Installation Method to Enhance Quality Control for Fiber Reinforced Polymer Spike Anchors

Summary

This manuscript presents a method for controlling the quality of installation for spike anchors designed to delay delamination of externally bonded fiber reinforced polymers. The protocol includes the preparation of the drill hole and the insertion process. The most influential parameters on the efficiency of the anchors are discussed.

Abstract

Fiber reinforced polymer (FRP) anchors are a promising way to enhance the performance of externally-bonded FRPs applied to existing structures, as they can delay or even prevent debonding failure. However, a major concern faced by designers is the premature failure of the anchors due to stress concentration. Poor installation quality and preparation of the clearance holes can result in stress concentration that provokes this premature failure. This paper deals with an installation method that aims to reduce the impact of the stress concentration and to provide a proper quality control of the preparation of the drill hole. The method involves three parts: the drilling and cleaning of the holes, the smoothing of the hole edges with a customized drill bit, and the installation of the anchor itself, including the impregnation of the anchor dowel and its insertion. Anchor fans (the free length of the spikes) are then bonded to the external FRP reinforcement. For the end anchorage, and in the case of reinforcements with multiple plies, it is recommended that the anchor fan be inserted between two plies to assist the stress-transfer mechanism.

The proposed procedure is complemented with a design approach for spike anchors, based on an extensive database. It is proposed that the design follow a number of steps, namely: selection of the anchor diameter and subsequent tensile strength of the connector (that is to say, the anchor before fanning out the free end), evaluation of the reduction in the tensile strength due to bending, provision of enough embedment to prevent slippage failure, and consideration of the number and spacing of anchors for a given reinforcement. In this sense, it should be noted that further research is needed in order to obtain a general expression for the contribution of spike anchors to overall bond strength of FRP reinforcements.

Introduction

FRP anchors offer a promising way to enhance the performance of externally bonded FRPs applied to existing structures, given that they can delay or even prevent debonding failure1,2. However, a major concern for designers entails the premature failure of the anchors in shear due to stress concentration in the bending region. Installation quality and preparation of the clearance holes are crucial to limit this stress concentration that provokes such premature failure.

This paper deals with an installation method that aims to reduce the impact of the stress concentration and to provide a proper quality control of the preparation of the drill hole and the installation of the anchors. The method involves four parts: drilling and cleaning the holes, smoothing the hole edges with a customized drill bit to avoid irregularities in the stress-distribution within the bending region, installation of the anchor itself, including the impregnation of the anchor dowel and its insertion, and adhesion of the anchor to the reinforcement.

From previously published research3,4,5,6,7, it can be concluded that spike anchors with a bending region (that is to say, with a certain angle between the free end and the embedded region), suffer stress concentration that is prone to provoke premature failure. This cannot always be avoided due to the geometry of the original members. In many cases, 90° dowel angles are broadly employed, although it is generally agreed that 135° dowel angles allow a reduction in stress concentration and lead to better performance of spike anchors. The main reasons for the use of 90° dowel angles are that they are simpler to execute and control in any direction and that they reduce the possibility to meet internal reinforcements.

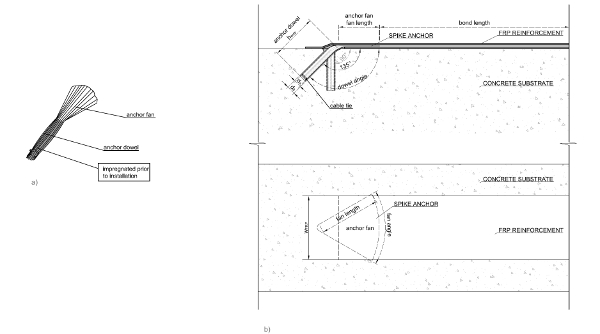

Figure 1 shows a typical spike anchor with the most common dowel angles. Spike anchors installed with 90° dowel angles can, nevertheless, display a relatively good performance if proper control of the stress concentration is provided. Limiting stress concentration generally involves designing the anchors with a large inner bending radius, as the inner bending radius has been found to play a major role in fiber kinking8,9. In this sense, authors such as Orton et al.3 suggest that a bending radius of four times the anchor diameter should be used. This recommendation results in impractical bending radii, even for small anchor diameters, as increasing the bending radius involves diminishing the actual embedment length for a given hole depth.

