Design and Use of Multiplexed Chemostat Arrays

Summary

We developed and validated a small-footprint array of miniature chemostats built from readily available parts for low cost. Physiological and experimental evolution results were similar to larger volume chemostats. The ministat array provides a compact, inexpensive, and accessible platform for traditional chemostat experiments, functional genomics, and chemical screening applications.

Abstract

Chemostats are continuous culture systems in which cells are grown in a tightly controlled, chemically constant environment where culture density is constrained by limiting specific nutrients.1,2 Data from chemostats are highly reproducible for the measurement of quantitative phenotypes as they provide a constant growth rate and environment at steady state. For these reasons, chemostats have become useful tools for fine-scale characterization of physiology through analysis of gene expression3-6 and other characteristics of cultures at steady-state equilibrium.7 Long-term experiments in chemostats can highlight specific trajectories that microbial populations adopt during adaptive evolution in a controlled environment. In fact, chemostats have been used for experimental evolution since their invention.8 A common result in evolution experiments is for each biological replicate to acquire a unique repertoire of mutations.9-13 This diversity suggests that there is much left to be discovered by performing evolution experiments with far greater throughput.

We present here the design and operation of a relatively simple, low cost array of miniature chemostats—or ministats—and validate their use in determination of physiology and in evolution experiments with yeast. This approach entails growth of tens of chemostats run off a single multiplexed peristaltic pump. The cultures are maintained at a 20 ml working volume, which is practical for a variety of applications. It is our hope that increasing throughput, decreasing expense, and providing detailed building and operation instructions may also motivate research and industrial application of this design as a general platform for functionally characterizing large numbers of strains, species, and growth parameters, as well as genetic or drug libraries.

Introduction

The dynamics of microbial growth and evolution are fundamental to microbiology, ecology, genetics, and biotechnology. The most common method of culturing microbes is in batch, where cells are inoculated at low density into nutrient-rich broth and grown to saturation. Though straightforward to perform using standard laboratory equipment, batch cultures experience a fluctuating chemical environment and correspondingly changing cellular physiology. This heterogeneous growth environment can result in secondary growth and stress effects that can mask subtle physiological differences. Experimental evolution by serial batch transfer can select for complex mixtures of growth-phase specific subpopulations, complicating attempts to connect adaptations to specific selective conditions. Measurement of quantitative phenotypes can be difficult due to noise from imprecise sample timing and variation in features such as lag time. Continuous cultures provide an alternative growth regime where cells can be reproducibly cultivated in a chemically homogeneous environment at a defined growth rate to reach a physiological steady state. Because of these advantages, studies of experimental evolution and characterization of cellular state often utilize the controlled environment of continuous cultures like the chemostat.14

Appreciation of these advantages has led to a resurgence in interest in chemostat cultures.15 Since their introduction in 1950,1,2 chemostat systems have been developed to function on a variety of scales ranging from liters to microliters and for a variety of applications.16-19 These various designs, which range from commercially produced bioreactors to glassblown vessels to custom microfluidics platforms, share general design principles. A culture chamber is stirred and aerated (usually by bubbling air through it) and the microbes contained therein are kept homogeneously dispersed throughout the culture chamber at all times. Fresh medium of defined composition is added continually and the rate of addition controls growth rate and influences the chemical environment experienced by the culture. An overflow sets the culture volume in the growth tube, and through this overflow the culture will be sampled at the same rate at which fresh medium enters. In this way cultures quickly reach a physiological steady state at which many biological parameters remain constant. Despite the advantages of chemostats and reports of these various platforms in the literature, widespread adoption has been limited by difficulties in building and operating these systems, and high costs associated with commercial options. Furthermore descriptions of how to make and use these devices can be opaque.

We present designs and instructions for use of a small-footprint array of miniature chemostats built from readily available parts at low cost. We observe highly consistent experimental parameters and reproducible results when comparing our device to reported data for yeast cultured in larger volume commercial bioreactors. This includes reproducibility of cellular physiology as seen through reaching steady-state equilibrium within 10-15 generations and obtaining similar culture densities at equilibrium. Additionally, gene expression patterns are consistent between ministats and a commercial larger-volume platform. Stability of dilution rate, optical density and reproducibility of gene expression between three replicate cultures demonstrate the robustness of our platform. We also show that the same adaptive mutations arise over similar experimental evolution timescales as with larger volume chemostats.

