Production of Disulfide-stabilized Transmembrane Peptide Complexes for Structural Studies

Summary

Biophysical and biochemical studies of interactions among membrane-embedded protein domains face many technical challenges, the first of which is obtaining appropriate study material. This article describes a protocol for producing and purifying disulfide-stabilized transmembrane peptide complexes that are suitable for structural analysis by solution nuclear magnetic resonance (NMR) and other analytical applications.

Abstract

Physical interactions among the lipid-embedded alpha-helical domains of membrane proteins play a crucial role in folding and assembly of membrane protein complexes and in dynamic processes such as transmembrane (TM) signaling and regulation of cell-surface protein levels. Understanding the structural features driving the association of particular sequences requires sophisticated biophysical and biochemical analyses of TM peptide complexes. However, the extreme hydrophobicity of TM domains makes them very difficult to manipulate using standard peptide chemistry techniques, and production of suitable study material often proves prohibitively challenging. Identifying conditions under which peptides can adopt stable helical conformations and form complexes spontaneously adds a further level of difficulty. Here we present a procedure for the production of homo- or hetero-dimeric TM peptide complexes from materials that are expressed in E. coli, thus allowing incorporation of stable isotope labels for nuclear magnetic resonance (NMR) or non-natural amino acids for other applications relatively inexpensively. The key innovation in this method is that TM complexes are produced and purified as covalently associated (disulfide-crosslinked) assemblies that can form stable, stoichiometric and homogeneous structures when reconstituted into detergent, lipid or other membrane-mimetic materials. We also present carefully optimized procedures for expression and purification that are equally applicable whether producing single TM domains or crosslinked complexes and provide advice for adapting these methods to new TM sequences.

Introduction

This protocol details a procedure we have developed to produce disulfide-stabilized complexes of transmembrane (TM) peptides for structural studies using solution NMR. The procedure takes advantage of the robust expression afforded by the ΔtrpLE1413 fusion system (see below) and allows TM peptide complexes of defined composition to be generated using sophisticated stable-isotope labeling techniques for modern multi-dimensional NMR experiments. We have employed these techniques to determine several NMR structures that revealed important new information about how lymphocyte-activating immunoreceptors are assembled from multiple membrane protein subunits through interactions among their TM domains (recently reviewed in 1). These techniques are applicable to many other membrane protein systems as well as a wide range of downstream analytical methods in addition to solution NMR. While the example given here utilizes native cysteine residues to create a complex that mimics the naturally disulfide-bonded protein, the design is equally well suited for creating engineered disulfide bonds to stabilize complexes that are normally held together by weaker, non-covalent interactions such as homo- and hetero-dimeric TM complexes of epidermal growth factor receptor (EGFR)-family proteins2-4 or heterodimeric αβ integrin complexes5,6.

Extremely hydrophobic peptide sequences such as those derived from the lipid bilayer-spanning portions of TM proteins are exceedingly difficult subjects for biochemical and biophysical studies. In addition to being very challenging to manipulate using standard protein and peptide chemistry techniques, they are often quite toxic to cells and are therefore difficult to produce recombinantly. We7,8 and others9-11 have had significant success expressing such difficult peptide sequences in bacteria as in-frame carboxy-terminal fusions to a modified version of the ΔtrpLE1413 sequence derived from the E. coli trp operon12. The ~13 kDa trpLE polypeptide encoded by this sequence can be produced at high levels under a T7 promoter and is entirely localized to inclusion bodies where problems relating to toxicity and/or instability are circumvented. Modification of the sequence by addition of an amino-terminal 9-histidine tag13 and elimination of internal methionine and cysteine residues from the trpLE sequence14 allowed trpLE-peptide fusions to be purified by metal-ion affinity chromatography and digested using cyanogen bromide (CNBr) to release the desired peptide sequence. We have successfully used this system to express more than a dozen different sequences as trpLE fusions representing membrane protein fragments that contain as many as four TM domains (7,8 and unpublished results; see also DISCUSSION section).

The key innovation in this protocol is the identification of conditions under which the unstructured and very poorly soluble trpLE-TM fusions can be efficiently disulfide-crosslinked in the context of a streamlined workflow. Several aspects of high-yield expression, handling and purification of peptide products have also been thoroughly optimized, and the recommendations presented here are equally relevant for production of non-disulfide-crosslinked (monomeric) TM peptide products.

Protocol

1. Cloning and Construct Design

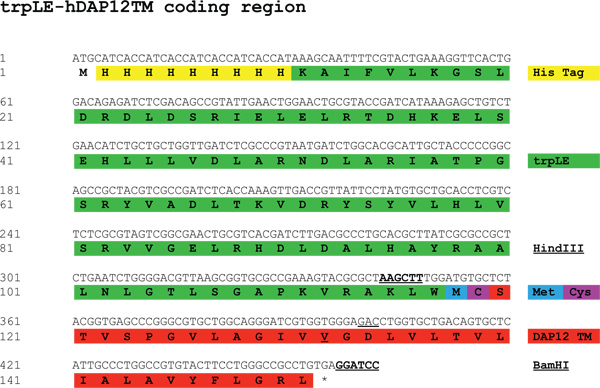

Clone the sequences of interest into the pMM-peptide vector (which can be provided on request) using HindIII and BamHI restriction sites (see Figure 1). The double-stranded DNA insert should incorporate, in the following order: a HindIII site; a single methionine codon for CNBr cleavage; the E. coli codon-optimized peptide coding sequence; a stop codon; a BamHI site. All other methionines in the peptide should be eliminated and the dipeptide sequence asp-pro should be avoided as it will also be cleaved in acidic conditions.

