Design and Optimization Strategies of a High-Performance Vented Box

Summary

Here, we present the range analysis method to optimize the sample points generated by an orthogonal experimental design to ensure that fresh food can be stored in a vented box for a long time by regulating the airflow pattern.

Abstract

This study aims to solve the problems of air flow chaos and poor performance in a vented box caused by the heterogeneous distribution of airflow through the design of the internal structure of the vented box with constant energy consumption. The final goal is to evenly distribute the airflow inside the vented box. Sensitivity analysis was performed for three structural parameters: the number of pipes, the number of holes in the middle pipe, and the number of each increment from the inside to the outside pipe. A total of 16 random array sets of three structural parameters with four levels were determined using the orthogonal experimental design. Commercial software was used for the construction of a 3D model for the selected experimental points, and this data was used to obtain the airflow velocities, which were then used to obtain the standard deviation of each experimental point. According to the range analysis, the combination of the three structural parameters was optimized. In other words, an efficient and economical optimization method considering the performance of the vented box was established, and it could be widely used to extend the storage time of fresh food.

Introduction

Fresh vegetables and fruits occupy a high proportion of human food consumption, not only because they have good taste and an attractive form, but also because they are of great benefit for people to obtain nutrition and maintain health1. Many studies have shown that fresh fruits and vegetables play a unique role in preventing many diseases2,3. In the storage process of fresh fruits and vegetables, fungi, light, temperature, and relative humidity are the important reasons for their deterioration4,5,6,7,8. These external conditions affect the quality of stored fresh fruits and vegetables by affecting the internal metabolism or chemical reactions9.

Common treatment technologies for fruits and vegetables include nonthermal and thermal preservation. Among them, thermal pretreatment has a positive effect on the drying process, but it can also have adverse effects on product quality, such as loss of nutrients, change of flavor and odor, and change of color10,11. Therefore, in recent years, the nonthermal preservation of products has received attention from the research perspective to meet the demand of consumers for fresh products. At present, there are mainly radiation processing, pulsed electric field, ozone processing, edible coatings, dense phase carbon dioxide, and other nonthermal preservation technologies to store fruits and vegetables, but these technologies often have shortcomings, such as the requirement of large equipment, high price, and the cost of use12. Therefore, the design of a simple structure, low cost, and convenient control of the preservation equipment is very meaningful to the food industry.

In the storage environment for fruits and vegetables, a proper air circulation system helps to eliminate the heat generated by the product itself, reduce the temperature gradient, and maintain the temperature and humidity in the space where it is located. Proper air circulation also prevents weight loss due to respiration and fungal infections13,14,15. Numerous studies have been conducted on airflow within different structures. Praeger et al.16,17 measured the wind speed at different positions under different fan operating powers in a warehouse through sensors and found that there could be as big as a sevenfold difference in air velocity due to different vertical heights, and the air velocity at each position was positively correlated with the fan operating power. Moreover, a study examined the effect of cargo arrangement and the number of fans on airflow, and it was concluded that increasing the distance of some fan positions and rationally choosing the number of fans was helpful in improving the effect. Berry et al.18 studied the effect of airflow in different fruit storage environments on stomata distribution in packing boxes. Using simulation software, Dehghannya et al.19,20 studied the air flow state of forced pre-cold air in the package with different vent areas, quantities, and distribution positions on the packaging wall, and obtained the nonlinear influence of each parameter on the air flow state. Delele et al.21 applied a computational fluid dynamics model to study the influence of products randomly distributed in different forms of ventilation boxes on airflow. They found that the product size, porosity, and box hole ratio had a greater impact on airflow, whereas random filling had a smaller impact. Ilangovan et al.22 studied airflow patterns and thermal behavior between the three packaging structures and compared the results with reference structural models. The results showed that the heat distribution in the box was not uniform because of the different locations and designs of the vent. Gong et al.23 optimized the width of the gap between the edge of the tray and the wall of the container.

The techniques used in this paper include simulation and optimization methods. The principle of the former is that the governing equations were discretized and numerically solved using the finite volume method21. The optimization method used in this paper is referred to as orthogonal optimization24. The orthogonal test is a typical multifactor and multilevel analysis method. The orthogonal table built using this method contains representative points uniformly distributed in the design space, which can visually describe the entire design space and be examined. That is, fewer points represent the full factor test, greatly saving time, manpower, material, and financial resources. The orthogonal test has been widely used in the design of experiments in the fields of power systems, chemistry, civil engineering, etc25.

The objective of this study is to design and optimize a high-performance vented box. A vented box can be defined as an original box including a gas control device that disperses the gas uniformly in the box. Velocity uniformity refers to how evenly air flows through the vented box. Yun-De et al.26 have previously shown that the property of multiporous material has an important effect on the velocity uniformity of a fresh vegetable box. In some experiments, a plenum or modulated chamber was left at both the top and the bottom of the test chamber to guarantee a homogenous distribution of either forced or induced air27. The vented box designed in this paper contains arrays of pipes with zigzag holes. Controlling the airflow distribution in the vented box is the main preservation strategy. There are two air inlets of equal size set parallelly at the left and right sides of the vented box, and an outlet is set at the upper side of the box. Designing the internal structure of a vented box is the key to this study. In other words, the number of pipes and holes is an important parameter for changing the internal structure of the vented box. The reference model has 10 pipes. The two middle pipes have 10 holes each, which are staggered across the pipes. The number of holes from the middle to the outer pipe increase by two at a time.