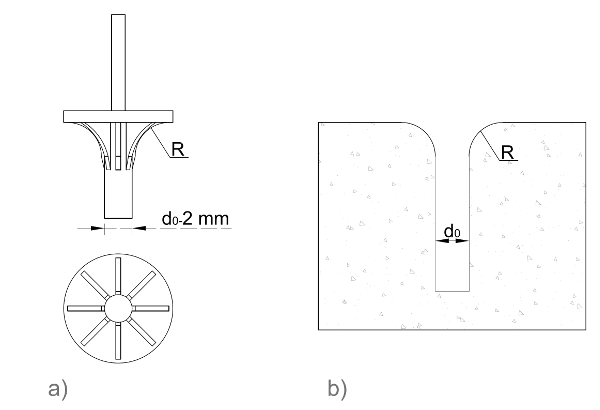

The authors believe that the recommendation of large bending radius is related to the difficulty of controlling the real inner bending radius, from a geometrical point of view, when smoothing is done by hand. A customized drill bit has been consequently designed that allows an easy quality control of the installation and ensures that the bending radius is considered in the design.

Two different processes are considered in the paper. The first one is related to the installation procedure for the connectors (anchors, especially before fanning out the free end), whereas the second includes the proposed method for design with spike anchors and the verification needs.

Protocol

1. Anchor Installation Method

NOTE: This method includes the hole drilling, cleaning, and smoothing of the hole edge, as well as impregnation and insertion of the anchor.

- Drill the hole to the required embedment length and with the specified diameter.

- Use an appropriate drilling tool (that is to say, electrical hammer or diamond core). For concrete structures, the criteria for selection of drilling tools are the same as in adhesive anchors, and can be found in previously published work10,11. For an electrical hammer, drill with a maximum speed of 800 rpm.

- Provide a hole clearance (i.e., the difference between the diameter of the drill and that of the connector) of no less than 4 mm. Furthermore, it is recommended that this difference be 8-10 mm. This eases the smoothing of the hole and allows bending of the anchor inside the drill.

NOTE: It should be noted that commercial fiber ropes have nominal diameters (when impregnated) ranging from 10 to 12 mm. The anchors displayed in the filmed protocol were made from fiber ropes with a nominal diameter of 12 mm.

- Provide a hole clearance (i.e., the difference between the diameter of the drill and that of the connector) of no less than 4 mm. Furthermore, it is recommended that this difference be 8-10 mm. This eases the smoothing of the hole and allows bending of the anchor inside the drill.

- Use an appropriate drilling tool (that is to say, electrical hammer or diamond core). For concrete structures, the criteria for selection of drilling tools are the same as in adhesive anchors, and can be found in previously published work10,11. For an electrical hammer, drill with a maximum speed of 800 rpm.

- Control the embedment length and smooth the hole. Length control is extremely important, as anchor performance is extremely length-sensitive. Embedment lengths ranging from 75 to 150 mm are recommended.

- To perform length control, insert a rigid bar into the drilling hole, and compare the total length of the bar and the length that remains out of the hole when inserted with a measuring tape.

- Use a blow-out hand pump, once the drilling is complete, to perform a first dust removal. Follow the instructions of the manufacturer of the pump. Blow out no less than two times for the first dust removal.

- Smooth the hole with a rotary, non-percussive tool. See Figure 2 for details of the customized drill bit. A drill bit such as that proposed can be easily adapted to most electrical hammers. Refrigerate the substrate continuously with water while working. Smoothing is complete when no sharp edges appear, and the upper part of the drill bit touches the concrete surface.

- Clean the hole with a combination of blowing and brushing cycles, as it is crucial to achieve the highest bond strength. The cleaning process is similar for FRP spikes and for adhesive anchors. It is recommended that at least two cleaning cycles be performed. Please refer to existing guidelines10 for additional recommendations on the cleaning process, and always follow the recommendations of the manufacturer if other cleaning tools are used.

- Always blow before and after brushing. Consequently, each cycle of mechanical brushing involves two blowings and one brushing.

