Sensitivity Enhancement of Soft Capacitive Pressure Sensors Using a Solvent Evaporation-Based Porosity Control Technique

Summary

A simple and cost-efficient fabrication method based on the solvent evaporation technique is presented to optimize the performance of a soft capacitive pressure sensor, which is enabled by porosity control in the dielectric layer using different mass ratios of the molding PDMS/toluene solution.

Abstract

Soft pressure sensors play a significant role in developing "man-machine" tactile sensation in soft robotics and haptic interfaces. Specifically, capacitive sensors with micro-structured polymer matrices have been explored with considerable effort because of their high sensitivity, wide linearity range, and fast response time. However, the improvement of the sensing performance often relies on the structural design of the dielectric layer, which requires sophisticated microfabrication facilities. This article reports a simple and low-cost method to fabricate porous capacitive pressure sensors with improved sensitivity using the solvent evaporation-based method to tune the porosity. The sensor consists of a porous polydimethylsiloxane (PDMS) dielectric layer bonded with top and bottom electrodes made of elastic conductive polymer composites (ECPCs). The electrodes were prepared by scrape-coating carbon nanotubes (CNTs)-doped PDMS conductive slurry into mold-patterned PDMS films. To optimize the porosity of the dielectric layer for enhanced sensing performance, the PDMS solution was diluted with toluene of different mass fractions instead of filtering or grinding the sugar pore-forming agent (PFA) into different sizes. The evaporation of the toluene solvent allowed the fast fabrication of a porous dielectric layer with controllable porosities. It was confirmed that the sensitivity could be enhanced more two-fold when the toluene to PDMS ratio was increased from 1:8 to 1:1. The research proposed in this work enables a low-cost method of fabricating fully integrated bionic soft robotic grippers with soft sensory mechanoreceptors of tunable sensor parameters.

Introduction

In recent years, flexible pressure sensors have been drawing attention due to their indispensable application in soft robotics1,2,3, "man-machine" haptic interfaces4,5, and health monitoring6,7,8. Generally, the mechanisms for pressure sensing include piezoresistive1,4,7, piezoelectric2,6, capacitive2,3,9,10,11,12,13, and triboelectric8 sensors. Among them, capacitive pressure sensors stand out as one of the most promising methods in tactile sensing due to their high sensitivity, low limit of detection (LOD), etc.

For better sensing performance, various microstructures such as micro-pyramids2,9,14, micro-pillars15, and micro-pores9,10,11,12,13,16,17 have been introduced to flexible capacitive pressure sensors, and the fabrication methods have also been optimized to further improve the sensing performances of such structures. However, most of these structures require sophisticated microfabrication facilities, which significantly increases the manufacturing costs and operational difficulties. For example, as the most commonly used microstructure in soft pressure sensors, micro-pyramids rely on lithographically defined and wet-etched Si wafers as the molding template, which requires precision equipment and a strict cleanroom environment9,14. Therefore, micropore structures (porous structures) that can be made by simple fabrication processes and with low-cost raw materials while maintaining high sensing performances have drawn increasing attention recently9,10,11,12,13,16,17. This will be discussed, alongside the disadvantages of changing the PFA and its amount, as the motivation for using our fraction control method.

Herein, this work proposes a simple and low-cost method based on the solvent-evaporation technique to fabricate a porous flexible capacitive pressure sensor with controllable porosity. The complete manufacturing process includes the fabrication of the porous PDMS dielectric layer, the scrape coating of the electrodes, and the bonding of three functional layers. Specifically, this work innovatively uses a PDMS/toluene mixed solution with a certain mass ratio to fabricate the porous PDMS dielectric layer based on the sugar/erythritol mixture template. Meanwhile, a uniform PFA particle size ensures uniform pore morphology and distribution; thus, the porosity can be controlled by changing the PDMS/toluene mass ratio. The experimental results show that the sensitivity of the proposed pressure sensor can be enhanced more than two-fold by increasing the PDMS/toluene mass ratio from 1:8 to 1:1. The variation in the micropore wall thickness due to different PDMS/toluene mass ratios is also confirmed by optical microscope images. The optimized soft capacitive pressure sensor shows a high sensing performance with a sensitivity and response time of 3.47% kPa−1 and 0.2 s, respectively. This method achieves the fast, low-cost, and easy-operation fabrication of a porous dielectric layer with controllable porosity.