In other words, when we keep fresh vegetables, fruits, and other products, continuous and stable airflow can reduce the respiration of products, reduce ethylene and other harmful substances for product preservation, and reduce the temperature produced by the products themselves. Due to the different parameters of the vented box, it is not easy to obtain the required airflow state, which will affect the preservation property of the vented box. Therefore, the project takes the internal airflow velocity uniformity of the vented box as the control objective. A sensitivity analysis was conducted for the structural parameters of the vented box. The samples were selected by orthogonal experimental design. We used range analysis to optimize the combination of the three structural parameters. Meanwhile, we verify the desirability of the optimization results.

Protocol

1. Pre-simulation processing

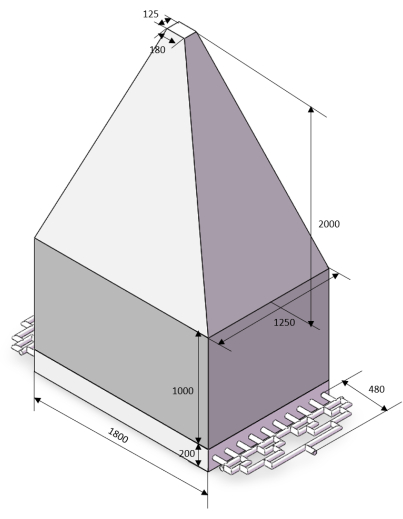

NOTE: Considering the arrays of pipes, the three-dimensional bottom half and the top half of the vented box models are established by using three-dimensional software and saving them as X_T files, the overall dimensions are shown in Figure 1. Configurations are shown in the table of materials.

- Run the simulation software and drag the Mesh component from the "Component Systems" to the "Project Schematic" window. Name it "the bottom". Right-click Geometry and click Browse to import the bottom X_T file.

- Right-click Geometry, click New DesignModeler Geometry to enter into the "Mesh-Designmodeler" window, and click Generate to display the bottom model.

- Right-click the upper surface and click Named Selection to rename it "vented box_upper". Select Selection Filter: Bodies. Right-click the bottom model to select the Named Selection and rename it as "the bottom".

- Select Selection Filter: Faces and switch the "Select Mode" to Box Select. Select all the inner surfaces, right-click to select the Named Selection, and rename it as "inner surfaces_external", defined as mech interfaces later. Return to the initial window.

- Double-click the bottom Mesh. Enter the "Meshing" window. Change the "Physical Preferences" from Mechanical to CFD. Click Update to generate the mesh model. Return to the initial window.

- Drag the Meshcomponent from the "Component Systems" to the "Project Schematic" window. Name it "top". Right-click Geometry and click Browse to import the top X_T file.

- Right-click Geometry and click New DesignModeler Geometry to enter into the "Mesh-Designmodeler" window. Click Generate to display the top model.

- Right-click the lower surface and click Named Selection to rename it as "vented box_lower". Select Selection Filter: Bodies. Right-click the top model to select the Named Selection and rename it as "top".

- Select Selection Filter: Faces. Right-click the upper surface and click Named Selection to rename it as the outlet. Return to the initial window.

- Double-click the top's Mesh. Enter the "Meshing" window. Change the "Physical Preferences" from Mechanical to CFD. Right-click Mesh to select the Sizing in the "Insert". Select Selection Filter: Bodies. Select the top model and type 18 in "Element Size". Click Update. Return to the initial window.

- Drag the Mesh component from the "Component Systems" to the "Project Schematic" window. Name it as the pipe. Import the pipe X_T file by clicking Geometry.

- Enter the "Mesh-Designmodeler" window. Click Generate to display the pipe model displays again.

- Select the two end faces of the pipe and label them as "inlet1" and "inlet2", and the pipe by body selecting and labeling as a pipe.

- All inner surfaces by box selecting are labeled as "inner surfaces_internal", defined as mesh interfaces later. Return to the initial window.

- DoubleClick the pipe's Mesh. Enter the "Meshing" window. Change the "Physical Preferences" from Mechanical to CFD. The mesh model can be generated by clicking "Update". Return to the initial window.

