Application of 3D Printing in the Construction of Burr Hole Ring for Deep Brain Stimulation Implants

Summary

Here, we present a protocol to demonstrate 3D printing in the construction of deep brain stimulation implants.

Abstract

3D printing has been widely applied in the medical field since the 1980s, especially in surgery, such as preoperative simulation, anatomical learning and surgical training. This raises the possibility of using 3D printing to construct a neurosurgical implant. Our previous works took the construction of the burr hole ring as an example, described the process of using softwares like computer aided design (CAD), Pro/Engineer (Pro/E) and 3D printer to construct physical products. That is, a total of three steps are required, the drawing of 2D-image, the construction of 3D-image of burr hole ring, and using a 3D printer to print the physical model of burr hole ring. This protocol shows that the burr hole ring made of carbon fiber can be rapidly and accurately molded by 3D printing. It indicated that both CAD and Pro/E softwares can be used to construct the burr hole ring via integrating with the clinical imaging data and further applied 3D printing to make the individual consumables.

Introduction

3D printing has been applied in the medical field since the 1980s, especially in surgery for preoperative simulation, anatomical learning and surgical training1. For example, in cerebrovascular operations, preoperative simulation can be conducted by using 3D printed vascular models2. With the development of 3D printing, the texture, temperature, structure and weight of cerebral blood vessels can be simulated to the greatest extent of clinical scenarios. Trainees can perform surgical operations such as cutting and clamping on such models. This training is very important for the surgeons3,4,5. Currently, titanium patches formed by 3D printing have also gradually been applied6, since the skull prostheses developed by 3D printing after imaging and reconstruction are highly conformal. However, the development and application of 3D printing in neurosurgery is still limited.

The burr hole ring, as a part of the lead fixation device, has been widely used in deep brain stimulation (DBS)7,8,9,10. However, current burr hole rings are made by medical device manufacturers according to the unified specifications and dimensions. This standard burr hole ring is not always suitable for all conditions, such as skull malformation and scalp atrophy. It may increase the uncertainties of operation and reduce the acurracy. The emergence of 3D printing makes it possible to develop individualized burr hole rings for patients in clinical scenarios5. At the same time, the burr hole ring, which is not easy to obtain, is not conducive to extensive preoperative demonstration and surgical training1.

To address the problems mentioned above, we proposed to construct a burr hole ring with 3D printing. A previous study in our lab described an innovative burr hole ring for DBS11. In this study, this innovative burr hole ring will be regarded as an excellent example to exhibit the detailed production process. Therefore, the purpose of this study is to provide a modeling process and a detailed technical process of building a solid burr hole ring using 3D printing.

Protocol

1. Drawing a two dimensional (2D)-image of a burr hole ring

- Open the 2D computer aided design (CAD) software and then create a graphical document.

- Click Draw | Line and draw a reference point with a solid line on the drawing. Click Modify | Offset, and type the specific offset distance in the command line.

- Click on the object and press by the left mouse button to create a solid line. Click Modify | Trim, select the area to be trimmed and click on the extra line.

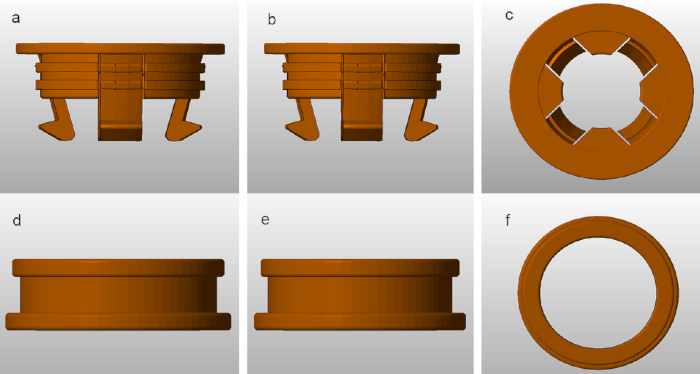

- Take the inner burr hole ring for example, draw three different views of the inner ring based on the predetermined size in the CAD software. First, draw the front view and modify the graph carefully until it matches the structure expected (Figure 1d).

- Draw the top view by clicking Draw | Line to construct the reference point first and then click on Draw | Circle | Center, Diameter, and input the quantitative value of specific radius of circle or diameter in the command window. Click on the center of the reference point to form a circle (Figure 1f).

- Draw the left view of the inner burr hole ring with the same approach as that of the front view (Figure 1e).

- Click on Dimension | Diameter, and then click on the circumference to mark the diameter of the circle (Figure 1f).

