A Flexible Wearable Supernumerary Robotic Limb for Chronic Stroke Patients

Summary

This protocol introduces a flexible wearable supernumerary robotic limb tailored to assist in finger rehabilitation for stroke patients. The design incorporates a bending sensor to facilitate seamless human-robot interaction. Validation through experiments involving both healthy volunteers and stroke patients underscores the efficacy and dependability of the proposed study.

Abstract

In this study, we present a flexible wearable supernumerary robotic limb that helps chronic stroke patients with finger rehabilitation and grasping movements. The design of this innovative limb draws inspiration from bending pneumatic muscles and the unique characteristics of an elephant’s trunk tip. It places a strong emphasis on crucial factors such as lightweight construction, safety, compliance, waterproofing, and achieving a high output-to-weight/pressure ratio. The proposed structure enables the robotic limb to perform both envelope and fingertip grasping. Human-robot interaction is facilitated through a flexible bending sensor, detecting the wearer’s finger movements and connecting them to motion control via a threshold segmentation method. Additionally, the system is portable for versatile daily use. To validate the effectiveness of this innovation, real-world experiments involving six chronic stroke patients and three healthy volunteers were conducted. The feedback received through questionnaires indicates that the designed mechanism holds immense promise in assisting chronic stroke patients with their daily grasping activities, potentially improving their quality of life and rehabilitation outcomes.

Introduction

According to previous research1, as of 2019, there were more than 100 million cases of stroke worldwide. Approximately two-thirds of these cases resulted in hemiplegic sequelae, and over 80% of severe hemiplegic stroke patients could not fully recover hand and arm function2. Furthermore, the aging population is expected to continue growing in the coming decades, leading to a significant increase in the number of potential stroke victims. The persistent upper extremity impairments following a stroke can significantly affect activities of daily living (ADLs), and hand rehabilitation has been clinically recognized as a critical objective for enhancing the activity and participation of chronic stroke patients3.

Traditional motor-driven robotic upper limb devices can provide substantial driving force, but their rigid structures often translate into large sizes and high weights. Moreover, they pose the risk of causing irreversible harm to the human body if they were to malfunction. In contrast, soft pneumatic actuators have demonstrated considerable potential in rehabilitation4, assistance5, and surgical applications6. Their advantages include safety, lightweight construction, and inherent compliance.

In recent years, numerous flexible wearable robots have emerged, designed and developed around soft pneumatic actuators. These robots have been intended for the rehabilitation and post-rehabilitation assistance of stroke patients' upper limbs. They primarily encompass hand exoskeletons7,8, and supernumerary limbs9,10. Although both are used in the fields of wearable robotics and rehabilitation, the former directly interacts with the human body, potentially constraining muscles or joints, while the latter supplements the human workspace or movement without direct constraint11,12. Wearable supernumerary robotic fingers based on servo motors were developed to assist occupational therapists in activities of daily living (ADLs) training9. A similar approach can be found in other research10. These two categories of robotic fingers have introduced novel possibilities for the application of such robots in the rehabilitation assistance of hemiparetic patients. Nonetheless, it is worth noting that the rigid structure employed in these robotic designs may introduce potential considerations regarding user comfort and safety. The design, fabrication, and evaluation of a soft wearable robotic glove were presented13, which can be used for hand rehabilitation and task-specific training during functional Magnetic Resonance Imaging (fMRI). The glove utilizes soft pneumatic actuators made of silicone elastomers to generate finger joint motion, and the device is MR-compatible without causing artifacts in fMRI images. Yun et al. introduced the Exo-Glove PM, a customizable soft pneumatic assistive glove that utilizes an assembly-based approach14. This innovative design features small modules and adjustable distances between them, allowing users to customize the glove based on their phalange length using spacers. This approach maximizes comfort and performance without the need for custom manufacturing. Researchers presented soft actuators composed of elastomeric materials with integrated channels functioning as pneumatic networks15. These actuators generate bending motions that safely conform to human finger movements. Additionally, researchers introduced the AirExGlove, a lightweight and adaptable inflatable soft exoskeleton device16. This system is cost-effective, customizable for different hand sizes, and has successfully accommodated patients with varying levels of muscle spasticity. It offers a more ergonomic and flexible solution compared to rigid-linked robotic systems. While these studies have made significant contributions to the development of flexible wearable hand rehabilitation and assistive robots, it's worth noting that none of them have achieved complete portability and human-robot interaction control.

