Micropunching Lithography for Generating Micro- and Submicron-patterns on Polymer Substrates

Summary

A micropunching lithography approach is developed to generate micro- and submicron-patterns on top, sidewall and bottom surfaces of polymer substrates. It overcomes the obstacles of patterning conducting polymers and generating sidewall patterns. This method allows rapid fabrication of multiple features and is free of aggressive chemistry.

Abstract

Conducting polymers have attracted great attention since the discovery of high conductivity in doped polyacetylene in 19771. They offer the advantages of low weight, easy tailoring of properties and a wide spectrum of applications2,3. Due to sensitivity of conducting polymers to environmental conditions (e.g., air, oxygen, moisture, high temperature and chemical solutions), lithographic techniques present significant technical challenges when working with these materials4. For example, current photolithographic methods, such as ultra-violet (UV), are unsuitable for patterning the conducting polymers due to the involvement of wet and/or dry etching processes in these methods. In addition, current micro/nanosystems mainly have a planar form5,6. One layer of structures is built on the top surfaces of another layer of fabricated features. Multiple layers of these structures are stacked together to form numerous devices on a common substrate. The sidewall surfaces of the microstructures have not been used in constructing devices. On the other hand, sidewall patterns could be used, for example, to build 3-D circuits, modify fluidic channels and direct horizontal growth of nanowires and nanotubes.

A macropunching method has been applied in the manufacturing industry to create macropatterns in a sheet metal for over a hundred years. Motivated by this approach, we have developed a micropunching lithography method (MPL) to overcome the obstacles of patterning conducting polymers and generating sidewall patterns. Like the macropunching method, the MPL also includes two operations (Fig. 1): (i) cutting; and (ii) drawing. The “cutting” operation was applied to pattern three conducting polymers4, polypyrrole (PPy), Poly(3,4-ethylenedioxythiophen)-poly(4-styrenesulphonate) (PEDOT) and polyaniline (PANI). It was also employed to create Al microstructures7. The fabricated microstructures of conducting polymers have been used as humidity8, chemical8, and glucose sensors9. Combined microstructures of Al and conducting polymers have been employed to fabricate capacitors and various heterojunctions9,10,11. The “cutting” operation was also applied to generate submicron-patterns, such as 100- and 500-nm-wide PPy lines as well as 100-nm-wide Au wires. The “drawing” operation was employed for two applications: (i) produce Au sidewall patterns on high density polyethylene (HDPE) channels which could be used for building 3D microsystems12,13,14, and (ii) fabricate polydimethylsiloxane (PDMS) micropillars on HDPE substrates to increase the contact angle of the channel15.

Protocol

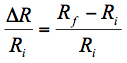

A. Schematics of the MPL

The macropunching method includes “cutting” and “drawing” operations. The “cutting” operation adopts molds of sharp-edged convex structures and includes three basic steps (Fig. 1(a1-a3)). First, place a sheet metal on a rigid substrate (Fig. 1(a1)). Second, bring a Si mold and the substrate into physical contact by a high force. During this second step, the part of the metal directly underneath convex mold structures is first cut off from the neighboring metal by the convex mold structures, and then pushed down to the bottom of the concave patterns in the substrate (Fig. 1(a2)). Finally, separate the mold and the substrate, completing the patterning of the sheet metal (Fig. 1(a3)). The “drawing” operation uses a similar fabrication process. However, it adopts molds of round-edged convex structures (Fig. 1(b1)). Furthermore, the applied insertion force and speed are much smaller and lower than their counterparts in the “cutting” operation. These differences lower the stresses present in the part of the sheet metal under convex structures. Consequently, this part of the sheet metal is just pushed down but not cut off in the “drawing” operation (Fig. 1(b2-b3)).

In the “cutting” operation of the MPL (Fig. 1(c1-c3)), (i) a Si substrate coated with a layer of an intermediate polymer and a layer of a material to be printed are heated above glass transition temperature (Tg: softening temperature) of the intermediate polymer and below Tm (melting temperature) or Tg of the targeted material (Fig. 1(c1)), (ii) the mold and the substrate are brought into physical contact by high pressure, followed by subsequent cooling (Fig. 1(c2)), and (iii) they are separated when their temperature is below Tg of the intermediate polymer, completing the pattern transfer from the mold to the targeted layer (Fig. 1(c3)). The “drawing” operation of the MPL (Fig. 1(d1-d3)) has fabrication steps similar to the “cutting.” Nevertheless, the “drawing” uses soft PDMS molds. It also involves a smaller insertion force, a lower insertion speed, and a higher printing temperature (which lowers the viscosity of the intermediate polymer and thus increases its mobility). Accordingly, the features at the top surface of the substrate curve up due to the surface tension and the high mobility of intermediate polymer. The Si mold may be cleaned and re-used for successive embossing steps. The mold may be cleaned with acetone and DI water; and dried thoroughly with N2 before each use. In case residues remain in the microfeatures of the mold, it may be cleaned with Nanostrip solution and DI water; and dried with N2.