- Click on Dimension | Linear and mark the length and thickness of all associated structures (Figure 1d,e). Click Dimension | Radius to mark the angle of the chamber (Figure 1d).

- Using the same protocol, construct two-dimensional drawings of the outer burr hole ring, and mark the actual size and the labeling (Figure 1a – c).

- Add technical requirements of the production process, including strength, toughness and lack of cracks. Moreover, smoothing of the outer wall is needed.

- Clink on Save to save the 2D-image of the burr hole ring.

NOTE: All of these structures mentioned above are in the units of millimeters (mm).

2. Construction of a 3D-image of the burr hole ring

- Start the 3D drawing software (see the Table of Materials). Select New | Part | Solid and uncheck using the default template. Select part_solid in new file options and click on Ok to create a new interface for setting up a physical part model.

- Click on Part feature in the menu manager on the right and select Create | Solid | Add sheet. In the SOLID drop-down menu, select Rotate | Done. Click on the trace of the preliminary sketch. Select the "front" plane as the sketch plane, then click default under SKET VIEW.

- Select the dotted line on the right toolbar of the window and draw the top section of the part in the two-dimensional sketch. The specific size shall be subject to the two-dimensional drawing. Then click Conform, and select Done in the Protrusion window of protrusion. Click on the Datum plane icon.

- In menu manager, select Create | Solid | Add sheet, and Rotate | Done. Click Bilateral in the properties menu and click Done.

- Click on Front | Forward | Default and then Datum plane | Dotted Line to construct the cross section of the hook of the outer burr hole ring. Then click Conform followed by Done in menu manager. Input "50" in Angle in indicated direction[45.0000], and then click Done in the Protrusion window and finally, click on the Coloring button.

NOTE: The unit of the angle is degree (°). - Select Redefine in the part feature and click the line structure of the hook. Input the command Section | Define | Sketch.

- Click the Dotted line icon, create two square embossments on the hook section, then input command OK | Done | Coloring.

- Click the Datum axis icon, then input the command Insert a datum | Cross, click the center axis of the line structure, click Angle in datum plane, and then click the "front" plane in the line structure view. Click input value in the offset menu. Input "-45" in "Angle in indicated direction[45.0000].

NOTE: The unit of the angle is degree (°). - Click on Features | Copy | Mirror. Click on the hook as the object and input command Done select | Done. Click the datum plane to complete the copy. Similarly, the remaining two hooks are copied in this way. Click on Create concentric circle to construct a circle with a radius of 7.23 mm, click the Segmentation of primitives at selected points icon to remove the unnecessary lines of the circle.

- Click the Solid line button in the right toolbar to create a complete outer wall section. Then input the command OK | Done.

NOTE: The unit of the radius is millimeter (mm). - Input "4" in Enter depth, then click on Coloring. Input the command Mirror | Done. Then click on the object and click Done. Click the datum plane to complete the copy.

- Input the command Copy | Mirror | Done, and select two outer walls in different directions, click Done to conform. Click the datum plane to complete the copy.

- Input the command View | Model Settings | Color and appearance | Add. Adjust the RGB color slider and adjust the color to brown to show the graphic details more visually. Then input the command Close | Settings | OK.

- Click the button Eliminating hidden lines, click the Create concentric circle, continue to create an outer edge on the outer wall, click the Segmentation of primitives at selected points button to remove excess lines, and click the Solid line button to connect the newly added outer edge into a complete section. Click Ok.

- Input "0.8" in Inter depth. Click Ok in the Protrusion window. In menu manager, input the command Copy | Mirror | Done. Click the object and click done. Input the command Generate benchmark | Offset.

NOTE: The unit of the depth is millimeter (mm). - Click the Input value in the Offset and enter "0.4" as the Isometric of the specified direction, then click Done.

NOTE: The unit of the offset is millimeter (mm). - Input the command Copy | Mirror | Done, click the outer wall. Input the command Done select | Done. Click Done select and click Done. Click the datum of the image to complete the copy. In this way, the mirror operation of the outer wall and the square embossing is completed respectively.

- Input the command File | Copy, select save format as STL (*stl) in the part type drop-down menu, enter part number and click Ok.

- In the Output STL dialog box, adjust the chord height to 0.006 and the angle control to 0.00001. Input the command Apply | OK.

- Use the same methods as above to build the 3D image of the inner ring.

