Summary

We describe the process of fabrication and testing of photonic thermometers.

Abstract

In recent years, a push for developing novel silicon photonic devices for telecommunications has generated a vast knowledge base that is now being leveraged for developing sophisticated photonic sensors. Silicon photonic sensors seek to exploit the strong confinement of light in nano-waveguides to transduce changes in physical state to changes in resonance frequency. In the case of thermometry, the thermo-optic coefficient, i.e., changes in refractive index due to temperature, causes the resonant frequency of the photonic device such as a Bragg grating to drift with temperature. We are developing a suite of photonic devices that leverage recent advances in telecom compatible light sources to fabricate cost-effective photonic temperature sensors, which can be deployed in a wide variety of settings ranging from controlled laboratory conditions, to the noisy environment of a factory floor or a residence. In this manuscript, we detail our protocol for the fabrication and testing of photonic thermometers.

Introduction

The gold standard for temperature metrology, the platinum resistance thermometer, was first proposed by Sir Siemens in 1871 with Callender1 developing the first device in 1890. Since that time incremental progress in the design and manufacturing of thermometers has delivered a wide range of temperature measurement solutions. The standard platinum resistance thermometer (SPRT) is the interpolating instrument for realizing International Temperature Scale (ITS-90) and its dissemination using resistance thermometry. Today, more than a century after its invention, resistance thermometry plays a crucial role in various aspects of industry and everyday technology ranging from biomedicine to manufacturing process control, to energy production and consumption. Although well-calibrated industrial resistance thermometers can measure temperature with uncertainties as small as 10 mK, they are sensitive to mechanical shock, thermal stress and environmental variables such as humidity and chemical contaminants. Consequently, resistance thermometers require periodic (and costly) off-line recalibrations. These fundamental limitations of resistance thermometry have produced considerable interest in developing photonic temperature sensors2 that can deliver similar to better measurement capabilities whislt being more robust against mechanical shock. Such a devcie will appeal to national and industrial labs and those interested in long-term monitoring where instrument drift can negatively impact productivity.

In recent years a wide variety of novel photonic thermometers have been proposed including photosensitive dyes3, sapphire-based microwave whispering gallery mode resonator4, fiber optic sensors5,6,7, and on-chip silicon nano-photonic sensors8,9,10. At NIST, our efforts are aimed at developing low-cost, readily-deployable, novel temperature sensors and standards that are easily manufactured using existing technologies, such as CMOS-compatible manufacturing. A particular focus has been the development of silicon photonic devices. We have demonstrated that these devices can be used to measure temperature over the ranges of -40 °C to 80 °C and 5 °C to 165 °C with uncertainties that are comparable to legacy devices8. Furthermore, our results suggest that with a better process control device interchangeability on the order of 0.1 °C uncertainty is achievable (i.e. the uncertainty of temperature measurement using nominal coefficients not calibration determined coefficients).

Protocol

1. Device Fabrication

Note: Silicon photonic devices can be fabricated using silicon-on-insulator (SOI) wafers applying conventional CMOS-technology via photo- or electron beam lithography followed by inductive plasma reactive ion etch (ICP RIE) of 220 nm-thick topmost silicon layer. After ICP RIE etch the devices can be top-cladded with a thin polymer film or SiO2 protective layer. Below are the main steps of in fabrication of SOI photonic devices.

- Clean an SOI wafer in a piranha solution for 10 min, a mixture 4:1 of sulfuric acid (H2SO4) and hydrogen peroxide (H2O2), followed by a deionized (DI) water rinse for 1 min and nitrogen gas blow dry.

- Spin coat about 20-50 mL of maN 2405 e-beam resist onto the wafer at 4,000 rpm for 60 s, followed by a hotplate bake at 90 °C for 15 min.

- Expose the device pattern on to the spin-coated resist using e-beam lithography and develop the resist. The usual base exposure dose is about 600 µC/cm2. Develop with MIF-319 developer for 60 s, followed by a 60 s water rinse.

- Perform an ICP RIE etch of the 220 nm thick silicon layer to remove the unprotected silicon. Use a pseudo-Bosch process with C4F8: 57 SCCM / SF6: 33 SCCM, ICP power: 3,000 W; RIE power: 15 W; pressure 10 mTorr, temperature: 15 °C; Etch rate: approximately 5-6 nm/s

- Dissolve the resist mask in pure acetone for 1 h, followed by an isopropanol rinse, a 60 s DI water rinse and nitrogen gas blow dry.