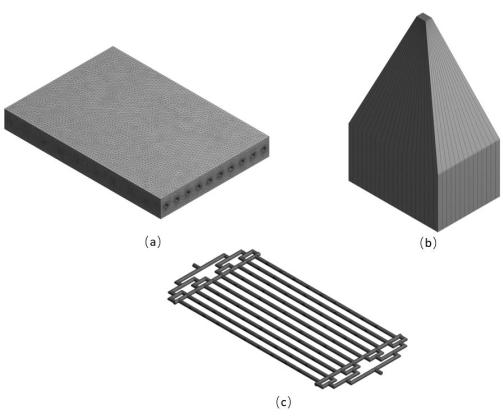

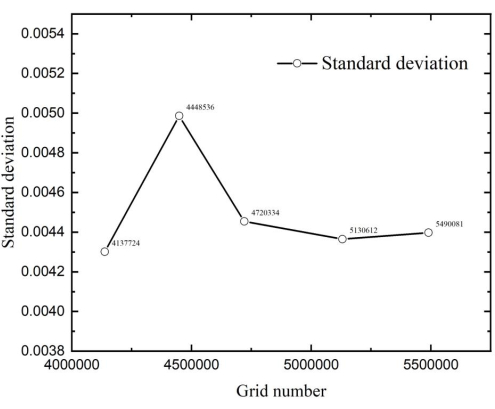

NOTE: Figure 2A shows the grid of the bottom half of the vented box, Figure 2B shows the grid of the top half of the vented box, and Figure 2C shows the grid of the pipe. As shown in Figure 3, with the number of grids increasing from 4,137,724 to 5,490,081, the standard deviation changes are less than 0.0008. Considering the computation ability and accuracy, the following analysis is based on a grid model with 4,448,536 grids.

2. Simulation analysis

NOTE: The following operations are described based on the general sequence of simulation analysis from setup to solution to result.

- Drag the Simulation component to the "Project Schematic" window. Link three Mesh components to the simulation component and update to enter.

- Setup

NOTE: The "Setup" consists of five steps: General, Models, Materials, Cell Zone Conditions, and Boundary Conditions.- General: Verify the validity of the mesh model. Check whether the mesh has negative volume. Select Steady. For the relaxation, residual, and time scale factors, select the default values. If there is any problem with the divided grid or model settings, an error message will pop up.

- Models: Enter the setting interface of "Viscous Model" to select the K-epsilon Model.

- Materials: Set the "air" material.

- Cell Zone Conditions: Change the type of cell zone to Fluid.

- Boundary Conditions

- Convert the type of vented box_upper, vented box_lower, inner surfaces_external, and inner surfaces_internal from the default "Wall" to "Interface".

NOTE: Simulation software immediately generates the "Mesh Interfaces" after ending the above step. - Open Mesh Interfaces and enter the "Create/Edit Mesh Interfaces" window. Match inner surfaces_external to inner surfaces_internal. Match vented box_upper to vented box_lower. Finally, the two mesh interfaces are created in the vented box and named interface1 and interface2, respectively.

- Set the airflow velocities of all inlets as 8.9525 m/s in the "Velocity Inlet" window and the gauge pressure of the outlet as zero in the "Pressure Outlet" window.

- Convert the type of vented box_upper, vented box_lower, inner surfaces_external, and inner surfaces_internal from the default "Wall" to "Interface".

- Solution

- Set the style of solution initialization as Standard Initialization before initializing.

- Set the Number of Iterations as 2,000.

- Click Calculate to start the simulation and return to the initial window until the simulation ends.

- Results

- Click Results. Enter the "CFD Post" window and click the streamline icon of in the toolbox.

- Select outlet in "Start From" and Backward in "Direction". Click Apply to generate the internal flow diagram of the vented box.

- Click Plane in "Location", select ZX Plane in "Method", and select the input value as 0.6. Click Apply to generate the plane 0.6 m from the bottom surface.

- Click the Contour icon in the toolbox, select Plane 1 in "Locations", select Velocity in "Variable", and select Local in "Range". Click Apply to generate the velocity contour.

- Export the flow rate data for the plane generated above. Acquire the standard deviation of the flow rate in spreadsheet software (e.g., Excel).

NOTE: Sensitivity analysis of three structural variables of the vented box was carried out. The number of pipes has four levels: eight, 10, 12, and 14. The number of holes in the middle pipes has four levels: eight, 10, 12, and 14. The number of each increment from the inside to the outside pipe has four levels: zero, two, four, and six. Modify the base model according to changes in these structural parameters. Repeat steps 1.1 through 2.5 10 times to obtain the data in Table 1. It can be seen from the table that the three structural parameters have certain effects on the standard deviation of the flow rate.

3. Orthogonal experiment design and range analysis

- Run the statistical analysis software. Click Data and Generate in "Orthogonal Design".

- Enter pipe_number into "Factor Name" and A in "Factor Label". Click Add and Define Values to set four levels for the number of pipes. Click Continue and return to the "Generate Orthogonal Design" window.

- Enter whole_number into "Factor Name" and B in "Factor Label". Click Add and Define Values to set four levels for the number of holes. Click Continue and return to the "Generate Orthogonal Design" window.

- Enter cumulative_number into "Factor Name" and C in "Factor Label". Click Add and Define Values to set four levels for the number of increments. Click Continue and return to the "Generate Orthogonal Design" window.

- Click Create new data file to generate 16 array samples. Click Variable View to select Nominal in "Measure" and Input in "Role". Rename it as "standard_deviation×100000".