3. Using 3D printer to print the physical model of burr hole ring

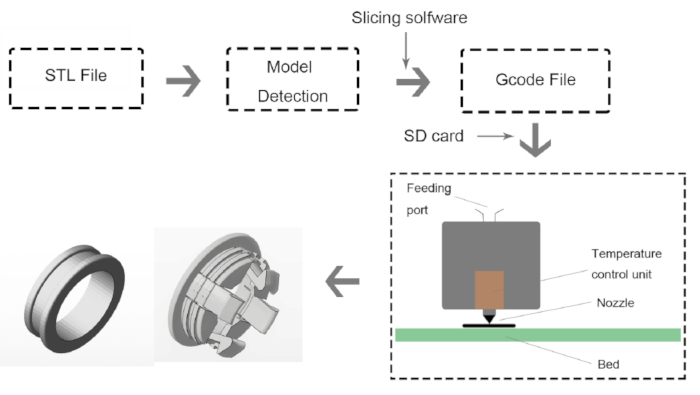

- Open the model detecting software, input the command Project | Open, choose one STL file in the Open file pop-up dialog box, then click Open. In this software, a warning will appear if defects are detected in this model (Figure 3). If found, repair the model before printing. If there are no defects, click Output.

- After confirming that the outer ring is complete, input the command Part | Export part | as STL | Save. Use the above instructions to detect the defects of the inner ring.

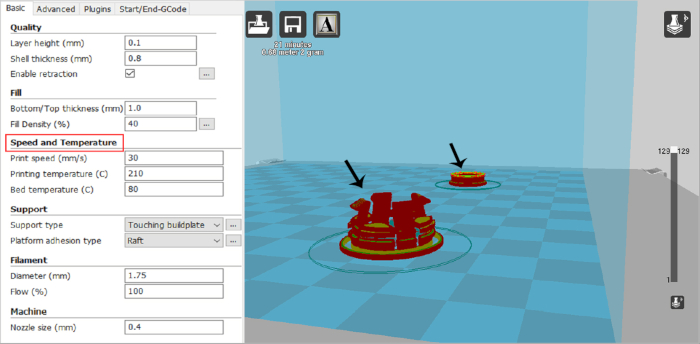

- Following model detection, the printed path needs to be designed. Open the slicing software, click File | Load model file, click on one STL file and click Open to import.

- Click the left mouse button to choose the moving track of the part, adjust the position of parts. On the left side of the screen, set the print speed to 30 mm/s, printing temperature to 210 °C and bed temperature to 80 °C (Figure 4).

- Click Toolpath to SD to save the file in Gcode format to generate printed path (Figure 3).

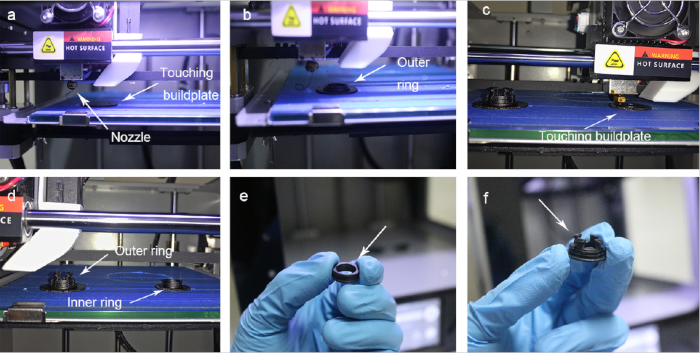

- Start the 3D printers, click the Preheating button on the main interface, set the preheat temperature of the bed to 80 °C and the nozzle temperature to 210 °C. Click Print when the temperature rises to the preset value, select the target file and click Confirm to start printing.

- The outer ring will be printed first (Figure 5a). After the bottom supporting grid has been constructed, the printing nozzle begins to construct the outer ring vertically layer by layer (Figure 5b – d). This process takes about 13 min.

- After the outer ring is formed, the printer nozzle continues to make the inner ring on the right side (Figure 5c,d), which takes about 8 min.

- Remove both parts from the platform after cooling and being formed (Figure 5e,f).

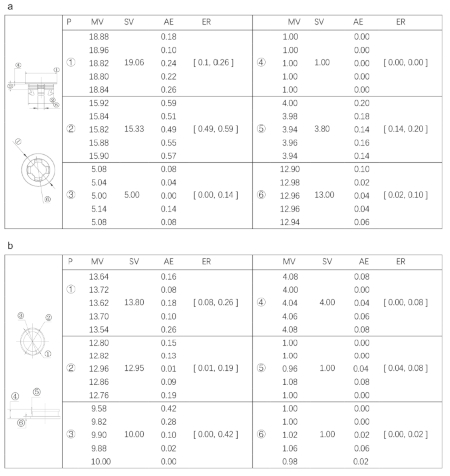

4. Measurement of absolute error

- To measure the absolute error, select five printed parts randomly. Measure and record the parameters of each part with Vernier calipers. Choose the measurement accuracy at 0.02 mm.