A unique cysteine residue should be introduced into each peptide sequence according to the desired positioning of the disulfide crosslink in the final complex, and all other cysteines should be mutated to serine. The plasmid carries a kanamycin resistance cassette for selection.

2. Expression of trpLE-peptide Fusion

- Make up and sterile filter M9/Kan minimal growth medium (0.1 mM CaCl2, 2 mM MgSO4, 3 g/L KH2PO4, 7.5 g/L Na2HPO4·2H2O, 0.5 g/L NaCl, 1 g/L NH4Cl, 4 g/L glucose, 50 mg/L kanamycin sulfate). Supplement with Centrum Complete A to Zinc to provide B-vitamins and trace metals: dissolve 1 tablet in 40 ml H2O with mixing for 30 min, centrifuge to remove insoluble material and sterile filter the orange supernatant. Store stock solution at 4 °C in the dark for up to 2 weeks and use 4 ml/L in M9.

NOTE: 15N-enriched NH4Cl, 13C-enriched glucose or other stable-isotope-labeled precursors may be included in M9 medium at this stage if desired. - Inoculate a 100 ml starter culture from freshly transformed BL21(DE3) strain E. coli in M9/Kan medium. Grow overnight at 37 °C with shaking at 200 rpm.

- The next morning, check the OD600 of the starter culture – this should be in the range of 2 or greater. Dilute the 100 ml starter culture into 1 L total volume of Centrum-supplemented M9 medium. Split into two 2 L baffled flasks (500 ml culture in each flask) and grow at 37 °C shaking at 140 rpm until the OD600 reaches 0.6.

- Set the shaker temperature to 18 °C and continue shaking for 1 hr, allowing cultures to cool completely before induction.

- Take a pre-induction sample for SDS-PAGE analysis (equivalent of 50 μl from a culture at OD600 = 1), then add IPTG to 0.1 mM final concentration to induce expression of the trpLE-peptide fusion. Continue growing at 18 °C/140 rpm overnight (16-20 hr) under IPTG induction.

3. Inclusion Body Preparation and Nickel Matrix Binding

- The final OD600 of overnight expression cultures in minimal medium is variable and should be between 2.5 and 5.0. Take a sample for SDS-PAGE analysis (equivalent of 50 μl from a culture at OD600 = 1) and collect cells by centrifugation for 20 min at 5,000 x g.

- Resuspend cell pellet from 1 L culture in 50 ml lysis buffer (50 mM Tris-HCl pH 7.5, 20 mM β-ME, 0.2 M NaCl). Cell suspensions can be stored frozen for later processing.

- Lyse cells by sonication on ice at maximum output for 1 min and rest on ice for 5 min. We use a Misonix Sonicator 3000 (max output 600 watts) with a ½-inch high-intensity replaceable tip. Repeat sonication/cooling for three cycles.

- Collect insoluble inclusion body (IB) material by centrifugation for 15 min at 20,000 x g and discard the supernatant. A loose, thin layer of lighter-colored cell debris may be visible on top of the dense IB pellet; this can be washed away using water or buffer with gentle agitation. Steps 3.3 and 3.4 may be repeated to improve the purity of the IB fraction if desired. Samples of pellet and supernatant material should be taken for SDS-PAGE analysis to confirm trpLE-TM fusion localisation to inclusion bodies.

- Dissolve IB pellets in guanidine solution (6 M guanidine HCl, 50 mM Tris-HCl pH 8.0, 200 mM NaCl, 1% Triton X-100, 5 mM β-ME), using 25-50 ml per liter of culture processed. This step will require several hours with agitation and occasional mild sonication.

- Clear the IB lysate by centrifugation for 1 hr at 75,000-100,000 x g and 20 °C. Decant the supernatant and filter through a 0.2 μm membrane.

- Combine the cleared IB lysate, in a 50 ml conical tube or a larger vessel that can be closed securely, with nickel affinity resin that has been washed with water and equilibrated to guanidine solution. Use 3-4 ml settled resin per liter of culture processed for fusions that express to a similar degree as trpLE-DAP12TM shown here (Figure 3, lane 2). Batch bind by incubating overnight at room temperature with gentle mixing.

4. On-column Oxidative Crosslinking

- Load the IB lysate/nickel resin suspension into an empty gravity flow column with porous bed support, adding continuously until the entire volume flows through. Collect and put aside the flowthrough, which may still contain unbound fusion protein.

- Wash the nickel resin by gravity flow with 5 bed volumes of urea solution (8 M urea, 50 mM Tris-HCl pH 8.0, 200 mM NaCl) containing 5 mM β-ME.

- Wash the nickel resin again with 5 bed volumes of urea solution without β-ME.

- Wash the nickel resin a third time with 5 bed volumes of urea solution that has been supplemented with 20 μM CuSO4 and 2 mM oxidized glutathione. After this wash, close the column outlet and incubate 30 min at room temperature to allow maximal disulfide bond formation.

5. TFA Elution and Quantitation

CAUTION: Trifluoroacetic acid (TFA) causes severe burns on contact with skin and fumes are highly irritating. Concentrated TFA should be used only in an approved chemical fume hood with eye protection and non-latex gloves. Check the chemical compatibility of all materials used; polypropylene is compatible with all steps of this protocol.