- Repeat steps 1.1 to 2.5 with the sample points above; the resulting 16 standard deviations multiplied by 100,000 are filled into the sample list for later optimization.

- Click Analyze and Univariate in "General Linear Model". Fill standard_deviation×100000 into "Dependent Variable" and pipe_number, hole_number, cumulative_number into "Fixed Factor(s)". Click Model and Build terms. Change Interaction to Main effects. Fill A, B, C into "Model". Click Continue and return to the "Univariate" window.

- Click EM Means and fill A, B, C into "Display Means For". Click Continue and go back to the "Univariate" window.

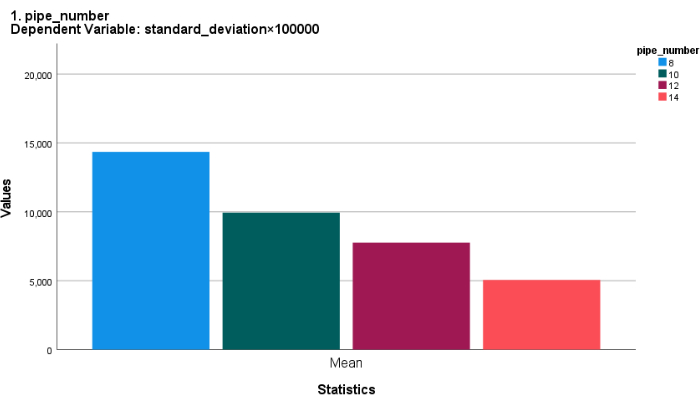

- Click OK and get the optimization result; the minimum value of the "mean" column in the table corresponds to the optimal variable. Double-click on the table, enter into the "Pivot Table" window, click Edit, and click Bar in "Create graph" to generate the histogram.