B. Cutting Operation in MPL for Generating Metal and Conducting Polymer Micropatterns

- Single-layer microstructures on a substrate: using the procedure illustrated in Fig. 1(c1-c3), a layer of microstructures is generated on a substrate. During the fabrication, the substrate is coated with a layer of intermediate polymer, followed by coating a layer of a single material (conducting polymer or metal) or a layer of multiple materials. Accordingly, after hot embossing, a layer of microstructures of single or multiple materials is produced on the substrate. The fabrication is detailed below.

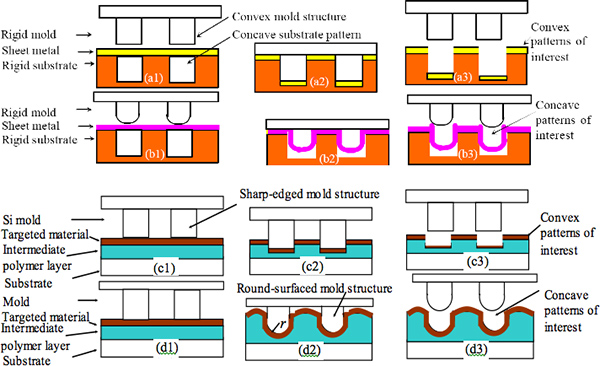

- Fabricate Si molds of the required dimensions using conventional UV lithography (Fig. 2a). The details of fabricating the Si mold are reported in 4. Fig. 2(a1-a4) show the layouts of the Si molds used for the processes.

- Use a non-conducting PMMA sheet of dimensions 500 μm x 170 mm x 170 mm as the intermediate layer, and place it on a rigid, flat substrate.

-

- To generate microstructures of a single material: spin-coat a conducting polymer (PPy, PEDOT or SPANI) on the PMMA sheet or deposit Al using thermal evaporation to a thickness of 100-500 nm.

- To fabricate microstructures of multiple conducting polymer materials: spin-coat PPy (at 2000 rpm), PEDOT (at 2500 rpm) and SPANI (at 1500 rpm) on different portions of the PMMA sheet. Prior to spin coating the first conducting polymer layer at a spot on the PMMA sheet, cover the other areas using adhesive tapes. For coating other conducting polymer layers, the previous coatings and empty areas should be covered by adhesive tape. This procedure should be repeated to coat multiple layers at the desired locations on the substrate. The coated PPy, PEDOT and SPANI are 500 nm, 5 μm and 200 nm thick, respectively.

- Emboss the substrate using a hot-embossing machine (model: Hex 01/LT, Jenoptik Mikrotechnik Company) (Fig. 2b). The temperature, force and mold insertion time are 130-160 °C, 1500-1800 N and 120-200 s, respectively. Perform demolding at 80-95 °C with a speed of 1.5 mm/min. The results of single-layer microstructures of a single material are shown in Fig. 2(c1-c3). The results of single-layer microstructures of multiple materials are given in Fig. 2(d2-d3).

- Application of PPy microwires as a humidity sensor

- Spin coat PPy at 1500 rpm to generate a 1-μm-thick film of area 1 x 1 cm2 and connect two external wires at opposite ends of the film using Ag epoxy for conductivity measurements.

- Spin coat at 1500 rpm to generate a PPy film of thickness 1 μm. Perform embossing with parameters in step 4 to generate PPy microwires of length 5000 μm and width 300 μm and attach external contact wires to the two ends of a single microwire using Ag epoxy.

- Place the PPy film and microwire sensors inside an airtight glove box with a humidity meter and humidifier. The humidifier would allow controlled increase of the humidity level inside the glove box. Attach the contact wires to a Keithley Probe station for I-V measurements for each sensor (Fig. 2e).

- Calculate the sensitivity of each sensor using the following formula:

where, Rf and Ri are the final and initial resistances of the film and microwire sensors, respectively. Measure Ri at the base humidity level (at room temperature) and Rf at each humidity levels for the film and microwire sensors. - Fig. 2f shows the results of sensitivity (ΔR/R) measurements done in8 for 48% to 85% relative humidity. It was observed that the sensitivity of the PPy microwire sensor was higher than the film sensor for 48% to 58%. Beyond 58% the sensitivities of film and microwire sensors were similar.

