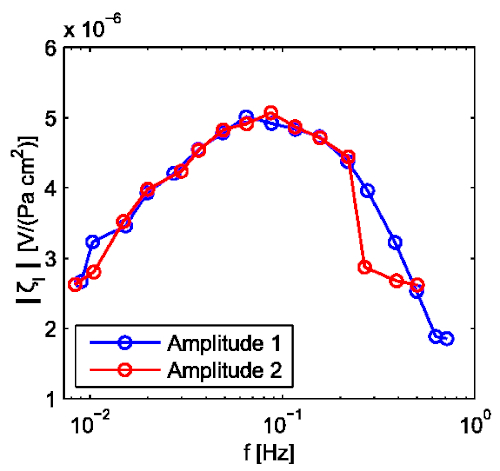

Another critical aspect affecting the quality of the measurements is the linearity of the measured transfer function. The use of too large an input amplitude could lead to an additional nonlinear contribution to the harmonics in the output response. One way to check the presence of the nonlinearities is to apply the homogeneity principle. Accordingly, the same measurement is repeated by using different input amplitude values. If the difference between the two transfer functions is negligible or below the noise level, the input/output correlation can be considered free from nonlinearities. An example of the application of this principle can be seen in Figure 7. The reference case Bode amplitude spectra (blue curve) is plotted together with the one measured at the same steady state conditions but using half of the reference amplitude value. The two Bode plots overlap, indicating the absence of nonlinearities.

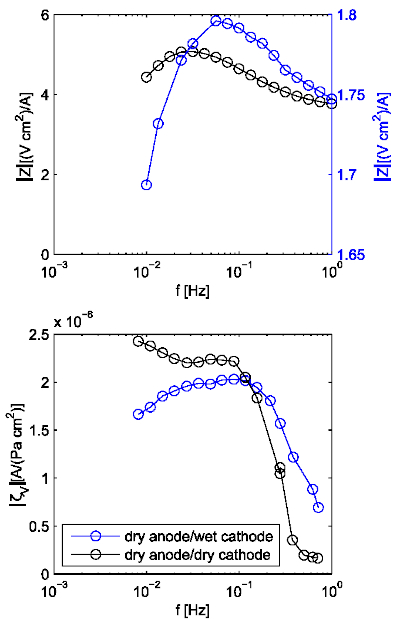

Figure 8A displays EIS magnitude spectra of a PEM fuel cell with dry anode/wet cathode and wet cathode/dry anode configurations. In Figure 8B, galvanostatic cFRA spectra at the same conditions are shown for comparison purposes. EIS only exhibits a quantitative difference between the two operating states. In contrast, cFRA can differentiate between them, showing different qualitative behavior. It is noticeable that the magnitude in the frequency region of Nafion membrane hydration decreases with a wet cathode, while it increases with a dry cathode.

Figure 1: Schematic representation of the experimental setup used to perform cFRA measurements. The main feed is a mixture of oxygen and nitrogen humidified by passing through a bubbler filled with water at a fixed temperature. Gas temperature, dew point temperature, total pressure and partial pressure of oxygen in the mixture are measured at the cell inlet. A small flow of oxygen is periodically added to the main feed by using a switching valve. Please click here to view a larger version of this figure.

Figure 2: Electrochemical impedance spectra at three different steady state current densities. Magnitude (A) and phase (B) of impedance in Bode plot representation. Experimental conditions: cell temperature of 80 °C, inlet gas temperature of 68 °C, cathode oxygen flow of 300 mL/min, cathode nitrogen flow of 300 mL/min, anode hydrogen flow of 850 mL/min. Please click here to view a larger version of this figure.

Figure 3: Periodic oxygen pressure input in time and frequency domain. (A) Periodic oxygen input over time at 500 mHz, (B) Fourier transform spectra of oxygen input at 500 mHz, (C) periodic oxygen input over time at 8 mHz, (D) Fourier transform spectra of oxygen input at 8 mHz. Please click here to view a larger version of this figure.

Figure 4: Cell potential output in time and frequency domains. (A) Cell potential output over time at 500 mHz, (B) Fourier transform spectra of cell potential response at 500 mHz, (C) cell potential output over time at 8 mHz, (D) Fourier transform spectra of cell potential response at 8 mHz. Please click here to view a larger version of this figure.

Figure 5: Cell potential output in time and frequency domain not processed by windowing procedure. (A) Cell potential output over time at 500 mHz, (B) Fourier transform spectra of cell potential response at 500 mHz. Please click here to view a larger version of this figure.