Representative Results

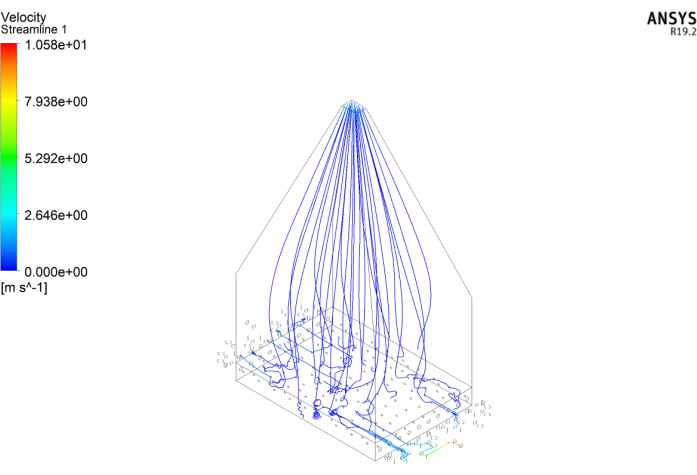

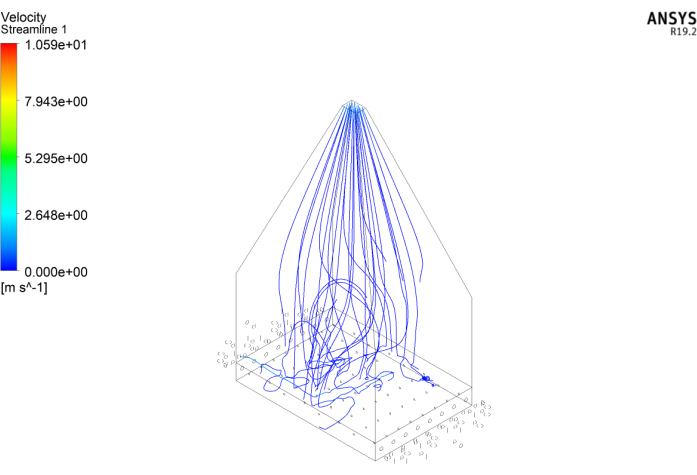

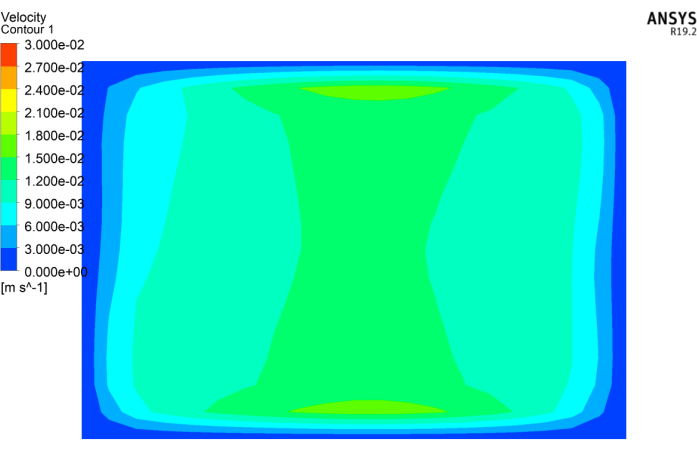

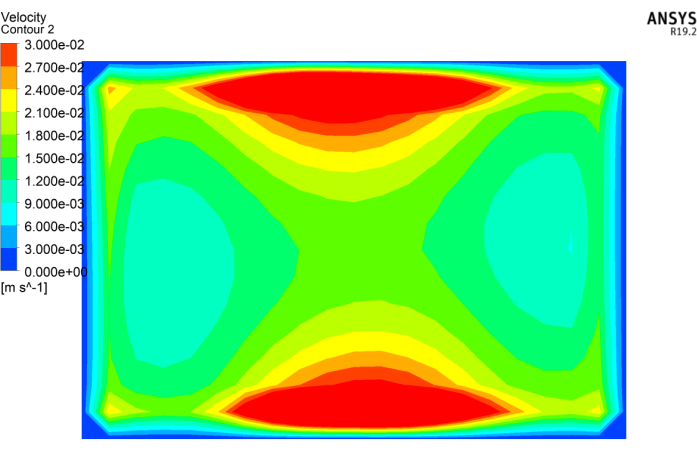

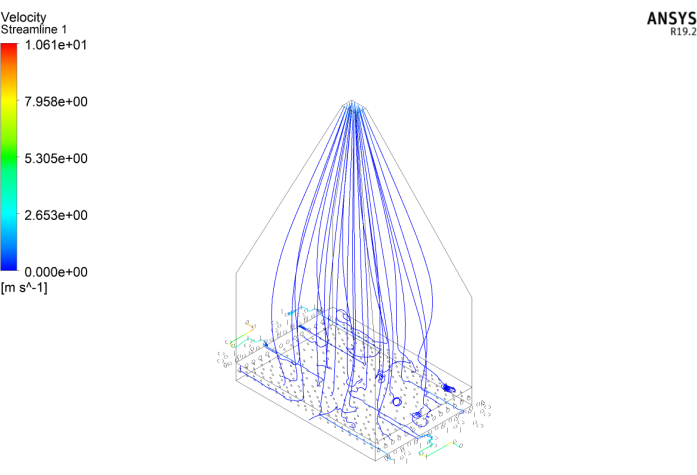

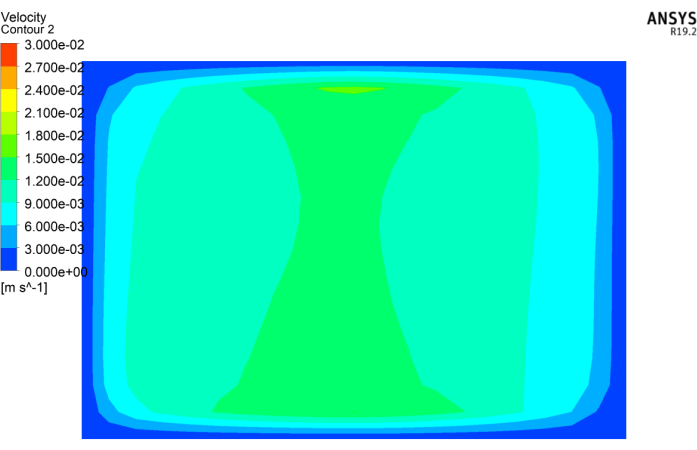

Following the protocol, the first three parts were the most important, which include modeling, meshing, and simulation, all in order to obtain the standard deviation of the flow rate. Then, we completed the structure optimization of the vented box through orthogonal experiments and range analysis. The model used in the protocol is the reference-vented box model, which is the initial model obtained from the reference. Figure 4 shows the result of the streamlined flow of the reference vented box model, and Figure 5 shows the result of the streamlined flow of the vented box, which is one of the models used for sensitivity analysis. This vented box model is model number one in Table 1. Streamline flows are the trajectories of fluid motion to visualize the flow of fluid inside the vented box. As shown in Figure 4 and Figure 5, the streamlined flow of the latter vented box is even messier than that of the former due to the inner structure of the vented box. Figure 6 shows the result for the flow velocity distribution inside the reference vented box model, and Figure 7 shows the result for the flow velocity distribution inside the vented box model, which is one of the models used for sensitivity analysis. As shown in Figure 6 and Figure 7, the flow rate inside the vented box, which is one of the models used for sensitivity analysis, is more uneven.

In order to understand the streamlined distribution inside the vented box more intuitively, we established a plane 0.6 m away from the bottom of the vented box. The flow rate of each node on the output plane is used for the mathematical statistics calculation. The standard deviation is calculated by  where xi and μ stand for the flow rate of each node and mean flow rate of all nodes, respectively. Table 1 shows the standard deviations of flow rates for the 10 groups of the vented box used for sensitivity analysis, including the reference model. It can be seen that the three structural variables have a certain impact on the standard deviation of the flow rate, and the number of pipes has the greatest impact on the standard deviation of the flow rate. A large standard deviation represents a large difference between most flow rates and their mean flow rate; a small standard deviation means that these flow rates are close to their mean flow rate. Thus, it can be seen that changing the internal structure of the vented box can change its internal flow and make the streamline more homogeneous.

where xi and μ stand for the flow rate of each node and mean flow rate of all nodes, respectively. Table 1 shows the standard deviations of flow rates for the 10 groups of the vented box used for sensitivity analysis, including the reference model. It can be seen that the three structural variables have a certain impact on the standard deviation of the flow rate, and the number of pipes has the greatest impact on the standard deviation of the flow rate. A large standard deviation represents a large difference between most flow rates and their mean flow rate; a small standard deviation means that these flow rates are close to their mean flow rate. Thus, it can be seen that changing the internal structure of the vented box can change its internal flow and make the streamline more homogeneous.