Protocol

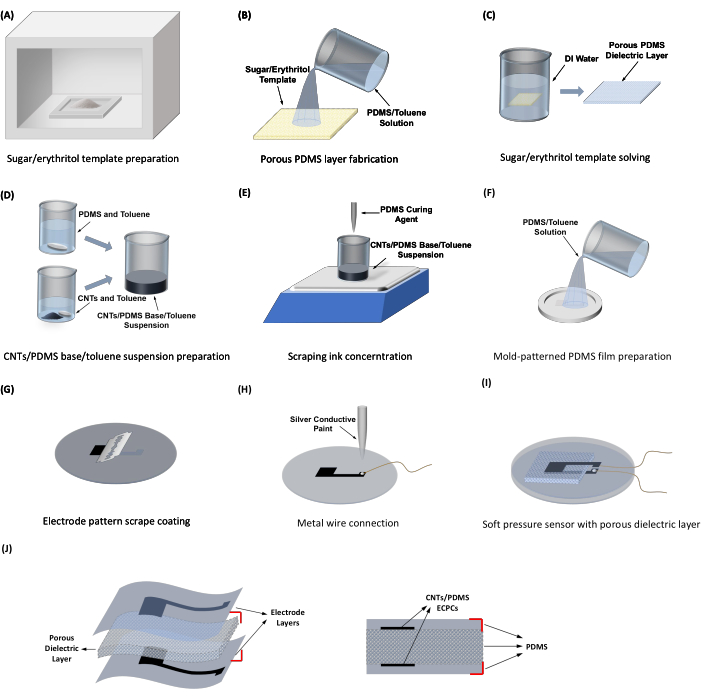

1. Fabrication of the soft capacitive pressure sensor with a porous PDMS dielectric layer

- Manufacturing of the porous PDMS dielectric layer

- Prepare the sugar/erythritol porous template following the steps below.

- Filter the sugar with sample sieves with apertures of 270 µm and 500 µm. Choose sugar with a particle diameter in the range of 270-500 µm.

NOTE: A larger or smaller sugar particle size is also acceptable as long as the uniformity is within the tolerance limits. The diameter of the sugar particle will affect the pore size of the porous PDMS layer manufactured in a later step but will not determine the pore size completely. - Grind erythritol (see Table of Materials) into powder to ensure a more uniform mixing with the sugar.

- Weigh a certain amount of filtered sugar and erythritol powder with a mass ratio of 20:1. Shake to mix them evenly.

- Fill the sugar/erythritol mixture into a commercially obtained sugar/erythritol metal mold (see Table of Materials). Press the surface to make the filler compact.

NOTE: To ensure easy demolding in the next step, a layer of Al foil can be placed in the mold before the sugar/erythritol. - Heat the mold with the sugar/erythritol mixture in a convection oven at 135 °C for 2 h, as shown in Figure 1A. After cooling at room temperature, take out the lump plate sugar (i.e., the porous template).

- Filter the sugar with sample sieves with apertures of 270 µm and 500 µm. Choose sugar with a particle diameter in the range of 270-500 µm.

- Fabricate the porosity-controllable PDMS dielectric layer.

- Weigh 5 g of toluene, 5 g of PDMS base, and 0.5 g of PDMS curing agent (see Table of Materials) in a centrifuge tube (i.e., the mass ratio of PDMS base/toluene/curing agent is 10:10:1). Stir the solution evenly.

NOTE: The mass ratio of PDMS base solution to curing agent is fixed at 10:1, while the mass ratio of PDMS to toluene is used to control the porosity of the PDMS dielectric layer. The porosity decreases when increasing the PDMS fraction. The minimum porosity is obtained when no toluene is added. - Centrifuge the solution at 875 x g for 30 s at room temperature to remove air bubbles.

