Dielectric RheoSANS — Simultaneous Interrogation of Impedance, Rheology and Small Angle Neutron Scattering of Complex Fluids

Summary

Here, we present a procedure for the measurement of simultaneous impedance, rheology and neutron scattering from soft matter materials under shear flow.

Abstract

A procedure for the operation of a new dielectric RheoSANS instrument capable of simultaneous interrogation of the electrical, mechanical and microstructural properties of complex fluids is presented. The instrument consists of a Couette geometry contained within a modified forced convection oven mounted on a commercial rheometer. This instrument is available for use on the small angle neutron scattering (SANS) beamlines at the National Institute of Standards and Technology (NIST) Center for Neutron Research (NCNR). The Couette geometry is machined to be transparent to neutrons and provides for measurement of the electrical properties and microstructural properties of a sample confined between titanium cylinders while the sample undergoes arbitrary deformation. Synchronization of these measurements is enabled through the use of a customizable program that monitors and controls the execution of predetermined experimental protocols. Described here is a protocol to perform a flow sweep experiment where the shear rate is logarithmically stepped from a maximum value to a minimum value holding at each step for a specified period of time while frequency dependent dielectric measurements are made. Representative results are shown from a sample consisting of a gel composed of carbon black aggregates dispersed in propylene carbonate. As the gel undergoes steady shear, the carbon black network is mechanically deformed, which causes an initial decrease in conductivity associated with the breaking of bonds comprising the carbon black network. However, at higher shear rates, the conductivity recovers associated with the onset of shear thickening. Overall, these results demonstrate the utility of the simultaneous measurement of the rheo-electro-microstructural properties of these suspensions using the dielectric RheoSANS geometry.

Introduction

Measurement of macroscopic properties are often used to gain fundamental insight into the nature of colloidal materials and self-assembled systems, usually with the goal of developing understanding in order to improve formulation performance. In particular, the field of rheology, which measures a fluid's dynamic response to an applied stress or deformation, provides valuable insight into colloidal behavior both under equilibrium conditions and also far from equilibrium, such as during processing1 Rheological tests of consumer and industrial fluids, gels, and glasses can also be used to measure rheological parameters, such as viscosity, that are targeted by formulators. While rheology is a powerful probe of material properties, it is an indirect measurement of colloidal information at the microscopic level, such that our understanding of fundamental colloidal behavior can be greatly enhanced by combining rheological measurements with complementary techniques.

One such orthogonal technique is impedance spectroscopy. Impedance spectroscopy is a bulk probe of dielectric relaxation behavior, which measures the response of a material to an applied oscillating electric field.2 The impedance spectrum results from electrical relaxation modes that are active within the material including charge transport and polarization.3,4 These measurements provide additional evidence for colloidal behavior particularly when combined with rheology.5 Therefore, the combination of these techniques is especially relevant when probing charged colloidal dispersions, proteins, ionic surfactants, nanocomposites, and other systems.6,7

A fundamental interest in investigations of colloidal behavior is the material's microstructure. The microstructure of a colloidal fluid is thought to encode all of the information necessary to reconstitute both its rheological and electrical behavior. Fundamentally, we seek to measure a snapshot of the nanoscale microstructural features that lead to a measured material response. Due to the complicated nature of many complex fluids' dependence on their process history, much of the effort on microstructural characterization has focused on making in situ measurements of the material as it undergoes deformation. This has challenged experimentalists to devise methods to be able to make measurements of nano-sized particles under for example steady shear, where the velocities of the particles have made direct visualization intrinsically challenging. Direct measurement of material microstructure under flow has taken on many forms ranging from rheo-optics, rheo-microscopy and even rheo-NMR.8,9,10 Small angle scattering methods, and in particular small angle neutron scattering (SANS) techniques, have proven themselves effective at measuring the time-averaged microstructure of samples at steady state in a bulk shear field including all three planes of shear.11,12,13 However, new data acquisition techniques have allowed structural transients to be captured with time resolution as fine as 10 ms.14 Indeed combining rheology with various in situ scattering methods has proven invaluable in hundreds of recent studies.15