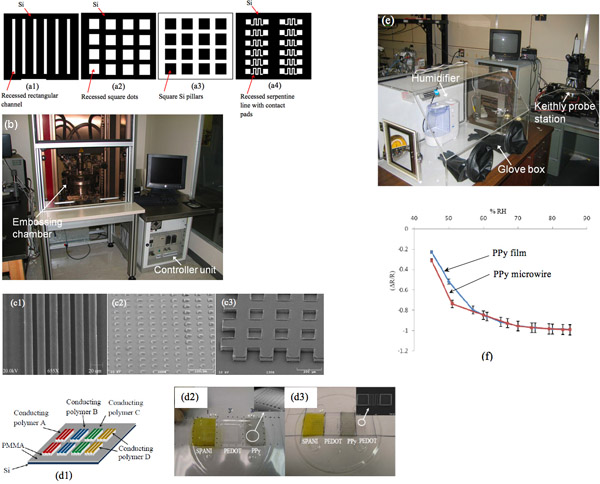

- Multi-layer microstructures on a substrate: based on the procedure shown in Fig. 1(c1-c3), the top layer is replaced by a combination of two and three polymers/metal layers, respectively, to generate multi-layer microstructures. The device layout is shown in Fig. 3(a1-a2). The fabrication is detailed below.

- Fabricate a Si mold of the required dimensions using conventional UV lithography (Fig. 3b).

- Use a non-conducting PMMA sheet of dimensions 500 μm x 170 mm x 170 mm as the intermediate layer, and place it on a rigid, flat substrate.

- To generate two-layer PPy-PEDOT heterojunction: (i) spin-coat at 1000 rpm to obtain a 10-μm-thick PEDOT layer on the PMMA sheet, (ii) bake the substrate at 80 °C for 1 h, (iii) spin-coat at 1500 rpm to obtain 1-μm-thick PPy film on the PEDOT layer, and (iv) bake the substrate at 80 °C for 5 min.

- To generate two-layer Al-PEDOT diodes: (i) spin-coat at 1000 rpm to obtain a 10-μm-thick PEDOT layer on the PMMA sheet, (ii) bake the substrate at 80 °C for 1 h, and (iii) coat a 200-nm-thick Al film on the PEDOT layer by thermal evaporation.

- To generate three-layer PEDOT-PMMA-PEDOT capacitors: (i) spin-coat at 1000 rpm to obtain a 10-μm-thick PEDOT layer on the PMMA sheet, (ii) bake the substrate at 80 °C for 1 h, (iii) spin-coat at 1000 rpm multiple times to obtain a PMMA film of thickness 15-20 μm on the PEDOT layer, (iv) bake the substrate at 80 °C for 30 min, (v) spin-coat at 2500 rpm to obtain a PEDOT layer of thickness 2-3 μm on the PMMA film, and (vi) bake the substrate at 80 °C for 5 min.

- Emboss the substrate using the hot-embossing machine. The temperature, force and mold insertion time are 140-150 °C, 1500-2000 N and 150-200 s, respectively. Perform demolding at 80-95 °C with a speed of 1.5 mm/min. The results are shown in Fig. 3(c-f) 11.

- Applications of generated multi-layer microstructures

- PPy/PEDOT heterojunction

- Use a Keithly Probe Station for the I-V measurements of the heterojunction structures obtained after step 2.1. The PEDOT layer is grounded and a bias potential (-20 V to 20 V) is applied to the PPy layer.

- Fig. 3(g1) shows the I-V characteristics of the PPy/PEDOT heterojunction in [9,11], the forward and reverse breakdown voltages of the PPy/PEDOT heterojunction were 5 V and -8 V, respectively. The rectification ratio was 24 at 10 V. The ideality factor was equal to 8.88.

- Al/PEDOT heterojunction

- Use a Keithly Probe Station for the I-V measurements of the Al/PEDOT heterojunction structure obtained after step 2.2. The Al layer is grounded and a bias potential (-5 V to 5 V) is applied to the PEDOT layer.

- Fig. 3(g2) shows the I-V characteristics of the Al/PEDOT junction measured at room temperature in 11, the forward and reverse breakdown voltages were 3 and -2.5 V, respectively. Rectification ratio of the Al/PEDOT heterojunction was 2 at 1 V. The ideality factor for this junction was calculated to be 19.