- Blow from the inside towards the opening of the hole in order to remove the loose particles inside the drilled hole. There are two ways of blowing. If the anchor is installed on dry concrete, blowing can be done with a blow-out hand pump. If it is installed on wet concrete, blowing must be done with pressurized air (maximum pressure of 10 bar).

NOTE: The protocol has been developed for dry supports, though it could be adapted to wet conditions. It is worth noting that the smoothing technique involves moisturizing the substrate. Therefore, the resulting grade of humidity will depend on the environmental conditions and on the time elapsed between the smoothing of the hole and the insertion of the connector. The condition of dry support is defined for a relative humidity of below 5%, which normally corresponds to normal drying conditions of several days. In the case of existing concrete structures, the holes can be considered dry when 24 h have elapsed between the smoothing of the hole edge and the insertion of the anchor. A humid condition refers to near 100% relative humidity, which typically corresponds to maritime structures. - Use a wire brush to radially brush the hole. The diameter of the brush must be equal or up to 20 mm greater than the diameter of the drill. Select the diameter of the brush to be as close as possible to that of the hole, to allow equal friction around the hole section.

- Install the anchors immediately after cleaning. If this is not possible (if the anchor is not inserted within 1 h from cleaning), perform an additional cleaning cycle before inserting the anchors. This last cleaning cycle is especially critical for horizontal anchors and holes made on the top surface of the substrate.

- Prepare and install the anchors. This involves three different processes.

- Cut the fiber bundle or rope to the required length. The length of the anchor must be equal to the embedment length (or dowel length) plus the length of the anchor fan.

- Impregnate the anchor dowel with low-viscosity epoxy primer with a soft brush. Always respect the pot-life of the resin, according to the manufacturer. Approximately 150 g of resin per anchor are needed. Impregnation requires partially fanning out the fiber bundle to maximize the penetration of the resin.

- Always impregnate towards the end of the connector to avoid bending the fibers. Hold the bending region to prevent slippage of some fibers from the bundle and to prevent the free end from being fanned out at this step.

- Fasten the impregnated end with a cable tie immediately after impregnation. Then, insert the anchor dowel. Assist the insertion with a wire that pushes the cable tie, to guarantee that the fibers actually reach the required embedment length.

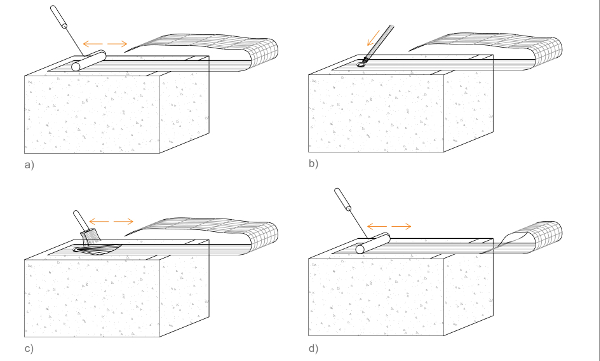

- Connect the reinforcement to the anchor to ensure a proper transfer mechanism to the connector. This protocol has been developed and is further explained for end anchorage of multiple-plied externally bonded FRP reinforcements. See Figure 3 for a graphic explanation of the process.

- Apply the first ply of the reinforcement before the insertion of the anchor (but always after preparation and cleaning of the hole), as shown in Figure 3. Alternatively, use a first ply shorter than the ones adhered onto the anchor fan, to allow insertion of the anchor before applying the first ply of the reinforcement.

- Provide end anchorage when end-plate debonding (or delamination) is expected to occur. For the wet application of the external reinforcement, always prepare the surface of the substrate according to current standards or guidelines12,13.

NOTE: Anchor fans should be fully bonded to the reinforcement, as this bond will accumulate the stress-transfer mechanism. In the case of FRP reinforcements made from multiple layers and with end-anchorage, anchor fan installation between two plies is recommended. This eliminates the need for piercing the laminate with the anchor, and avoid damaging the reinforcement. To date, no minimum fan length has been determined in the literature. The authors recommend that fan lengths of no less than 50 mm be used. - Apply epoxy resin to both the external FRP reinforcement and the anchor fan. The resin can be applied with either a roller or a brush. Use the same resin to bond the external FRP reinforcement to the substrate and the anchor fan to the external reinforcement. Always consider the pot life of the resin, according to the manufacturer.