An emerging engineering challenge is the use of colloidal suspensions as conductive additives in semi-solid flow battery electrodes.16 In this application, conductive colloidal particles must maintain an electrically percolated network while the material is pumped through an electrochemical flow cell. The performance demands on these materials require that they maintain high conductivity without detrimental effect on the rheological performance over a wide range of shear rates.17 It is therefore highly desirable to be able to make measurements of the colloidal behavior under steady and time-dependent shear conditions in order to quantify and characterize the underlying rheological and electrical response of these materials far from their equilibrium state. A significant complicating factor that has hindered further theoretical development in this regard is the thixotropic nature of carbon black slurries.18 These history dependent rheological and electrical properties make experiments notoriously difficult to reproduce; thus, making it difficult to compare data sets measured using varying protocols. Furthermore, to date there is no single geometry capable of performing all three, dielectric, rheological, and microstructural characterizations, simultaneously. Simultaneous measurement is important as the flow can change the structure, such that rest measurements of processed materials may not provide accurate indications of the properties under flow, which are more relevant for their use. Additionally, as many of the measured properties of carbon black slurries are geometry dependent, there are complications with comparing data obtained from the same sample on different instruments.19

In order to meet this challenge in metrology, we have developed a new dielectric RheoSANS geometry at the NIST Center for Neutron Research and the University of Delaware capable of in situ impedance spectroscopy, rheology and SANS measurements of a material under arbitrary deformation on a commercial strain controlled rheometer. This is enabled by developing a Couette geometry capable of measuring the microstructural, electrical and rheological response of a material confined between the gap of two concentric cylinders. As the outer cylinder spins, torque imposed by the deformation of the sample is measured on the inner cylinder and the impedance measurement is made radially across the gap. The cylinders are machined from titanium so as to be transparent to neutrons and robust enough to withstand the shear stress experienced in the rheometer. We perform the SANS measurement through the radial position of the Couette, and have demonstrated that it is possible to measure high quality SANS patterns from the sample undergoing deformation. In this way, all three measurements are made on the same region of interest in the sample as it undergoes a well-defined deformation profile. The goal of this article is to describe the dielectric Couette geometry, its installation onto the RheoSANS instrument, and the successful execution of a simultaneous measurement. This rheometer is available at the NIST Center for Neutron Research at the National Institute of Standards and Technology. It has been designed to work on the NG-7 SANS beam line. We have provided drawings and a detailed description of the custom components that have been machined and assembled in order to enable this measurement.

Protocol

1. Mounting the Rheometer onto the SANS Beamline

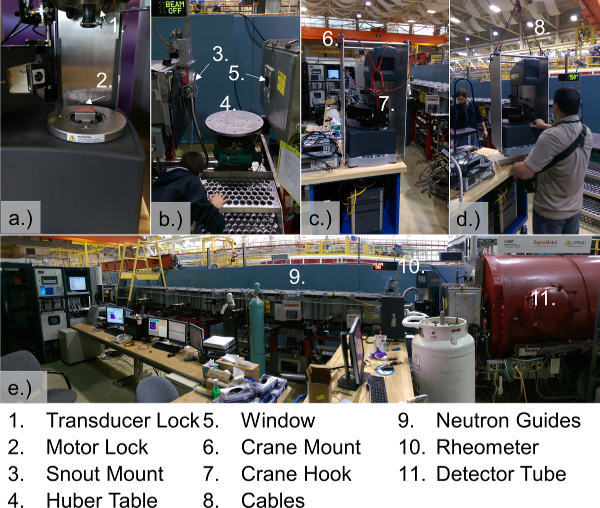

NOTE: See Figure 1 for definitions of named components.

- Ensure that the power to the rheometer is off, the transducer is locked and the motor air bearing protector is installed. Turn off the neutron beam, and close the oven door.

- Install the large base plate onto the table, remove the snout, install the window, and secure the 4 eyelets to the mounting brackets on the rheometer's crane adapter such that the cables do not tangle and are not twisted.

- Using the crane, lift the rheometer and maneuver it from the rheometer table to rest centered on the table with the LCD screen of the rheometer facing outward, taking care to guide the cables to minimize tangling.

- Using the SANS control software, send the table to the minimum Z position.

- Remove the rheometers' crane adapter and lift away from the platform using the crane.