- Wash out the oxidizing urea solution with 10 bed volumes of water and dry the column bed by applying a vacuum line to the column outlet.

- Close the column outlet and add 1.5 bed volumes of neat (99-100%) TFA. Stir the nickel resin with a small spatula to ensure even exposure to acid and incubate for 5 min. Open the column outlet and collect the acid eluate, pressurizing gently with a syringe or compressed air line if necessary to push out all of the liquid.

- Repeat the acid elution step with another 1.5 bed volumes of neat TFA. Work quickly at this step to avoid complete dissolution of the beaded agarose matrix. Protein yield can be determined at this point according to the Beer-Lambert equation and the theoretical molar extinction coefficient of the trpLE-peptide sequence. Dilute a sample of the TFA eluate (1:20 to 1:50) in trifluoroethanol (TFE) and measure the absorbance at 280 nm, using TFA/TFE at the same dilution as a blank.

6. CNBr Digestion

CAUTION: Cyanogen bromide (CNBr) is extremely toxic and should be handled only in an approved chemical fume hood. PPE including safety glasses, lab coat and non-latex gloves are absolutely required. CNBr is reactive to moisture and should be brought to room temperature before opening. Contact your institutional safety office for instructions on neutralization/disposal of CNBr-contaminated solutions and materials.

- Dilute the acid eluate to 80% final TFA concentration by dropwise addition of water while mixing gently. If a precipitate forms, add back a small volume (0.5 to 1 ml) of neat TFA until the solution clarifies, then re-correct to 80% with water. Take a 5 μl pre-digest sample for SDS-PAGE analysis, freezing in liquid nitrogen and lyophilizing the sample immediately.

- Add CNBr crystals to approximately 0.2 g/ml, taking care to weigh the toxic chemical safely in closed, pre-weighed tubes or using a balance inside the chemical fume hood. Mix gently until completely dissolved. Flush and seal the reaction vessel under inert gas (nitrogen or argon stream) and incubate 3-4 hr at room temperature, protected from light.

- Take a 5 μl post-digest sample for SDS-PAGE analysis and freeze and lyophilize immediately. Transfer the digest reaction to a regenerated cellulose dialysis cassette or tubing (cellulose acetate will dissolve in concentrated acid) with a molecular weight cutoff of 3.5 kDa or less, according to the size of the expected peptide complex. Dialyze overnight to 4 L of water in the chemical fume hood to reduce the TFA concentration and decompose any unreacted CNBr. Leave room in the dialysis cassette or tubing for a significant increase in volume (as much as two- to three-fold) during overnight dialysis.

- Remove the dialyzed reaction solution with suspended precipitate from the dialysis cassette or tubing (most of the protein will precipitate when the TFA concentration is reduced) and transfer the suspension to 50 ml conical tubes. Freeze and lyophilize to remove water and traces of CNBr/TFA. This step is likely to require several days.

CAUTION: Both the dialyzed digest reaction and the dialysis water should continue to be treated as toxic and handled/disposed with appropriate precautions. - Samples of cultures from pre-induction and harvest stages, inclusion body supernatant and pellet, TFA eluate and CNBr-digested material may be analyzed by SDS-PAGE. Prepare samples by heating to 95 °C in Invitrogen NuPAGE LDS sample buffer. TFA eluate and digest samples should be prepared in both reducing and non-reducing conditions to facilitate product identification and evaluation of oxidative crosslinking.

- Separate the samples on a 12% NuPAGE bis-tris pre-cast acrylamide gel using MES-SDS running buffer for optimal resolution of the smallest digest products.

7. Reversed-phase HPLC Purification of Disulfide-crosslinked Peptide Complexes

- Dissolve up to 100 mg of lyophilized digest products into 2-3 ml neat formic acid and load onto a preparative-scale (21.2 x 150 mm) Agilent ZORBAX SB-300 C3 PrepHT column in solvent A (typically 10-20% acetonitrile or 5-10% isopropanol in water with 0.1% TFA).

- Elute the digest products in a gradient of solvent B (acetonitrile or isopropanol with 0.1% TFA) over at least 5 column volumes. See DISCUSSION for suggestions on the selection of optimal gradient conditions for different peptide sequences.

- Take 50-100 μl samples from each HPLC fraction for SDS-PAGE analysis and freeze and lyophilize immediately. Removal of HPLC solvents is rapid and should be complete in 1-2 hr.

- Prepare lyophilized HPLC samples for SDS-PAGE by heating to 95 °C in Invitrogen NuPAGE LDS sample buffer with no reducing agent. Cool and split each sample evenly into 2 microcentrifuge tubes, adding 100 mM DTT to one of them and re-heating briefly.

- Separate the reduced and non-reduced HPLC samples on a 12% NuPAGE bis-tris pre-cast acrylamide gel with MES-SDS running buffer as above. Small, hydrophobic peptides often do not take up Coomassie stain well and may not run at their expected molecular weights. However, comparison of reduced and non-reduced samples should facilitate identification of the crosslinked peptide products and assessment of purity.