NOTE: If the solution volume is large, the solution can be prepared in a beaker. The centrifugal treatment is replaced by vacuum degassing for 15 min. - Place the square sugar/erythritol porous template obtained in step 1.1.1 in a Petri dish. Insert double-sided tape as spacers beneath the four corners to lift the template from the Petri dish surface.

NOTE: The template can also be placed on a Si wafer, but this method will lead to a thicker layer of PDMS on the interface between the template and the Si wafer, which may affect the sensor performance. - Pour the PDMS/toluene solution onto the template, and slightly incline the Petri dish so that the solution can completely fill all the gaps among the sugar particles, as shown in Figure 1B.

- Place the Petri dish with the PDMS/toluene solution-filled porous template in a vacuum desiccator, and degas for 20 min.

- Transfer the Petri dish from the vacuum desiccator into the oven at 90 °C for 45 min to evaporate the toluene and cure the liquid PDMS.

- Immerse the cured PDMS embedded in the porous template in deionized water (DI water), as shown in Figure 1C. Heat on a hot plate at 140 °C until the sugar template completely dissolves. Clean the porous PDMS with DI water.

- Weigh 5 g of toluene, 5 g of PDMS base, and 0.5 g of PDMS curing agent (see Table of Materials) in a centrifuge tube (i.e., the mass ratio of PDMS base/toluene/curing agent is 10:10:1). Stir the solution evenly.

- Prepare the sugar/erythritol porous template following the steps below.

- Fabrication of the flexible electrode layers based on ECPCs

- Synthesize the ECPCs ink.

- Weigh 0.16 g of CNTs (diameter: 10-20 nm, length: 10-30 µm, see Table of Materials) and 4 g of toluene in a beaker, and magnetically stir at 250 rpm for 1.5 h. Meanwhile, weigh 2 g of PDMS base and 2 g of toluene into a beaker, and magnetically stir at 200 rpm for 1 h. Cover the beaker with sealing film while stirring to prevent solvent evaporation.

- Mix the CNTs/toluene suspension with the PDMS base/toluene solution, and cover the beaker with a sealing film. Magnetically stir at 250 rpm for 2 h.

- Add 0.2 g of PDMS curing agent into the mixed solution. Magnetically stir at 75 °C and 250 rpm for 1 h. Uncover the beaker for solvent evaporation and suspension concentration when stirring, as shown in Figure 1D, E.

NOTE: The duration of stirring and heating is adjustable. The viscosity of the mixture increases with stirring time, which facilitates the following scrape coating operation. However, the duration should not be too long to prevent the PDMS solution from curing. When the mixture is concentrated to a viscosity convenient for scrape coating, the ECPCs ink synthesis process is finished.

- Scrape-coat the electrodes following the steps below.

- Weigh toluene, PDMS base, and PDMS curing agent in a centrifuge tube with a mass ratio of 2:10:1. Stir the solution evenly.

- Centrifuge the solution at 875 x g for 30 s at room temperature to remove air bubbles.

- Pour 1.3 g of PDMS/toluene solution into a commercially obtained electrode metal mold (see Table of Materials) with an embossed electrode pattern, as shown in Figure 1F.

NOTE: The embossed pattern at the bottom of the mold is 0.2 mm thick. - Place the mold in a vacuum desiccator, and degas for 10 min.

- Cure the PDMS in the mold on a hot plate at 90 °C for 15 min. Peel off the patterned PDMS film after cooling at room temperature.

- Attach the flat side of the PDMS film onto a Si wafer (i.e., expose the side with the electrode pattern). Ensure no air bubbles exist between the PDMS film and the Si wafer.

- Scrape-coat the ECPCs ink prepared in step 1.2.1 into the electrode pattern, as Figure 1G shows. Clean the excessive ink with an isopropyl alcohol (IPA)-dipped dust-free wipe.

- Cure the ECPCs ink on a hot plate at 90 °C for 15 min.

- Repeat steps 1.2.2.3-1.2.2.8 to manufacture both the upper and lower electrode layers.

- Synthesize the ECPCs ink.