Numerous studies have explored the correlation between biological signals, such as electroencephalogram (EEG)17 or electromyogram (EMG) signals18, and human intention. However, both approaches have certain limitations within the constraints of existing devices and technological conditions. Invasive electrodes require surgical procedures on the human body, while non-invasive electrodes suffer from issues such as high noise levels and unreliability in signal acquisition. Detailed discussions of these limitations can be found in the literature19,20. Therefore, the pursuit of research into the portability and user-friendly human-machine interaction capabilities of flexible wearable supernumerary robotic limbs remains highly relevant.

In this study, a unique flexible wearable supernumerary robotic limb was designed and fabricated to assist chronic stroke patients in finger rehabilitation and gripping assistance. This robotic limb is characterized by its lightweight, safety, compliance, waterproofing, and impressive output-to-weight/pressure ratio. Two gripping modes, envelope and fingertip grasping, have been achieved while maintaining portability and ensuring a user-friendly human-robot interaction. The protocol details the design and fabrication process of the pneumatic gripper and the wearable scheme. Additionally, a human-robot interaction method based on flexible bending sensors has been proposed, allowing for convenient and user-friendly control through threshold segmentation. All these aspects have been validated through practical experiments.

The main contributions of this study are summarized as follows: (1) A lightweight, friendly, and wearable flexible supernumerary robotic limb for chronic stroke patients has been designed and fabricated. (2) A reliable method of human-robot interaction has been realized based on flexible bending sensors. (3) Real-world experiments have been conducted to verify the effectiveness and reliability of the proposed mechanism and method, which include output force testing and involve six chronic stroke patients.

Protocol

This protocol has been approved by the Ethics Review Board of Union Hospital, Tongji Medical College, Huazhong University of Science and Technology. Patients with upper limb functional disorders who met the diagnostic criteria and were receiving treatment at the author's hospital's rehabilitation department outpatient and inpatient units were selected as participants. The patients' motor function recovery was assessed according to the Brunnstrom recovery stages21, and patients in stages 3-5 were chosen to participate in the experiments. Written informed consent was obtained from the patients who participated in the study. The procedure includes mold design for the pneumatic gripper, the fabrication process of the pneumatic gripper based on cured silicone rubber, integration of portable devices, and software and hardware implementation for grasp intention detection. Except for silicone rubber and common fabrics, all wearable components are produced using 3D printing technology (see Supplementary Coding Files 1-5).

1. Designing and fabricating the pneumatic gripper

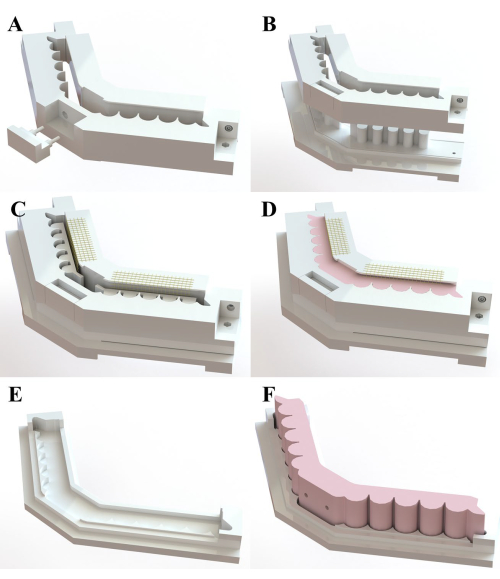

- Assemble the pre-designed mold22 as shown in Figure 1A,B. Then use hot melt glue to secure the glass fibers at the designated positions in the mold, as depicted in Figure 1C. Ensure to use hot melt glue to seal any potential areas that may cause silicone leakage.

- Weigh an appropriate amount of Component A and Component B of the silicone elastomer (9:1 by weight) (see Table of Materials), and mix them in the specified ratio. After mixing, utilize a vacuum mixing and degassing machine with a variable centrifugal force, determined by the internal preset program of the machine. Once the mixture is ready, promptly inject it into the assembled mold, as illustrated in Figure 1D.

NOTE: The variable centrifugal force is controlled by the vacuum mixing and degassing machine through its internal preset program (see Table of Materials). The centrifugal force must be incrementally increased to ensure thorough mixing of the silicone rubber and the removal of any trapped air bubbles. - Allow the mold to sit for approximately 30 s, then place it in a vacuum dryer for about 1 min to enable any small air bubbles in the silicone rubber to escape. Remove the mold from the dryer and place it as a whole in a thermostatic chamber set at 30 °C for 12 h, allowing the silicone rubber to cure.