- Prevent the emergence of air voids between the plies of the reinforcement by using a bubble roller that allows air relief after the impregnation of each layer (including the anchor fan).

NOTE: For the development of the protocol, a resin with a pot life of 90 min at 20 °C was employed.

- Prevent the emergence of air voids between the plies of the reinforcement by using a bubble roller that allows air relief after the impregnation of each layer (including the anchor fan).

2. Design with Spike Anchors

NOTE: The design method is explained here for fan anchors, but similar procedures could be followed for different anchorage devices. This method consists of the evaluation of anchor capacity, bond strength, and contribution of the anchors to the overall strength of the reinforced member.

- Evaluate the anchor's capacity. This primarily depends on whether the anchor is subjected to tensile or shear forces. In the most common cases with dowel angles less than 180° (shear applications), the dowel angle will limit the efficacy of the connector due to stress concentration in the bend region. Control the bend strength by following the installation method presented above.

- Express the anchor capacity as a fraction of its tensile strength. The design capacity for the anchor will be the minimum of the following: the concrete cone strength, bond strength (calculated as in any post-installed anchor in concrete10), bend strength, and tensile strength, with a safety factor. This results in a design capacity of the anchors (). In Villanueva Llauradó et al.14, expressions for all the expectable failure modes of spike anchors are discussed.

- Estimate the concrete cone strength with an expression such as the one in Kim and Smith15 in order to prevent the concrete cone failure. The concrete cone strength is only critical for extremely shallow anchors, and, in general, it can be disregarded for anchors with embedment lengths greater than 75 mm.

- Calculate the bond strength of the anchor dowel. This can be performed with the general expressions for post-installed anchors from codes and design guidelines. According to those expressions, the bond strength depends on the following: the tensile strength of the concrete, the diameter of the drilled hole, and the embedment length15,16. Adopt a value for the average shear strength in the concrete-to-resin interface ranging from 8 to 15 MPa when epoxy resin is used.

- Estimate the reduction of strength due to bending. This mainly depends on the inner bending radius, in accordance with the expression provided by JSCE8, which has been widely adopted for internal FRP rebars. However, complementary testing on isolated anchors is recommended in order to evaluate the real as-built strength of the connectors in a given geometrical configuration. This testing should be performed with shear tests and with anchors installed following the procedure proposed in this paper.

- Calculate the tensile strength of the anchor with the fraction of fibers in the cross section of the connectors and the tensile strength of the fiber. For fiber ropes, manufacturers generally specify the tensile strength of the impregnated connector, which could be adopted for design with a sufficient reduction factor (from 1.25 to 1.5). For fiber bundles of hand-made anchors, flat coupon tests should be conducted as in ASTM standards17.

- Calculate the bond strength of unanchored reinforcements with any expression from international codes or from analytical models such as those provided in the references18,19. Alternatively, single or double shear tests on bonded, unanchored specimens can be conducted. The design value of bond strength (Pdb,d) must be used in further calculations.

- Estimate the overall strength as the result of the bond strength of the reinforcement plus anchor capacity, for reinforcements with one anchor. This hypothesis can be accepted, according to the existing data, when the anchor fan completely covers the width of the FRP, which is coherent with the findings by authors comparing the performance of bonded and unbonded anchored specimens20,21. Calculate the design strength for anchored FRP with one spike anchor with the following equation:

Pd = Pdb,d + Panc,d (1) - For multiple anchors, determine the anchor efficiency and contribution as a function of the arrangement of the anchors (number of plies and rows, anchor spacing). Please test the desired arrangement in order to assess the reduction of efficiency due to multiple anchors, and express the design strength of the anchored joint (Pd) as follows:

Pd = Pdb,d + y' • n • Panc,d (2)

Obtain the coefficient y' from tests with each specific arrangement of the project, given the number of spike anchors, as in the references20,23. As an alternative to testing, consider the efficiency y' as suggested in the approaches reported from such tests in those same publications20,23.