- PEDOT/PMMA/PEDOT capacitor

- Use a Keithly Probe Station for the C-V measurements of the PEDOT/PMMA/PEDOT capacitor obtained after step 2.3.

- Fig. 3(g3) shows the C-V of the PEDOT/PMMA/PEDOT capacitor measured at room temperature in 11. The measured capacitance of the capacitor at low frequency bias was about 0.06 pF, while the theoretically calculated quantity was 1.38 pF.

- PPy/PEDOT heterojunction

C. Cutting Operation of the MPL for Generating Sub-micron Ppatterns of Metal and Conducting Polymer

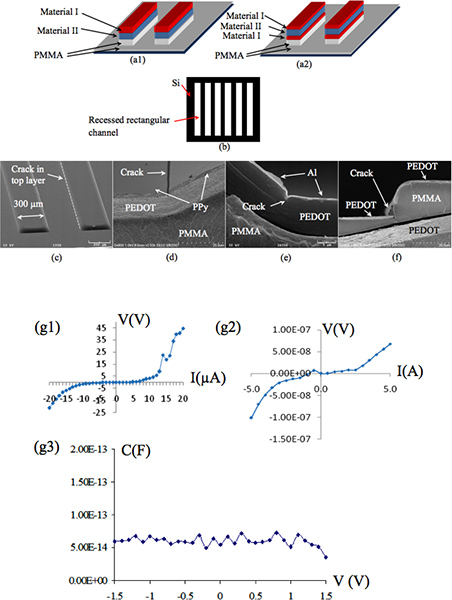

Based on the procedure illustrated in Fig. 1(c1-c3), Si molds with sub-micron features are used to generate desired patterns of metal and conducting polymers. The fabrication is detailed below.

- Fabricate a silicon mold with sub-micron features using Focused Ion Beam (FIB) lithography. Two different types of Si molds, of widths 100 and 500 nm, depth of 1 – 1.5 μm, length of 20 μm and pitch of 1 μm, are generated.

- Surface preparation of the silicon mold before use: (i) rinse the mold with DI water, acetone and Nanostrip solution thoroughly at room temperature, blow dry with nitrogen gas and bake at 150 °C for 30 min followed by cooling to room temperature, and (ii) if the mold is not clean after the above cleaning steps, subject it to oxygen plasma clean. The recipe is as follows: plasma power at 300 watts, oxygen flow rate at 80 sccm and duration of 5 – 7 min.

-

- Coat the PMMA layer: spin-coat PMMA solution (molecular weight 495 K in 9% chlorobenzene) at 3000 rpm to obtain a thickness of about 1.2 μm, bake the wafer at 150 °C for 1 h and allow it to cool, and expose the PMMA coated surface to oxygen plasma for 3 min at 300 W with 50 sccm oxygen flow rate to make it hydrophilic for the next step.

-

- Spin-coat PPy solution (diluted by 1:2 (V/V) with DI water) at 3000 rpm to obtain a thickness of about 75 nm and bake the substrate at 60 °C for 1 h to cure the PPy layer.

- Coat a Au film of a thickness of 10-25 nm using sputtering deposition.

-

- Generate PPy wires using the following steps.

- Imprint the 500-nm-wide Si channels: perform imprinting at 160 °C with a speed of 1 mm/min and insert duration of 600 s using the mode of position control in the hot-embossing machine. The maximum force used is 1085 N in this case.

- Imprint the 100-nm-wide Si channels: perform imprinting at 140 °C with a speed of 1mm/min and insert duration of 500 s using the mode of force control in the hot-embossing machine. Fix the embossing force at 2300 N.

- Generate Au nanowires using a Si mold with 100-nm-wide channels: perform imprinting at 160 °C with a speed of 1mm/min and insert duration of 700 s using the mode of force control in the hot-embossing machine. Fix the embossing force at 2300 N.

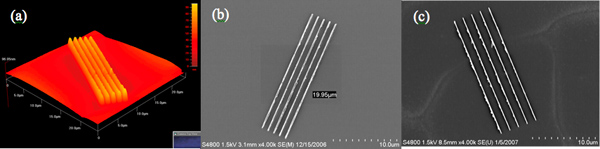

- For steps 4.1-4.2, perform demolding at 95 °C with speed of 3 mm/min. The results are shown in Fig. 4.

- Generate PPy wires using the following steps.