2. Dielectric Cell Assembly

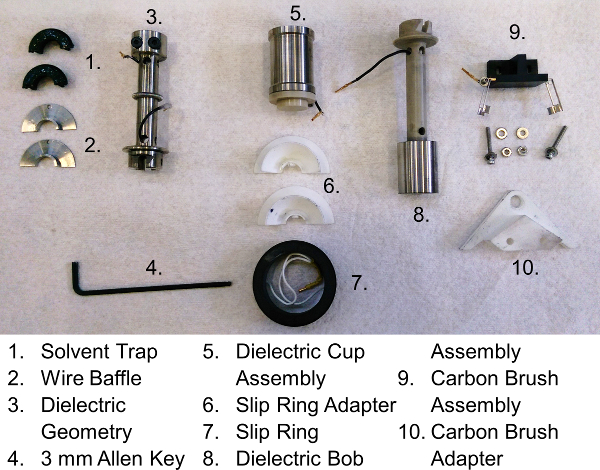

NOTE: See Figure 2 for definitions of named components.

- Ensure that the power to the rheometer is off, the transducer is locked and the motor air bearing protector is installed. Before use, clean the dielectric cup and bob assemblies using detergent solution followed by several deionized water rinses, and allow to fully dry.

- Open the oven door, unlock the transducer and remove the motor bearing lock. Mount the dielectric geometry and dielectric bob assembly onto the upper and lower tool mounts of the rheometer. Loosen both set screws on the dielectric geometry using a 2-mm Allen key and place the dielectric cup assembly so that it is mounted on the dielectric geometry.

- Using the rheometer control software, zero the gap from the sample geometry drop-down menu, and apply 10 N normal force using the axial force drop-down menu. Under compression, tighten screws using a 3-mm Allen key until the dielectric cup assembly is fully secured to the dielectric geometry.

- Set the gap to the measurement gap using the rheometer control software, and close the oven door. Ensure that the oven can fully enclose the dielectric cell with adequate vertical clearance on the top and bottom of the geometry. If a height adjustment is needed, adjust the set screw so that the oven enclosure fits with adequate tolerance around the dielectric cell. Adequate clearance is achieved when the dielectric geometry fits within the oven and can undergo a full revolution without touching the oven walls.

- Remove both the dielectric bob assembly and the dielectric cup assembly/dielectric geometry as one piece and replace with the rheometer alignment tool on the lower tool head.

3. Install the Slip Ring

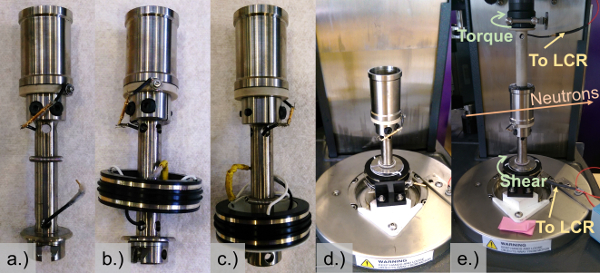

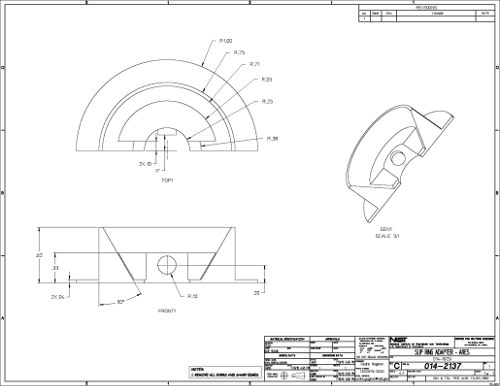

NOTE: See Figure 3 for step-by-step pictorial summary.

- Install the wire baffle onto the shaft of the dielectric geometry and connect the dielectric cup connector to the slip ring connector.

- Hold the slip ring so that it is concentric with the shaft of the dielectric cup assembly/dielectric geometry but above the flange on the dielectric geometry. Place the slip ring adapters (x2) such that their nobs insert into the holes drilled into the dielectric geometry and their base rests on the dielectric geometry flange.

- Gently slide the slip ring over the slip ring adapters. The slip ring should slide effortlessly around the slip ring adapters holding them in place.

4. Alignment of the Rheometer

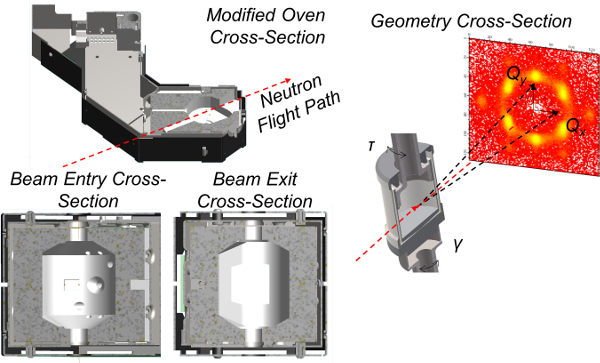

NOTE: See Figure 4 for schematic of beam path.