Representative Results

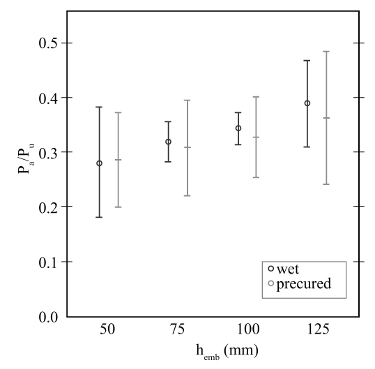

Tests were conducted on isolated connectors to evaluate the effectiveness of the smoothing method. In addition, two methods of impregnation and insertion of the connectors were compared. The wet method involved impregnating the anchors immediately before insertion, as in the presented protocol. The hardened (or pre-impregnated) method consisted of impregnation of the embedded region of anchors in advance, at least 24 h before insertion.

In tests conducted following the proposed method, an average increase of 27 MPa was achieved compared with non-smoothed specimens of the same embedment length and hole diameter. Of note is the difference in terms of the standard deviation, which was only 10.9 MPa for smoothed specimens following the method, whereas for an identical configuration and non-smoothed specimens it was 88.2 MPa. It should be noted that the tensile strength of the tested carbon fiber ropes was not achieved in any test, as all anchors exhibited premature failure due to being in shear.

The difference between the two impregnation and installation methods was not important in terms of the ultimate load, but it was significant in terms of the scatter. This has been related to the relative ease of quality control, which is critical for spike anchors. It should be noted that the handling of FRP anchors requires skillful workers. Nevertheless, given that the quality of the impregnation is difficult to control in the hardened method, this method is not recommended. Pre-impregnated connectors had higher standard deviations when embedment length was sufficient to prevent adherent failure (100 and 125 mm embedment lengths, hemb). Results obtained from wet and hardened anchors with smoothed holes are displayed in Figure 4.

Load-bearing capacity calculated according to the equations presented fits the available data in pull-out and shear. To find out more about this design modeling and the test results, please see previous works by the authors7,14.

Once the load bearing capacity of isolated spike anchors has been addressed, it is crucial to evaluate the contribution to the overall strength of externally bonded reinforcements. The existing data for anchored FRP joints in simple situations with spike anchors (i.e., single or double shear tests on concrete specimens) are quite limited. The proposed steps for design with FRP anchors were found to fit acceptably well to the existing database including tests by different authors5,19,20,21,22.

Figure 1: Configuration and dowel angles of FRP spike anchors. The dowel angle, together with the embedment length, plays a major role in stress concentration in spike anchors. The fan angle must be adapted to the width of the external reinforcement. (a) Typical FRP spike anchor. (b) Variables for design (fan angle, dowel angle, embedment length, and fan length) are summarized. The parameters d0 and da are the nominal diameter of the anchor and the hole diameter, respectively. This figure has been modified from Villanueva Llauradó et al. 201714. Please click here to view a larger version of this figure.

Figure 2: Customized drill bit. Generate customized drill bits with the desired radius. Diamond bits may be of choice for durability reasons. The proposed tool (a) has eight cutters. The smoothing process is terminated when the tool round plate of the tool touches the surface of the substrate. The resulting profile of the hole is shown in (b). Please click here to view a larger version of this figure.

Figure 3: Connection between spike anchor and external reinforcement. The main steps involved in the installation and connection between the external reinforcement and the spike anchor are pictured here. (a) The first ply (or layer) of the FRP reinforcement is applied to the substrate with resin. (b) The insertion of the anchor dowel in the hole. (c) The free length of the anchor is fanned out and bonded to the reinforcement with resin. (d) After each step of application of resin, the air voids must be removed with a bubble roller. Please click here to view a larger version of this figure.

Figure 4: Influence of the insertion method on the scatter of results. Results of tests performed by the authors (mean values and error bars representing the central 95% range). There is an almost linear increase of the anchor capacity with embedment length. This is displayed together with the influence of the installation method in the scatter of results. The horizontal and vertical axes represent, respectively, the embedment length (hemb) and the ratio between the actual performance of the anchors (Pa) and their tensile strength (Pu). Please click here to view a larger version of this figure.

Discussion

A step-by-step protocol for installation and design of FRP spike anchors is presented. To the best of the authors' knowledge, no detailed protocols on spike anchors have been developed regarding the effect of installation parameters and process on anchor capacity.

