Recording Ultra-Realistic Full-Color Analog Holograms for Use in a Moving Hologram Display

Summary

We present a protocol to record a set of ultra-realistic full-color analog holograms, showing the same brightness, transparency, and homogeneous colors, on ultra-fine-grain silver-halide holographic emulsions for the fabrication of a dynamic holographic 3D display.

Abstract

This paper demonstrates a method to record a set of twelve ultra-realistic full-color analog holograms presenting the same brightness, transparency and homogeneous colors for the fabrication of a Fantatrope, a dynamic holographic 3D display, without the need for special viewing aids. The method involves the use of 3D printer technology, a single-beam full-color Denisyuk optical setup with three low-power lasers (red, green, and blue) and an iso-panchromatic high-sensitive silver-halide holographic emulsion specially designed for recording analog holograms without any diffusion. A cyclic animation is created with a 3D computer graphics program and different elements are 3D printed to form models for the holograms. Holograms are recorded with a full-color holographic setup and developed using two simple chemical baths. To prevent any emulsion thickness variations, the holograms are sealed with optical glue. Results confirm that all holograms recorded with this protocol present the same characteristics, which allow them to be used in the Fantatrope.

Introduction

Three-dimensional (3D) displays are an important research topic1,2,3 and most of the current approaches use the stereoscopic principle4 that causes visual discomfort and fatigue5,6. The Fantatrope is a convenient new type of dynamic holographic 3D display that can show a short animation in full color without the need for special viewing aids7. A Fantatrope uses a series of twelve full-color holograms corresponding to the different phases of an animation. All holograms used in this device must be ultra-realistic and present the same brightness, transparency, and homogeneous colors. The recording of a single high-quality full-color hologram remains difficult even for experienced practitioners. While the choices of the recording technique and holographic material are important key points, there are several more details that are crucial to successfully record such holograms.

For this protocol, a cyclic sequence of twelve different images is first created with a 3D computer graphics program and all the elements are 3D printed to become hologram models. These holograms are recorded with the single-beam method8 introduced by Yuri Denisyuk in 1963 that allows the recording of ultra-realistic holograms with a 180° full-parallax. A Denisyuk full-color setup uses three different lasers (red, green, and blue) combined to get a white laser beam. Silver-halide emulsions are the best choice of recording material9 and only a few silver-halide full-color emulsions are available9,10. Furthermore to record the blue wavelength without blur, an iso-panchromatic emulsion with a resolution of more than 10,000 lines/mm is required.

In this protocol, the set of holograms are recorded on 4 inch x 5 inch plates, using a material that is specially designed for recording full-color analog holograms without any diffusion and is made isopanchromatic for all the common visible lasers used in color holography (see Table of Materials). The grain is so fine (4 nm) that any visible wavelength can be recorded inside without any diffusion11. Furthermore, each hologram is developed using a safe, non-staining chemical process developed for the ultimate emulsions.

This detailed protocol is intended to help new and experienced practitioners in the field of analog holography to avoid many common pitfalls associated with recording full-color Denisyuk holograms; it can also provide an approach to learn how to use ultimate silver-halide holographic materials and chemicals to obtain reliable and reproducible results.

Protocol

CAUTION: All appropriate safety practices must be followed when using lasers12 and chemical products, including the use of personal protective equipment such as safety goggles, glasses, gloves, and lab coats.

1. Content creation

- Model the different elements of the scene (character and background) with 3D computer graphics programs such as Blender, a free and open-source 3D software toolset.

- Create a 12-frame cyclic animation with the 3D computer graphics program.

- 3D print and paint the different elements.

- Print characters and background at the same scale using a fused deposition modeling (FDM) monochrome 3D printer13, with a white polylactic acid (PLA) filament.

- Use sandpaper to eliminate printing defects.

- Hand-paint the different elements with acrylic paint.

CAUTION: To avoid unpleasant odors, paint outdoors or use ventilation.

- Set up the recording box. Fix the background in a rigid wooden box to avoid movement and place the different 3D printed characters inside one after another to allow the recording of the different 4 inch x 5 inch holograms.

NOTE: To avoid movement during hologram recording, firmly attach the individual elements using glue or plasticine, without applying stress.