Protocol

Use appropriate sterile technique throughout the protocol.

1. Assembling Parts for and Preparing the Ministat Array

- Order all parts.

- Clean glass tubes. Mark tubes at 20 ml volume.

- Make cork assemblies with air, media, and effluent ports and place them at the top of the cleaned glass culture tubes.

- Prepare humidifying chambers and arrange all non-autoclaved parts.

- Make air, effluent, and media tubing using sufficient tubing lengths and compatible couplings.

- Connect each type of tubing (air, media, and effluent) to the cork assemblies and foil filters and the media quick-connect to prepare them for the autoclave.

- Prepare a carboy for use in making sterile chemostat medium.

- Prepare the culture sampling bottles by inserting a two-hole rubber stopper with appropriate fittings. Foil each filter to prepare them for the autoclave.

- Fit the assembled array neatly into one or more autoclave trays and autoclave all parts.

- Make and filter chemostat media into autoclaved carboys.

2. Setting Up an Experiment

- Fill each hydration flask with 700 ml ddH2O.

- Place the autoclaved ministats into the heating block set at the desired temperature.

- Place the airlines into the 4-port manifold and turn on the air pump.

- Connect the effluent lines to the 100 ml collection bottles.

- Remove the foil from the end of the media tubing and media carboy and connect the two quick connects. Thread each length of pump tubing through a peristaltic pump cartridge and click them into place. Turn on the media pump.

- Let the chambers fill. Turn off the media pump.

- Spray the cork assemblies with 70% ethanol and inoculate the cultures using a syringe. Save a sample of the inoculum as a frozen glycerol stock if desired. Let cultures grow for 30 hr.

- Adjust the height of the effluent needle until the culture volume is set to 20 ml with the air flow turned off. This may take several adjustments over the course of an hour. When finished turn the air flow back on.

- Turn the media pump on.

- Empty the effluent sampling bottles, which contain media collected while setting the working culture volume, and record the time.

- To take a time-zero measurement place the effluent lines into sterile collection tubes for 15 min-2 hr (depending on what volume you wish to sample for DNA analysis). Also make a glycerol frozen stock for each culture at this time if desired.

3. Daily Measurements

- As with your time-zero measurement, sample on ice for 15 min-2 hr (as required for your experiment) on ice and record the time sampled for DNA and frozen stock samples.

- For RNA samples either collect a small volume using a syringe and 22G 5″ needle from the culture or uncork each ministat to harvest the entire culture. Samples must be taken quickly, collected by filtration, and frozen immediately in liquid nitrogen.

- Measure the effluent collected since the last sampling for each ministat to quantify dilution rate. Adjust dilution rates if needed by readjusting the pump setting or tuning the fine adjust on individual pump lines.

- Replace effluent lines in empty collection bottles.

- Quantify cells/ml as well as other endpoints of interest and make a glycerol frozen stock.

4. Post-experiment Cleanup

- Place all tubing in separate trays and rinse excessively with ddH2O. Dry tubing using an aquarium pump.

- Clean the cork assemblies with ddH2O and use needle insert to clean the needles, aspirating and dispensing water in turn. Wipe the outside of the needles and cork to remove any residual media.

- Clean the glass tubing with water and ethanol, and remove physical contaminants with 3 balled up Kimwipes and forceps.

- Rinse and dry all parts again before use.

Representative Results

The ministat array described above and in (Figure 1A, B) was used to culture a haploid MATa laboratory strain of budding yeast (S288c) under sulfate-limiting conditions as described previously.10 We tested efficacy for common chemostat applications including determination of physiology and experimental evolution. To validate the ministats, we repeated several experiments previously performed in industrial fermentors modified for chemostat use.10,20,21 ATR Sixfors fermentors were run at a 300 ml working volume, over ten times the volume of the ministats, and have considerably different modes of culture aeration and agitation. We attempted to replicate equipment stability, steady state physiology, experimental evolution results, and gene expression patterns obtained with these fermentors.