- Repeat the steps outlined in the second step by injecting the mixed silicone rubber into the mold shown in Figure 1E. Next, place the demolded rubber body shown in Figure 1F into the mold filled with silicone rubber. Put the entire assembly in a thermostatic chamber set at 30 °C for 12 h to allow the silicone rubber to cure.

- Remove the cured silicone rubber body from the mold and trim off any excess silicone rubber. The fabrication of the flexible gripper is now complete.

NOTE: The cavity consists of two sets of pneumatic grids, which are independent of each other. Due to the significant difference in elastic modulus between the glass fibers and the corrugated structure, the pneumatic gripper bends inward when inflated, allowing for envelope-grasping actions. The fingertip is designed with a protrusion resembling an elephant trunk, enabling fingertip-grasping actions.

2. Assembling the wearable flexible supernumerary robotic limb

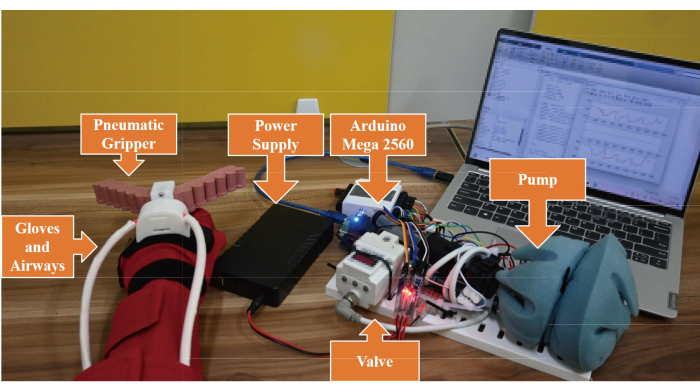

NOTE: The wearable supernumerary robotic limb includes a mini air pump, air valves, a single-chip microcomputer, pneumatic gripper, power supply, flexible bending sensors, a wearable glove, and accessories for pneumatic and electrical connections (see Table of Materials), as shown in Figure 2.

- Meticulously handcraft the wearable glove with the help of a tailor. Ensure it undergoes multiple iterations and improvements based on wearer feedback and the tailor's experience.

- Secure the pneumatic gripper with 3D-printed parts and attach it to the appropriate position on the glove using adhesive tape.

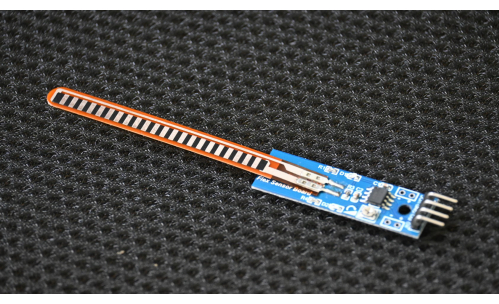

- Embed three flexible bending sensors (see Table of Materials) as shown in Figure 3 into the glove. Place them on the index, middle, and ring fingers, respectively, aligning them with the backside of the fingers. Use a data acquisition card to record signals from the sensors.

- Amplify the sensor signals and route them to an Arduino (see Table of Materials). Process these signals using a sliding window and least squares filtering within the Arduino23. Utilize these estimated values as baseline data for intent detection.

- Place components such as the air pump, air valves, control board, and power supply into a backpack for portability. Refer to Figure 4 for a visual representation of the wearing effect.

3. Detecting the grasping intention

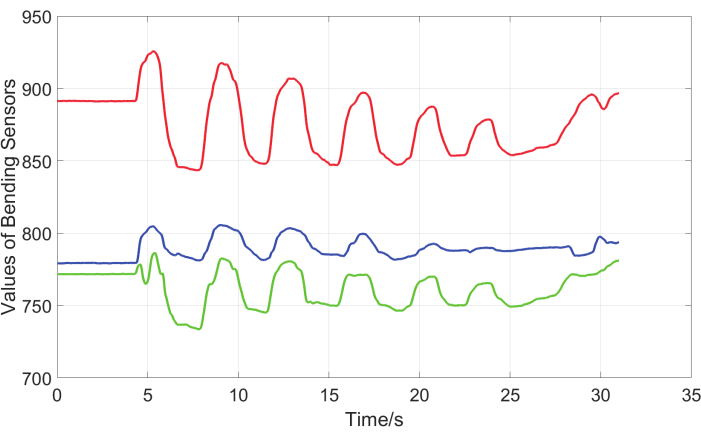

NOTE: When the wearer's fingers generate movement, the sensor feedback signal changes accordingly. It works by increasing the resistance in the circuit as the component bends more. Figure 5 shows the recorded signal values of the flexible bending sensor during the finger movement of one volunteer. The three curves correspond to the signals obtained from sensors placed on the three fingers. Patients with hemiparesis often have limited finger mobility, but the sensor is capable of detecting significant changes.