- Bonding and packaging of the soft capacitive sensors

- Attach the metal wire (see Table of Materials) to the electrode. Drop silver conductive paint (see Table of Materials) at the connection location to ensure good conductivity, as shown in Figure 1H. Wait until the silver conductive paint dries at room temperature.

- Drop the liquid PDMS solution prepared in step 1.2.2.1 onto the connection to seal the dried silver conductive paint completely. Cure the PDMS on a hot plate at 90 °C for 15 min.

- Repeat steps 1.3.1-1.3.2 to connect the wire for both the upper and lower electrode layers.

- Apply a thin layer of liquid PDMS prepared in step 1.2.2.1 evenly onto the electrode film as an adhesion layer for bonding between the electrode layer and the dielectric layer.

- Place the porous PDMS dielectric layer fabricated in step 1.1.2 onto the electrode layer.

- Cure the PDMS glue on a hot plate at 95 °C for 10 min. Place a glass Petri dish onto the porous PDMS to ensure good contact between the two layers during heating.

- Repeat step 1.3.4 for the other electrode layer. Reverse the bonded electrode-dielectric layer obtained in step 1.3.6, and place it on the other single electrode layer (i.e., to have the porous PDMS layer in direct contact with the electrode layer). Ensure that the two electrodes are strictly aligned opposite to each other.

- Repeat step 1.3.6 to finish the bonding between the porous PDMS layer and the other electrode layer.

NOTE: An illustration of the final sensor is shown in Figure 1I. Illustrations of the structure and materials of the sensor are shown in Figure 1J.

2. Experimental process of sensor performance characterization

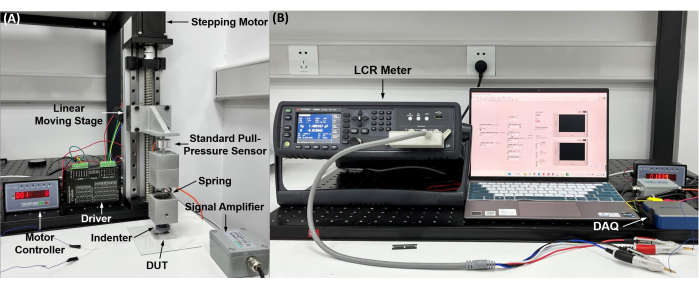

- Stepping pressure loading setup and data acquisition system

- Use a 3D-printed indenter with a loading area that is a circle of 2.5 cm in diameter for the pressure loading (see Table of Materials) of the sensor under test.

- Fix the indenter on a vertical linear moving stage controlled by a stepping motor (see Table of Materials) through a standard pull-pressure sensor.

- Measure the capacitance of the soft capacitive pressure sensor with an LCR meter while recording the standard pressure data using a data acquisition (DAQ) device. Connect both the LCR meter and the DAQ to a computer running the LabVIEW data-logging program (see Table of Materials).

NOTE: Illustrations of the experimental setup are shown in Figure 2. A spring is applied between the indenter and the standard pull-pressure sensor, which converts the vertical displacement of the linear moving stage to loading pressure.

- Testing the sensing performance

- Control the stepping motor to drive the indenter to move down vertically by a programmed distance. Record the capacitance and the standard pressure data by increasing the loading force with the same interval in each consecutive loading cycle until the loading pressure reaches 40 N (~80 kPa).

- Control the stepping motor to drive the indenter to move up vertically by the same distance as in the last step. Record the capacitance and the standard pressure data after the indenter has stabilized. Repeat the operation by decreasing the loading force with the same interval; in each consecutive loading cycle, the loading pressure drops to 0 N.

- Control the stepping motor to drive the indenter to move down vertically by a programmed distance. Record the capacitance and the standard pressure data. Repeat the loading and unloading tests for 2,500 cycles while recording the capacitance of the device under test (DUT) as a function of the standard pressure reading.

- Control the indenter to press down rapidly and remain steady for a few seconds before returning to 0 N loading. Repeat this five times, and record the capacitance as a function of time.