The proposed smoothing drill bit is beneficial in the performance of spike anchors, by means of reducing the stress concentration, and has proven its efficacy in reducing the scatter of the tests performed on isolated anchors. This is related to the enhancement in the quality control of the installation. Also, the low scatter of the anchors executed following the proposed installation protocol allows a reduction of the standard deviation, thus contributing to a reliable design.

Regarding the test results presented, there are no significant differences between pre-impregnated and wet installation in terms of the ultimate load. However, for the proposed protocol it is recommended that the anchor dowels be impregnated immediately prior to insertion, to guarantee proper impregnation of the bending region. In addition, this prevents brittle failure due to hardened resin in the bending region. If pre-impregnated installation is employed, then it must be guaranteed that the hardened portion is shorter than the straight leg of the anchor dowel. Proper impregnation of the bending region after insertion is difficult to achieve for test conditions. It should be noted, however, that this problem is reduced when the splay region of the connector is fanned out.

The main disadvantage associated with the customized drill bit is that it was designed with a radius of 20 mm, resulting in a 25 mm inner bending radius for 10 mm diameter anchors in 20 mm diameter holes. When compared with a larger inner bending radius, there is lower connector efficiency. It is recommended that, if high bend strength is required, that the drill bit be designed with a non-constant radius able to minimize stress concentration (by means of maximizing the inner bending radius).

The proposed design procedure includes all the necessary steps for a complete design of anchored externally bonded FRP reinforcements. The contribution of the anchors must always be considered in terms of an addition to the bond strength. It should be noted that tests on isolated anchors must be conducted on specimens with the designed geometry (hole and anchor diameter, embedment length, and bending radius, in particular) for the anchors. Then, the contribution of the anchors can be calculated as an addition to the bond strength of the FRP reinforcement. To date, the main limitations for design are the maximum contribution of the anchors and the optimum arrangement of multiple anchors. The authors wish to indicate that, according to the available databases, spike anchors alone can carry as much load as the adherent mechanism alone, which would mean that the overall strength of the anchored joints could be expected to be twice that of unanchored bonded joints. However, this value cannot be confidently adopted as a design value given the limited number of existing data.

The presented protocol for installation and design aims to be a basis for future developments in the field of anchorage of externally bonded FRP reinforcements.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors wish to express their gratitude to Sika SAU for their support and, particularly for their supply of the material for the anchors and for the reinforcements. Betazul is especially acknowledged for their help with the customized drill bit and with the preparation of the video.

Materials

| Concrete | The concrete for support has a dosage made by the authors, and a strength class no lower than C40 | ||

| SikaWrap anchor C | SIKA | This material has been used for the FRP spike anchors. SikaWrap Anchor C is a unidirectional, carbon fiber rope, sheathed in an elastic gauze. The gauze can be cut onsite to create a fan end that anchors CFRP fabrics and plates used in the structural strengthening of masonry and concrete. | |

| Sikadur 330 | SIKA | Impregnating resin, apt for manual saturation methods. The product was used for impregnating the anchor dowel before insertion | |

| Sikadur 30 | SIKA | Thixotropic, two part epoxy resin applied by spatula and therefore suitable for virtually any application, including overhead | |

| Drill bit | Betazul | Drill bit employed to smooth the holes that was designed by the authors and developed by Betazul SA | |

| Hammer drill | Hilti | Tool for the execution of anchor holes on masonry and concrete, for different drilling ranges | |

| Wire brush | Hilti | Hit series | For the proper brushing of drilled holes of varying diameters and embedment depths |

| Blow-out pump | Hilti | Hit series | Manual blow-out pump |

| SikaWrap-230 C | SIKA | Unidirectional woven carbon fiber fabric for dry application process | |

| Aluminium Bubble Roller | Fibre glast | For laminations where increased pressure is necessary to release air bubbles. They are straight across the width of the head and provide excellent air relief for nearly all applications. | |

| Brush | For impregnation of FRP bundle and sheet | ||

| 600 kN testing machine | Proeti | DI-CP/S | This is used for the shear test of anchors, in order to evaluate the efficacy of the proposed insertion method |

| Cable ties | Cable ties are needed to fasten the end of the anchor dowel in order to prevent fanning out of the fibers during insertion | ||

| Measuring tape | The measuring tape is necessary to control the embedment length as well as the diameter of the drill bit and hole clearance | ||

| Steel wire | Required to assist insertion | ||

| Rigid (steel) bar | A rigid bar of any material (in this case, it was made with a steel bar) is needed to control the embedment length |

References

- Grelle, S., Sneed, L. An evaluation of anchorage systems for fiber-reinforced polymer (FRP) laminates bonded to reinforced concrete elements. Struct Cong. , 1157-1168 (2011).