When designing the orthogonal experiment, there are three design variables in this article: the number of pipes, the number of holes in the middle pipes, and the number of each increment from the inside to the outside pipe. Each of these three variables has four levels. As shown in Table 2, 16 groups of experimental design points were obtained by orthogonal experimental design. The standard deviations were calculated by simulation software. From the number of sample points taken out, it can be seen that the orthogonal experimental design can achieve the purpose of providing maximum parameter value coverage with the least number of test cases.

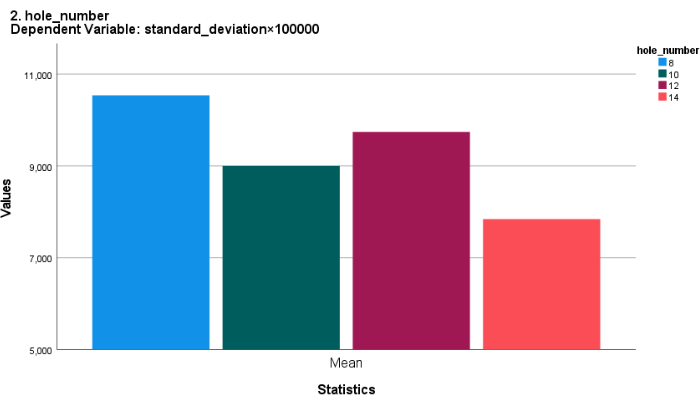

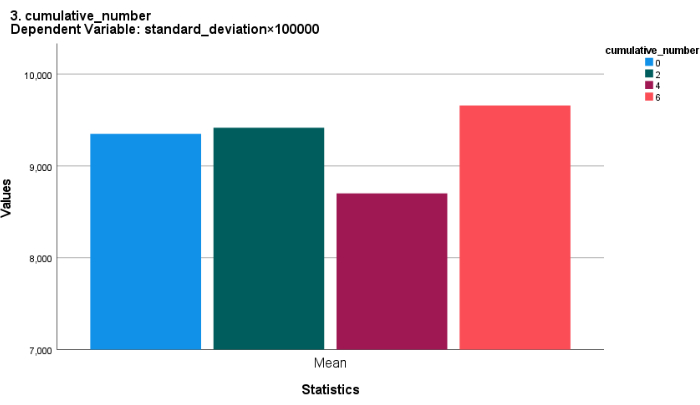

In the end, the range analysis method is used as the optimization method for finding the optimal structure parameter combination. Figure 8 shows the optimization result for the structural parameter of the number of pipes. From this, we can see that the minimum value is obtained when the number of pipes is 14. Figure 9 shows the optimization result for the structural parameter about the number of holes in the middle pipes. From this, we can see that the minimum value is obtained when the number of holes in the middle pipes is 14. Figure 10 shows the optimization result for the structural parameter about the number of increments from the inside to the outside pipe. From this, we can see that the minimum value is obtained when the number of increments from the inside to the outside pipe is four. The above analysis shows that the optimal combination is "pipe_number 14, hole_number 14, cumulative_number 4"". To confirm the accuracy, the optimal case was analyzed by simulation software. Figure 4 and Figure 11 show the streamline flow of the reference model versus the optimized model. Figure 6 and Figure 12 show the flow velocity distribution inside the reference model versus the optimized model. Table 3 shows a comparison between the optimization results and the results of the reference model. It can be seen that the standard deviation calculated from the optimized model is lower compared to the standard deviation of the reference model. Table 4 shows the increase in the number of holes from four to six, with little change in standard deviation, and model number three is the optimized model from the perspective of machining costs. In this paper, the internal environment of the vented box is improved by optimizing its structure, and the quality of its internal environment is measured by standard deviation; the smaller the standard deviation, the more homogeneous the airflow inside the vented box, which indicates that the optimization method adopted in this work is effective and feasible.

Table of materials. The table shows the basic configurations for this study, which includes the necessary computer with a high-performance graphics processing unit (GPU) and three software from SolidWorks, Ansys-Workbench, and SPSS.

Table 1: Parameter sensitivity analysis. The table shows the standard deviations of flow rates for the 10 groups of the vented box used for sensitivity analysis. Please click here to download this Table.

Table 2: Experimental design points. Please click here to download this Table.

Table 3: Comparison between the optimization results and the results of the reference model. Please click here to download this Table.

Table 4: Comparison of the cumulative number of 14 pipes and 14 holes. Please click here to download this Table.