D. Drawing Operation of the MPL for Generating Micropatterns on Sidewalls of Polymer and Si Substrates.

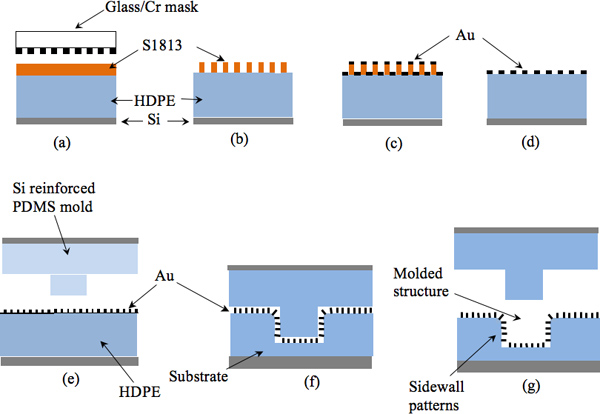

Following the procedure in Fig. 1(d1-d3), the “drawing” operation is used to generate Au and PDMS micropatterns on the sidewalls of HDPE microchannels. The corresponding material on the HDPE substrate is Au or PDMS, which follows the surface profile of the intermediate-layer polymer during imprinting. The fabrication is detailed below.

- Au sidewall patterns on HDPE channels

- Spin-coat at 3000 rpm to obtain a 1-μm-thick layer of a positive photoresist (S1813) on a 1.5-mm-thick HDPE sheet (1.5 mm x 40 mm x 40 mm).

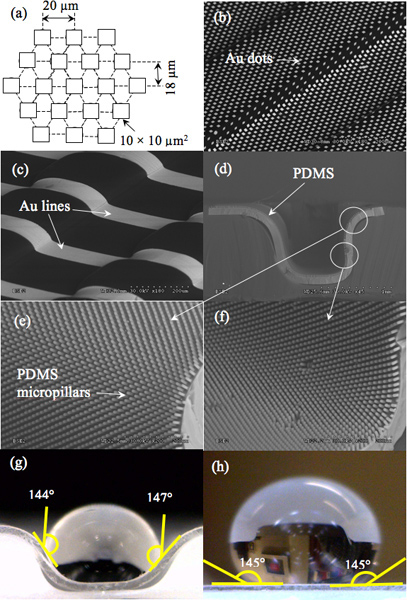

- Using UV lithography to transfer mask patterns into the S1813 layer (Fig. 5(a-b)). The mask patterns consist of 10 x 10 μm2 dots (Fig. 7a) and 110-μm-wide lines.

- Coat a 100-nm-thick Au film on the S1813 layer using a thermal evaporator (Fig. 5c).

- Remove the S1813 with acetone rinse, leaving Au patterns on the HDPE sheet (Fig. 5d).

- Heat the HDPE sheet up to a temperature range of 131-136 °C on a hot plate, which is slightly higher than Tg of HDPE (i.e., 128 °C) but below Tm of Au (i.e., 1063 °C) (Fig. 5e).

- Use a Si-reinforced PDMS mold16 to imprint the Au-patterned HDPE sheet with pressure range of 40-120 KPa, for 1 hr followed by subsequent cooling (Fig. 5f) .

- Separate the mold and the HDPE sheet when their temperatures are below Tg of the HDPE, completing the pattern transfer from the PDMS mold to the substrate. The Au patterns, which are pushed into the HDPE sheet by the PDMS mold, stay on the sidewalls and bottom surfaces of the formed microstructures (Fig. 5g). Since the bonding strength between the PDMS mold and the Au patterns are weaker than that between the HDPE sheet and Au patterns, Au patterns do not stick to the PDMS mold and remain on the HDPE surface. The results of this process are shown in Fig. 7(b-c) 12.

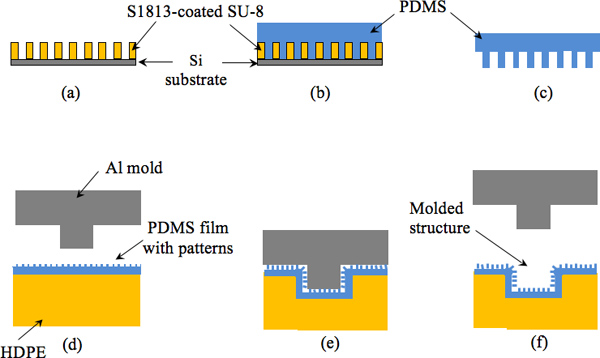

- PDMS micropillars on HDPE channel sidewalls

- Spin-coat at 3000 rpm to obtain a 1-μm-thick layer of S1813 on a SU-8 mold (Fig. 6a). The SU-8 mold is generated using conventional UV lithography17.