2. Hologram recording

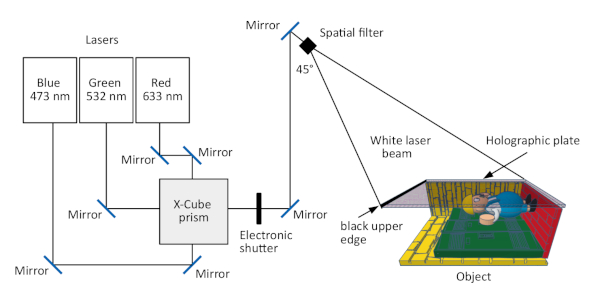

- On an optical table, assemble a Denisyuk single-beam full-color optical setup9,10 to record the holograms.

NOTE: To record the different holograms, the three RGB lasers used are a red HeNe, 633 nm, 20 mW; a green diode-pumped solid-state (DPSS), 532 nm, 100 mW adjusted to 20 mW; and a blue DPSS 473 nm 50 mW adjusted to 20 mW. The spatial filter is equipped with a 40x, 0.65 NA achromatic microscope objective and a 10 μm pinhole.- Combine the 3 laser beams (red, green, and blue) with an X-cube prism to get a white laser beam that passes through the same spatial filter.

NOTE: Use two mirrors for the red and blue lasers to get four degrees of freedom and perfectly align the three beams. - From a distance of 1 m and an angle of 45°, illuminate the recording box with the divergent beam.

- Adjust the distance of the three lasers from the cube to get similar beam diameters projected on the object plane.

NOTE: The recording box has to be illuminated with a wide, clean and homogeneous divergent white beam.

- Combine the 3 laser beams (red, green, and blue) with an X-cube prism to get a white laser beam that passes through the same spatial filter.

- Use a power meter to adjust the color balance and determine the exposure time.

- Measure the intensity of each laser horizontally, at the position of the holographic plate (see Table of Materials). Since the plate material is isopanchromatic, adjust the color balance equally for the 3 lasers.

NOTE: The power-meter used allows direct reading of the power of the 633 nm red laser. For the 473 nm blue and 532 nm green lasers, it is necessary to apply a correction coefficient (x0.4 for blue and x0.6 for green). - Determine the exposure time before recording the hologram, according to the following formula:

(1)

(1) - where t is the exposure time (s), H the sensitivity of the material (J/cm2) and E the intensity of the laser (W/cm2). E is measured at the position of the holographic plate with a power meter.

NOTE: The sensitivity of the materials used here is 200 μJ/cm2 per laser for a full-color (RGB) hologram. The intensity of each laser at the position of the holographic plate, measured with the power-meter is 17 μW/cm² per laser, and the exposure time is 12 s according formula (1).

- Measure the intensity of each laser horizontally, at the position of the holographic plate (see Table of Materials). Since the plate material is isopanchromatic, adjust the color balance equally for the 3 lasers.

- Close the laser beam with a shutter.

NOTE: Use an electronic shutter with a timer to control the exposure time precisely. - Prepare plates.

CAUTION: Handle the plate edges using gloves, and do not allow skin contact with the emulsion at any time.- Remove holographic plates them from the refrigerator to avoid a shift and store them at room temperature (20–25 °C) for 1 h before recording.

NOTE: The plates used here have to be refrigerated at 4 °C. - Darken the upper edge of the plate with a black marker to avoid internal reflection.

- Remove holographic plates them from the refrigerator to avoid a shift and store them at room temperature (20–25 °C) for 1 h before recording.

- Set up the recording plate under a green safelight.

- Blow onto the plate to determine the emulsion side. Steam appears only on the glass side.

- Place the holographic plate emulsion-side down on the recording box. Allow it to stabilize for 5 min before recording.

- Open the shutter to expose the recording plate, during the time previously calculated with the formula (1).

- Keep the recorded plate in a closed box away from light.

3. Hologram development

NOTE: Holograms are developed with a safe and non-staining chemical process developed for the ultimate emulsions.

- Once the plate has been exposed, prepare 100 mL of developer for a 4 inch x 5 inch plate. Mix the developer at a ratio of 1 part developer to 10 parts distilled or demineralized water (1:10).

NOTE: The developer is stocked in a concentrated solution in a closed bottle to prevent oxidation and needs to be diluted with distilled or demineralized water just before processing. - Heat the developer to 22 °C precisely.