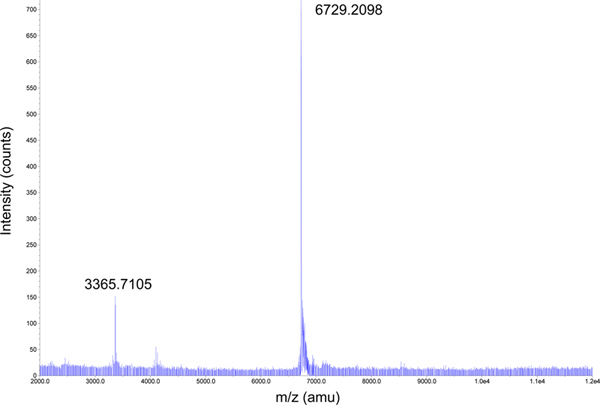

- Analyze the candidate peptide-containing fractions by matrix-assisted laser desorption ionization time-of-flight (MALDI-TOF) mass spectrometry (see DISCUSSION) to identify the species of interest and confirm its expected mass.

- Combine, freeze and lyophilize HPLC fractions containing the pure, crosslinked TM peptide complex and take a dry weight of the final product to determine yield. Fractions with high isopropanol content may not remain frozen. If peptide fractions dry down to a film rather than a fluffy lyophilized product, re-dissolve the film completely in a small volume of pure hexafluoroisopropanol (HFIP), freeze and lyophilize again. The HFIP-treated product should be a small, white cone that is easily tipped out and weighed.

Representative Results

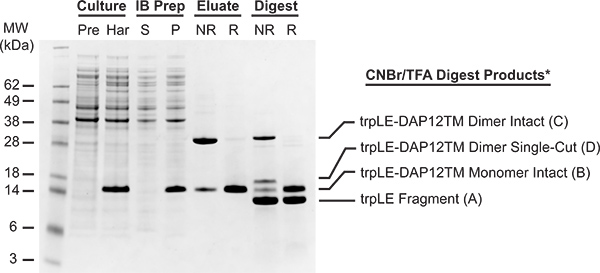

The level of expression achieved for trpLE fusions is variable and heavily dependent on the amino-acid sequence of the attached peptide. Figure 3 shows the SDS-PAGE analysis of pre-induction (lane 1) and time-of-harvest (lane 2) samples from a culture that yielded approximately 120 mg of pure, intact trpLE-DAP12TM fusion from 1 liter of culture and 4 ml nickel matrix. All of the trpLE-DAP12TM fusion was localized to the inclusion body pellet (lane 4) as opposed to supernatant (lane 3).

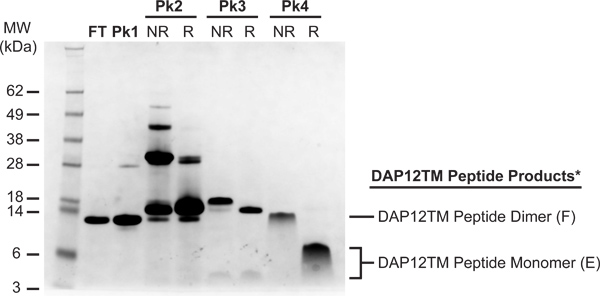

Approximately 70% of the nickel-purified trpLE-DAP12TM fusion was disulfide-crosslinked to the dimeric form (Figure 3, lanes 5 and 6: non-reduced and reduced samples of TFA eluate). This is a typical result for the trpLE-DAP12TM fusion, but crosslinking efficiency will vary with the placement of engineered cysteines. The DAP12TM peptide products are not readily identifiable in total CNBr digest samples (lanes 7 and 8), but comparison of the intact fusion and trpLE fragment bands in the reduced digest sample (lane 8) indicates that digestion of the fusion was ~60% complete.

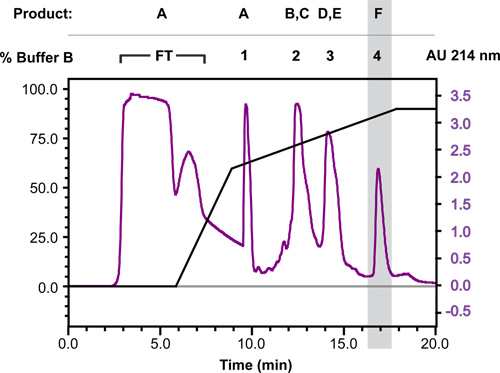

Figure 4 shows the separation of digest products by reversed-phase HPLC using a preparative-scale C3 column (total binding capacity ~200 mg of protein). Because the aromatic content of the fusion is low we typically monitor the absorbance at 214 nm rather than 280 nm. For this run 90 mg of oxidized, CNBr-digested trpLE-DAP12TM fusion was dissolved in 3 ml neat formic acid and loaded onto the column in 100% solvent A (60% H2O, 40% acetonitrile, 0.1% TFA). Bound products were eluted in a two-stage gradient of 0-60% followed by 60-90% solvent B (75% isopropanol, 25% acetonitrile, 0.1% TFA) at a flow rate of 10 ml/min. The major products contained in each fraction according to SDS-PAGE analysis (Figure 5) are indicated above the chromatogram using the codes assigned in Figure 2. See Optimization of HPLC gradient elution in the DISCUSSION section for more details on optimizing gradient conditions for different peptide sequences.