- Spin-coat PDMS (ratio between PDMS and its curing agent is 10:1) at 1000 rpm on the S1813-coated SU-8 mold, and bake the sample at 85 °C for 3 h on a hot plate followed by cooling down to room temperature (Fig. 6b).

- Release the thin PDMS film from the SU-8 mold by etching S1813 with acetone, completing the generation of the micropillar-formed PDMS film (Fig. 6c).

- Place the micropillar-formed PDMS film on a 1.5-mm-thick HDPE sheet (Fig. 6d).

- Insert an Al mold (with rounded edges) into both PDMS film and HDPE sheet at 140 °C with a pressure of 52.5 kPa (Fig. 6e). The printing time is 1 h. At 140 °C, the PDMS film is pushed down into the soft HDPE sheet by the mold.

- After the sample is cooled down to room temperature followed by removal of the Al mold, a channel is generated on the HDPE sheet. Part of this micropillar-formed PDMS film is transferred to the bottom and two sidewalls of the channel (Fig. 6f). The results are shown in Fig. 7(d-f)15.

- Measure the contact angle of a water droplet placed on top of the PDMS micropillars inside the HDPE channel. Fig. 7(g-h) shows the average contact angle measured as 145.5°15.

E. Representative Results

In summary, the results of MPL are listed below:

- Single layer conducting polymer and metal micropatterns were formed as in Fig. 2(b1-b3, c2-c3).

- PPy film and microwire humidity sensing results in Fig. 2d.

- Multiple layer conducting polymer and metal micropatterns were formed as in Fig. 3(c-f).

- Junction characterization results in Fig. 3(g1-g3).

- 100- and 500-nm-wide PPy wires were formed as in Fig. 4(a-b).

- 100-nm-wide Au nanowires were formed as in Fig. 4c.

- Au patterns were generated on 300-μm-wide and 42-μm-deep HDPE channels as in Fig. 7(b-c).

- PDMS micropillars were generated on the top, bottom and sidewall surfaces of 1-mm-wide and 1-mm-deep HDPE channels as in Fig. 7(d-f).

- Water contact angles measured inside the HDPE channel in Fig. 7(g-h).

Figure 1. The “cutting” process in creation of convex macropatterns in a sheet metal (cross-section schematics): (a1) place a sheet metal on the top of the substrate, (a2) insert the mold into the substrate, and (a3) separate the mold and the substrate. The “drawing” process in fabrication of concave macropatterns: (b1) place a sheet metal on the substrate, (b2) insert the mold into the substrate, and (b3) separate the mold and the substrate. The “cutting” operation of the MPL method in the fabrication of convex structures (cross-section schematics): (c1) heat the substrate, (c2) insert the mold into the substrate, and (c3) separate the mold and the substrate. The “drawing” operation of the MPL approach in the fabrication of concave structures: (d1) heat the substrate, (d2) insert the mold into the substrate, and (d3) separate the mold and the substrate.

Figure 2. Designs of Si molds (top view): (a1) straight lines; (a2) square dots; (a3) truss structures; and (a4) serpentine lines. (b) The hot embossing machine. SEM images of generated Al structures: (c1) 10-μm-wide lines; (c2) 20×20 μm2 dots; and (c3) truss structures. (d1) Schematic of microstructures consisting of multiple structures; (d2) 300-μm-wide straight; (d3) 50-μm-wide serpentine microwire patterns of PPy, PEDOT, and SPANI fabricated simultaneously using the “cutting” operation of the MPL. (e) The humidity sensing experimental setup; and (f) humidity sensing results with PPy film and microwire sensor 4, 7, 8. Click here to view larger figure.

Figure 3. Layouts of: (a1) two- and (a2) three-layer devices; (b) layout of a Si mold (top view) used to fabricate multi-layer devices; (c) SEM image of a 300-μm-wide, microline-shaped PPY-PEDOT heterojunction; and close-up SEM views of cross-sections of: (d) PPy-PEDOT heterojunction; (e) Al-PEDOT diode; (f) PEDOT-PMMA-PEDOT capacitor; heterojunction characterization results: (g1) PPy/PEDOT; (g2) Al/PEDOT; and (g3) PEDOT/PMMA/PEDOT 9,11.

Figure 4. (a) AFM scan of the embossed 500-nm-wide PPy wires; SEM images of (b) embossed 100-nm-wide PPy lines and (c) 100-nm-wide Au wires. Click here to view larger figure.

Figure 5. Fabrication of a HDPE substrate with Au patterns: (a-b) using a mask of desired features, expose and develop the S1813 layer; (c-d) deposit Au and remove the S1813 layer; (e-f) imprinting the substrates using a Si reinforced PDMS mold; and (g) after demolding, a substrate with sidewall patterns consisting of Au features 12.