Representative Results

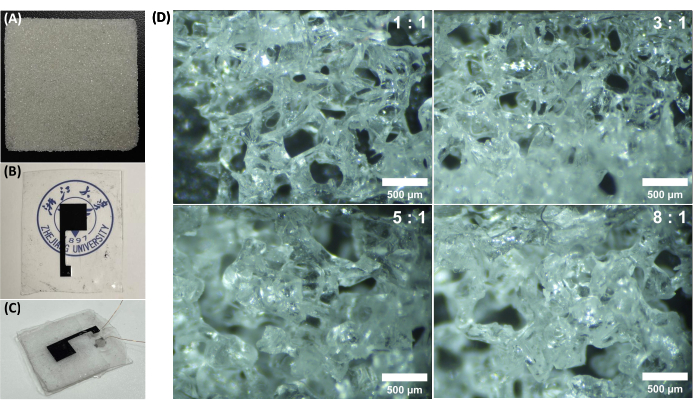

The photograph of the lumped sugar/erythritol porous template is shown in Figure 3A. Figure 3B shows the flexible electrode layer with a scrape-coated ECPCs pattern. Figure 3C shows the soft capacitive pressure sensor with a porous dielectric layer fabricated with the proposed method. Four porous PDMS dielectric layers were fabricated based on PDMS/toluene solutions with different mass ratios of 1:1, 3:1, 5:1, and 8:1, respectively. Optical microscope images showing the pore morphologies of the different structures are presented in Figure 3D. It was found that the pore wall thickness increased with an increasing mass ratio of the PDMS/toluene solution.

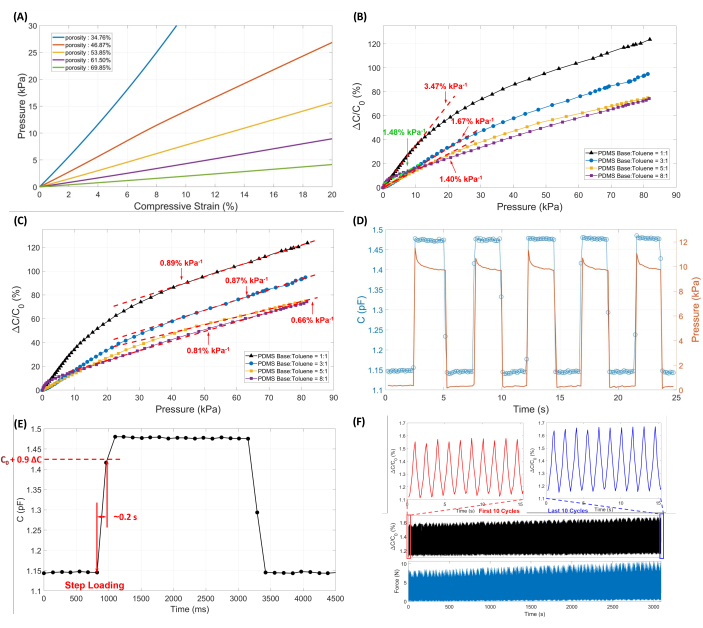

To verify the dependence of the mechanical properties on the porosity, a finite element analysis (FEA) was carried out to simulate the pressure developed in the porous PDMS dielectric layer as a function of the compressive strain using advanced numerical modeling software (see Table of Materials). A 3D model of the porous PDMS with open pores was created, with a length of 2 mm on the z-axis. The location of the pores was fixed, while the diameters were changed to obtain different porosities. An increasing pressure was applied in the z-axis, while periodic and symmetric boundary conditions were applied in the x-axis and y-axis. The simulation result in Figure 4A shows that a higher porosity contributed to a larger compressive strain with improved linearity under the same applied compression pressure. Figure 4B,C shows the capacitance-pressure response curve of the sensors with porous PDMS dielectric layers with different PDMS/toluene mass ratios. In the pressure loading range of 0-10 kPa, the sensor with a 1:1 PDMS/toluene mass ratio exhibited the highest sensitivity of 3.47% kPa−1, which was more than two-fold higher than that of the sensor with the 8:1 PDMS/toluene mass ratio (1.48% kPa−1). As the pressure increased, the pores in the dielectric layer gradually reduced in size, leading to a decrease in the sensitivity until it reached the same level of 0.66%-0.89% kPa−1 for all porosities, as shown in Figure 4C. Figure 4D shows the capacitive response to five consecutive loading-unloading tests under the same loading pressure of approximately 10 kPa. The response time of loading (i.e., the time required for the sensor capacitance to reach 90% of its steady-state value) was determined to be about 0.2 s, as shown in Figure 4E. In addition, as shown in Figure 4F, the cyclic tests also revealed that the as-fabricated soft capacitive sensor had excellent repeatability after 2,500 cycles.