- Collect data on the range and pattern of sensor changes during finger movements. Select appropriate threshold values based on the detected sensor amplitude to control pump activation. Instruct participants to move their fingers freely within their range of ability. Determine the threshold values as the averages of the peak and valley values of the sensor feedback.

NOTE: When the sensor signal exceeds the set threshold value, the pump starts operating. The air pressure increases as the fingers bend further. Conversely, when the bending angle of the fingers decreases, and the sensor detects a signal below the threshold, the air valve releases the pressure to zero, and the pneumatic gripper releases. - Ask the user to observe the state of the pneumatic gripper and determine the appropriate time to stop inflating the air and cease further finger bending.

- Repeat the above tests to establish a reasonable threshold and to become familiar with using this device.

4. Testing the device with healthy volunteers

- Enlist three healthy volunteers with normal upper limb motor abilities for the study to confirm the wearing and grasping effects of the prototype.

- Set the maximum air pressure for the pneumatic gripper to 100 kPa. Instruct the participants to flex and extend their fingers. Have the participants wear the prototype and conduct gripping and releasing experiments on objects of various shapes using the method mentioned earlier.

- Solicit feedback from the wearers regarding their experience and adjust the wearing scheme based on their suggestions.

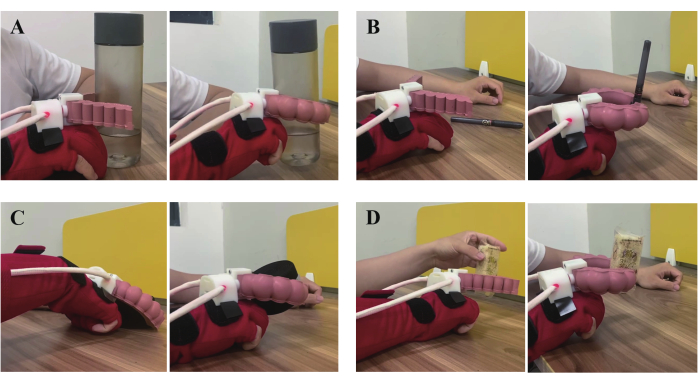

NOTE: As depicted in Figure 6, the participants successfully enveloped and grasped cylindrical objects of different sizes using the prototype. Additionally, they also completed fingertip grasping tasks on rectangular block-shaped objects.

5. Rehabilitation and grasp assistance for patients

- Evaluate the patients' motor function recovery according to the Brunnstrom recovery stages21 by medical professionals. Only allow patients in stages 3-5 to participate in the experiments for rehabilitation training or daily assistance.

- Enlist six chronic hemiparetic patients to validate the reliability and effectiveness of the prototype. Instruct the patients to independently wear the glove (excluding the backpack) and move their fingers within their range of ability for calibrating the threshold values.

- During the rehabilitation phase, encourage patients to engage in various gripping tasks to exercise their finger muscles. Have the patients sit at the edge of a table and use the prototype to perform a series of grasping activities, including grasping a water bottle, a banana, a cube, and a toothbrush.

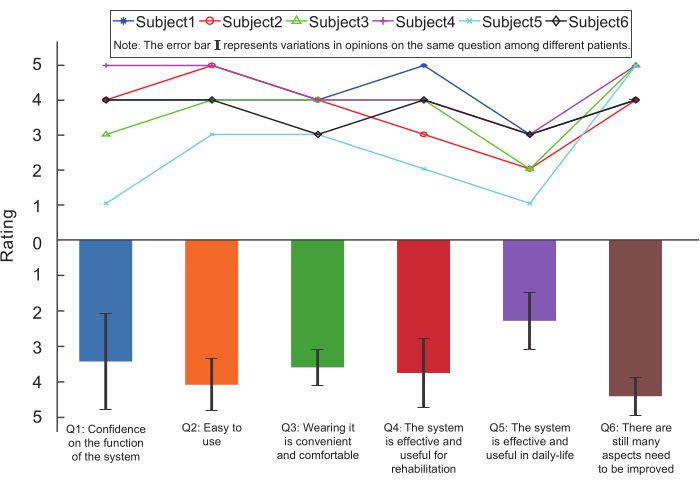

- Ask the patients to complete relevant survey questionnaires (Supplementary File 1) based on their personal experiences after the experiment. Assess the following six subjective feelings: confidence in the function of the system; ease of use; convenience and comfort of wearing it; effectiveness and usefulness for rehabilitation; effectiveness and usefulness in daily life; areas that still need improvement.