Peptide products are easily identifiable in the SDS-PAGE (Figure 5) and MALDI-TOF (Figure 6) analyses of the major HPLC fractions. DAP12TM peptides and, in our experience, many other hydrophobic TM peptides, run with significantly reduced migration rates compared to their expected molecular weights (3366 Dalton monomer and 6730 Dalton dimer for the 15N-labelled species shown here). This behavior is directly related to the quantity of peptide loaded on the gel and results in a continuum of apparent molecular weights as the amount loaded is varied (data not shown). However, the alteration in electrophoretic mobility of peak 5 upon reduction with 100 mM DTT (compare lanes 7 and 8) identifies this as the crosslinked peptide product. MALDI-TOF MS analysis confirms the identity of the dimeric peptide with the major peak at 6729.2 Daltons and reveals no other major products (Figure 6). The final yield of pure disulfide-crosslinked DAP12TM peptide homodimer from this preparation was 7.5 mg per liter of culture.

Figure 1. DNA sequence of the trpLE-DAP12TM coding region with its amino acid translation. Key regions of the polypeptide sequence are highlighted and color-coded with labels to the right. The unique internal methionine (Met) and cysteine (Cys) residues for cyanogen bromide (CNBr) cleavage and oxidative crosslinking are highlighted in cyan and purple, respectively. HindIII and BamHI restriction sites (bold and underlined) are unique in the plasmid and may be used to replace the TM peptide sequence with another sequence of interest.

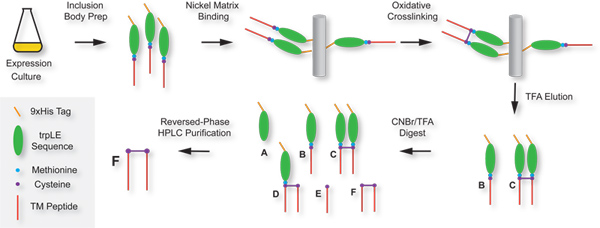

Figure 2. Schematic diagram of the procedure. The major steps in the protocol are indicated in text labels. Key segments of the trpLE-DAP12TM fusion are color-coded as in Figure 1. Major polypeptide products from the crosslinking and digest steps are labeled A-F and are listed here with their description and expected molecular weights (15N-labeled): [A] trpLE fragment: 13,769 Daltons; [B] intact trpLE-DAP12TM fusion: 17,118 Daltons; [C] intact trpLE-DAP12TM fusion dimer: 34,233 Daltons; [D] single-cleaved trpLE-DAP12TM fusion dimer: 20,482 Daltons; [E] monomeric DAP12TM peptide: 3366 Daltons; [F] dimeric DAP12TM peptide: 6730 Daltons. Click here to view larger figure.

Figure 3. SDS-PAGE analysis of trpLE-DAP12TM expression, purification, crosslinking and digest steps. Culture samples (lane 1, pre-induction, step 2.5; lane 2, harvest, step 3.1) and inclusion body prep samples (lane 3, supernatant; lane 4, pellet; step 3.4) were reduced with 100 mM DTT. TFA eluate from nickel column (lanes 5 and 6; step 6.1) and post-CNBr sample (lanes 7 and 8; step 6.3) were run non-reduced (NR) and reduced with 100 mM DTT (R) as indicated to confirm the disulfide-crosslinked products. *Monomeric and dimeric peptide products E and F are poorly visualized by Coomassie staining and therefore are not detectable on this gel.

Figure 4. Reversed-phase HPLC purification of DAP12TM disulfide-crosslinked dimer. Oxidized, CNBr-digested and lyophilized trpLE-DAP12TM fusion products (90 mg) were dissolved in 3 ml formic acid (100%) and loaded onto an Agilent ZORBAX SB-300 C3 PrepHT (21.2 x 150 mm) column in solvent A (60% H2O, 40% acetonitrile, 0.1% TFA). A two-stage gradient of 0-60% followed by 60-90% solvent B (75% isopropanol, 25% acetonitrile, 0.1% TFA) was run at a flow rate of 10 ml/min to elute bound products. Fractions collected as flow-through (FT) and four major peaks are marked above the 214 nm absorbance trace (AU: arbitrary units) and the major products contained in each fraction are indicated using the codes assigned in Figure 2. The desired DAP12TM crosslinked product peak is shaded.

Figure 5. SDS-PAGE analysis of reversed-phase HPLC products. Flow-through (FT) and peak 1 samples were run non-reduced. Peak 2, 3 and 4 samples were run both non-reduced (NR) and reduced by treatment with 100 mM DTT (R) to verify the identity of disulfide crosslinked products. The major products in each fraction (with their codes assigned in Figure 2) were [FT, Pk1]: A, trpLE fragment; [Pk2]: B, intact trpLE-DAP12TM fusion monomer and C, intact fusion dimer; [Pk3]: D, single-cleaved trpLE-DAP12TM dimer and E, monomeric DAP12TM peptide; [Pk4]: F, disulfide-crosslinked DAP12TM dimer. *As discussed (see REPRESENTATIVE REULTS), a concentration-dependent shift in mobility makes the low-MW products in Pk3 (NR and R) and Pk4 (R) appear to be different molecular weights even though both products are monomeric peptide.

Figure 6. MALDI-TOF mass spectrometric analysis of HPLC-purified DAP12TM peptide dimer. A sample of HPLC fraction 4 (1 μl) was mixed 1:1 with a saturated solution of sinapinic acid (SA) matrix in acetonitrile and spotted on top of a thin layer of dried SA matrix from a saturated solution prepared in ethanol. MALDI-TOF analysis reveals a product at the expected DAP12TM peptide crosslinked dimer mass of 6730 Daltons (6729.2098; 15N-labeled) as well as a minor product at 3365.7105, most likely the double-ionized species. Click here to view larger figure.