Figure 6. Fabrication of a PDMS film with micropillars: (a) fabricate an SU-8 mold; (b) spin-coat and cure a PDMS layer; (c) remove the PDMS layer from the SU-8 mold; (d) imprinting the substrate using an Al mold; and (e-f) after demolding, a substrate with sidewall patterns consisting of PDMS micropillars, are obtained 15.

Figure 7. (a) layout of the Au dots; SEM images of: (b) 10 x 10 μm2 dots; and (c) 110-μm-wide-lines. The dimensions of the channels generated in HDPE are 1 cm x 300 μm x 42 μm (length x width x depth); PDMS micropillars generated on the top, bottom and sidewall surfaces1-mm-wide HDPE channels: (d) cross-section view of the channel; SEM images of (e) top; (f) bottom corner of the channel; and (g-h) contact angle measurement results on PDMS pillars12,15. The PDMS pillars have the dimensions 10 μm x 10 μm x 27 μm. The dimensions of the channels in HDPE are 20 mm x 1 mm x 1 mm (length x width x height).

Discussion

Troubleshooting information: Critical points regarding generation of single- and multiple-layer micropatterns of conducting polymers and metals using the “cutting” operation: (1) Temperature of embossing ensures fluidity of the intermediate PMMA layer which generates optimum results. It is advisable to start at the lower limit of the range and increase temperature gradually if desired results are not achieved. Too high temperature may cause the conducting polymer layer to change its chemical and/or electrical properties. (2) If imprinting force is too high, it may cause the Si mold to crack during embossing; whereas low force may result in improper mold filling and the polymer layers may not be cut-off. (3) The embossing machine should be programmed to start imprinting only after the substrate has attained the set temperature value. (4) The profile of the imprint depends upon feature size, imprinting force, temperature and mold insert time; and may vary between one with sharp edges to a more rounded one. As the number of polymer layers increase, the profile tends to be rounded at the edges. (5) Si molds with sharp edges are preferred to ensure that the conducting polymer/metal layers are cut-off as desired. Use of a Si mold with sloping sidewalls is not recommended. (6) Use of very deep Si mold may cause stiction between the mold and polymer layer(s). If the mold is too shallow it may not be able to achieve “cutting” of the top layer(s). (7) It is recommended that an anti-stiction film (e.g., teflon) should be coated on the Si mold for easily separating it from the substrate during the demolding process. (8) Low mold insert time may not result in “cutting” and the mold profile may be rounded. If the feature size is small, longer insert times are required and vice versa. (9) Thicker conducting polymer/metal films are more mechanically stronger compared to thinner ones. However, the combined thickness of the top layer should not be more than the thickness of the intermediate PMMA layer. (10) Demolding temperature should be below 105 °C (Tg of PMMA). A high value may result in the substrate being curved-up after demolding and a low value may cause the Si mold to stick to the substrate and break apart.

Critical points regarding the generation of the sub-micron PPy and Au wires: (1) Before using the Si molds for the first time, no AFM and SEM scans of the mold should be performed. This is necessary to maintain the pristine surface of the silicon mold. (2) Aggressive cleaning procedures such as using NanoStrip solution or oxygen plasma should be avoided, as there is a possibility of increasing the surface roughness of the silicon mold. This may induce stiction between the silicon mold and the conducting polymer layer. (3) The thickness of the top layer (conducting polymer or metal) should be less than the depth of the mold for cutting-off of the layer at the edges. There is no such limitation on the thickness of the insulating polymer layer. (4) The surface roughness of the silicon mold should be minimum. In case the surface of the silicon mold is rough due to processing or contamination, there may not be perfect contact between the mold and the substrate, resulting in improper pattern transfer.

Critical points regarding generation of Au micropatterns on HDPE channels: (1) At higher embossing temperatures (≥136 °C), the Au lines do not curve up to follow the surface as the HDPE is softened. (2) At higher mold depths (≥42 μm), the Au lines may break at the edges of the HDPE channels due to stress 12.

Critical points regarding the generation of HDPE channels with PDMS micropillars: (1) If the height of the PDMS micropillars is large, it may fall down after release from the SU-8 mold. (2) High aspect ratio of PDMS pillars may be damaged during the “drawing” step 15.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work was supported in part through NSFDMI-0508454, NSF/LEQSF(2006)-Pfund-53, NSF-CMMI-0811888, and NSF-CMMI-0900595 grants.