Since uniformity of dilution rate and aeration are important aspects of the chemostat design, we measured the actual dilution rate across 32 ministats after 15 generations of growth and found that with a target dilution rate of 0.17 vol/hr (4-5 drops/min) we achieved an average dilution rate of 0.17208 with a standard deviation of 0.0075 across 32 replicates. This range was within our typical tolerance of +/-0.01 vol/hr difference from the target setting, beyond which large-scale changes in gene expression have been observed.22-23 Across 4 ministats the air flow rate was determined to be 307.5 ml/min with a standard deviation of 9.57 ml/min. This suggests that air-flow into the chambers is robust and evenly divided between the 4 chambers and is a value similar to that described for aeration in industrial fermentors.20

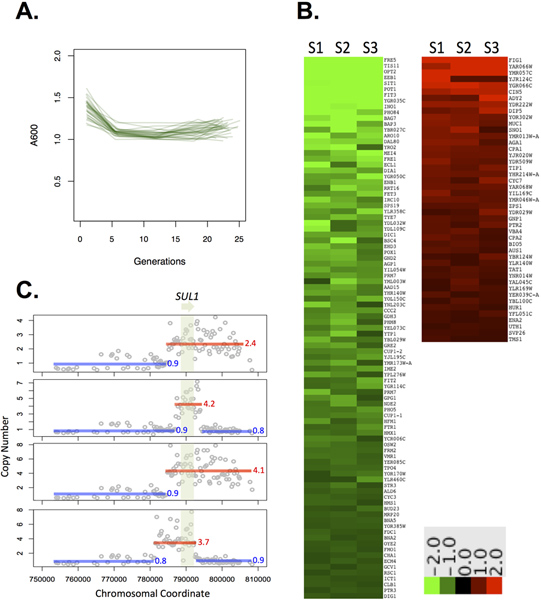

We previously observed recurrent amplification of the high-affinity sulfur-ion transporter SUL1 in 8/8 sulfate-limited evolution experiments in yeast.10 Given the consistency of results under this condition we chose sulfate-limitation to test our system’s ability. A requisite element of chemostat culture is the need to maintain a constant chemical environment. Fluctuations in the abundance of a limiting nutrient or other changes in the environment typically result in a change in the number of cells in a given culture. We measured optical density as a proxy for cell number (Figure 2A) and measured reproducibility across 16 replicate cultures, finding an average A600 of 1.12 (~109 cells) after ~15 generations of growth with a standard deviation of 0.057 units, or 5.1%. For comparison, measurements taken from 4 replicate cultures grown in the industrial fermentors showed a standard deviation of 2.5%. Cells were well-mixed in the growth chamber: measurements of OD and cell count taken from the effluent track were equivalent to samples taken directly from the culture tube (data not shown). These results demonstrate the robustness of our platform and ability to maintain a constant chemical environment within a similar tolerance as the industrial fermentor.

As a more sensitive readout of physiology, we compared genome-wide steady state gene expression from cultures grown under sulfate limitation in the ministats and in the industrial fermentor. Gene expression in the ministats showed a high degree of similarity across three biological replicates (Figure 2B). We previously noted that for RNA derived from two replicate Sixfors chemostats and co-hybridized to a microarray, expression of 99% of genes fell within a 1.5-fold range, allowing the use of 1.5X as an empirical significance cutoff.21 Gene expression from three replicate ministats, compared pairwise, showed 99% of genes fell within a 1.5-1.7 fold range, comparable to results from the industrial fermentors. The three samples were hybridized to individual arrays and the pairwise ratios calculated afterwards, so these values include inter-array noise in addition to biological noise, potentially overestimating the variation between replicates as compared to the published, co-hybridized results. 138 genes were differentially expressed >1.5-fold in all three ministat replicates as compared to a sample collected from a matched culture grown in the industrial fermentor. Genes decreased in expression in the ministats were heavily enriched for iron metabolism. This signature may reflect the different metal composition of each device configuration: the Sixfors apparatus includes a metal impeller and aeration assembly immersed in the culture, and the media carboys previously used also required metal hardware. The ministat utilizes stainless steel needles, but no other metal components. Genes with increased expression were largely associated with cell membranes, though the biological significance of this association is unclear.