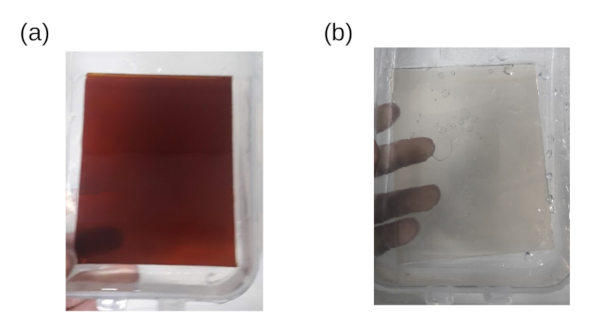

NOTE: The water temperature must be equal to or greater than 20 °C for the developer to function properly. For repetitions, control the temperature before development with a thermometer. - Under a green safelight, place the exposed plate in the tray and submerge it quickly, emulsion-side up, into the developer and agitate slowly for 4 min precisely. At the end of the development, the plate attains a pale yellow/orange color.

NOTE: The development process becomes visible a few seconds after the plate is fully covered with the developer. Use an insulated tray with a lid to maintain a constant temperature during development. Further development to attempt to get a black density is not required. - Remove the developer and wash the plate in its tray under running tap water for 30 s, allowing the water to overflow into a sink.

- Under normal light, place the developed plate in the tray and submerge it quickly, emulsion-side up, into the bleach without agitation until the plate becomes fully transparent. The bleaching process becomes visible a few seconds after the plate is fully submerged.

NOTE: The typical bleaching time is 3 to 5 min at room temperature (20–25 °C). - Remove the bleach and wash the plate in its tray under running tap water for 2 min, allowing the water to overflow into a sink.

NOTE: When the plate is still in a wet state after bleaching, a hologram can be observed by transmission with a halogen spot. When the hologram is successful, this image will appear very strong. - Place the plate in the tray and submerge it, emulsion-side up, into a demineralized or distilled water solution with some drops of wetting agent without agitation for 1 min.

- Remove the plate from the tray and dry it vertically for 15-20 min.

- Repeat these operations for each of the 12 holograms. Before recording, in order to place the different objects in the recording box with great precision, apply a holographic onion-skin method by replacing the previous transparent hologram at its recording position, and observe both images at the same time under laser illumination to check that the new character is well-positioned.

NOTE: Onion skinning is a procedure usually used in stop-motion animation to see two different frames at the same time.

4. Hologram sealing

NOTE: Holograms are protected by a second clean glass plate sealed to the hologram using optical ultraviolet (UV) glue.

- Use a scalpel to scrape off 5 mm of the emulsion around the edges.

NOTE: This operation is easier when the plate is still wet. - Laminate the hologram to a clean glass plate of equal size (4 inch x 5 inch), with 1 mL of UV glue.

NOTE: To facilitate lamination, pre-heat the glue, the hologram and the clean glass plate in an oven at 30 °C for 10 min. - Expose the clean glass side of the hologram to sunlight; the UV glue will harden within 5 min.

NOTE: It is also possible to use a UV lamp, but strong UV exposure should be avoided. - Wash the sealed hologram with water and soap, dry it with tissue paper and blacken the back of it with matte black spray paint.

5. Fantatrope assembly and operation

- Mount the 12 holograms in chronological order in the regularly placed frames of a Fantatrope.

NOTE: Gentet et al. 20197 describe the manufacture and operation of a Fantatrope. - Rotate the Fantatrope at constant speed. An RGB LED strobe light synchronized with the rotation speed successively illuminates the different frames to create a rapid succession of images and produce the illusion of movement.

NOTE: A rotation of one turn per second is enough to get the sense of a fluid motion.