Figure 1: 3D model of the vented box. Please click here to view a larger version of this figure.

Figure 2: Grid diagram. (A) The grid of the bottom half of the vented box, (B) the grid of the top half of the vented box, and (C) the grid of the pipe. Please click here to view a larger version of this figure.

Figure 3: Grid independence test. The X-axis is the different total number of grids in the mesh model, and the Y-axis is the standard deviation. Please click here to view a larger version of this figure.

Figure 4: Streamline flow of the reference-vented box model. Please click here to view a larger version of this figure.

Figure 5: Streamline flow of the vented box model. The figure shows the result of the streamline of the vented box, which is a model used for sensitivity analysis. Please click here to view a larger version of this figure.

Figure 6: Flow velocity distribution inside the reference-vented box model. Please click here to view a larger version of this figure.

Figure 7: Flow velocity distribution inside the vented box model. The figure shows the result for the flow velocity distribution inside the vented box, which is a model used for sensitivity analysis. Please click here to view a larger version of this figure.

Figure 8: Optimization results for the number of pipes. Please click here to view a larger version of this figure.

Figure 9: Optimization results for the number of holes in the middle pipes. Please click here to view a larger version of this figure.

Figure 10: Optimization result of the number of increments from the inside to the outside pipe. Please click here to view a larger version of this figure.

Figure 11: Streamline flow of the optimized vented box model. Please click here to view a larger version of this figure.

Figure 12: Flow velocity distribution inside the optimized vented box model. Please click here to view a larger version of this figure.

Discussion

Due to its high performance and complex structure, in this study, we built a ventilated box based on modeling software. We analyzed the internal flow by simulation software. Simulation software is known for its advanced physics modeling capabilities, which include turbulence modeling, single- and multiphase flows, combustion, battery modeling, fluid-structure interaction, and much more. The sample selection method used in this paper is the orthogonal experimental design method, which is suitable for mechanical production and other fields because of its scientific method, simple operation, cost-saving benefit, and remarkable effect. The range analysis method can obtain the primary and secondary factors and the optimal combination of the experiment through a simple calculation.

The results are dependent on some critical components of this setup within the protocol. First, when creating the 3D model of the battery pack, giving each body and surface in the model an easily recognizable name is a key step for subsequently adding material, creating a mesh interface, and setting boundary conditions. Second, before determining important structural parameters, parameter sensitivity analysis must be carried out to select the more important structural parameters. Third, when operating each software, it is necessary to set each parameter accurately, especially the unit of the parameter.

After importing the grid model, one should troubleshoot the mesh model and click Check to check whether the mesh has a negative volume. If there is any problem with the divided grid or model settings, an error message will pop up. The main limitation of this study is that the 3D model used is built after simplifying the real vented box. The internal flow of the simulated vented box will be slightly different from the real one. The result can be close to reality, but not exactly. This optimization method applies to integer-type structural parameters, such as the number of pipes and holes. Compared with genetic algorithm and annealing algorithm optimization, the optimization results in this paper are inferior to the results of algorithm optimization; however, in engineering, aspect integer-type parameter structure is more suitable for the production of products.

This technology can not only obtain high-quality and high-reliability test data and test products, but also help us master the internal relationship between test subjects in the analysis of test data. This protocol will help establish an optimization method while simultaneously considering the energy consumption and performance of the vented box, and it can be widely used to extend the storage time of fresh food. This technique can also be used in mechanical design, architectural design, and other fields.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This research is supported by Wenzhou Science and Technology Bureau of China (Wenzhou major scientific and technological innovation project under Grant No. ZG2020029). The research is funded by the Wenzhou Association for Science and Technology with Grant No. KJFW09. This research was supported by the Wenzhou Municipal Key Science and Research Program (ZN2022001).

Materials

| Hardware | |||

| NVIDIA GPU | NVIDIA | N/A | An NVIDIA GPU is needed as some of the software frameworks below will not work otherwise. https://www.nvidia.com |

| Software | |||

| Ansys-Workbench | ANSYS | N/A | Multi-purpose finite element method computer design program software.https://www.ansys.com |

| SOLIDWORKS | Dassault Systemes | N/A | SolidWorks provides different design solutions, reduces errors in the design process, and improves product quality www.solidworks.com |

| SPSS | IBM | N/A | Software products for statistical analytical operations, data mining, predictive analysis, and decision support tasks software.https://www.ibm.com |

References

- Villa-Rodriguez, J. A., et al. Maintaining antioxidant potential of fresh fruits and vegetables after harvest. Critical Reviews in Food Science and Nutrition. 55 (6), 806-822 (2015).

- Mozaffari, H., Lafrenière, J., Conklin, A. Does eating more variety of fruits and vegetables reduce risk of cancer? Findings from a systematic review and meta-analysis. Current Developments in Nutrition. 4, 339-339 (2020).

- Wu, S., Fisher-Hoch, S. P., Reininger, B. M., Lee, M., McCormick, J. B. Fruit and vegetable intake is inversely associated with cancer risk in Mexican-Americans. Nutrition and Cancer. 71 (8), 1254-1262 (2019).