- Deposit a 1 µm thick protective top-layer on the wafer (a thin polymer film) via a spin coating (spin coat 20-50 mL PMMA at 4,000 rpm for 60 s followed by a hotplate bake at 180 °C for 2 min).

- Dice the wafer with a wafer dicing saw (saw blade thickness: 35 µm) into small easy to handle chips (e.g., 20 mm × 20 mm).

2. Photonic Chip Packaging

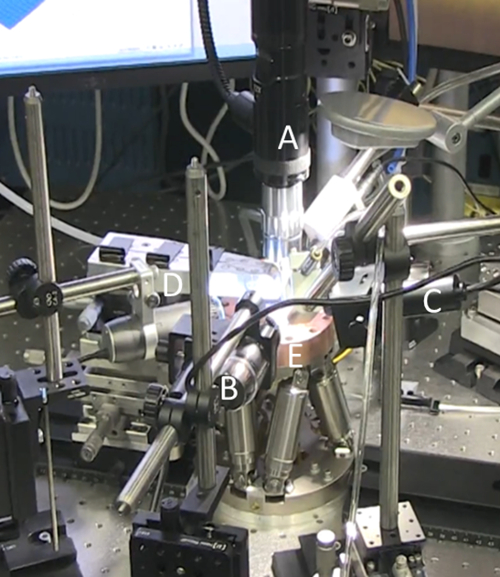

Note: The fabricated photonic chips are packaged on a custom design packaging setup where a custom-built packaging setup is used to align and bond an array of optical fibers to a photonic chip. The packaging setup shown on Figure 1 consists of (i) 6-axis micro-positioning stage, that allows 6-degree of freedom movement (X, Y, Z coordinates, and three corresponding angles of rotation relative to X, Y, Z coordinates) with submicron precision; (ii) on-stage integrated Peltier module that allows to heat or cool the top stage platform; (iii) v-groove array holder arm; epoxy adhesive micro-dispensing module; (iv) ultra violet (UV) light exposure module to cure UV adhesives, and (v) four high magnification digital cameras for top, front, and two side angle views. Optical fibers package in v-groove array are procured from a commercial source.

- Rough alignment procedure

- Place the photonic chip on the 6-axis stage, and orient the chip so the on-chip input/output ports are aligned with the v-groove array.

- Turn on vacuum suction through on-stage integrated vacuum pumping port to hold the chip in place.

- Use the top-view digital camera to locate and place the photonic devices of interest in the center of the 6-axis stage.

- Position the v-groove array holder arm close to the chip and use vacuum suction through an integrated pumping port to hold the array in place.

- Use the side-view digital cameras as a visual feedback to help position the fiber array above the on-chip grating couplers.

- Raise the 6-axis stage to bring the photonic chip to within 10 µm of the fiber array's bottom edge.

NOTE: The edge of the v-groove fiber array should be roughly aligned (within 50 µm to 100 µm accuracy) relative to on-chip alignment marks. This procedure brings the optical fiber facets within a relative proximity of the corresponding grating couplers.

- Automated optimal alignment

- Once a rough manual alignment is achieved, activate the automated search using the vendor supplied software for the 6-axis stage.

NOTE: This algorithm performs a pre-defined walk over the 6-degrees of movements (translational and rotational) until the maximum transmission of broadband light through the chip's input and output ports is achieved. It should take no longer than 20 s to 30 s.

- Once a rough manual alignment is achieved, activate the automated search using the vendor supplied software for the 6-axis stage.

- Photonic chip testing

NOTE: Once the optimal alignment is achieved, check device viability before proceeding with the bonding.- Use the on-stage integrated Peltier module to thermally cycle the chip's temperature while recording the spectral response. For thermal cycling, we used a custom script written in LabView.

- Analyze the recorded spectra is to verify the temperature sensitivity of the device (recommended values are 70 pm/°C to 80 pm/°C).

NOTE: The laser spectrometer has been described elsewhere in detail2. The recorded spectra are analyzed to determine the temperature sensitivity of the device which should be in the 70 pm/°C to 80 pm/°C range.

- Bonding of optical fibers

- Slowly lower the array down to the chip surface.

- Carefully position the epoxy filled syringe in close vicinity of the fiber array's edge using another XYZ micron precision stage.

- Dispense a single micro-droplet of an epoxy and initiate the curing process (either via UV irradiation or a thermal cycling).

- Periodically run the automated alignment (peaking/maximization) routine to prevent drift induced loss of signal until such a time that the epoxy starts to harden.