- Close the oven around the rheometer alignment tool. Install the truncated snout and the sample aperture (1 mm wide × 8 mm tall), and using rheometer control software, set the geometry displacement angle to 0.49 rad in the motor control drop-down menu.

- Using the SANS instrument control software, ensure that all the neutron guides are removed, and open the oven door so that the laser is visible. Perform a rough alignment of the rheometer by changing the height and angle of the table from the SANS instrument control software so that the beam passes through the oven and crosses through the slit in the center of the rheometer alignment tool.

- Using the SANS instrument control software, adjust the height of the table and its rotation to optimize laser alignment. Note the rheometer is aligned when the laser beam passes through the slit in the rheometer alignment tool with the geometry displacement set at 0.49 rad without impinging on its walls and the beam passes through the center line in the oven.

5. Calibration of the SANS Instrument

- Once the desired SANS instrument configuration is aligned by the instrument scientist, measure the open beam transmission, empty cell scattering, and dark current scattering measurements.

- Perform the open beam transmission measurement by performing a beam transmission measurement at the desired detector position for 3 min.

- Perform the empty cell scattering measurement by installing the dielectric geometry and measuring a scattering measurement at the desired detector position.

- Perform the dark current scattering measurement using a 3-mm thick piece of cadmium that totally attenuates the main beam scattering signal.

6. Connecting the Electric Components

- Set the gap using the LCD screen to 100 mm.

- Remove the rheometer alignment tool from the bottom tool flange. Reinstall the dielectric bob assembly on the upper tool head and the dielectric cup assembly/dielectric geometry/slip ring assembly onto the lower tool head as one piece and re-zero the gap.

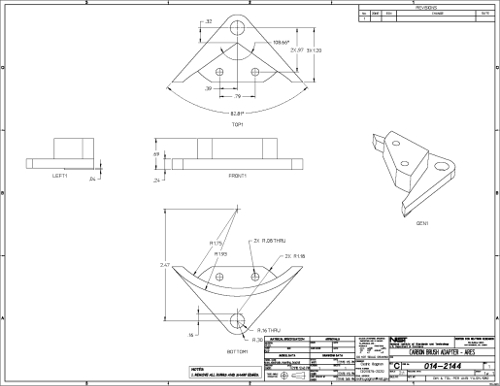

- Ensure that the carbon brush assembly is secured to the carbon brush adapter using screws, and secure the carbon brush adapter and carbon brush assembly to the rheometer using screws. Ensure that the carbon brushes on the carbon brush assembly mate with the grooved metal rings of the slip ring. This ensures maintenance of the electrical contact.

- Connect the female pin connectors on the carbon brush assembly and the dielectric bob assembly to the male pin connectors of the top and bottom bus bars respectively. Ensure that the labeled shielded BNC cables connected to the bus bars and terminating at the LCR meter are installed in their corresponding BNC connectors.

- Connect the BNC cable labeled "TO SANS" to the BNC cable connected to the DAQ card labeled "AO0". Connect the BNC cable labeled "FROM SANS" to the BNC cable connected to the DAQ card labeled "AI0". Connect the BNC cable labeled "TRIGGER" to the BNC cable connected to the DAQ card labeled "AO1". Connect the BNC cable connected to the 15 pin connector on the back of the rheometer to the BNC cable labeled "AI3". Ensure that the LCR meter and rheometer are communicating with the control computer.

7. Preparing the Instrument for a Measurement

- Open the oven, set the gap to 100 mm, and load 4 mL of the carbon black dispersion in propylene carbonate into the temperature equilibrated dielectric cup assembly, taking care to minimize sample left on the cup wall.

- Lower the geometry to 40 mm using the front LCD screen. Set the velocity on the rheometer control software using the motor control settings to 1 rad/s. Using the slew option on the rheometer, lower the dielectric bob assembly until the gap distance is at 0.5 mm.

- Using the equipment software, go to dielectric geometry measurement gap, and set the motor velocity on rheometer control software using the motor control settings to 0 rad/s. At this stage, the sample is loaded.

Note: Check the sample fill level once more to ensure that the sample level fills all the way up the Couette wall without overfilling. - Install the solvent trap by filling the inner dielectric bob assembly wall with the desired solvent and place the solvent trap on the rim of the dielectric cup assembly.