- Nan, M., Xue, H., Bi, Y. Contamination, detection and control of mycotoxins in fruits and vegetables. Toxins. 14 (5), 309 (2022).

- Alothman, M., Bhat, R., Karim, A. A. Effects of radiation processing on phytochemicals and antioxidants in plant produce. Trends in Food Science & Technology. 20 (5), 201-212 (2009).

- Ayala-Zavala, J. F., Wang, S. Y., Wang, C. Y., González-Aguilar, G. A. Effect of storage temperatures on antioxidant capacity and aroma compounds in strawberry fruit. LWT-Food Science and Technology. 37 (7), 687-695 (2004).

- Piljac-Žegarac, J., Šamec, D. Antioxidant stability of small fruits in postharvest storage at room and refrigerator temperatures. Food Research International. 44 (1), 345-350 (2011).

- Lal Basediya, A., Samuel, D. V. K., Beera, V. Evaporative cooling system for storage of fruits and vegetables – a review. Journal of Food Science and Technology. 50 (3), 429-442 (2013).

- Sandhya, Modified atmosphere packaging of fresh produce: Current status and future needs. LWT-Food Science and Technology. 43 (3), 381-392 (2010).

- Bassey, E. J., Cheng, J. H., Sun, D. W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends in Food Science & Technology. 112, 137-148 (2021).

- Mieszczakowska-Frąc, M., Celejewska, K., Płocharski, W. Impact of innovative technologies on the content of vitamin C and its bioavailability from processed fruit and vegetable products. Antioxidants. 10 (1), 54 (2021).

- Xue, Z., Li, J., Yu, W., Lu, X., Kou, X. Effects of nonthermal preservation technologies on antioxidant activity of fruits and vegetables: A review. Food Science and Technology International. 22 (5), 440-458 (2016).

- Olaimat, A. N., Holley, R. A. Factors influencing the microbial safety of fresh produce: a review. Food Microbiology. 32 (1), 1-19 (2012).

- Caleb, O. J., Mahajan, P. V., Al-Said, F. A. J., Opara, U. L. Modified atmosphere packaging technology of fresh and fresh-cut produce and the microbial consequences-a review. Food and Bioprocess Technology. 6 (2), 303-329 (2013).

- Waghmare, R. B., Mahajan, P. V., Annapure, U. S. Modelling the effect of time and temperature on respiration rate of selected fresh-cut produce. Postharvest Biology and Technology. 80, 25-30 (2013).

- Praeger, U., et al. Airflow distribution in an apple storage room. Journal of Food Engineering. 269, 109746 (2020).

- Praeger, U., et al. Influence of room layout on airflow distribution in an industrial fruit store. International Journal of Refrigeration. 131, 714-722 (2021).

- Berry, T. M., Delele, M. A., Griessel, H., Opara, U. L. Geometric design characterisation of ventilated multi-scale packaging used in the South African pome fruit industry. Agricultural Mechanization in Asia, Africa, and Latin America. 46 (3), 34-42 (2015).

- Dehghannya, J., Ngadi, M., Vigneault, C. Mathematical modeling of airflow and heat transfer during forced convection cooling of produce considering various package vent areas. Food Control. 22 (8), 1393-1399 (2011).

- Dehghannya, J., Ngadi, M., Vigneault, C. Transport phenomena modelling during produce cooling for optimal package design: thermal sensitivity analysis. Biosystems Engineering. 111 (3), 315-324 (2012).

- Delele, M. A., et al. Combined discrete element and CFD modelling of airflow through random stacking of horticultural products in vented boxes. Journal of Food Engineering. 89 (1), 33-41 (2008).

- Ilangovan, A., Curto, J., Gaspar, P. D., Silva, P. D., Alves, N. CFD modelling of the thermal performance of fruit packaging boxes-influence of vent-holes design. Energies. 14 (23), 7990 (2021).

- Gong, Y. F., Cao, Y., Zhang, X. R. Forced-air precooling of apples: Airflow distribution and precooling effectiveness in relation to the gap width between tray edge and box wall. Postharvest Biology and Technology. 177, 111523 (2021).

- Guo, R., Li, L. Heat dissipation analysis and optimization of lithium-ion batteries with a novel parallel-spiral serpentine channel liquid cooling plate. International Journal of Heat and Mass Transfer. 189, 122706 (2022).

- Chen, J., et al. Optimization of geometric parameters of hydraulic turbine runner in turbine mode based on the orthogonal test method and CFD. Energy Reports. 8, 14476-14487 (2022).

- Yun-De, S., Hai-Dong, Q., Sun, B., Li, Z. Z., Cao, K. B. Flow analysis of fresh vegetable box based on multiporosity material. International Journal of Education and Management Engineering. 2 (1), 29 (2012).

- Elansari, A. M., Mostafa, Y. S. Vertical forced air pre-cooling of orange fruits on bin: Effect of fruit size, air direction, and air velocity. Journal of the Saudi Society of Agricultural Sciences. 19 (1), 92-98 (2020).