Discussion

Expression of trpLE-TM fusions. In our experience, trpLE-TM fusions are poorly expressed in rich culture medium at 37 °C, and the culture conditions described here have proven successful for many different sequences containing from one to four TM domains with yields ranging from 50 to 150 mg/L of pure, intact fusion. Fusions encoding three- or four-TM GPCR fragments (human CCR5 TM1-TM3 and TM4-TM7, respectively) or a core catalytic fragment of human signal peptide peptidase (four TM domains; see ref 15) represent the lowest in this range of expression levels, while DAP12TM variants closely related to the sequence used here represent the highest end of the range (unpublished data). The optimal IPTG concentration should be determined experimentally for each new sequence. Our standard is 0.1 mM, and higher concentrations (up to 1 mM) usually result in significantly reduced yield due to both lower expression levels and lower culture density at harvest (see for example Figure 1A in reference7).

Variations on the presented protocol. The protocol outlined here describes the production of a disulfide-crosslinked TM peptide complex, the DAP12TM homodimer8. Alternatively, the protocol is easily adapted to produce monomeric peptides by omitting the two wash steps designed to remove reducing agent and oxidize the bound products (4.3 and 4.4). We have previously used another variation of the procedure reported here to produce a covalently stabilized TM peptide complex representing the trimeric DAP12-DAP12-NKG2C TM assembly (see reference8 and methods described therein). In this application, a 1-TM trpLE-DAP12 fusion and a 2-TM trpLE-DAP12-NKG2C fusion were mixed at the culture harvest stage prior to inclusion body preparation (step 3.1-3.2). The procedure included an extra HPLC step to isolate the heterodimeric crosslinked trpLE fusion product from the acid eluate (step 5.3) before CNBr digest. C3 purification of the peptide products resulted in recovery of a disulfide-crosslinked DAP12TM dimer in which one strand carried the NKG2C TM domain as an in-frame C-terminal fusion. The solution NMR structure of this complex in detergent micelles confirmed that the NKG2C TM domain assembled with DAP12 in its native, anti-parallel orientation8. The extra steps in this variation significantly reduced the yield of the final product: a typical preparation yielded 8-10 mg of peptide “trimer” from 4L of one fusion combined with an excess of the second. This variation represents a good starting protocol for researchers wishing to produce disulfide-stabilized complexes containing two different TM sequences.

Notes on nickel-affinity purification. The elution of protein from the dried nickel column using concentrated acid is an unusual procedure and is not amenable to re-use of the nickel matrix. Attempts to elute the extremely hydrophobic trpLE-TM fusions using imidazole or EDTA resulted in incomplete recovery of protein and the crosslinked species were preferentially retained on the column (unpublished results). The recommended quantity of nickel matrix and the overnight batch-binding protocol have been carefully optimized to saturate the matrix with trpLE-TM protein and thereby minimize the co-purification of contaminants. We routinely recover very pure products with yields that significantly exceed the advertised binding capacity of the Sigma HIS-Select Nickel Affinity Matrix (15-20 mg/ml resin). The acid elution also eliminates intermediate steps required to transition into the CNBr digest, and the increased yield of crosslinked products more than offsets the cost of the nickel matrix, particularly when labeling with expensive stable-isotope reagents for NMR.

Cyanogen bromide digest conditions. Release of the fused TM peptides from trpLE in CNBr is commonly performed using 70% formic acid as the solvent because both the reaction rate and protein solubility are highly favorable under these conditions. However, treatment times must be kept comparatively short (under 1 hr for digest) to avoid formyl esterification of serine and threonine residues16,17 and possibly I-formylation of tryptophan residues18, modifications which are detectable by mass spectrometry as species whose observed mass is +28(n) Daltons relative to the expected mass. Our preference for TFA as described here avoids these modifications altogether. Enzymatic cleavage of a trpLE-TM fusion using factor Xa protease in 1% Triton X-100 has been reported11, but the poor solubility of most trpLE-TM fusions and the complication of cleavage site inaccessibility in detergent micelles probably limit the general utility of this approach.

Reversed-phase HPLC purification of peptide products from the CNBr digest is the most challenging step in this procedure and is likely to require optimization for each new trpLE-TM sequence. The following observations come from processing many different sequences and are likely to hold true for most trpLE-TM fusions:

Selection of stationary phase. We find Agilent ZORBAX Stable-Bond C3 columns (300 Å pore size; 5 μm particle size) to be a superior stationary phase in terms of selectivity, resolving power and stability under heavy exposure to concentrated acid. Semi-preparative (9.4 mm diameter) and preparative-scale (21.2 mm diameter) sizes are available and have performed very well in our hands. C4, diphenyl and cyanopropyl stationary phases may also provide useful alternative peptide selectivity in a similar hydrophobicity range compared to C3.

Preparation of digest products for HPLC. Dissolution of lyophilized CNBr digest products in neat formic acid provides the best results for HPLC separation. Preparation in TFA or organic solvents such as acetonitrile, trifluoroethanol and dimethylformamide often results in lower solubility, reduced column binding and/or elution of products in broad peaks containing multiple species. Care must be taken to prepare products in formic acid immediately before column loading because prolonged exposure can result in formyl modification of peptide sidechains16-18 as discussed above.