Finally, we tested experimental evolution under these conditions. After 250 generations of sulfate-limited growth, 4/4 clones tested from 4 independent evolving populations showed amplification of SUL1 as detected by array Comparative Genomic Hybridization (CGH, Figure 2C). This result is consistent with findings in larger volume chemostats over similar time intervals.10

Figure 1. A. Design and arrangement of the ministat array. B. Design of the culture chamber.

Figure 2. A. Experimental data showing that cultures reach equilibrium within ten generations of growth (n=16). B. Expression data for three biological replicates S1-3 sampled during steady state under sulfate limitation compared to a common reference grown in a matched sulfate-limited Sixfors chemostat. C. SUL1 amplifications recovered in ministats after 250 generations of growth in a sulfate-limited environment. Genomic DNA from each evolved clone was compared to ancestral DNA by CGH as described.21 Mean copy number was calculated for each amplified region and is shown next to each amplicon. All microarray data are deposited in the GEO database under accession GSE36691. Click here to view larger figure.

Discussion

Chemostat cultivation in the ministats, as with any chemostat, requires attention to detail and trouble-shooting. Since contamination is of great concern in continuous culture experiments, we typically look via microscope for bacterial and fungal contamination upon inoculation and every 50 generations during long-term evolution experiments. To date we have not observed contamination across 96 evolution experiments of greater than 300 generations (data not shown). To test for cross-contamination between ministats and the potential for microbes to colonize the culture chamber by way of the effluent line we ran 16 ministats such that every other ministat was inoculated with yeast as above and the remainder were not inoculated with any culture. The cultures were sampled into a communal waste container, which was emptied every other day. Thus if it were possible for contaminants to enter through the effluent line we likely would have observed that in this experiment. During three weeks and greater than 100 generations of growth in this checkerboard pattern of inoculated and non-inoculated cultures we did not observe growth in non-inoculated ministat culture tubes, suggesting that contamination from outside yeast or other microbes is unlikely to occur in experiments of similar time frames.

Although the ministats were designed to operate in a fashion analogous to commercial chemostats, the modular nature of this arrangement allows for optimization to fit the users’ needs and budget. The peristaltic pump used in this protocol can achieve flow rates between 0.0186 vol/hr to 3.6 vol/hr (data not shown). Increased control of dilution rates could be achieved with alternative pump models. Note that operation at lower dilution rates may require substitution of a higher gauge needle to achieve the same frequency of droplet delivery. Population size is an important consideration for proper design of evolution experiments. The standard dilution rate and nutrient concentration used here provides a relatively large population size (~109 cells) of the same order of magnitude as published evolution studies.11 Larger or smaller populations could be maintained by changing the working volume or limiting nutrient concentration. Increased mutation supply could also be obtained by working with strains with elevated mutation rates.

The ministats could also be improved over our current design. For instance condensation can collect on the culture tube walls and can be greatly reduced by using a deep waterbath, incubator, or constant temperature room. Though clumping and wall growth in sulfate limited cultures appears to be relatively rare, appearing in 5/48 evolution experiments by 300 generations (data not shown), a variety of surfactants are available that may aid in decreasing or delaying this trait. In the event that clumping interferes with adequate culture mixing, increased agitation can be achieved by reducing the number of ways each air pump is divided, or by adding a stirring apparatus. Additional probes for dissolved gas concentration, pH, or other parameters could also be included, as in some other designs.17

Despite potential modifications, using the ministats as described in this protocol, we observed highly consistent experimental parameters and reproducible results when comparing our device to reported data for larger volume commercial chemostats. This included reproducibility of cellular physiology as seen through reaching steady-state equilibrium within 10-15 generations (Figure 2A) and obtaining similar culture densities at equilibrium. Gene expression patterns were consistent across three biological replicates in ministats and between ministats and commercial large-volume platforms (Figure 2B), with the exception of iron metabolism genes. These expression differences are likely caused by changes in metal content of the two devices or improvements in the quality of media ingredients. Our data suggest that ministats will be useful for physiology or competition experiments where a consistent environment is required.