- Rate their responses on a scale of 1 to 5, where 1 represents strongly disagree and 5 represents strongly agree. Record the data and analyze the issues with the prototype and potential areas for improvement based on the questionnaire.

NOTE: This not only adds interest to the rehabilitation training but also enhances the patient's willingness to participate in the recovery process. In cases where patients have reached a stable condition but still struggle to perform gripping tasks with their fingers, the use of the robotic limb can assist in carrying out certain daily grasping actions required for everyday life.

Representative Results

Output force experiments

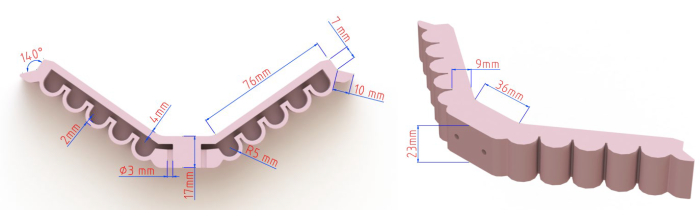

Figure 7 vividly depicts the structural design and dimensions of our actuator, providing a cross-sectional illustration. This actuator comprises two distinct sets of chambers, each containing five elegantly curved air chambers. Remarkably, at the actuator's terminus, we have ingeniously integrated a protruding structure, reminiscent of an elephant's trunk tip, significantly expanding the actuator's gripping radius.

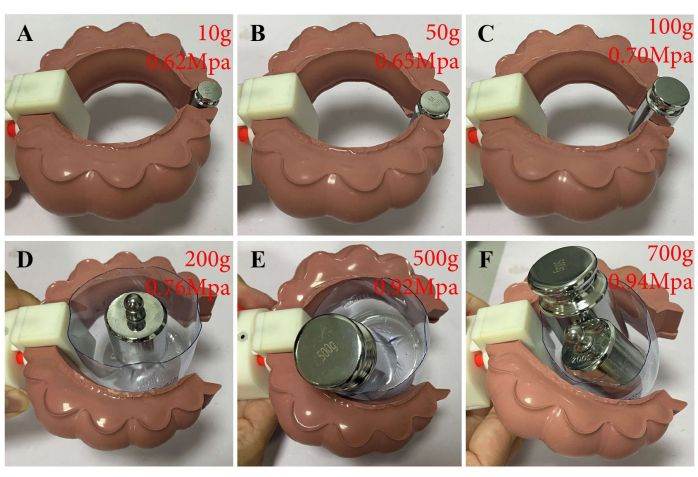

To assess the output force of the soft pneumatic actuator, a series of static grasping experiments were conducted. Weights, individually weighing 20 g, 50 g, 100 g, 200 g, and 500 g, were selected. After the actuator was appropriately positioned and inflated, it was lifted upward following its bending and enveloping of the weights to evaluate slippage. The experimental outcomes are depicted in Figure 8, with Figure 8A–C representing the experimental results of fingertip grasping, while Figure 8D–F display the experimental results of envelope grasping.

In the aforementioned six grasping conditions, the input air pressure to the actuator ranged from 0.62 MPa to 0.94 MPa. Due to variations in manufacturing processes and the structure of the constraining layer among different actuators, this numerical range may vary for different actuators. Considering that the actuator itself weighs only 63 g, it can be substantiated that such actuators exhibit a substantial output force-to-weight/air pressure ratio. Furthermore, as depicted in Figure 8F, it can be observed that with an increasing load, the actuator undergoes significant deformation during the grasping process. This is attributed to the limited stiffness of the soft actuator itself.

Subjective evaluation from patients

Figure 9 displays the results of the questionnaire survey from six patients. It is evident that a consensus exists among the majority of participants regarding the comfort and user-friendliness of the designed wearable system. Nevertheless, a distinct outlier, Participant 5, provides an overall less favorable evaluation and raises significant concerns about the device. Notably, the responses to the first question exhibit considerable variability among participants, which may be attributed to differences in hand recovery status and the learning curve associated with machine usage. Moreover, a prevailing sense of skepticism emerges among most participants regarding the system's functionality in their daily lives, underscoring the scope for substantial enhancements in the device.