Optimization of HPLC gradient elution. We usually begin with 10-20% acetonitrile or 5-10% isopropanol in water with 0.1% TFA as solvent A. TrpLE-TM fusions and their digest products dissolved in formic acid will bind the C3 column in as much as 40% acetonitrile as shown here (Figure 4). Much of the liberated trpLE fragment may flow through under these conditions (Note that trpLE fragment is the only protein product in the FT fraction: Figure 5, lane 1), and we have taken advantage of this observation to increase the overall binding capacity of the column for the desired products. Acetonitrile and isopropanol are very effective as gradient solvents, and we often arrive at our final gradient conditions by mixing pre-existing solvent solutions to modify elution profiles, resulting in sometimes odd but effective recipes such as the 75% isopropanol, 25% acetonitrile, 0.1% TFA solution used as solution B for the DAP12TM purification shown here. Extremely hydrophobic products that were problematic have been eluted using acetonitrile or isopropanol with addition of up to 10% trifluoroethanol (TFE) and increased concentrations of TFA (up to 0.3%) in both A and B (unpublished results). Others have reported good results using butanol/acetic acid mobile phases with a C4 stationary phase9.

Analysis of digest products. Both of the major analysis techniques used here, SDS-PAGE and MALDI-TOF MS, can be complicated by the extremely hydrophobic nature of trpLE-TM products. Lyophilized analytical samples from CNBr/TFA digest reactions and HPLC fractions sometimes run as high-molecular-weight aggregates on SDS-PAGE gels. We find that treatment of lyophilized samples with a small volume of HFIP and re-lyophilization before preparation for SDS-PAGE often remedies this problem. TM peptide sequences also may not readily ionize during MALDI-TOF MS analysis, and can therefore give very weak signals. We have used an optimized procedure for preparing TM peptide samples in which a saturated solution of sinapinic acid (SA) in ethanol is first spotted on the plate and dried to make a uniform thin layer of matrix. A sample of peptide-containing HPLC fraction mixed 1:1 with a saturated solution of SA in acetonitrile is then spotted on top of the dried matrix layer. In our hands, this method yields between two- and six-fold greater signal-to-noise compared to spotting the peptide:SA mixture directly onto a clean MALDI plate.

Downstream applications. Methods for reconstituting TM peptide complexes into lipid or detergent systems for solution NMR and other downstream applications vary widely and must usually be carefully tailored for each new system and application. A full discussion of the parameters involved is therefore well beyond the scope of this protocol article. For details of sample preparation from successful applications using solution NMR, we refer the reader to these recent reviews on the topic1,19 and references therein.

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

Funding for this work is provided by the National Health and Medical Research Council of Australia (NHMRC project grant 1011352 to M.E.C and M.J.C.; Independent Research Institutes Infrastructure Support Scheme [IRIISS] grant to WEHI) and the Victorian Government (VESKI Innovation Fellowship to M.E.C.; Victorian State Government Operational Infrastructure Support to WEHI). M.E.C. is a Queen Elizabeth II Fellow of the Australian Research Council. E.F.X.B acknowledges support from the Norma Hilda Schuster Scholarship Program at the University of Melbourne.

Materials

| Name of Reagent/Material | Company | Catalogue Number | Comments |

| Cyanogen bromide | ALDRICH | P.No- C91492,CAS-506-68-3 | HAZARDOUS SUBSTANCE. DANGEROUS GOODS. Very toxic by inhalation, in contact with skin and if swallowed. Contact with acids liberates very toxic gas. Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment. |

| Trifluoroacetic acid | SIGMA-ALDRICH | P.CODE-1000984387, CAS Number 76-05-1 | HAZARDOUS SUBSTANCE. DANGEROUS GOODS., Causes severe burns. Harmful by inhalation. Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. |

| 2-Mercaptoethanol | SIGMA-ALDRICH | P.No M7154, CAS Number 60-24-2 | HAZARDOUS SUBSTANCE. DANGEROUS GOODS. Toxic by inhalation, in contact with skin and if swallowed. Irritating to skin. Risk of serious damage to eyes. May cause sensitization by skin contact. Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment. |

| 1,1,1,3,3,3-Hexafluoro-2-propanol | SIGMA-ALDRICH | Product Number 52512, CAS-No. 920-66-1 | HAZARDOUS SUBSTANCE. DANGEROUS GOODS. Harmful by inhalation and if swallowed. Causes burns. |

| Formic acid | Merck KGaA | K41186564 | Flammable liquid and vapour. Causes severe skin burns and eye damage. |

| Urea | UNIVAR, AJAX FINECHEM | Product Number, 817, CAS-No 57-13-6 | When heated, decomposes to carbon dioxide and ammonia; if burned, emits small amounts of nitrogen oxides. Can cause redness and irritation of skin and eyes. |

| GUANIDINE HYDROCHLORIDE | Amresco | P.No-M110, CAS Number: 50-01-1 | Harmful if swallowed, Causes serious eye irritation,Causes skin irritation, Acute Toxicity Oral, Skin Irritant, Eye Irritant. |

| TRITON X-100 | SIGMA | Product Number- T8532 CAS No: 9002-93-1 | Triton X-100 is a nonionic detergent, 100% active ingredient, which is often used in biochemical applications to solubilize proteins. Triton X-100 has no antimicrobial properties and considered a comparatively mild non-denaturing detergent |

| His-Select Nickel-Affinity gel | SIGMA-ALDRICH | Catalog Num- P6611 | IS-Select Nickel Affinity Gel is an immobilized metal- ion affinity chromatography (IMAC) product. The HIS-Select Nickel Affinity gel is a proprietary quadridentate chelate on beaded agarose charged with nickel that is designed to specifically bind histidine containing proteins. |