- Kalfat, R., Al-Mahaidi, R., Smith, S. Anchorage devices used to improve the performance of reinforced concrete beams retrofitted with FRP composites: State-of-the-art review. J Compos Constr. , 14-33 (2013).

- Orton, S. L., Jirsa, J. O., Bayrak, O. Design considerations of carbon fibre anchors. J Compos Constr. 12 (6), 608-616 (2008).

- Ozbakkaloglu, T., Saatcioglu, M. Tensile behavior of FRP anchors in concrete. J Compos Constr. 13 (2), 82-92 (2009).

- Zhang, H. W., Smith, S. T. Influence of FRP anchor fan configuration and dowel angle on anchoring FRP plates. Compos Part B: Eng. 43 (8), 3516-3527 (2012).

- Koutas, L., Triantafillou, T. Use of anchors in shear strengthening of reinforced concrete T-beams with FRP. J Compos Constr. 17 (1), 101-107 (2012).

- Villanueva-Llauradó, P., Fernández-Gómez, J., González-Ramos, F. J. Influence of geometrical and installation parameters on performance of CFRP anchors. Compos Struct. 176, 105-116 (2017).

- Machida, A. Recommendation for design and construction of concrete structures using continuous fiber reinforcing materials. Japan Society of Civil Engineers (JSCE). , (1997).

- Lee, C., Ko, M., Lee, Y. Bend strength of complete closed-type carbon fiber reinforced polymer stirrups with rectangular section. J Compos Constr. 18 (1), 04013022 (2013).

- . . Qualification of post-installed adhesive anchors in concrete and commentary. , 4-11 (2011).

- . . Metal anchors for use in concrete. Part 5: Bonded Anchors. , (2013).

- . . Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. , (2008).

- . . Design Guidance for Strengthening Concrete Structures Using Fibre Reinforced Composite Materials. , (2012).

- Villanueva-Llauradó, P., Ibell, T., Fernández-Gómez, J., González-Ramos, F. J. Pull-out and shear-strength models for FRP spike anchors. Compos B Eng. 116, 239-252 (2017).

- Kim, S., Smith, S. Pullout strength models for FRP anchors in uncracked concrete. J Compos Constr. 14 (4), 406-414 (2010).

- Cook, R. A., Konz, R. C. Factors influencing bond strength of adhesive anchors. ACI Struct J. 98 (1), 76-86 (2001).

- . . Standard test method for Tensile Properties of Polymer Matrix Composite Materials. , (2014).

- Chen, J., Teng, J. Anchorage strength models for FRP and steel plates bonded to concrete. J Struct Eng. 127 (7), 784-791 (2001).

- Lu, X. Z., Teng, J. G., Ye, L. P., Jiang, J. J. Bond-slip models for FRP and steel plates bonded to concrete. Eng Struct. 27 (6), 920-927 (2005).

- Brena, S. F., McGuirk, G. N. Advances on the behavior characterization of FRPanchored carbon fiber-reinforced polymer (CFRP) sheets used to strengthen concrete elements. Int J Concr Struct Mater. 7 (1), 3-16 (2013).

- Eshwar, N., Nanni, A., Ibell, T. J. Performance of two anchor systems of externally bonded fiber-reinforced polymer laminates. ACI Mater J. 105 (1), 72-80 (2008).

- Zhang, H. W., Smith, S. T., Kim, S. J. Optimisation of carbon and glass FRP anchor design. Constr Build Mater. 32, 1-12 (2012).

- Zhang, H. W., Smith, S. T. FRP-to-concrete joint assemblages anchored with multiple FRP anchors. Compos Struct. 94 (2), 403-414 (2012).