8. Running the Dielectric RheoSANS Experiment

- Configure code labeled "TA_ARES_FlowSweep.vi". A GUI will appear with modifiable fields that specify the experimental run conditions of the dielectric RheoSANS experiment. Set these fields in the following order.

- Specify a path for the log file to and the base name of the log file. Run the code by pressing the "Run" arrow button on the menu bar.

- Select rheological parameters — the starting shear rate (25 rad/s), ending shear rate (1 rad/s), the number of shear rate points (6) and whether the points should be logarithmically or linear spaced (radio button). Select temperature to 25 °C for this experiment. Select preshear conditions (if desired, enable radio button to "ON") — in this experiment, use a 25 rad/s preshear for 600 s with a 300 s wait time after the preshear step.

- Specify time per shear rate and collection rate. Enable handshaking radio button. On test parameters tab select logarithmic or linear sweep — if radio button is green, a list of N number of points will be logarithmically spaced from min shear rate to max shear rate.

- Specify discrete shear rates and times via the "Discrete Values" tab if desired. Select the number of frequency points, the frequency minimum and the frequency maximum default. Set the time dependent frequency — specifies the desired time dependent frequency for all shear rates. Set the time for steady state — sets the amount of time that the code will measure dielectric parameters at a fixed frequency as a function of time for each shear rate.

- Specify the signal type and amplitude. Specify the number of cycles to average and the measurement time.

- Turn on autoLogging on the SANS computer. Set the SANS configuration. Select the configuration and specify the run time to be at least 1 min longer than the total time contained within the shear rate list in the code.

Note: When the configuration is achieved VIPER should read "dio stat 16" which indicates that it will be waiting for the analogue signal from the data acquisition card to change. - Configuring the rheometer control software. In the experiment tab, Press "Open Procedure File" in the "Procedure" drop down menu. Navigate to the procedure file labeled "Dielectric RheoSANS Script File". Ensure that rheometer is ready to execute experiment.

- When the SANS is ready, ensure control software is configured and rheometer control software script file is open, press "Parameters Set". This triggers execution of the specified experiment and all data should be logged throughout the preprogrammed sample run.

9. End of Experiment

- Turn off the neutron beam and disable auto-logging. Unload the sample and remove the dielectric cup and bob assemblies from the rheometer. Install the motor air bearing protector and lock the transducer.

- Power down the computer, LCR meter, and rheometer power supplies. Disconnect the air line. Disconnect all BNC cables and reinstall the crane lift onto the rheometer.

- Uninstall the truncated snout. Reinstall the rheometer's crane adapter. Lift the rheometer from the table and place onto the rheometer table ensuring that the cables remain untangled.

Figure 1: a.)-e.) Pictures of Components of the SANS Beamline and the Rheometer necessary to Install Rheometer on the Beamline that are Labelled and Defined Below. Please click here to view a larger version of this figure.

Figure 2: Pictures of Components Dielectric RheoSANS Geometry with Labels Defining Terms Below. Please click here to view a larger version of this figure.

Figure 3: a.-d.) Pictures of Procedure for Installing the Slip-ring onto the Dielectric RheoSANS Geometry, and e.) Picture of Fully Assembled Dielectric RheoSANS Geometry. Please click here to view a larger version of this figure.

Figure 4: Schematic of Beam Path through Oven Geometry and Dielectric RheoSANS Geometry. Please click here to view a larger version of this figure.

Representative Results

Representative results from a dielectric RheoSANS experiment are shown in Figure 5 and 6. These data are taken on a suspension of conductive carbon black in propylene carbonate. These aggregates flocculate due to attractive interactions at relatively low solids loadings forming gels that are electrically conducting. The rheological and conductivity responses of such suspensions are an active area of research and current investigations seek to understand the microstructural origins of these measurements. The dielectric RheoSANS instrument is a tool uniquely suited to address this question as it probes simultaneously the electrical and mechanical properties of a material as it undergoes deformations similar to those found in an application such as in a semi-solid electrochemical flow cell. In such a cell the carbon black forms the conducting additive that provides volumetric conductivity to the flowing electrodes.