NOTE: After epoxy curing the photonic chip performance and light coupling efficiency are tested again by recording transmission spectra of the device at different temperatures. Light coupling efficiency typically increases after the bonding process, likely because the refractive index matched optical epoxy reduces reflection losses at the fiber-chip interface.

- Packaging of Photonic Thermometer

- Place the fiber bonded photonic chip on a copper cylinder (h = 25 mm, dia.= 5.79 mm) with a small amount (about 1 mg) of thermal grease applied to the copper mounting surface.

NOTE: Thermal grease ensures good even thermal contact between the metal heat conductor and the chip. Furthermore, thermal grease provides a weak adhesion between the two parts which facilitates the process of lowering the copper cylinder-chip assembly down a glass tube (h = 50 mm; inner dia. = 6.0 mm). - Gently lower the chip-copper cylinder down the glass tube.

- Backfill the glass tube with Argon gas and seal with a rubber cork.

- Place the fiber bonded photonic chip on a copper cylinder (h = 25 mm, dia.= 5.79 mm) with a small amount (about 1 mg) of thermal grease applied to the copper mounting surface.

3. Temperature Measurement

- Place the packaged photonic thermometer (glass tube + copper cylinder + fiber coupled photonic device) into a metrology temperature dry well (temperature should be stable to within 1 mK).

- Using the custom-built computer program set the settling time (20 min to 30 min), number of thermal cycles (minimum 3), temperature step size (1 °C to 5 °C), number of consecutive scans (minimum recommendation 5) and laser power (exact power delivered is specific to individual cases but generally is in the nanowatt to microwatt range).

NOTE: A calibrated platinum resistance thermometer bonded to the copper cylinder is used to concurrently record the bath temperature as the photonic measurements are carried out.

Representative Results

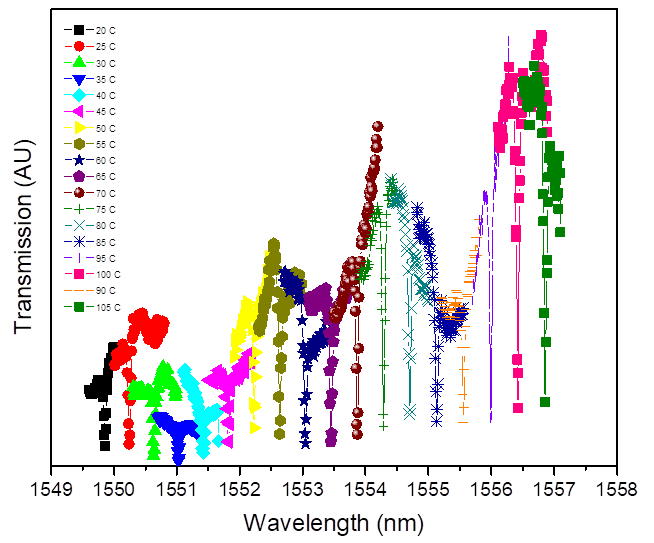

As shown in Figure 2, the ring resonator transmission spectra shows a narrow dip in transmission corresponding to the resonance condition. The resonance fringe shifts to longer wavelengths as temperature is increased from 20 °C to 105 °C in 5 °C increments. The transmission spectrum is fitted to a polynomial function from which the peak center is extracted. The polynomial fit was found to give the most consistent results in the presence of a sloping baseline which can make a Lorentzian or Gaussian fit more prone to offset errors. The wavelength response of the device is plotted against the calibrated platinum resistance thermometer's response and residuals to linear and quadratic fits are computed. Fit residuals are useful tools in understanding the temperature behavior of the sensors. Comparison of temperature points in up and down cycles and between cycles is used to determine the hysteresis in the packaged device.

Our preliminary analysis of the thermal cycling experiments suggests that humidity induced changes in epoxy are likely the largest driver of hysteresis in packaged photonic thermometers. We note that unpackaged devices do not show any significant hysteresis. The hysteresis in the packaged device can be ameliorated by using a hydrophobic epoxy, adding desiccants to the glass tube before sealing and a tighter seal around the rubber cork-glass junction. Tabulating the various sources of uncertainty using repeated, detailed measurements allows us to compute a detailed uncertainty budget for the photonic thermometer.

Figure 1: Packaging apparatus. Photonic chip packaging setup consists of a top-view camera (A), two side-view cameras (B and C), a fiber-array holder arm (D) and a six-axis stage (E).

Figure 2: Temperature response of photonic sensor. Temperature dependent response of a photonic resonator shows a systematic upshift in resonance wavelength with increasing temperature.