Materials

| Name of the reagent | Company | Catalogue number | Comments |

| PMMA | Sigma-Aldrich Co. | 495C9 | The solvent is cholorobenzene. Handle PMMA solution under a fume hood with adequate ventilation. Do not breathe the vapor. Refer to MSDS for safe handling instructions. |

| PPy | Sigma-Aldrich Co. | — | 5% by weight in water. Used as received. |

| PEDOT-PSS | H. C. Starck Co. | Baytron P HC V4 | Proprietary solvent. Used as received. |

| SPANI | Sigma-Aldrich Co. | — | Water soluble form. Used as received. |

| Hot embossing machine | JenoptikMikrotechnik Co. | HEX 01/LT | |

| Sputter machine | Cressington Co. | 208HR | |

| FIB machine | Zeiss Co. | FIB Crossbeam 1540 XB | |

| Spin coater | Headway Reseach Co. | PWM32-PS-R790 Spinner System | |

| RIE machine | Technics MicroRIE Co. | — | |

| Photoresist | Shipley Co. | S1813 | |

| PDMS | Dow Corning | Sylgard 184 Silicone elastomer kit | |

| HDPE sheet | US Plastic Incorporate | — | |

| PMMA sheet | Cyro Co. | — | |

| Double-sided adhesive tape | Scotch Co. | — | |

| Single-sided tape | Delphon Co. | Ultratape # 1310 | |

| Glass micropipettes | FHC Co. | 30-30-1 | |

| Clip | Office Depot Co. | Bulldog clip | |

| Humidifier | Vicks Co. | Filter free humidifier |

References

- Menon, R. Conducting polymers: Nobel Prize in Chemistry, 2000. Current Science. 79, 1632 (2000).

- Inzelt, G., Pineri, M., Schultze, J. W., Vorotyntsev, M. A. Electron and proton conducting polymers: recent developments and prospects. Electrochimica Acta. 45, 2403 (2000).

- Adhikari, B., Majumdar, S. Polymers in sensor applications. Progress in Polymer Science. 29, 699 (2004).

- Chakraborty, A., Liu, X., Parthasarathi, G., Luo, C. An intermediate-layer lithography method for generating multiple microstructures made of different conducting polymers. Microsystem Technologies. 13 (8), 1175 (2007).

- Madou, M. . Fundamentals of Microfabrication. , (1995).

- Bustillo, J. M., Howe, R. T., Muller, R. S. Surface micromachining for microelectromechanical systems. Proceedings of the IEEE. 86, 1552 (1998).

- Liu, X., Luo, C. Intermediate-layer lithography for producing metal micropatterns. Journal of Vacuum Science and Technology B. 25, 677 (2007).

- Chakraborty, A., Luo, C. Multiple conducting polymer microwire sensors. Microsystem Technologies. 15, 1737 (2009).

- Chakraborty, A., Liu, X., Luo, C., Mason, E. C., Weber, A. P. . Polypyrrole: A new patterning approach and applications. Polypyrrole: Properties, Performance and Applications. , (2011).

- Poddar, R., Luo, C. A novel approach to fabricate a PPy/p-type Si heterojunction. Solid-State Electronics. 50, 1687 (2006).

- Liu, X., Chakraborty, A., Luo, C., Martingale, J. P. . Generation of all-polymeric diodes and capacitors using an innovative intermediate-layer lithography. Progress in Solid State Electronics Research. , 127-139 (2008).

- Liu, X., Luo, C. Fabrication of Au sidewall micropatterns using a Si-reinforced PDMS mold. Sensors and Actuators A. 152, 96 (2009).

- Liu, X., Chakraborty, A., Luo, C. Fabrication of micropatterns on the sidewalls of a thermal shape memory polystyreme block. Journal of Micromechanics and Microengineering. 20, 095025 (2010).

- Chakraborty, A., Liu, X., Luo, C. Fabrication of micropatterns on channel sidewalls using strain-recovery property of a shape-memory polymer. Sensors and Actuators A. , (2011).

- Liu, X., Luo, C. Fabrication of supe-hydrophobic channels. Journal of Micromechanics and Microengineering. 20, 25029 (2010).

- Luo, C., Meng, F., Liu, X., Guo, Y. Reinforcement of PDMS master using an oxide-coated silicon plate. Microelectronics Journal. 37, 5 (2006).

- Luo, C., Garra, J., Schneider, T., White, R., Currie, J., Paranjape, M. Thermal ablation of PMMA for water release using a microheater. Sensors and Actuators A. 114, 123 (2004).