The experiment outlined in the procedure is designed to test a conductive material as it undergoes a flow sweep test, where the shear rate is stepped logarithmically from a maximum value to a minimum value holding at each shear rate for a specified period of time. Rheology, dielectric data and neutron scattering are measured continuously during the course of this experimental sequence. Upon completion of a dielectric RheoSANS experiment, the data is stored in three independent formats. The SANS data is stored as an event mode file that is a binary file generated by the detector containing the list of the time of arrival of each neutron on the detector and the x, y position of the pixel on which it was detected. The rheology data is stored within the rheometer control software as a separate data file and can be exported as a column delimited text file containing the relevant rheological parameters (i.e., torque, shear rate, and normal force). Finally, the dielectric data is contained within the log file written by the control interface to the specified folder that records the impedance magnitude and phase shift as a function of the applied frequency. The first post-processing task is to synchronize and then sort the raw data. A detailed description of this process is published elsewhere, but briefly, the synchronization is made possible by a data acquisition card that monitors a digital signal from the rheometer and uses an analogue triggering protocol to encode measurement condition transitions into the SANS detector clock time.20 Using this approach, the raw measured signals from the SANS, rheometer and LCR meter can be reconstructed as a function of both shear rate and time.

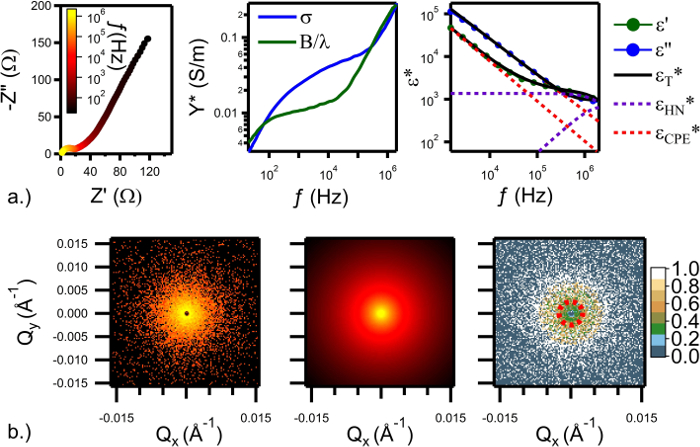

After the raw signals are sorted, they are corrected using the known rheological and electrical cell constants and using standard SANS reduction methods. The dielectric data correction and analysis procedure is shown in Figure 5a after removing the open and short circuit measurements at each frequency and shear rate. Once corrected the dielectric signals are converted to the real and imaginary components of the impedance versus frequency. In Figure 5a, there is a plot of Nyquist representation of dielectric measurement of an 0.08 weight fraction Vulcan XC72 sample undergoing steady shear averaged over the last 900 s of the acquisition. In the Nyquist representation, the real and complex components of the impedance are plotted parametrically against one another. On the top left plot, the data points are logarithmically colorized by the frequency at which the measurement is taken with yellow representing the highest frequency (20 MHz) and black representing the lowest accessible frequency (20 Hz). In the middle plot, the sample admittance, Y*, or the inverse of the complex impedance, Z*, is plotted against the frequency. It is normalized by the known cell constant, λ, and the sample conductivity and electrical susceptibility are defined as the imaginary and real components of the admittance. This normalized sample response can be converted to the complex permittivity, ε*, by dividing the admittance by 2πƒε0. Finally, we fit the complex permittivity of the sample response using the dielectric response model as a sum of a Havriliak-Nagami Relaxation and a constant phase element that accounts for the effects of electrode polarization.20

Figure 5: a.) Summary of dielectric data analysis; left Nyquist representation, middle: Conductivity and susceptibility vs frequency, right: complex permittivity versus frequency — dielectric model accounts for electrode polarization and Havriliak-Negami relaxation shown overlaid on top of data, b.) Summary of SANS data analysis; left: I(Q) from 0.08 weight fraction Vulcan XC72 at 1 rad/s averaged for last 900 s of shear rate, middle: scaled model fit to dilute sample P(Q), right: sample structure factor, S(Q)=I(Q)/(A·P(Q)) — red circle denotes Q-position position where data is averaged to obtain the minimum structure factor depth, S0. Please click here to view a larger version of this figure.