To test if the ministat design is sufficient for experimental evolution applications we evolved cultures under sulfate limitation for 250 generations and used CGH to characterize amplification at the SUL1 locus – a hallmark of long-term evolution under these conditions in larger volume chemostats.10 We observed amplification of SUL1 in clones from 4/4 independent evolution experiments in sulfate-limited media (Figure 2C). Taken as a whole these data suggest that ministats are a robust platform that may be useful for a variety of traditional chemostat applications. Though we demonstrated their use in culturing budding yeast, the ministats should also be compatible with other organisms and similar designs have in fact been used for culturing bacteria and other yeast species.16,17,25 Furthermore the smaller culture volume and correlated decreased need for media may make ministats an attractive alternative for experiments requiring expensive or exotic reagents as can be the case in chemical or genetic screens.

Offenlegungen

The authors have nothing to disclose.

Acknowledgements

Creation of the video was supported by grants from the National Center for Research Resources (5P41RR011823-17) and the National Institute of General Medical Sciences (8 P41 GM103533-17) from the National Institutes of Health. This work was also supported by NSF grant 1120425. MJD is a Rita Allen Foundation Scholar. AWM is supported in part by NIH T32 HG00035. We thank Anna Sunshine for assistance with improving protocols. Additionally, we acknowledge Sara DiRienzi, Celia Payen, and Amy Sirr as early users of the ministats.

Materials

| Name of the reagent | Company | Catalogue number | Comments (optional) |

| 3/32″ x 7/32″ silicone tubing | VWR | 63009-260 | Tubing: Order: (50′ coil pack) |

| 1/2″ x 5/8″ silicone tubing (extra large) | VWR | 63009-299 | Tubing: Order: (50′ coil pack) |

| 1/4″ x 3/8″ silicone tubing (medium) | VWR | 63009-279 | Tubing: Order: (50′ coil pack) |

| Orange green marprene pump tubing | Watson-Marlow | 978.0038.00+ | Tubing: Order: 6x(pack of 6) |

| Female luer, 1/8″ barb | Cole Parmer | HV-45500-04 | Connectors: Order: 4x(pack of 25) |

| Male luer lock, 1/8″ barb | Cole Parmer | HV-45503-04 | Connectors: Order: 1x (pack of 25) |

| Reducing connector, PVDF, 1/4″ to 1/8″ | Cole Parmer | EW-30703-50 | Connectors: Order: 1x (pack of 10) |

| Barbed Y connector, 1/8″ ID | Cole Parmer | HV-30703-92 | Connectors: Order: 3x(pack of 10) |

| Medium tubing clamps | VWR | 63022-405 | Clamps: Order: 1x(pack of 12) |

| Day Pinchcock (metal clamp for tubing) | VWR | 21730-001 | Clamps: Order: 1x(pack of 10) |

| Male inline valved quick-connector, Fits tubing: 1/4 in. | Fisher | 05-112-39 | Connectors: Order: 1x(pack of 25) |

| Female inline valved quick-connector, Fits tubing: 1/4 in. I.D.,Polypropylene | Fisher | 05-112-37 | Connectors: Order: 1x(pack of 5) |

| Silent Air Pumps | Aquarium Guys.com | 212422 | Air Supply: Order: 4 pumps |

| PTFE filters, 0.45 μm, for air filtration | Cole Parmer | HV-02915-22 | Air Supply: Order: 1x(box of 100) |

| 1L Flask with sidearm | Fisher | 10-181F | Air Supply: Order: 2x(Pack of 6) |

| #8 silicone stopper, 3/8 in hole, for sidearm flasks | Fisher | K953715-0801 | Air Supply: Order: 8 stoppers |