Figure 1: Schematic of the fabrication process. (A–C) The fabrication flow of the porous PDMS dielectric layer. (D,E) The preparation of the ECPCs ink. (F,G) The scrape-coating process of the electrode layer. (H,I) The wire connection and bonding process of the soft capacitive pressure sensor with the electrode-porous dielectric layer-electrode sandwich structure. (J) Illustrations of the structure and materials of the sensor. Please click here to view a larger version of this figure.

Figure 2: Experimental setup. (A) Stepping pressure loading setup. (B) Data acquisition system. Please click here to view a larger version of this figure.

Figure 3: Sensor structures. (A) Photograph of the sugar/erythritol template. (B) The flexible electrode layer with the scrape-coated ECPCs pattern. (C) Photograph of the soft capacitive pressure sensor with the porous dielectric layer. (D) Optical microscope images of the porous PDMS dielectric layers fabricated with different PDMS/toluene mass ratios (PDMS base:toluene = 1:1, 3:1, 5:1, and 8:1). Please click here to view a larger version of this figure.

Figure 4: Simulation and characterization result. (A) Simulated stress-strain curve of the porous PDMS layers with different porosities under low-pressure loadings. (B,C) Pressure-response curve of the capacitive pressure sensors fabricated with PDMS/toluene solutions with different mass ratios (PDMS base:toluene = 1:1, 3:1, 5:1, and 8:1). (D,E) Dynamic response of the sensor (PDMS base:toluene = 1:1). (F) The stability test result of the porous capacitive pressure sensor (2,500 cycles of loading). Please click here to view a larger version of this figure.

Discussion

This work proposes a simple method based on solvent evaporation to control the porosity, and a series of experimental results have proved its feasibility. Although the porous structure has been widely used in the flexible capacitive pressure sensor, the porosity control still needs further optimization. Unlike existing methods for changing the particle size of the PFA11,12,13,18,19 and the ratio of polymer substrate to PFA17,20, we change the concentration of the polymer substrate solution while keeping the size of the PFA (i.e., sugar) uniform. As a result, the thickness of the pore wall changes while the pore distribution holds, which means that the porosity can be controlled by the solution concentration.

The most critical step for the porosity control is preparing the PDMS/toluene solution. The mass ratios of the PDMS/toluene solution were chosen as 1:1, 3:1, 5:1, and 8:1, respectively, to fabricate dielectric layers with different porosities. It was experimentally confirmed that the decrease in the mass ratio led to higher porosity and increased sensitivity in the low-pressure range.

Heating the sugar/erythritol mixture to fabricate the porous template is also a critical, innovative step. Different from existing methods of heating pure sugar21,22, adding water23, and applying pressure24, the melting point difference of these two PFA components was utilized to fabricate the porous template. In this protocol, the heating temperature is higher than the melting point of erythritol and lower than the melting point of sugar. Thus, the erythritol powder gradually melts during the heating process and bonds the solid sugar particles into a plate sugar lump. The mass ratio of sugar to erythritol was also found to be essential to the success of this step. A higher fraction of the erythritol will fill the gap among the sugar particles, while a lower fraction will lead to a failure in bonding.