Figure 1: Actuator fabrication and assembly. (A–C) illustrate the mold structure and assembly procedure used in the actuator fabrication process. (D) shows the state after pouring the silicone rubber, resulting in two sets of chambers. (E) and (F) showcase the mold for sealing the bottom and the corresponding assembly outcome. Please click here to view a larger version of this figure.

Figure 2: Supernumerary robotic limb. This figure displays all hardware components included in the supernumerary robotic limb, excluding the portable backpack. Please click here to view a larger version of this figure.

Figure 3: Flex sensor. An overview of the flexible bending sensor embedded in the glove. Please click here to view a larger version of this figure.

Figure 4: Prototype wearing effect. This figure illustrates the overall wearing effect of the prototype. The total mass of the arm wear part is less than 300 g. Please click here to view a larger version of this figure.

Figure 5: Flexible bending sensor signals. This figure presents a section of sensor values recorded when the patient wears the glove and moves their fingers freely. The three curves correspond to the signals obtained from sensors placed on the three fingers. Please click here to view a larger version of this figure.

Figure 6: Grasping experiments by healthy volunteers. (A–C) demonstrate the effect of the pneumatic gripper gripping three different sizes of cylinders. (D) shows the effect of grasping a rectangular block-shaped object. In (A) and (C), the operating mode is envelope-grasping. In (B) and (D), the operating mode is fingertip-grasping. Please click here to view a larger version of this figure.

Figure 7: Flexible bending sensor dimensions and structure. This image annotates key dimensions and the structure of the flexible bending sensor. It provides information on the actuator wall thickness, external dimensions, and chamber sizes, including a cross-sectional view of the actuator's structure. Please click here to view a larger version of this figure.

Figure 8: Experimental results of output forces. (A–C) demonstrate fingertip grasping results with load weights of 20 g, 50 g, and 100 g, respectively. (D–F) showcase enveloping grasping outcomes with load weights of 200 g, 500 g, and 700 g, respectively, in two grasping modes. Please click here to view a larger version of this figure.

Figure 9: Questionnaire survey results. The results of a questionnaire survey from six patients are presented. Ratings range from 1 to 5, where 1 means "totally disagree," and 5 means "totally agree." Please click here to view a larger version of this figure.

Supplementary File 1: Questions for the patients based on their personal experiences after the experiment. Please click here to download this File.

Supplementary Coding Files 1-5: Designs for fabricating the wearable components using 3D printing technology. Please click here to download this File.

Discussion

This study presents an innovative, flexible, wearable supernumerary robotic limb designed to assist chronic stroke patients in finger rehabilitation and gripping tasks. This robotic system prioritizes portability and offers both envelope grasp and fingertip grasp functionalities. It incorporates a flexible bending sensor for user-friendly human-machine interaction control. Static grasping experiments validate the gripping capabilities of the designed mechanism in two distinct grasping modes. The study involves experiments with hemiparetic patients to confirm the gripping functionality and assess the user experience, showcasing the potential of this robot in aiding chronic stroke patients during rehabilitation and grasping activities.

In the context of this research, critical procedural steps can be succinctly summarized as follows: (1) During the silicone injection process into the mold, it is imperative to maintain an optimal injection velocity. Excessively rapid injection may lead to an overabundance of air bubbles, while overly slow injection may compromise the silicone’s fluidity. (2) Following silicone injection, the removal of minute air bubbles within the silicone can be achieved using a vacuum pump. However, it is essential to exercise caution and avoid prolonged exposure to the vacuum pump, as this may result in silicone overflow. (3) To ensure the evenness of motion in the fabricated actuators, it is paramount to maintain a high degree of symmetry in securing the glass fibers. (4) Prior to experimentation, meticulous verification of the actuators’ airtightness and the safety of associated equipment, including the air pump, is mandatory. This precautionary measure ensures that the circuitry remains free from any risk of short-circuiting. (5) Given the substantial variability among patients in terms of their medical conditions and significant differences in hand dimensions due to gender disparities, the production of gloves in various sizes is indispensable to cater to individual needs.