The raw event mode data is histogrammed with respect to time onto the two-dimensional SANS detector representing I(Qx, Qy). This raw signal intensity is then corrected for the empty cell, blocked beam, and transmission and converted to absolute scale with units cm-1. After these corrections, the absolute intensity can be plotted as a function of shear rate and time. In Figure 5b, on the left, the two-dimensional reduced scattering intensity versus Qx and Qy is plotted. In the middle we plot the form factor, P(Q), scaled by a prefactor, A, of the model fit to the dilute carbon black suspension over an identical Q-range. We then divide I(Q) by A*P(Q) to obtain S(Q) which represents an apparent structure factor for the interactions between the fractal carbon black aggregates that comprise the sample. Next the two-dimensional S(Q) plot is integrated at the minimum accessible Q value = 0.0015 A-1 to calculate S0, which is an estimate of the apparent repulsive interaction between fractal aggregates. This result is then converted to an equivalent hard sphere volume fraction.

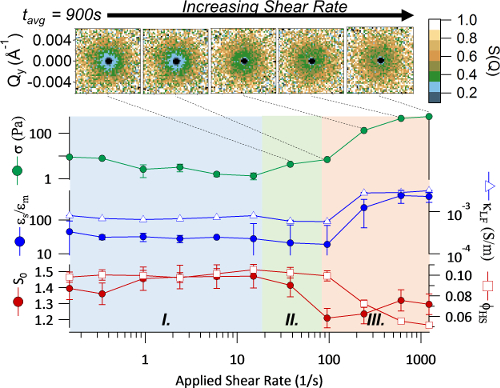

Using this approach, the steady-state data can be analyzed at each shear rate and the extracted parameters that result from both the structural analysis and the dielectric analysis can be plotted as a function of the applied shear rate and rheological shear stress as shown in Figure 6. Also plotted are the two-dimension S(Q) plots for several shear rates of interest that mark important microstructural transitions. Because these values are all measured at the same time from the same region within the Couette, they can be directly compared and correlated. This is emphasized by the fact that transitions in conductivity, κLF, and effective volume fraction, ϕHS, correspond with the increase of stress when the shear stress exceeds the yield stress marked by the transition from region I-II. In this transition, both ϕHS and κLF decrease which is associated with the yielding of the macroscopic gel. As the shear rate is further increased, the sample shear thickens as indicated by the apparent increase in the viscosity and the κLF increases while ϕHS continues to decrease. This transition is marked by region II-III. For concentrated colloidal suspensions, shear thickening is associated with the formation of large structures that form as result of hydrodynamic interactions imposed by the flow of the bulk fluid around the primary carbon black particles. These hydrodynamic forces draw the aggregates together resulting in an abrupt increase in conductivity and viscosity.

Figure 6: top: two-dimensional S(Q) plots at shear rates that represent important microstructural transitions in the sample, bottom: summary of rheological (shear stress), dielectric (static permittivity and low frequency conductivity) and SANS parameters (scale factor and effective excluded volume fraction) as a function of applied shear rate. The regions of interests are marked as I-III. In region I, creep maintains an interconnected network structure. In region II, the gel macroscopically yields leading to a decrease in the overall conductivity. In region III, there is an apparent shear thickening resulting in clustering and an increase in conductivity. Error bars represent one standard deviation of the average. Please click here to view a larger version of this figure.