However, some limitations exist in the device fabricated by this method. As the loading pressure increases, the pores in the dielectric layer gradually close, and the pore walls come into contact with each other, resulting in a more solid PDMS-like mechanical property. This phenomenon explains the independence of sensitivity from porosity, which was found in the higher pressure range above 40 kPa for our sensor. It is also worth noting that the sensor made with an 8:1 PDMS base/toluene mass ratio showed a significantly higher sensitivity of 3.78% kPa−1 compared to other sensors below 5 kPa, which may be attributed to a coupling of the mechanical and electrical properties induced by the porous structure.

The research proposed in this work enables a low-cost and easy-operation fabrication method of porous capacitive pressure sensors with tunable sensor parameters, which has broad application prospects in soft robotics, haptic interfaces, etc. In the future, fully integrated bionic soft robotic grippers with soft sensory mechanoreceptors of tunable sensor parameters can be further researched based on this method.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant 62273304.

Materials

| 3D printer | Zhejiang Qidi Technology Co., Ltd | X-MAX | |

| 3D printing metarials | Zhejiang Qidi Technology Co., Ltd | 3D Printing Filament PLA 1.75 mm | |

| Carbon nanotubes (CNTs) | XFNANO | XFM13 | |

| Data acquisition (DAQ) | National Instruments | USB6002 | |

| Double side tape | Minnesota Mining and Manufacturing (3M) | 3M VHB 4910 | 1 mm thick |

| Electrode metal mold | Guangdong Shunde Molarobot Co., Ltd | This metal mold is a round metal plate with a flat bottom round groove and an embossed electrode pattern of 0.2 mm thick in the middle of the groove. | |

| Erythritol | Shandong Sanyuan Biotechnology Co.,Ltd. | ||

| Isopropyl Alcohol (IPA) | Sinopharm chemical reagent Co., Ltd | 80109218 | |

| LabVIEW | National Instruments | LabVIEW 2019 | |

| LCR meter | Keysight | EA4980AL | |

| Metal wire | Hangzhou Hongtong WIRE&CABLE Co., Ltd. | 2UEW/155 | |

| Microscope | Aosvi | T2-3M180 | |

| Numerical modeling software | COMSOL | COMSOL Multiphysics 5.6 | |

| Polydimethylsiloxane (PDMS) | Dow Chemical Company | SYLGAR 184 Silicone Elastomer Kit | Two parts (base and curing agent) |

| Sealing film | Corning | PM-996 | parafilm |

| Si wafer | Suzhou Crystal Silicon Electronic & Technology Co.,Ltd | ZK20220416-03 | Diameter (mm): 50.8 +/- 0.3 Type/Orientation: P/100 Thickness (µm): 525 +/- 25 |

| Silver conductive paint | Electron Microscopy Sciences | 12686-15 | |

| Stepping motor | BEIJING HAI JIE JIA CHUANG Technology Co., Ltd | 57H B56L4-30DB | |

| Sugar/erythritol template metal mold | Guangdong Shunde Molarobot Co., Ltd | This metal mold is a 5 mm thick square metal plate with a flat bottom square groove of 2.5 mm deep. | |

| Toluene | Sinopharm chemical reagent Co., Ltd | 10022819 |

References

- Ozioko, O., et al. SensAct: The soft and squishy tactile Sensor with integrated flexible actuator. Advanced Intelligent Systems. 3 (3), 1900145 (2021).

- Qiu, Y., et al. A biomimetic drosera capensis with adaptive decision-predation behavior based on multifunctional sensing and fast actuating capability. Advanced Functional Materials. 32 (13), 2110296 (2021).

- Ntagios, M., Nassar, H., Pullanchiyodan, A., Navaraj, W. T., Dahiya, R. Robotic hands with intrinsic tactile sensing via 3D printed soft pressure sensors. Advanced Intelligent Systems. 2 (6), 1900080 (2019).

- Tang, Z., Jia, S., Zhou, C., Li, B. 3D Printing of highly sensitive and large-measurement-range flexible pressure sensors with a positive piezoresistive effect. ACS Applied Materials & Interfaces. 12 (25), 28669-28680 (2020).

- Dai, Y., Chen, J., Tian, W., Xu, L., Gao, S. A PVDF/Au/PEN multifunctional flexible human-machine interface for multidimensional sensing and energy harvesting for the internet of things. IEEE Sensors Journal. 20 (14), 7556-7568 (2020).