| 4-Port manifold | Cole Parmer | EW-06464-85 | Air Supply: Order: 8 manifolds |

| 55 ml Screw cap culture tubes | Corning Life Sciences | 9825-25 | Culture Chamber: Order: 2x(pack of 48) |

| Regular hypodermic white hub needle, 16G, 5 in. length for effluent line | Fisher | 14-817-105 | Culture Chamber: Order: 1x(pack of 100) |

| Spinal tap needle | VWR | BD40836 | Culture Chamber: Order: 4x(pack of 10) |

| Regular hypodermic pink needle | Fisher | 14-817-104 | Culture Chamber: Order: 1x(pack of 100) |

| Foam Silicone stopper size “2”, pink | Cole Parmer | EW-06298-06 | Culture Chamber: Order: 2x(pack of 20) |

| 8-Well tube Rack | VWR | 82024-452 | Culture Chamber: Order: 4 racks |

| 10L Reservoir bottle with bottom hose outlet: vacuum safe | VWR | 89001-530 | Media: Order: 2 or more |

| Yellow foam silicone stopper, non-standard size 12 | Cole Parmer | EW-06298-22 | Media: Order: 2 or more |

| Carboy Venting Filter | Fisher | SLFG 050 10 | Media: Order: 1x(pack of 10) |

| Electrical tape, green | Amazon.com | 10851-BA-10 | Media: Order 1 roll. |

| Bottle top filter, 1L, .2 μm, 45 mm | VWR | 29442-978 | Media: Order: (1 case of 12) |

| 5000 ml Reservoir bottle with bottom outlet: vacuum safe | VWR | 89003-384 | Media: (Optional) |

| Blue Foam Silicone stopper, nonstandardsize 10 1/2 | Cole Parmer | EW-06298-18 | Media: (Optional) |

| 205S/CA16, 16 Cartridge pump | Watson-Marlow | 020.3716.00A | Media Pump: Order: 1 |

| 16-channel 205CA Extension pump head | Watson-Marlow | 023.1401.000 | Media Pump: Order: 2 extension pump heads |

| Silicone aquarium sealer | Fisher | S18180B | Media Pump: Order: 1 |

| 6-block dry bath | VWR | 12621-120 | Heatblock: Order: 2 for 32 ministats or 1 for 16. |

| Block for drybath, 6 x 25 mm test tube per block | VWR | 12621-120 | Heatblock: Order: 12 for 32 ministats or 6 for 16. |

| Nylon Membrane Filters, 0.45 μm Pore Size; Dia.: 25 mm | Fisher | R04SP02500 | Harvesting: Order: 1x(pack of 100) (optional) |

| Nylon Membrane Filters,0.45 μm Pore Size; 45 mm | Fisher | R04SP04700 | Harvesting: Order: 1x(pack of 100) (optional) |

| 47 mm, large filter apparatus | Fisher | XX10 047 30 | Harvesting: Order: 1 (optional) |

| Glass filter holder, 25 mm, small filter apparatus | VWR | 26316-692 | Harvesting: Order: 1 (optional) |

| Dewar flask, 1L for Liquid Nitrogen | VWR | 63380-052 | Harvesting: Order: 1 (optional) |

Referenzen

- Monod, J. Récherches sur la Croissance des Cultures Bacteriennes. Ann. I. Pasteur. 79, 390-410 (1950).

- Novick, A., Szilard, L. Description of the chemostat. Science. 15, 715-716 (1950).

- Daran-Lapujade, P., Daran, J. -. M., van Maris, A. J. A., de Winde, J. H., Pronk, J. T. Chemostat-based micro-array analysis in baker’s yeast. Adv. Microb. Physiol. 54, 257-311 (2009).

- ter Linde, J. J. M., Pronk, J. T., et al. Genome-wide transcriptional analysis of aerobic and anaerobic chemostat cultures of Saccharomyces cerevisiae. J. Bacteriol. 181, 7409-7413 (1999).

- Boer, V., de Winde, J., Pronk, J., Piper, M. The genome-wide transcriptional responses of Saccharomyces cerevisiae grown on glucose in aerobic chemostat cultures limited for carbon, nitrogen, phosphorus, or sulfur. J. Biol. Chem. 278, 3265-3274 (2003).