Figure 6: cFRA spectra at three different steady state conditions. (A) cFRA magnitude Bode plot under voltastatic control, (B) cFRA magnitude Bode plot under galvanostatic control, (C) cFRA phase angle Bode plot under voltastatic control, (D) cFRA phase angle Bode plot under voltastatic control. Experimental conditions: cell temperature of 80 °C, inlet gas temperature of 68 °C, cathode and anode dew point temperature of 55 °C, cathode oxygen flow of 300 mL/min, cathode nitrogen flow of 300 mL/min, anode hydrogen flow of 850 mL/min. Please click here to view a larger version of this figure.

Figure 7: cFRA spectra using different oxygen pressure amplitudes. cFRA magnitude Bode plots under galvanostatic conditions using an oxygen input amplitude of 7000 Pa (blue curve) and 3500 Pa (red curve). Experimental conditions: cell temperature 80 of °C, inlet gas temperature 68 of °C, cathode and anode dew point temperature 55 of °C, cathode oxygen flow of 300 mL/min, cathode nitrogen flow of 300 mL/min, anode hydrogen flow of 850 mL/min. Please click here to view a larger version of this figure.

Figure 8: Comparison between EIS and cFRA spectra at low humidity conditions. (A) EIS magnitude Bode plots, (B) cFRA magnitude Bode plots. Humidification conditions with dry anode/wet cathode configuration: anode dew point temperature of 30 °C, cathode dew point temperature of 55 °C. Humidification conditions with wet anode/dry cathode configuration: anode dew point temperature of 55 °C, cathode dew point temperature of 30 °C. Steady state current: 100 mA/cm2. Please click here to view a larger version of this figure.

Discussion

In contrast to classical EIS, cFRA is a diagnostic tool focused on the characterization of dynamics related to the different mass transport phenomena occurring in the fuel cell. It is not able to detect any transients having a time constant below the oxygen diffusion in the electrode, as for example the charging/discharging of the double layer6. Therefore, unlike EIS where several phenomena are coupled, cFRA can help to identify patterns related to specific dynamics more clearly. This would decrease the correlation effects between different parameters improving estimation quality. Additionally, its ability to differentiate between the humidification states of the cathode can be used as an online diagnostic tool. However, many aspects of the technique must be improved and accounted for in order to make optimal use of it. This protocol aims to provide an example of how to apply dynamic concentration input to PEM fuel cells and how to analyze it. Different technical issues and room for improvements to cFRA are discussed below.

The sampling and treatment of the input and output data are crucial to the quality of the measured cFRA spectra. Stability of the system over a time of at least three hours is required. Therefore, it is difficult to perform experiments in highly instable conditions such as in extremely flooded or dry conditions9. The time-consuming steps are the equilibration of the cell, which takes between 30 min and 1 h, and the sampling of the periodic input/output signals, which takes approx. 1 h and 15 min for all the frequency points and arrangements considered in this protocol. The latter step can be dramatically decreased by using all the harmonics contained in the square wave inputs and outputs to determine the cFRA spectra rather than only the one at the fundamental frequency. Basically, as shown in Figure 3, the periodic square wave is equivalent to a multi-sinusoidal input which can be used to capture the response of different frequencies (see Figure 3 and Figure 4) in just one signal. Therefore, only two oxygen pressure inputs per frequency decade could be enough to measure a complete cFRA spectra. In this way, the duration sampling would decrease to half an hour at most.

The procedure is not automated. The switching time of the valve used to add the additional periodic flow of oxygen is changed using the PCS 7 software by Siemens, which also controls all the other devices used in the experimental setup. Other system design platforms could be used for the same task, for example LabVIEW. On the other hand, the data treatment is automatic and straightforward. It is only necessary to insert the location of the data folder in a Matlab script created ad-hoc, run it and the spectra will be plotted after a few seconds.

A limitation of the experimental setup used is the highest frequency of the oxygen pressure input that can be obtained and analyzed. The features of two devices determine the value of this limit: the switching valve and the fiber optic oxygen sensor. The performance of the first is dominated by a maximum switching rate of 0.5 s which makes it possible to produce a periodic oxygen perturbation of up to 1 Hz. The use of a switching valve with magnetic solenoid technology having a switching rate of around hundreds of Hz could increase the value of this limit. On the other hand, the constraints related to the fiber optic sensor concern its ability to detect the fast changes of the oxygen partial pressure. The maximum sampling frequency of the sensor used is 7 Hz which means a periodic signal with a frequency up to 3.5 Hz can be meaningfully analyzed according to the Nyquist-Shannon sampling theorem. Here again, the performance can be improved by using a faster sensor reader able to process more data, which would make it possible to have a sampling rate in the order of hundreds of Hz. However, the time response of the sensor is a parameter that must be taken into consideration as well. In our case, it is around 0.3 s (t90).