- Yang, Y., et al. Flexible piezoelectric pressure sensor based on polydopamine-modified BaTiO3/PVDF composite film for human motion monitoring. Sensors and Actuators A: Physical. 301, 111789 (2020).

- Gao, Y. J., et al. Wearable microfluidic diaphragm pressure sensor for health and tactile touch monitoring. Advanced Materials. 29 (39), 1701985 (2017).

- Meng, K., et al. Flexible weaving constructed self-powered pressure sensor enabling continuous diagnosis of cardiovascular disease and measurement of cuffless blood pressure. Advanced Functional Materials. 29 (5), 180688 (2019).

- Yang, J. C., et al. Microstructured porous pyramid-based ultrahigh sensitive pressure sensor insensitive to strain and temperature. ACS Applied Materials & Interfaces. 11 (21), 19472-19480 (2019).

- Chen, S., Zhuo, B., Guo, X. Large area one-step facile processing of microstructured elastomeric dielectric film for high sensitivity and durable sensing over wide pressure range. ACS Applied Materials & Interfaces. 8 (31), 20364-20370 (2016).

- Ding, H., et al. Influence of the pore size on the sensitivity of flexible and wearable pressure sensors based on porous Ecoflex dielectric layers. Materials Research Express. 6 (6), 066304 (2019).

- Yoon, J. I., Choi, K. S., Chang, S. P. A novel means of fabricating microporous structures for the dielectric layers of capacitive pressure sensor. Microelectronic Engineering. 179, 60-66 (2017).

- Wang, J., Li, L., Zhang, L., Zhang, P., Pu, X. Flexible capacitive pressure sensors with micro-patterned porous dielectric layer for wearable electronics. Journal of Micromechanics and Microengineering. 32 (3), 034003 (2022).

- Mannsfeld, S. C. B., et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nature Materials. 9 (10), 859-864 (2010).

- Wan, Y., et al. A highly sensitive flexible capacitive tactile sensor with sparse and high-aspect-ratio microstructures. Advanced Electronic Materials. 4 (4), 1700586 (2018).

- Kwon, D., et al. Highly sensitive, flexible, and wearable pressure sensor based on a giant piezocapacitive effect of three-dimensional microporous elastomeric dielectric layer. ACS Applied Materials & Interfaces. 8 (26), 16922-16931 (2016).

- Li, W., et al. A porous and air gap elastomeric dielectric layer for wearable capacitive pressure sensor with high sensitivity and a wide detection range. Journal of Materials Chemistry C. 8 (33), 11468-11476 (2020).

- Kim, J. O., et al. Highly ordered 3D microstructure-based electronic skin capable of differentiating pressure, temperature, and proximity. ACS Applied Materials & Interfaces. 11 (1), 1503-1511 (2019).

- Lo, L. W., et al. A soft sponge sensor for multimodal sensing and distinguishing of pressure, strain, and temperature. ACS Applied Materials & Interfaces. 14 (7), 9570-9578 (2022).

- Hwang, J., Kim, Y., Yang, H., Oh, J. H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Composites Part B: Engineering. 211, 108607 (2021).

- Jung, Y., et al. Linearly sensitive pressure sensor based on a porous multistacked composite structure with controlled mechanical and electrical properties. ACS Applied Materials & Interfaces. 13 (24), 28975-28984 (2021).

- Choi, J., et al. Synergetic effect of porous elastomer and percolation of carbon nanotube filler toward high performance capacitive pressure sensors. ACS Applied Materials & Interfaces. 12 (1), 1698-1706 (2020).

- Choi, S. J., et al. A polydimethylsiloxane (PDMS) sponge for the selective absorption of oil from water. ACS Applied Materials & Interfaces. 3 (12), 4552-4556 (2011).

- Rinaldi, A., Tamburrano, A., Fortunato, M., Sarto, M. S. A flexible and highly sensitive pressure sensor based on a PDMS foam coated with graphene nanoplatelets. Sensors. 16 (12), 2148 (2016).