Assessment of Methane and Nitrous Oxide Fluxes from Paddy Field by Means of Static Closed Chambers Maintaining Plants Within Headspace

Summary

The overall goal of this protocol is to measure greenhouse gas emissions from paddy fields using the static closed chamber technique. The measurement system needs specific adjustments due to the presence of both a permanent water layer in the field and of the plants within the chamber headspace.

Abstract

This protocol describes the measurement of greenhouse gas (GHG) emissions from paddy soils using the static closed chamber technique. This method is based on the diffusion theory. A known volume of air overlaying a defined soil area is enclosed within a parallelepiped cover (named "chamber"), for a defined period of time. During this enclosure period, gases (methane (CH4) and nitrous oxide (N2O)) move from soil pore air near their microbial source (i.e., methanogens, nitrifiers, denitrifiers) to the chamber headspace, following a natural concentration gradient. Fluxes are then estimated from chamber headspace concentration variations sampled at regular intervals throughout the enclosure and then analyzed with gas chromatography. Among the techniques available for GHG measurement, the static closed chamber method is suitable for plot experiments, as it does not require large homogenously treated soil areas. Furthermore, it is manageable with limited resources and can identify relationships among ecosystem properties, processes, and fluxes, especially when combined with GHG driving force measurements. Nevertheless, with respect to the micrometeorological method, it causes a minimal but still unavoidable soil disturbance, and allows a minor temporal resolution. Several phases are key to the method implementation: i) chamber design and deployment, ii) sample handling and analyses, and iii) flux estimation. Technique implementation success in paddy fields demands adjustments for field flooding during much of the cropping cycle, and for rice plant maintenance within the chamber headspace during measurements. Therefore, the additional elements to be considered with respect to the usual application of non-flooded agricultural soils consist of devices for: i) avoiding any unintended water disturbance that could overestimate fluxes, and ii) including rice plants within the chamber headspace to fully consider gases emitted through aerenchyma transportation.

Introduction

Agriculture is a productive sector that, together with forestry and other land use, produces approximately 21% of global GHG emissions1. Accurate measurement of agricultural soil GHG emissions is key not only to establish the proper role determination of agroecosystems as both source and sink in climate change2, but also to define appropriate and effective mitigation strategies within the framework of the Paris agreement targets.

Emission fluxes of the two most important GHGs produced by agricultural soils (i.e., N2O and CH4) are measurable by either micrometeorological methods or the closed-chamber technique3. The vast majority of studies reporting data on GHG emissions from soils over the past three decades applied the closed-chamber technique4,5 that was first described in 19266. Several efforts have been made to fine-tune the technique, and overcome all sources of experimental artifact and bias7,8,9,10,11,12,13,14. Specific protocols, compiled at different times, aimed to standardize the methodologies15,16,17,18,19, and scientific attempts are still underway to establish the best practices for employing the technique and minimizing bias in flux estimates.

The static closed-chamber technique, whose application to paddy soils is described in this paper, relies on the diffusion theory and provides the enclosure of a known volume of air above a portion of soil surface for a precise period. During the enclosure, CH4 and N2O molecules migrate by diffusion along a natural concentration gradient from soil pore air, where they are produced by specific microorganisms (methanogens in the case of CH4; nitrifiers and denitrifiers for N2O), to the air enclosed within chamber headspace, eventually through the flooding water or the plant aerenchyma. The concentrations of the two gases within the chamber headspace increase over time, and occurrence of these increases provides for flux estimates.

With respect to the micrometeorological methods, closed chamber measurements are often preferred for differing land use types and ecosystems when studying GHG fluxes at the plot scale, because they are not encumbered by a large homogenous field2 or high logistical and investment requirements20. Moreover, they allow the simultaneous analysis of manipulated experiments, such as different agronomical practices or other field treatments12,21. Finally, the technique allows identification of the relationships among ecosystem properties, processes, and fluxes. Alternatively, two main drawbacks of the technique include the relatively inefficient exploration of spatial and temporal heterogeneity, and the effects of soil disturbance due to chamber deployment22. However, these detriments can, at least partially, be overcome with: proper chamber design (to minimize soil disturbance), adoption of a sufficient number of replicates (to explore spatial variability), and automated system use that permits intensification of the frequency of daily measurements (to account for diurnal variability) or regular (same time of day) measurement (to omit the effect of temperature in residual variability).