In the domain of actuator fabrication, ensuring structural consistency poses a significant challenge. Due to the inherent limitations of flexible material molding and imprecise limited layer positioning, issues such as inconsistent actuator performance and asymmetry may arise24. Furthermore, while these actuators exhibit natural compliance, their low stiffness presents a limitation that hinders further development. In the context of the designed structure in this study, the actuators undergo significant deformation when subjected to a 0.7 kg load, impeding their ability to handle heavy grasping tasks. Besides, precise force control between the actuators and the load remains a challenging issue25,26. In comparison to human hands, which possess both the capability to perform actions and a strong external environmental perception ability, the continuous deformation structure, flexible force sensing, and tactile sensing have been ongoing challenges in related applications.

In terms of functionality, the current pneumatic gripper has limited capabilities in achieving various grasping actions. In contrast, human hands excel at grasping various complex-shaped objects and performing intricate actions such as tearing, flicking, and smearing24,27. Expanding the range of grasping functionalities poses a significant challenge for pneumatic grippers. Furthermore, although this study proposes a portable structure, the miniature air pump used generates relatively high noise levels and provides a small output gas flow, exacerbating the existing elastic deformation effects. Therefore, the development of a quiet and more efficient miniature air source is another issue that needs to be addressed.

During patient experiments, researchers observed that participants were prone to experiencing finger spasms. Specifically, patients exhibited a gradual reduction in finger mobility and were unable to complete finger extension and flexion movements as they spent more time in the experiment. Therefore, further exploration is required to detect abnormal finger states in patients and provide appropriate support or reminders. Additionally, because hemiparetic patients cannot freely adjust the posture of their upper limbs like healthy individuals, most patients maintain their arms in a forward position. This results in a partial mismatch between the current wearing scheme and the condition of the patients’ affected limbs, leading to interference between the actuators and the patients’ arms.

In this study, the human-machine interaction strategy we designed is only suitable for patients in stages 3-5. This is because patients in earlier stages have higher finger muscle tone and cannot perform finger extension and flexion movements. Therefore, there are still significant limitations to the human-machine interaction strategy based on finger movements.

In summary, there are numerous challenging issues to be addressed in the research of wearable supernumerary robotic limbs, including the structural design of soft actuators, perception modeling, interaction force control, human-machine interaction strategies for wearable robotic limbs, and wearable scheme design. These challenges warrant continuous exploration by researchers in the field of wearable robotics.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work is supported by the National Natural Science Foundation of China under Grant U1913207 and by the Program for HUST Academic Frontier Youth Team. The authors would like to thank the support from these foundations.

Materials

| Air Compressor | Xinweicheng | F35L-JJ-24V | Provide air supply for the pneumatic gripper |

| Arduino | Emakefun | Mega 2560 | Single-chip microcomputer/data acquisition card |

| Backpack | Mujin | Integrating external devices | |

| Flex Sensor | Spectra Symbol | Flex Sensor 2.2 | Flexible bending sensors |

| Power supply | Yisenneng | YSN-37019200 | Provide power |

| PU quick-plug connector | Elecall | PU-6 | Connector for PU tube |

| PU tube | Baishehui | ZDmJKJJy | Air line connection |

| Silicone elastomer | Wacker | ELASTOSIL M4601 A/B | Material of the pneumatic gripper |

| Thermostatic chamber | Ruyi | 101-00A | Constant temperature to accelerate the curing of silicone |

| Vacuum dryer | Fujiwara | PC-3 | Further defoaming |

| Vacuum mixing and degassing machine | Smida | TMV-200T | Mix silicone thoroughly and get it defoamed |

| Valve | SMC | NTV1030-312CL | Control the air pressure |

References

- Feigin, V. L., et al. Global, regional, and national burden of stroke and its risk factors, 1990-2019: A systematic analysis for the global burden of disease study 2019. The Lancet Neurology. 20 (10), 795-820 (2021).

- Nakayma, H., Jørgensen, H. S., Raaschou, H. O., Olsen, T. S. Compensation in recovery of upper extremity function after stroke: The copenhagen stroke study. Archives of Physical Medicine and Rehabilitation. 75 (8), 852-857 (1994).

- Faria-Fortini, I., Michaelsen, S. M., Cassiano, J. G., Teixeira-Salmela, L. F. Upper extremity function in stroke subjects: Relationships between the international classification of functioning, disability, and health domains. Journal of Hand Therapy. 24 (3), 257-265 (2011).

- Al-Fahaam, H., Davis, S., Nefti-Meziani, S., Theodoridis, T. Novel soft bending actuator-based power augmentation hand exoskeleton controlled by human intention. Intelligent Service Robotics. 11, 247-268 (2018).