Representative Results

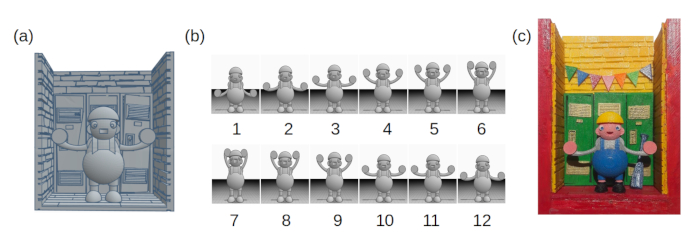

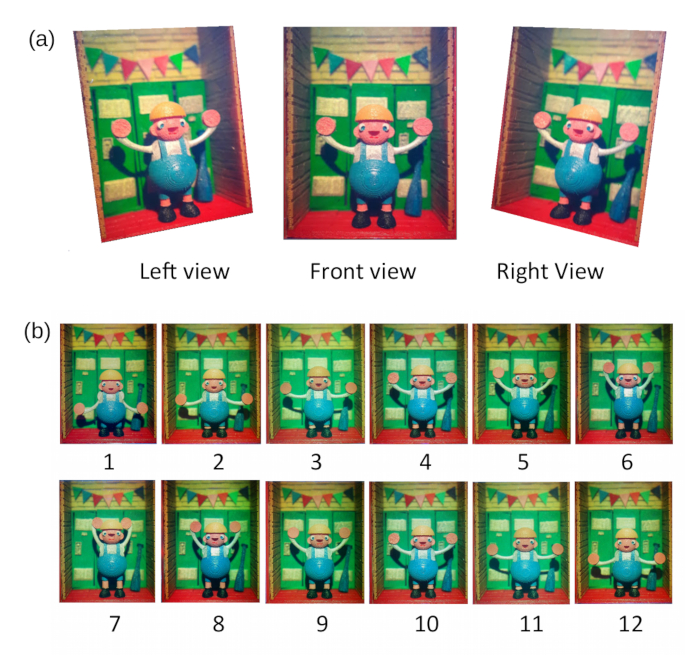

3D content was created and a cyclic sequence of twelve images was imagined, and the different elements were then 3D printed and painted (Figure 1). A Denisyuk single-beam full-color optical setup was assembled to record holograms (Figure 2). After recording, the holograms were developed and sealed (Figure 3) to obtain a set of twelve ultra-realistic full-color analog holograms with a 180° full-parallax, showing the same brightness, transparency and homogeneous colors (Figure 4). The Fantatrope with the twelve holograms mounted in chronological order was successfully operated and generated the effect of a dynamic 3D display without the need for any special viewing aids (Video 1).

Figure 1: 3D Content. (A) Computer generated character and background. (B) The complete cyclic sequence. (C) 3D printed character and background after painting, fixed in the recording box. This figure has been modified from Gentet et al. 20197. Please click here to view a larger version of this figure.

Figure 2: Schematic single-beam full-color Denisyuk optical holographic setup. Please click here to view a larger version of this figure.

Figure 3: Development and sealing of holographic plates. (A) Plate with a pale orange color after development. (B) Transparent plate with almost no noise after bleaching. Please click here to view a larger version of this figure.

Figure 4: Final holograms. (A) Three different views of one of the holograms with a 180° full-parallax. (B) Final set of the twelve holograms showing the same brightness, transparency and homogeneous colors. This figure has been modified from Gentet et al. 20197. Please click here to view a larger version of this figure.

Video 1: Fantatrope in operation with the 12 holograms mounted in chronological order. Please click here to download this file.

Discussion

Traditionally, stop-motion film uses puppets or clay models. To avoid movement and obtain a bright image at the time of hologram recording, a set of 3D printed characters and backgrounds are chosen. Furthermore, the different elements are attached firmly and without stress in the box. If an element is fixed with constraint or moves during the recording, it will appear black or fringed in the final hologram. 3D printing is a very interesting new tool for creating original models for analog holography.

The main advantage of photopolymer films, like Covestro Bayfol HX20014, over silver-halide materials is their dry processing. The material used here requires wet processing, but it remains fast and simple, and uses non-toxic products. It also has a much higher sensitivity (200 µJ/cm2 versus 20 mJ/cm2) and the resulting shortened exposure time is preferred for recording bright holograms in analog holography to avoid vibration and movement problems. Furthermore, many users, especially hobbyists or schools, have low-power lasers (less than 20 mW); highly sensitive recording material is an important factor to obtain a high-quality hologram with a short exposure time. The substrate material is also important in determining the final hologram quality, and glass proves to be the best choice for this because it is mechanically stable and optically inactive.

Each hologram recorded in this procedure is developed with non-toxic and non-staining chemical baths. These chemicals, which are safe and easy to use, are very different from the dangerous, toxic and environmentally harmful ones generally used in holography. In particular, the recommended process15, established 25 years ago for the Russian Slavich PFG-03C holographic emulsion16, uses chemicals such as formaldehyde or catechol, which are unsafe, messy and difficult to handle. Furthermore, U04 plates are pre-hardened during the manufacturing process and do not require any dangerous hardening baths. Most other silver-halide holographic materials have to be treated before exposure with a hyper-sensitizing solution of triethanolamine (TEA)17 or a hardening pre-bath16 to increase their sensitivity, with a high risk of damaging the plate.