A first application of the method to a paddy field dates back to the early 80's23, and the main peculiarities of its use with respect to upland fields are the presence of flooding water on soil and the need to include plants within the headspace during chamber enclosure. As carefully described in this paper, the first trait implies the need for specific systems to prevent water disturbance during measurement events, to avoid flux overestimates caused by turbulence-induced enhancement of gas diffusion through flooding water. The second essential trait is to account for gas transport through rice aerenchyma, representing up to 90% of emitted CH424, which requires proper devices to include plants during measurement events.

Protocol

1. Chamber Design

- Assemble each chamber with three main elements: an anchor, a lid, and at least four extensions.

- Build the anchor in the shape of a 75 cm x 36 cm x 25 cm (L x W x H) rectangular box made of stainless steel. Weld a water-fillable channel 10-13 mm (w) x 13-20 mm (h) to the upper rectangular perimeter of the anchor. Drill two holes (1 cm in diameter) on each of the four sides of the anchor 5 cm from the upper water channel.

NOTE: Anchors isolate the soil column beneath the chamber and prevent lateral diffusion. The channel is necessary to achieve an effective seal between the anchor and the lid. The holes ensure a fast discharge of ponding water within the chamber during the field drainage events. - Build a lid in a rectangular box shape of stainless steel and sized 75 cm x 36 cm x 20 cm (L x W x H) with an internal volume of 54 L. Ensure that it fits the water-fillable channel perfectly.

- Cover the lid with a 4-cm thick closed cell foam that is, in turn, covered by a light reflective (aluminum-like) coating.

NOTE: It is necessary to equip the chamber with a temperature control system so as not to promote microbial activity artificially, consequent to an unintended temperature increase during chamber closure. - Equip each lid with a vent valve, made of a curved piece of plastic tubing (1.5 cm x 24 cm, D x L) sized for the chamber volume and wind conditions25. Connect the vent valve to the lid by drilling a 1.5 cm hole in the center of one of the two 36-cm lateral faces of the lid. Then secure the plastic tube with a screw connector.

NOTE: The vent valve is recommended for transmitting any barometric changes to the enclose air volume and compensating for volume changes that occur during chamber enclosure and air sampling withdrawal, and/or associated with the uncontrolled, enclosed air temperature changes. The vent should be a tube and not simply a hole, so that air exhausted from the enclosure during a drop in external pressure is captured within the tube and then returned to the enclosure in case the pressure increases again. The curved shape minimizes the potential of chamber depressurization due to wind flow over its external opening, i.e., the Venturi effect26. - Provide a sampling port for withdrawing gas samples. Make a 1 cm hole in the center of the top of the lid in a 7-cm x 7-cm niche dug into the cell foam. Close the hole with a rubber stopper that fits a Teflon tube (3 mm internal diameter, 20 cm length). Ensure that the Teflon tube extrudes 3 cm and intrudes 17 cm when the stopper is placed in its niche. Connect the outwards part of the tube to a one-way stopcock to manage the opening/closure of the sampling port.

- Equip each lid with a 12V PC fan powered by a 12V-7Ah rechargeable and portable battery, to ensure air mixing. Situate the PC fan on the internal upper side of the lid by means of two steel fasteners bolted to the internal side of the chamber.

NOTE: Air mixing is necessary to prevent any gas stratification within the chamber headspace during enclosure, especially when large quantities of vegetation are present. - Build a number of extensions to include the plants inside the chamber when they are fully grown. For example, if the plants will not exceed 80 cm height at their final size, build 4 extensions for each chamber. Ensure that each is a rectangular box made of stainless steel and 75 x 36 x 25 cm (L x W x H) in size, and with an upper water-fillable channel, as described for the anchor. Add these extensions between an anchor and lid during the chamber enclosure, depending on the crop stage.

2. Anchor Deployment and Arrangement of the System for Preventing Soil Disturbance

- Insert anchors into the soil after field preparation (i.e., after all tillage operations) and before rice seeding. If possible, do not remove the anchors for the duration of the measurement period unless strictly necessary, such as for tillage operation between two subsequent cropping seasons. Insert the anchors a few days (minimum of 2 days) before flux measurement starts, so that the soil re-equilibrates after disturbance during installation.

- Before distributing any anchor on the bare soil, place 30 cm x 3 m (W x L) wood planks (in the field and walk exclusively on them during the following operations to avoid soil compaction. Place the planks at least 0.5 m from each anchor.