- Wu, J., Zhang, N., Hayes, A., Panoutsopoulou, K., Oliver, S. Global analysis of nutrient control of gene expression in Saccharomyces cerevisiae during growth and starvation. 101, 3148-3153 (2004).

- Diderich, J. A., Kruckeberg, A. L., et al. Glucose Uptake Kinetics and Transcription of HXT Genes in Chemostat Cultures of Saccharomyces cerevisiae. J. Biol. Chem. 274, 15350-15359 (1999).

- Novick, A., Szilard, L. Experiments with the Chemostat on spontaneous mutations of bacteria. Proc. Natl. Acad. Sci. U.S.A. 36, 708-719 (1950).

- Kubitschek, H. E., Bendigkeit, H. E. Mutation in continuous cultures. I. Dependence of mutational response upon growth-limiting factors. Mutation Res. 1, 113-120 (1964).

- Gresham, D., Dunham, M. J., et al. The Repertoire and Dynamics of Evolutionary Adaptations to Controlled Nutrient-Limited Environments in Yeast. PLoS Genet. 4, e1000303 (2008).

- Kao, K. C., Sherlock, G. Molecular characterization of clonal interference during adaptive evolution in asexual populations of Saccharomyces cerevisiae. Nat. Genet. 40, 1499-1504 (2008).

- Kvitek, D. J., Sherlock, G. Reciprocal Sign Epistasis between Frequently Experimentally Evolved Adaptive Mutations Causes a Rugged Fitness Landscape. PLoS Genet. 7, e1002056 (2011).

- Helling, R. B., Adams, J. Evolution of Escherichia coli during Growth in a Constant Environment. Genetik. 116, 349-358 (1987).

- Dunham, M. J. Experimental Evolution in Yeast: A Practical Guide. Methods Enzymol. 470, (2010).

- Hoskisson, P. A., Hobbs, G. Continuous culture – making a comeback. Microbiology. 151, 3153-3159 (2005).

- Nanchen, A., Schicker, A., Sauer, U. Nonlinear dependency of intracellular fluxes on growth rate in miniaturized continuous cultures of Escherichia coli. Appl. Environ. Microbiol. 72, 1164-1172 (2006).

- Klein, T., Schneider, K., Heinzle, E. A system of miniaturized stirred bioreactors for parallel continuous cultivation of yeast with online measurement of dissolved oxygen and off-gas. Biotechnol. and bioeng. , (2012).

- Balagadde, F. K., You, L., Hansen, C. L., Arnold, F. H., Quake, S. R. Long-term monitoring of bacteria undergoing programmed population control in a microchemostat. Science. 309, 137-140 (2005).

- Groisman, A., Lobo, C., Cho, H., Campbell, J. K., Dufour, Y. S., Stevens, A. M., Levchenko, A. A microfluidic chemostat for experiments with bacterial and yeast cells. Nat. Methods. 2, 685-689 (2005).

- Brauer, M. J., Botstein, D., et al. Homeostatic Adjustment and Metabolic Remodeling in Glucose-limited Yeast Cultures. Mol. Biol. Cell. 16, 2503-2517 (2005).

- Torres, E. M., Amon, A., et al. Effects of Aneuploidy on Cellular Physiology and Cell Division in Haploid Yeast. Science. 317, 916-924 (2007).

- Regenberg, B., Nielsen, J., et al. Growth-rate regulated genes have profound impact on interpretation of transcriptome profiling in Saccharomyces cerevisiae. Genome Biology. 7, R107 (2006).

- Castrillo, J. I., Oliver, S. G., et al. Growth control of the eukaryote cell: a systems biology study in yeast. Journal of Biology. 6, 4 (2007).

- Brauer, M. J., Botstein, D., et al. Coordination of growth rate, cell cycle, stress response, and metabolic activity in yeast. Molecular Biology of the Cell. 19, 352-367 (2008).

- Ferenci, T. Bacterial physiology, regulation and mutational adaptation in a chemostat environment. Adv. Microb. Physiol. 53, 169-229 (2008).