| (-)-Glutathione, oxidized | SIGMA-ALDRICH | Catalog num 150568 | |

| Misonix S-3000 sonicator | QSONICA | S-3000 (discontinued) | Max power output 600 watts. 1/2-inch replaceable-tip probe takes 1/2-inch high-intensity, high-volume tips and a range of high-intensity, low-volume tips. Closest models currently available from this company are Q500 and Q700. |

| RP-HPLC: BioLogic DuoFlow chromatography system, Software Version 5.3 | Bio-Rad Laboratories | Catalog Num 760-0047, Config No: AU500571, Serial No: 484BR3705 | Peptides binds to reverse phase HPLC columns in high aqueous mobile phase and are eluted from RP HPLC columns with high organic mobile phase. In RP HPLC peptides are separated based on their hydrophobic character. Peptides can be separated by running a linear gradient of the organic solvent. |

| Prep HT C3 ZORBAX 300SB-Analytical HPLC Column, 21.2 x 150 mm, 5 μm particle size | Agilent | Product No: 895150-909 | Reversed-phase HPLC colum |

| NuPAGE 12% Bis-Tris Gels | Life Technologies | NP0341BOX | Pre cast gels for protein electrophoresis |

| Slide-A-Lyzer G2 Dialysis Cassettes, 3.5K MWCO | Thermo Scientific | Product No: 87724 | Sample dialysis |

Referencias

- Call, M. E., Chou, J. J. A view into the blind spot: solution NMR provides new insights into signal transduction across the lipid bilayer. Structure. 18, 1559-1569 (2010).

- Bocharov, E. V., et al. Spatial structure of the dimeric transmembrane domain of the growth factor receptor ErbB2 presumably corresponding to the receptor active state. The Journal of Biological Chemistry. 283, 6950-6956 (2008).

- Mineev, K. S., et al. Spatial structure of the transmembrane domain heterodimer of ErbB1 and ErbB2 receptor tyrosine kinases. J. Mol. Biol. 400, 231-243 (2010).

- Mineev, K. S., et al. Spatial structure and dimer–monomer equilibrium of the ErbB3 transmembrane domain in DPC micelles. Biochim. Biophys Acta. 1808, 2081-2088 (2011).

- Lau, T. L., Kim, C., Ginsberg, M. H., Ulmer, T. S. The structure of the integrin alphaIIbbeta3 transmembrane complex explains integrin transmembrane signalling. The EMBO Journal. 28, 1351-1361 (2009).

- Zhu, J., et al. The structure of a receptor with two associating transmembrane domains on the cell surface: integrin alphaIIbbeta3. Molecular Cell. 34, 234-249 (2009).

- Call, M. E., et al. The structure of the zetazeta transmembrane dimer reveals features essential for its assembly with the T cell receptor. Cell. 127, 355-368 (2006).

- Call, M. E., Wucherpfennig, K. W., Chou, J. J. The structural basis for intramembrane assembly of an activating immunoreceptor complex. Nat. Immunol. 11, 1023-1029 (2010).

- Diefenderfer, C., Lee, J., Mlyanarski, S., Guo, Y., Glover, K. J. Reliable expression and purification of highly insoluble transmembrane domains. Anal. Biochem. 384, 274-278 (2009).

- Schnell, J. R., Chou, J. J. Structure and mechanism of the M2 proton channel of influenza A virus. Nature. 451, 591-595 (2008).

- Xie, X. Q., Zhao, J., Zheng, H. E. x. p. r. e. s. s. i. o. n. purification, and isotope labeling of cannabinoid CB2 receptor fragment, CB2(180-233). Protein Expr. Purif. 38, 61-68 (2004).

- Miozzari, G. F., Yanofsky, C. Translation of the leader region of the Escherichia coli tryptophan operon. J. Bacteriol. 133, 1457-1466 (1978).

- North, C. L., Blacklow, S. C. Structural independence of ligand-binding modules five and six of the LDL receptor. Bioquímica. 38, 3926-3935 (1999).

- Staley, J. P., Kim, P. S. Formation of a native-like subdomain in a partially folded intermediate of bovine pancreatic trypsin inhibitor. Protein Sci. 3, 1822-1832 (1994).

- Narayanan, S., Sato, T., Wolfe, M. S. A C-terminal region of signal peptide peptidase defines a functional domain for intramembrane aspartic protease catalysis. The Journal of Biological Chemistry. 282, 20172-20179 (2007).

- Klunk, W. E., Pettegrew, J. W. Alzheimer’s beta-amyloid protein is covalently modified when dissolved in formic acid. J. Neurochem. 54, 2050-2056 (1990).

- Klunk, W. E., Xu, C. J., Pettegrew, J. W. NMR identification of the formic acid-modified residue in Alzheimer’s amyloid protein. J. Neurochem. 62, 349-354 (1994).

- Previero, A., Coletti-Previero, M. A., Cavadore, J. C. A reversible chemical modification of the tryptophan residue. Biochim. Biophys. Acta. 147, 453-461 (1967).

- Kim, H. J., Howell, S. C., Van Horn, W. D., Jeon, Y. H., Sanders, C. R. Recent Advances in the Application of Solution NMR Spectroscopy to Multi-Span Integral Membrane Proteins. Prog. Nucl. Magn. Reson. Spectrosc. 55, 335-360 (2009).