- Insert anchors at a depth of 40 cm into the ploughed pan to secure the anchor and avoid accidental lateral bending after field flooding, especially when extension is used. After the anchors have been positioned on the soil in the assigned field area, place a custom-assembled steel frame atop the anchor, while maintaining proper alignment of both components. Hammer the anchor into the soil, and pay attention to hit the frame and not the anchor, to prevent damage to the anchor. After insertion, ensure that the anchors are perfectly flat by using a bubble level.

- Insert at least three anchors for each monitored treatment (i.e., replicates). Respect a minimum distance between adjacent chambers of 1 m, in case more than one chamber within the same experimental unit needs to be used.

- Once all the anchors are inserted, temporarily remove the wooden walking planks, and then rearrange the field with a system of catwalks originating from the lateral banks of the field. In detail, place in the field concrete blocks at least 0.5 m far from the anchors, in numbers sufficient to hold a system of wooden planks.

NOTE: Catwalks are necessary to prevent soil disturbance during subsequent GHG measurement events. The number of concrete blocks will depend on the distance of the anchors from the lateral banks of the field. Each 3-m long plank will require two concrete blocks for stability.

3. Chamber Closure and GHG Measurements

- Run measurement events always at the same time each day, to minimize diurnal variability.

NOTE: The moment best representing average daily flux is when temperatures are close to the daily mean, i.e., at 10 a.m. This is the best way to estimate the daily cumulative value from a unique measurement in the day27. - When arriving in the field, place wooden planks on the concrete blocks to reach anchors. Afterwards, fill the channels placed on the upper perimeter of the anchors with water. Carefully add extensions as necessary to enclose all the plants within the chamber headspace.

NOTE: This operation should be performed by two operators in order to avoid any crop damage. Fill with water the channel of each used extension as well. - Close each chamber, placing the lid in the water-filled channel of the upper extension. During the closing period (typically 15-20 min, but modifiable for meeting experimental needs), withdraw at least three gas samples at equal time-intervals (e.g., just after closure, after 10 min, and after 20 min). At samplings, connect a 50-mL syringe equipped with a one-way stopcock to the sampling port, then open the two stopcocks (one in the syringe and one in the sampling port), "rinse" the syringe by moving the plunger up and down three times before withdrawing 35 mL of chamber headspace, and then finally close the two stopcocks. Disconnect the syringe from the sampling port, and store it apart.

NOTE: When operating near the chambers during field flooding, avoid any disturbance or turbulence of ponding water as it can produce atypical gas bubbles and alter GHG flux estimates. - Add several extensions suitable to contain rice plants. Interpose extensions between the anchor and lid, filling all water-fillable channels. Use one extension when the rice is 20-40 cm above the soil surface (as measured with a folding ruler); use two extensions when the rice is 40-60 cm, and so on.

- During the chamber closure, measure the headspace temperature every 3-5 min with a temperature datalogger.

- Consider the sampling event complete after the closure period. Remove the lid and subsequently all used extensions.

NOTE: To shorten the time required to monitor several chambers, and avoid diurnal variability bias, it is possible to measure contemporaneously more than one chamber. For example, with a team of two operators, it is possible to manage sampling from up to 10 adjacent chambers in 30 min. - After each sampling event, measure the headspace height of each chamber from the soil (when the field is drained) or from ponding water (when the field is flooded) using a folding ruler.

4. Sample Handling and Analyses

- Prior to each paddy field visit, evacuate three (or more) 12-mL glass vials closed with butyl-rubber septa per field chamber in the laboratory.

NOTE: Vials can be re-used. Before each re-use, it is necessary to substitute the rubber septum and restore the vacuum. - Following the withdrawal of gas from the chamber headspace, transfer the syringe-filed samples to the evacuated vials quickly because plastic syringes, even with closed stopcock, cannot guarantee no leakage28. Perform the transfer with a 25-gauge hypodermic needle. First, fit the needle into the stopcock, then open it and flush the needle with 5 mL of sample. Next, insert the needle into the septum and push the remaining 30 mL sample into a pre-evacuated vial, and then withdraw the needle.

NOTE: The sample inside the vial is > 2 atm pressurized to provide gas for multiple analyses and to avoid any mass flux from the external environment toward the sample, which would alter its GHG concentration. The 5-mL sample flush of the needle allows it to be reused for other samples. - At the end of each sampling event, transfer the vials to the laboratory for analysis.