- Thalman, C. M., Hsu, J., Snyder, L., Polygerinos, P. IEEE International Conference on Robotics and Automation (ICRA). , 8436-8442 (2019).

- Miron, G., Plante, J. S. Design principles for improved fatigue life of high-strain pneumatic artificial muscles. Soft Robotics. 3 (4), 177-185 (2016).

- Yun, Y., et al. IEEE International Conference on Robotics and Automation (ICRA). , 2904-2910 (2017).

- Tran, P., Jeong, S., Herrin, K. R., Desai, J. P. Hand exoskeleton systems, clinical rehabilitation practices, and future prospects. IEEE Transactions on Medical Robotics and Bionics. 3 (3), 606-622 (2021).

- Ort, T., Wu, F., Hensel, N. C., Asada, H. H. Dynamic Systems and Control Conference. , (2023).

- Hussain, I., et al. A soft supernumerary robotic finger and mobile arm support for grasping compensation and hemiparetic upper limb rehabilitation. Robotics and Autonomous Systems. 93, 1-12 (2017).

- Yang, B., Huang, J., Chen, X., Xiong, C., Hasegawa, Y. Supernumerary robotic limbs: A review and future outlook. IEEE Transactions on Medical Robotics and Bionics. 3 (3), 623-639 (2021).

- Tong, Y., Liu, J. Review of research and development of supernumerary robotic limbs. IEEE/CAA Journal of Automatica Sinica. 8 (5), 929-952 (2021).

- Yap, H. K., et al. A magnetic resonance compatible soft wearable robotic glove for hand rehabilitation and brain imaging. IEEE Transactions on Neural Systems and Rehabilitation Engineering. 25 (6), 782-793 (2016).

- Yun, S. S., Kang, B. B., Cho, K. J. Exo-glove pm: An easily customizable modularized pneumatic assistive glove. IEEE Robotics and Automation Letters. 2 (3), 1725-1732 (2017).

- Polygerinos, P., et al. IEEE International Workshop on Intelligent Robots and Systems (IROS). , 1512-1517 (2013).

- Stilli, A., et al. IEEE International Conference on Soft Robotics (RoboSoft). , 579-584 (2018).

- Zhang, D., et al. Making sense of spatio-temporal preserving representations for eeg-based human intention recognition. IEEE Transactions on Cybernetics. 50 (7), 3033-3044 (2019).

- Sirintuna, D., Ozdamar, I., Aydin, Y., Basdogan, C. IEEE International Workshop on Robot and Human Communication (ROMAN). , 1280-1287 (2020).

- Mahmud, S., Lin, X., Kim, J. H. 2020 10th Annual Computing and Communincation Workshop and Conferenece (CCWC). , 0768-0773 (2020).

- Asghar, A., et al. Review on electromyography based intention for upper limb control using pattern recognition for human-machine interaction. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine. 236 (5), 628-645 (2022).

- Naghdi, S., Ansari, N. N., Mansouri, K., Hasson, S. A neurophysiological and clinical study of brunnstrom recovery stages in the upper limb following stroke. Brain Injury. 24 (11), 1372-1378 (2010).

- Ru, H., Huang, J., Chen, W., Xiong, C. Modeling and identification of rate-dependent and asymmetric hysteresis of soft bending pneumatic actuator based on evolutionary firefly algorithm. Mechanism and Machine Theory. 181, 105169 (2023).

- Qin, L., Wu, W., Tian, Y., Xu, W. Lidar filtering of urban areas with region growing based on moving-window weighted iterative least-squares fitting. IEEE Geoscience and Remote Sensing Letters. 14 (6), 841-845 (2017).

- Liu, S., et al. A two-finger soft-robotic gripper with enveloping and pinching grasping modes. IEEE/ASME Transactions on Mechatronics. 26 (1), 146-155 (2020).

- Tawk, C., Sariyildiz, E., Alici, G. Force control of a 3D printed soft gripper with built-in pneumatic touch sensing chambers. Soft Robotics. 9 (5), 970-980 (2022).

- Zuo, W., Song, G., Chen, Z. Grasping force control of robotic gripper with high stiffness. IEEE/ASME Transactions on Mechatronics. 27 (2), 1105-1116 (2021).

- Watanabe, T., Morino, K., Asama, Y., Nishitani, S., Toshima, R. Variable-grasping-mode gripper with different finger structures for grasping small-sized items. IEEE Robotics and Automation Letters. 6 (3), 5673-5680 (2021).