- Calculate the mean error of each part and the error range of the absolute error (Figure 6a,b).

Representative Results

Three views of 2D images were built through commercial CAD software (see the Table of Materials). In these images, practical size and technical requirements have also been added (Figure 1). Further, three-dimensional data were constructed in (Figure 2) and saved in STL format (Figure 3). As presented in Figure 4, solid parts were built on the platform of the printer. Choosing five groups of these parts, absolute error and error range was calculated (Figure 6a,b). The result showed that, in outer ring, the maximum absolute error and minimum absolute error were found in the outside diameter of the waist and in the thickness of the top respectively. In the inner ring, the maximum absolute error and the minimum absolute error were found in the inside diameter and thickness of the top respectively. The total error range was [0.00, 0.59] (Figure 6a,b).

The STL file is further be converted to Gcode file in the slicing solfware. After that, the Gcode file is transmitted into the 3D printer using an SD card. In the 3D printer, carbon fiber was fed through feeding port. A temperature control unit was used to control the melting of the carbon fiber and the nozzle was used to control the release of printing material and construct the solid model.

Figure 1: 2D image of burr hole ring. (a–c) 2D views (front view, left view and top view, respectively) of the outer ring. (d–f) 2D views (front view, left view and top, view respectively) of the inner ring. Unit: mm. Please click here to view a larger version of this figure.

Figure 2: 3D image of the burr hole ring. (a–c) 3D views (front view, left view and top view, respectively) of the outer ring. (d–f) 3D views (front view, left view and top view, respectively) of the inner ring. Please click here to view a larger version of this figure.

Figure 3: The flowchart for constructing a burr hole ring via 3D printing. Please click here to view a larger version of this figure.

Figure 4: The process of slicing the burr hole ring by slicing solfware. In the slicing solfware, the STL model was sliced into 0.1 mm thick layers (the black solid arrows). Parameters such as speed and temperature were set (red box) as follows: printing speed at 30 mm/s, printing temperature at 210 °C and bed temperature at 80 °C. Finally, we pressed Save toolpath, and the STL file was converted into Gcode files for 3D printing directly. Please click here to view a larger version of this figure.

Figure 5: The example of constructing burr hole ring via 3D printing. (a)The solid arrow on the left indicated the nozzle and the solid arrow on the right side showed the touching buildplate, which was used to host the solid model. (b) The outer ring (the solid arrow) was constructed on the touching buildplate. (c) The inner ring was built on the touching builplate (the solid arrow). (d) The inner ring was built on the right side of the bed (the solid arrow). (e-f) Example of inner ring and the outer ring (the solid arrow) after polishing. Please click here to view a larger version of this figure.

Figure 6: Measurement of absolute error. (a) Absolute error and error range of outer rings (AE = | MV – SV |; main structures: (1) outer diameter of the top; (2) outer diameter of the waist; (3) thickness of main body; (4) thickness of the top; (5) width of the hook; (6) inner diameter of the top). (b) Absolute error and error range of inner rings (AE = | MV – SV |; main structures: (1) outside diameter of the top; (2) outer diameter of the bottom; (3) inner diameter; (4) total height; (5) thickness of the bottom; (6) thickness of the top. P = part, MV = measured values, SV = standard values, AE = absolute error, ER = error range. Accuracy = 0.02 mm; Unit = mm. Please click here to view a larger version of this figure.

Supplemental File 1: Outer Burr Hole Ring. Please click here to view this file. (Right-click to download.)

Supplemental File 2: Inner Burr Hole Ring. Please click here to view this file. (Right-click to download.)

Discussion

These results showed that the software used were practicable to build 3D models of burr hole rings (Figure 1 and Figure 2), and 3D printing can be used to build solid models with designated materials (Figure 4). In terms of the size of the solid model, there was an absolute error from 0 to 0.59 mm determined through the measurement made by Vernier calipers (Figure 6). To some extent, the error is unavoidable since such absolute error comes from many factors, such as the quality of the printing instrument. Industrial printers can have better precision. In addition, when building smaller and more precise parts, the absolute error is more obvious. In general, as shown in Figure 3, the process that constructed the model and further formed the solid model by 3D printing is effective and feasible. Although there is an absolute error, such error can be reduced by improving the quality of the printers and accurately adjusting the printing parameters.