NOTE: Although conservation of the sample is guaranteed at 20 °C for more than four months28, it is always preferable to perform analytical procedures as soon as possible. - Determine gas concentrations in the collected samples using an automated gas chromatograph equipped with an electron capture detector for N2O determination and a flame ionization detector for CH4 determination29. In addition to the samples, measure the concentrations of a number of known N2O and CH4 samples (standards) in order to perform an accurate calibration.

NOTE: The concentration of the standards should cover the range of expected concentrations of the samples.

5. Flux Estimation

- The model chosen for flux estimation should predict the flux at the moment of chamber deployment, i.e., the ideal moment at which the true exchange rate is unaffected by chamber presence.

- After determining the concentration of gas on a base volume via gas chromatographic analysis and subsequent calibration, calculate the absolute amount of substance (N2O or CH4) present within the headspace, according to the air molar volume derived from the Ideal Gas Law.

NOTE: It is highly advisable to produce a calibration curve associated with each sampling event, since gas chromatograph can suffer slight signal alterations as a function of temperatures, which can lead to errors. - Choose between a linear or non-linear model, depending on the emission pattern. Among available non-linear models, select the HM model25, eventually relying on the HMR package9. If you have three time-points (time 0, time 1 and time 2) choose based on the slope of the two segments: in the event that the slope between time 0 and time 1 is greater in absolute values than the slope between time 1 and time 2 and slopes are concordant, use the HM model; in all the other cases, use a linear model. If you have more than three time-points, fit the two models using HMR, but afterwards choose on your own based on visual evaluation of the model best fitting the trend.

- Set to zero fluxes under the Minimum Detectable Flux, calculated according to the detection limit of gas chromatograph and operating conditions (temperature, pressure, headspace volume).

- To describe the seasonal variability of fluxes properly, provide at least 40 sampling events throughout the year (monitoring both cycles and intercropping periods), intensifying the sampling frequency near pivotal events of the cropping cycle, such as tillage, fertilizations, drainage, establishment of flooding conditions, surfacing of rice seedlings from ponding water, and so on. Transition from a maximum frequency of daily (e.g., at drainage periods, fertilizations, etc.) to a minimum of once bi-weekly (e.g., during winter).

Representative Results

Every measurement event produces a series of GHG concentrations over time for each of the monitored chambers that is the basis for estimating GHG fluxes. Basically, there is no particular need to discard data, but a high incidence of situations that fall outside the theoretical model of monotonic function (strictly increasing or decreasing) warrants attention on the accuracy of protocol application and possible unpredicted errors (e.g., vials leakage).

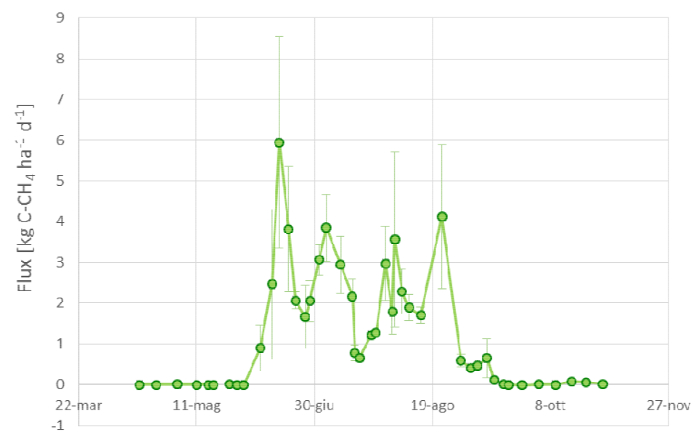

Figure 1 reports an entire year of correct example CH4 fluxes. As demonstrated with error bars, such results may vary greatly, mainly as a consequence of to the spatial heterogeneity of microbial processes responsible for GHG production. For users who experience high variability, such results do not necessarily signal bad results. To address high variability that makes treatment differences impossible to detect, simply increase the number of replicates.