Discussion

The objective of this experiment was to quantify the temperature dependent response of a photonic thermometer. For quantitative measurements of temperature, it is prudent to utilize a stable heat source such as a metrology grade deep dry well, small volume sensors, ensure good thermal contact between the well and the sensor, and minimize heat loses to the environment. These requirements are easily met by bonding optical fibers to the chip, effectively creating a packaged device that can be lowered deep into the metrology temperature well. The purpose of the copper cylinder in the glass tube is to provide a good thermal contact between the chip and glass tube, and to provide a large thermal mass that dampens transient thermal fluctuations, thus improving temperature stability. The glass tube is backfilled with dry argon gas to prevent condensation at low temperatures which can negatively impact the uncertainty in temperature measurement.

The most common source of error in temperature measurements, however, is insufficient equilibration time. Air is an excellent insulator and any airgaps between the bath and glass tube or sample can slow down thermal transport. It is important to verify that the device is settled into equilibrium with the temperature well before detailed measurements are made. We determined the equilibration time by repeatedly measuring the resonator response over the course of an hour once the bath itself has reached equilibrium. Our results indicate that depending upon the photonic chip package geometry it can take up to 20 minutes to reach the equilibrium. Typically, we wait 30 minutes to ensure that the equilibrium is reached.

Photonic thermometry presents a disruptive new route for the realization, dissemination and measurement of thermometry upending a century old paradigm. At its simplest photonics could enable us to overcome the limitations of resistance thermometry (strain induced hysteresis, chemical and environmental sensitivity, etc.) while providing equivalent or better measurement performance. The best case scenario for photonics thermometry envisions leveraging the recent advances in optomechanics to realize thermodynamic temperature measurements11, thus enabling the untethering of temperature measurements from it traceability chain.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors acknowledge the NIST/CNST NanoFab facility for providing opportunity to fabricate silicon photonic temperature sensors and Wyatt Miller and Dawn Cross for assistance in setting up the experiments.

Materials

| Packaging process | |||

| 6-axis stage | PI instruments | ||

| video cameras | |||

| epoxy dispensation system | |||

| Fiber array | |||

| Temperature Measurement | |||

| Metrology Well | Fluke | 9170 | Dry well stable to better than .01 K |

| Laser | Newport | TLB6700 | 1520-1570 nm tunable laser |

| Wavemeter | HighFinesse | WS/7 | 100 Hz wavemeter |

| Power meter | Newport | 1936-R | power meter with broad range |

References

- Price, R. The Platinum resistance Thermometer. Platinum Metals Review. 3 (3), 78-87 (1959).

- Xu, H., et al. Ultra-Sensitive Chip-Based Photonic Temperature Sensor Using Ring Resonator Structures. Optics Express. 22, 3098-3104 (2014).

- Donner, J. S., Thompson, S. A., Kreuzer, M. P., Baffou, G., Quidant, R. Mapping Intracellular Temperatrure Using Green Flurorescent Protein. Nano Letters. 12 (4), 2107-2111 (2012).

- Ahmed, Z., et al. Towards Photonics Enabled Quantum Metrology of Temperature, Pressure and Vacuum. arXiv:1603.07690 [physics.optics]. , (2016).

- Ahmed, Z., Filla, J., Guthrie, W., Quintavall, J. Fiber Bragg Gratings Based Thermometry. NCSL International Measure. 10, 24-27 (2015).

- Hill, K. O., Meltz, G. Fiber Bragg Grating Technology Fundamental and Overview. J. of Lightwave Technology. 15, 1263-1275 (1997).

- Liacouras, P. C., Grant, G., Choudhry, K., Strouse, G. F., Ahmed, Z. Fiber Bragg Gratings Embedded in 3D-printed Scaffolds. NCSL International Measure. 10 (2), 50-52 (2015).

- Klimov, N. N., Mittal, S., Berger, M., Ahmed, Z. On-chip silicon waveguide Bragg grating photonic temperature sensor. Optical Letters. 40 (17), 3934-3936 (2015).

- Klimov, N. N., Purdy, T., Ahmed, Z. On-Chip Silicon Photonic Thermometers: from Waveguide Bragg Grating to Ring Resonators sensors. Proceedings. , (2015).

- Kim, G. D., et al. Silicon photonic temperature sensor employing a ring resonator manufactured using a standard CMOS process. Optical Express. 18 (21), 22215-22221 (2010).

- Purdy, T., et al. Thermometry with Optomechanical Cavities. , STu1H.2 (2016).