While recording, it is preferable to place the object and the holographic plate in a horizontal position for better stability due to gravity. Using an electronic shutter with a timer is important to precisely control the exposure time precisely and allow repetition. A 10% overexposure can produce a milky hologram, and a 10% lack of exposure time can produce a dim hologram. As room temperature or humidity change, the gelatin in which the holograms are recorded can swell or shrink. Colors and reconstruction angles of the holograms are then changed. Therefore, to prevent any emulsion thickness variations that may affect color rendition, each hologram needs to be protected by a second clean glass plate sealed to the hologram using optical glue.

This protocol allows bright, colorful, transparent, and homogeneous holograms to be obtained, and it is highly repeatable. The twelve holograms were recorded over several days, following this method, and they all present the same final characteristics, which allow them to be used in the Fantatrope. Using this protocol, every practitioner in the field of analog full-color holography can get reliable and reproducible results.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The present research was conducted by the Research Grant of Kwangwoon University in 2019.

Materials

| Black marker | Monami | Magic Cap | |

| FDM monochrome 3D printer | Anet | A8 | |

| Holographic bleach | Ultimate Holography | BLEACH-1L | Non-toxic |

| Holographic developer | Ultimate Holography | REV-U08-1.2 | Non-toxic |

| Holographic plates | Ultimate Holography | U04P-VICOL-4X5 | Light-sensitive |

| Laser (DPSS 532 nm 100 mW) | Cobolt | Samba | Follow safety practices |

| Laser (DPSS 473 nm 50 mW) | Cobolt | Blue | Follow safety practices |

| Laser (HeNe 633 nm 21 mW) | Thorlabs | HNL210L | Follow safety practices |

| Laser power meter | Sanwa | LP1 | |

| Matte black spray paint | Plasti-kote | 3101 | |

| Microscope objective | Edmund Optics | 40X 0.65 NA | |

| Pinhole | Edmund Optics | 10 μm | |

| Spatial Filter Movement | Edmund Optics | 39-976 | |

| UV glue | Vitralit | 6127 | Use gloves |

| Wetting agent | Kodak | Photo-Flo | |

| White PLA filament | Hatchbox | PLA-1KG1.75-BLK | |

| X-cube | Edmund Optics | 54-823 |

References

- Geng, J. Three-dimensional display technologies. Advances in Optics and Photonics. 5 (4), 456-535 (2013).

- Lim, Y., et al. 360-degree tabletop electronic holographic display. Optics Express. 24 (22), 2499 (2016).

- Sugie, T., et al. High-performance parallel computing for next-generation holographic imaging. Nature Electronics. 1 (4), 254 (2018).

- Ogle, K. N. Some aspects of stereoscopic depth perception. JOSA. 57, 1073-1081 (1967).

- Read, J. C. A., et al. Balance and coordination after viewing stereoscopic 3D television. Royal Society Open Science. 2, 140522 (2015).

- Lambooij, M., Ijsselsteijn, W., Fortuin, M., Heynderickx, I. Visual discomfort and visual fatigue of stereoscopic displays: a review. Journal of Imaging Science and Technology. 53 (3), 1-14 (2009).

- Gentet, P., Joung, J., Gentet, Y., Hamacher, A., Lee, S. H. Fantatrope, a moving hologram display: design and implementation. Optics Express. 27 (8), 11571-11584 (2019).

- Denisyuk, Y. N. On the reproduction of the optical properties of an object by the wave field of its scattered radiation. Optics and Spectroscopy. 14, 279-284 (1963).

- Bjelkhagen, H. I., Brotherton-Ratcliffe, D. . Ultra-realistic imaging: advanced techniques in analogue and digital colour holography. , (2013).

- Graham, S., Zacharovas, S. . Practical Holography, Fourth Edition. , (2015).

- Gentet, P., Gentet, Y., Lee, S. H. Ultimate 04 the new reference for ultra-realistic color holography. 2017 International Conference on Emerging Trends & Innovation in ICT (ICEI). , 162-166 (2017).

- International Electrotechnical Commission. IEC 60825-1: 2014. Safety of laser products-Part 1: Equipment classification and requirements. IEC Geneva. 3, (2014).

- Kun, K. Reconstruction and development of a 3D printer using FDM technology. Procedia Engineering. 149, 203-211 (2016).

- . . Covestro Deutschland AG, Bayfol HX200 Datasheet. , (2018).

- Bjelkhagen, H. I. Silver Halide Recording Materials for Holography and Their Processing. Springer Series in Optical Sciences. 66, (1993).