An innovative burr hole ring for DBS was published previously11. In this study, the same model was applied as an example to further demonstrate the systematic process of making the related implants. Currently, in the limited clinical application of 3D printing, model building generally adopts two methods: Firstly, CAD modeling has been used to generate 3D models for further 3D printing operations12. Secondly, imaging data (like in the format of DICOM) has been used to reconstruct the bone structure of patients in three dimensional models according to CT and MRI data. After rendering, the data could be further converted into editable STL files, and then the highly simulated anatomical structure can be produced by 3D printing12,13,14. Similarly, patching or implanting materials that are highly suitable for morphology can be designed according to the anatomical structure of three dimensional reconstruction15,16,17. This method has been applied in cranioplasty. A previous study showed titanium skull patches constructed by 3D printing technology6. Although using 3D printing technology to construct burr hole rings through credible flow visualization in this study in possible, this modeling method has certain limitations in practice.

Being different from the traditional production of burr hole rings, this study proposed to use 3D printing to construct these implantable parts. In fact, traditional products are mostly uniform in size, which does not apply to some patients with skull shape variation and scalp atrophy. The application of 3D printing would potentially provide the implants customized for different patients. Previous studies have proposed and implemented the application of 3D printing to produce skull fragments for skull defect repairment, and has showed its permanent effect6. The efficacy of DBS for functional neurosurgical diseases has been widely recognized (such as Parkinson's disease, dyskinesia)18,19,20, but the popularity of this treatment is limited, which may be the result of economic burden caused by high consumable costs. Products made by 3D printing have the advantages of high production efficiency, low cost and customization, which makes 3D printing of great potential in the field. The development and application of this technology may provide more patients with an opportunity to receive DBS surgery. However, there are few reports on the use of 3D printing to produce consumables for DBS in the literature.

Moreover, the burr hole ring constructed by 3D printing can have other advantages. This rapid prototyping product can be used for preoperative demonstration, which will better inform patients and their families about the procedure of electrode implantation and enhance doctor-patient communication effectively. Clinicians can carry out preoperative simulation and surgical training through 3D printed products to maximize the simulation of DBS surgery, which will effectively improve their surgical skills. In the surgical treatment of cerebrovascular tumors and cranioplasty, 3D printed products have been applied to surgical training2,5.

This study used carbon fiber, which has good strength and toughness, as the printing material to show the production process of 3D printing. In practice, many factors of implant material should be considered. Firstly, whether the implant has excellent disinfection performance and can keep its properties unchanged under ethylene oxide and hot steam for a long time12. Secondly, implants need to have good biocompatibility and can be placed for a long time without rejectiong by the body. Thirdly, implants need to have excellent mechanical strength, toughness and chemical resistance.

In this study, the construction of a burr hole ring as an example was demonstrated to systematically describe the process from modeling to 3D printing. This is a complete process example. In the future, the use of CAD software, imaging data (e.g., DICOM) and 3D printing to construct the burr hole ring should be encouraged. As mentioned above, 3D reconstruction of DICOM data obtained by imaging can be further converted into STL files that can be used for 3D printing. This is also the mainstream modeling method in clinical scenarios12,13. This method has not been applied in the DBS surgery.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work is supported by grants from Natural Science Fund of Guangdong Province (No. 2017A030313597) and Southern Medical University (No. LX2016N006, No. KJ20161102).

Materials

| Adobe Photoshop Version 14.0 | Adobe System,US | _ | Only available with a paid subscription. |

| Allcct 3D printer | Allcct technology co., LTD, WuHan, China | 201807A794124CN | |

| Allcct_YinKe_V1.1 | Allcct technology co., LTD, WuHan, China | The software is provided by the 3D printer manufacturer and there is no Catalog number associated with it | |

| AutoCAD 2004 | Autodesk co., LTD,US | 666-12345678 | Software for 2D models |

| Carbon Fibre | Allcct technology co., LTD, WuHan, China | PLA175Ø5181Ø3ØB | The material is provided by the 3D printer manufacturer |

| Netfabb Studio Basic 4.9 | Autodesk co., LTD,US | – | The software is provided by a 3D printer manufacturer and is open to access |

| Pro/E 2001 | Parametric Technology Corporation, PTC, US | _ | Software for 3D models; Only available with a paid subscription. |

| Vernier caliper | Beijing Blue Light Machinery Electricity Instrument Co,. LTD, China | GB/T 1214.1-1996 |

References

- Pucci, J. U., Christophe, B. R., Sisti, J. A., Connolly, E. S. Three-dimensional printing: technologies, applications, and limitations in neurosurgery. Biotechnology Advances. 35 (5), 521-529 (2017).