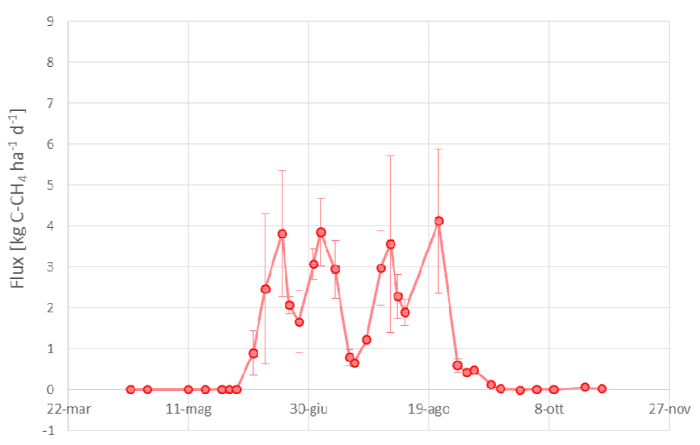

In Figure 2, an example of poor exploration of seasonal variability is shown: the insufficient number of measuring events led to an underestimation of yearly fluxes.

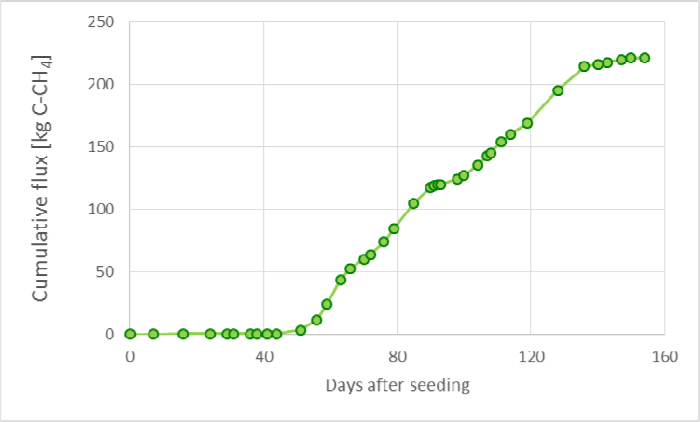

Daily fluxes can be subsequently combined to calculate cumulative emissions over a solar year, over a cropping season, or over specific cropping stages. Typically, the calculation of cumulative fluxes relies on the linear change of fluxes between two subsequent measuring events. An example of cumulative fluxes is shown in Figure 3 for CH4.

Figure 1. Example of seasonal variation of CH4 daily fluxes from a flooded paddy field over a full year, including both a cropping cycle (from May to September) and inter-cropping periods. Error bars represent standard errors. Please click here to view a larger version of this figure.

Figure 2. Example of seasonal variation of CH4 daily fluxes from a flooded paddy field over a whole year, with an insufficient number of measuring events not well covering all the pivotal moments for GHG emissions. Error bars represent standard errors. Please click here to view a larger version of this figure.

Figure 3. Example of cumulative CH4 emissions over a cropping season. Please click here to view a larger version of this figure.

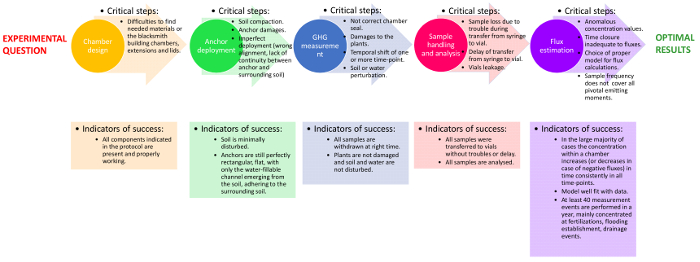

Figure 4. Main phases of method application with corresponding critical points and indicators of success. Please click here to view a larger version of this figure.

Discussion

The application of the static closed-chamber technique in paddy rice consists of five essential phases, corresponding to the main sections described in the Protocol. Each phase contains critical points of which to be aware, and indicators to check the success of phase implementation, as summarized in Figure 4.

Most critical points described in Figure 4 are already addressed in the protocol and could be easily resolved by following the included recommendations. The trickiest critical point of the present protocol is the calculation of fluxes based on GHG concentration variation during chamber enclosure. Also when using the package HMR for calculations, it is advisable to select the best model to apply, independent of the HMR suggestion, based on visual evaluation. This is even more important when concentrations in time deviate from the expected behavior of consistent increase or decrease.