Besides the current modus operandi and technical limitations, another aspect related to the present arrangement of the experimental setup must be considered with respect to the analysis of data and their interpretation. The addition of the small additional flow of oxygen to the main feed after humidification of the latter (see Figure 1) implies not only the variation of the oxygen pressure, but also the water pressure. Basically, an increment of the oxygen partial pressure means a decrement of the water pressure and vice versa, resulting in a simultaneous periodic perturbation with the two inputs in antiphase. Therefore, the measured transfer function is not the one in the equation (1) but a linear combination of the two and respectively obtained for oxygen and water perturbation. It reads:

where the variable  quantifies the fraction of the water contribution to the measured transfer function. Therefore, the contribution water pressure must be evaluated in order to decouple the single transfer functions. A way to solve this problem is displayed in the reference [7]. In future, the methodology will be improved by implementing the solutions detailed in this section.

quantifies the fraction of the water contribution to the measured transfer function. Therefore, the contribution water pressure must be evaluated in order to decouple the single transfer functions. A way to solve this problem is displayed in the reference [7]. In future, the methodology will be improved by implementing the solutions detailed in this section.

Disclosures

The authors have nothing to disclose.

Acknowledgements

Max Planck Institute for Dynamics of Complex Technical Systems assisted in meeting the publication costs of this article.

Materials

| Membrane Electrode Assemby N115 25,8 cm2 | QuinTech | EC-NM-115 | cathode/anode loding: 1mg Pt/cm2 |

| Potentiostat | Metrhohm | PGSTAT302N | |

| Booster | Metrohm | BOOSTER20A | |

| Retractable fiber oxygen sensor | Pyro Science | OXR430-UHS | |

| Dew Point and Temperature Meter | VAISALA | DMT340 | |

| Software process control system | Siemens | Simatic PCS 7 | |

| Software MATLAB2012a | Mathworks | ||

| Hydrogen | Linde | Hydrogen 6.0 | |

| Nitrogen | Linde | Nitrogen 5.0 | |

| Oxygen | Linde | Oxygen 5.0 |

References

- Yuan, X., Wang, H., Sun, J. C., Zhang, J. AC impedance technique in PEM fuel cell diagnosis – a review. International Journal of Hydrogen Energy. 32 (7), 4365-4380 (2007).

- Niya, S. M. R., Hoorfar, M. Study of proton exchange membrane fuel cells using electrochemical impedance spectroscopy technique – a review. Journal of Power Sources. 240 (8), 281-293 (2013).

- Niroumand, A. M., Merida, W., Eikerling, M., Safi, M. Pressure voltage oscillations as diagnostic tool for PEFC cathode. Electrochemistry Communications. 12 (1), 122-124 (2010).

- Engebretsen, E., et al. Electro-thermal impedance spectroscopy applied to an open-cathode polymer electrolyte fuel cell. Journal of Power Sources. 302, 210-214 (2014).

- Engebretsen, E., Mason, T. J., Shearing, P. R., Hinds, G., Brett, D. J. L. Electrochemical pressure impedance spectroscopy applied to the study of polymer electrolyte fuel cells. Electrochemistry Communications. 75, 60-63 (2016).

- Sorrentino, A., Vidaković-Koch, T., Hanke-Rauschenbach, R., Sundmacher, K. Concentration frequency response analysis: A new method for studying polymer electrolyte membrane fuel cell dynamics. Electrochimica Acta. 243, 53-64 (2017).

- Sorrentino, A., Vidaković-Koch, T., Sundmacher, K. Studying mass transport dynamics in polymer electrolyte membrane fuel cells using concentration-alternating frequency response analysis. Journal of Power Sources. 412, 331-335 (2019).

- Pivac, I., Barbir, F. Inductive phenomena at low frequencies in impedance spectra of proton exchange membrane fuel cells-A review. Journal of Power Sources. 326, 112-119 (2016).

- Benziger, J., Chia, J. E., Kimbal, E., Kevrekidis, I. G. Reaction Dynamics in a Parallel Flow Channel PEM Fuel Cell. Journal of Electrochemical Society. 154, B835-B844 (2007).

- Rannow, M. B. Achieving Efficient Control of Hydraulic Systems Using On/Off Valves. Doctoral Dissertation. , (2016).