- Mashiko, T., et al. Development of three-dimensional hollow elastic model for cerebral aneurysm clipping simulation enabling rapid and low cost prototyping. World Neurosurgery. 83 (3), 351-361 (2015).

- Chae, M. P., et al. Emerging Applications of Bedside 3D Printing in Plastic Surgery. Frontiers in Surgery. 2, 25 (2015).

- Doyle, B. J., et al. Improved assessment and treatment of abdominal aortic aneurysms: the use of 3D reconstructions as a surgical guidance tool in endovascular repair. Irish Journal of Medical Science. 178 (3), 321-328 (2009).

- Kimura, T., et al. Simulation of and training for cerebral aneurysm clipping with 3-dimensional models. Neurosurgery. 65 (4), 719-725 (2009).

- Park, E. K., et al. Cranioplasty Enhanced by Three-Dimensional Printing: Custom-Made Three-Dimensional-Printed Titanium Implants for Skull Defects. Journal of Craniofacial Surgery. 27 (4), 943-949 (2016).

- Ray, C. D. Burr-hole ring-cap and electrode anchoring device. Technical note. Journal of Neurosurgery. 55 (6), 1004-1006 (1981).

- Yamamoto, T., Katayama, Y., Kobayashi, K., Oshima, H., Fukaya, C. Dual-floor burr hole adjusted to burr-hole ring and cap for implantation of stimulation electrodes. Technical note. Journal of Neurosurgery. 99 (4), 783-784 (2003).

- Wharen, R. E., Putzke, J. D., Uitti, R. J. Deep brain stimulation lead fixation: a comparative study of the Navigus and Medtronic burr hole fixation device. Clinical Neurology and Neurosurgery. 107 (5), 393-395 (2005).

- Patel, N. V., Barrese, J., Ditota, R. J., Hargreaves, E. L., Danish, S. F. Deep brain stimulation lead fixation after Stimloc failure. Journal of Clinical Neuroscience. 19 (12), 1715-1718 (2012).

- Chen, J., et al. 3-D printing for constructing the burr hole ring of lead fixation device in deep brain stimulation. Journal of Clinical Neuroscience. 58, 229-233 (2018).

- Hoang, D., Perrault, D., Stevanovic, M., Ghiassi, A. Surgical applications of three-dimensional printing: a review of the current literature & how to get started. Annals of Translational Medicine. 4 (23), (2016).

- Bustamante, S., Bose, S., Bishop, P., Klatte, R., Norris, F. Novel application of rapid prototyping for simulation of bronchoscopic anatomy. Journal of Cardiothoracic and Vascular Anesthesia. 28 (4), 1122-1125 (2014).

- Lan, Q., et al. Development of Three-Dimensional Printed Craniocerebral Models for Simulated Neurosurgery. World Neurosurgery. 91, 434-442 (2016).

- Li, W. Z., Zhang, M. C., Li, S. P., Zhang, L. T., Huang, Y. Application of computer-aided three-dimensional skull model with rapid prototyping technique in repair of zygomatico-orbito-maxillary complex fracture. The International Journal of Medical Robotics. 5 (2), 158-163 (2009).

- Wang, L., Cao, T., Li, X., Huang, L. Three-dimensional printing titanium ribs for complex reconstruction after extensive posterolateral chest wall resection in lung cancer. The Journal of Thoracic and Cardiovascular Surgery. 152 (1), e5-e7 (2016).

- Xu, N. F., et al. Reconstruction of the Upper Cervical Spine Using a Personalized 3D-Printed Vertebral Body in an Adolescent With Ewing Sarcoma. Spine. 41 (1), E50-E54 (2016).

- Brozova, H., Barnaure, I., Alterman, R. L., Tagliati, M. STN-DBS frequency effects on freezing of gait in advanced Parkinson disease. Neurology. 72 (8), 770 (2009).

- Moreau, C., et al. STN-DBS frequency effects on freezing of gait in advanced Parkinson disease. Neurology. 71 (2), 80-84 (2008).

- Oyama, G., et al. Unilateral GPi-DBS as a treatment for levodopa-induced respiratory dyskinesia in Parkinson disease. Neurologist. 17 (5), 282-285 (2011).