Several variations of the described technique are possible within the structure of the main principles, especially related to chamber geometry (the chamber can also be cylindrical), chamber material (any non-permeable, non-reactive, non-source/sink of gas molecules under consideration, and easy to use material, such as Teflon which is suitable, but more expensive), and type of GHG analyzer (portable systems are available that do not require gas transfer in syringes and vials). Nevertheless, measuring GHG fluxes from soils is a pivotal step required to monitor climate change sources, to understand processes leading to emissions, to study the effectiveness of possible mitigation strategies, and to inform models for predicting future scenarios. It is more important than ever to adopt common protocols that will build a uniform body of knowledge to monitor agroecosystems for the global GHG budget.

The Ideal Gas Law is here applied to calculate the molar volume of real gases. This application is widely used and accepted in the specific body of literature, and the ideal gas approximation can be used with reasonable accuracy30.

Finally, depending on the experimental questions to be addressed within the context of GHG measurements, consider measuring the main drivers of CH4 and N2O emissions, such as soil temperature, redox potential, soil pore Dissolved Organic Carbon concentrations, soil pore nitrates, and ammonium concentration.

Offenlegungen

The authors have nothing to disclose.

Acknowledgements

The authors are grateful to Marco Romani and Eleonora Francesca Miniotti and the staff of Research Centre of Ente Nazionale Risi, who hosted the experimental trial where the video was created. We also want to thank Francesco Alluvione for the first scientific flash leading to protocol realization and to Joan Leonard for her precious work of English editing of the manuscript.

Materials

| Anchor/Chamber | – | – | Self-produced |

| 5 cm thick closed cell foam | – | – | It is an insulating material, to be found in a store of building materials. |

| Light reflective (aluminum-like) coating | – | – | We use a shiny blanket, but it is possible to use aluminium foil for food. |

| Curved piece of plastic tubing (1.5 cm and 24 cm, DxL) | – | – | We use an electrical duct, to be found in a hardware store. |

| Screw connector | – | – | We use a connector for electrical ducts, to be found in a hardware store. |

| Rubber stopper (1 cm D) | – | – | To be found in a store for laboratory equipments. |

| Teflon tube (3 mm internal D) | – | – | To be found in a store for laboratory equipments. |

| One-way stopcock | – | – | We use stopcock for drip, to be found in a store for medical equipments. |

| 12V PC fan | – | – | To be found in a PC store. |

| 12V-7Ah rechargeable and portable battery | – | – | To be found in a store for electrical material. |

| Steel fasteners | – | – | To be found in a hardware store. |

| 30 cm X 3 m (WxL) wood planks | – | – | To be found in a store of building materials. |

| Steel frame | – | – | Self-produced |

| Bubble level | – | – | To be found in a hardware store. |

| Concrete blocks | – | – | To be found in a store of building materials. |

| 50 ml syringe | – | – | To be found ina store for medical/veterinary equipments. |

| Folding Ruler | – | – | To be found in a hardware store. |

| Temperature datalogger | Onset | HOBO U23 Pro v2 External Temperature Data Logger | |

| Exetainer 12ml Vial – Flat Bottom | Labco UK | 736 W | |

| Butil rubber septa for vials | Labco UK | VW101 | |

| 25-gauge hypodermic needle | – | – | To be found in a store for medical equipments. |

| CH4 and N2O standards | – | – | To be found at a supplier of gas bottles. |

Referenzen

- Tubiello, F. N., et al. . Agriculture, Forestry and Other Land Use Emissions by Sources and Removals by Sinks. , 4-89 (2014).

- Oertel, C., Matschullat, J., Zurba, K., Zimmermann, F., Erasmi, S. Greenhouse gas emissions from soils-A review. Chemie der Erde. 76, 327-352 (2016).

- Hutchinson, G. L., Livingston, G. P., Dane, J. H., Topp, G. C. Soil-atmosphere gas exchange. Methods of soil analysis. , 1159-1182 (2002).

- Nakano, T., Sawamoto, T., Morishita, T., Inoue, G., Hatano, R. A comparison of regression methods for estimating soil-atmosphere diffusion gas fluxes by a closed-chamber technique. Soil Biol. Biochem. 36, 107-113 (2004).

- Rochette, P., Eriksen-Hamel, N. S. Chamber Measurements of Soil Nitrous Oxide Flux: Are Absolute Values Reliable?. Soil Sci. Soc. Am. J. 72 (2), 331-342 (2008).

- Lundegardh, H. Carbon dioxide evolution of soil and crop growth. Soil Sci. 23 (6), 417-450 (1926).

- Buendia, L. V., et al. An efficient sampling strategy for estimating methane emission from rice field. Chemosphere. 36, 395-407 (1998).

- Khalil, M. A. K., Butenhoff, C. L. Spatial variability of methane emissions from rice fields and implications for experimental design. J Geophys. Res. 113, 1-11 (2008).

- Pedersen, A. R., Petersen, S. O., Schelde, K. A comprehensive approach to soil-atmosphere trace-gas flux estimation with static chambers. Eur. J. Soil Sci. 61, 888-902 (2010).

- Christiansen, J. R., Korhonen, J. F. J., Juszczak, R., Giebels, M., Pihlatie, M. Assessing the effects of chamber placement, manual sampling and headspace mixing on CH4 fluxes in a laboratory experiment. Plant Soil. 343, 171-185 (2011).

- Minamikawa, K., Tokida, T., Sudo, S., Padre, A., Yagi, K. . Guidelines for measuring CH4 and N2O emissions from rice paddies by a manually operated closed chamber method. , (2015).

- Parkin, T. B., Venterea, R. T., Hargreaves, S. K. Calculating the detection limits of chamber-based soil greenhouse gas flux measurements. J. Environ. Qual. 41, 705-715 (2012).

- Pihlatie, M. K., et al. Comparison of static chambers to measure CH4 emissions from soils. Agr. Forest. Meteorol. 171-172, 124-136 (2013).

- Sander, B. O., Wassmann, R. Common practices for manual greenhouse gas sampling in rice production: a literature study on sampling modalities of the closed chamber method. Greenhouse Gas Meas. Manage. 4, 1-13 (2014).

- IAEA. . Manual on measurement of methane and nitrous oxide emissions from agriculture. , (1992).

- IGAC. . Global Measurement Standardization of Methane Emissions from Irrigated Rice Cultivation: A Report of the Rice Cultivation and Trace Gas Exchange Activity (RICE) of the International Global Atmospheric Chemistry (IGAC) Project. , (1994).

- Parkin, T. B., Venterea, R. T., Follett, R. F. Chapter 3. Chamber-Based Trace Gas Flux Measurements. Sampling Protocols. , 3.1-3.39 (2010).

- Minamikawa, K., Tokida, T., Sudo, S., Padre, A., Yagi, K. . Guidelines for measuring CH4 and N2O emissions from rice paddies by a manually operated closed chamber method. , (2015).

- Firbank, L. G., et al. Towards the co-ordination of terrestrial ecosystem protocols across European research infrastructures. Ecol Evol. 7 (11), 3967-3975 (2017).

- FAO, , IFA, . Global estimates of gaseous emissions of NH3, NO and N2O from agricultural land. , (2001).

- Denmead, O. T. Approaches to measuring fluxes of methane and nitrous oxide between landscapes and the atmosphere. Plant Soil. 309, 5-24 (2008).

- Cleemput, O. V., Boeckx, P., Lal, R. Greenhouse gas fluxes: measurement. Encyclopedia of Soil Science. , (2005).

- Cicerone, R. J., Shetter, J. D. Sources of atmospheric methane: Measurements in rice paddies and a discussion. J Geophys. Res. 86, 7203-7209 (1981).

- Le Mer, R., Roger, J. Production, oxidation, emission and consumption of methane by soils: A review. Eur. J. Soil Biol. 37, 25-50 (2001).

- Hutchinson, G. L., Mosier, A. R. Improved soil cover method for field measurement of nitrous oxide fluxes. Soil Sci. Soc. Am. J. 45, 311-316 (1981).

- Conen, F., Smith, K. A. A re-examination of closed flux chamber methods for the measurement of trace gas emissions from soils to the atmosphere. Eur. J. Soil Sci. 49, 701-707 (1998).

- Minamikawa, K., Yagi, K., Tokida, T., Sander, B. O., Wassmann, R. Appropriate frequency and time of day to measure methane emissions from an irrigated rice paddy in Japan using the manual closed chamber method. Greenhouse Gas Meas. Manage. 2, 118-128 (2012).

- Rochette, P., Bertrand, N. Soil air sample storage and handling using polypropylene syringes and glass vials. Can. J. Soil Sci. 83, 631-637 (2003).

- Peyron, M., et al. Greenhouse gas emissions as affected by different water management practices in temperate rice paddies. Agr. Ecosyst. Environ. 232, 17-28 (2016).

- Ussiri, D., Lal, R. . Soil Emission of Nitrous Oxide and its Mitigation. , (2012).