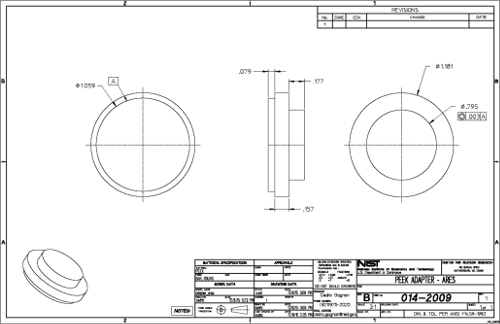

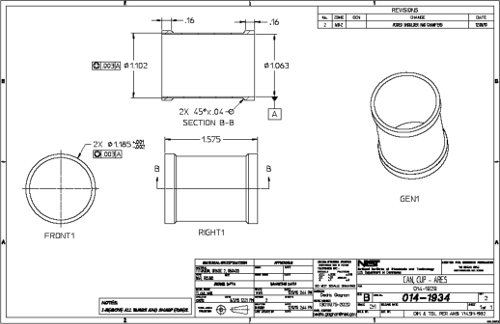

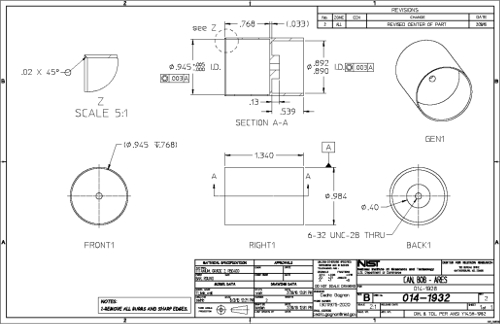

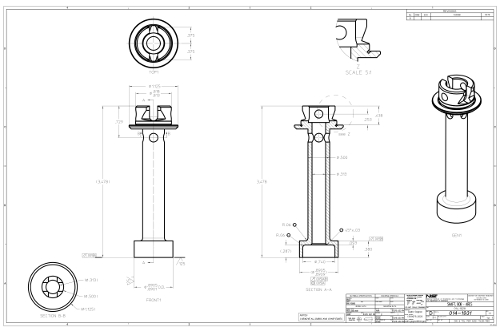

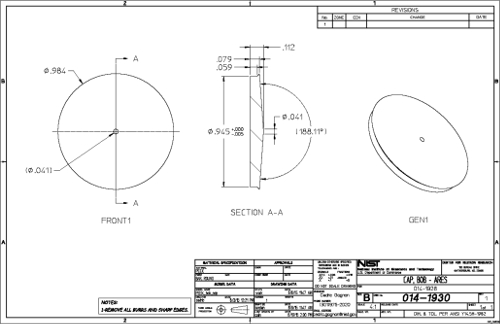

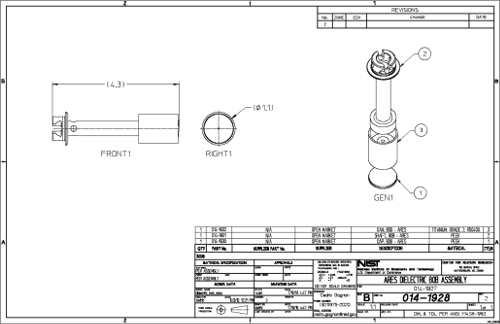

The technical schematics of the key components of the dielectric RheoSANS geometry shown in Figure 2 are provided in Supplementary Figures 1 – 8, such that this geometry can be reproduced on similar strain controlled rheometers.

Supplementary Figure 1: Technical Schematic of the Dielectric Cup Adapter. Please click here to view a larger version of this figure.

Supplementary Figure 2: Technical Schematic of the Dielectric Cup Wall. Please click here to view a larger version of this figure.

Supplementary Figure 3: Technical Schematic of the Dielectric Bob Wall. Please click here to view a larger version of this figure.

Supplementary Figure 4: Technical Schematic of the Dielectric Bob Shaft. Please click here to view a larger version of this figure.

Supplementary Figure 5: Technical Schematic of the Dielectric Bob Cap. Please click here to view a larger version of this figure.

Supplementary Figure 6: Technical Schematic of the Dielectric Bob Assembly. Please click here to view a larger version of this figure.

Supplementary Figure 7: Technical Schematic of the Slip Ring Adapter. Please click here to view a larger version of this figure.

Supplementary Figure 8: Technical Schematic of the Carbon Brush Adapter. Please click here to view a larger version of this figure.

Discussion

A dielectric RheoSANS experiment measures simultaneously the rheological, electrical and microstructural responses of a material as it undergoes a predefined deformation. The example shown here is an electrically conductive carbon black suspension that forms the conductive additive used in electrochemical flow cells. The dielectric RheoSANS instrument enables the interrogation of the radial plane of shear within a narrow gap Couette cell without compromising the fidelity of either the electrical or rheological measurement. Additionally, the geometry allows for conversion of raw signals, torque, resistance, and phase shift, to appropriate intrinsic variables such as shear stress, conductivity and permittivity. In the experiment outlined in this procedure, a flow sweep is performed where the shear rate is logarithmically stepped from a maximum value to a minimum value while the time-dependent and shear rate dependent rheo-electro-structural properties are recorded. From this measurement, it is possible to examine the evolution of microstructure and conductivity of the carbon black gel as it yields and then undergoes macroscopic flow. Because of the simultaneous dielectric measurement, we are able to probe the origin of conduction in these gelled materials far from equilibrium as they melt.20 A flow sweep is just one type of potential test that can be performed, and the geometry is design to accommodate a wide range of potential time-dependent shear profiles. These results have a potential to improve the performance of flow battery electrodes by guiding the formulation of low-viscosity, high conductivity fluids.21

A critical enabling component of a dielectric RheoSANS experiment is the synchronization of all three measurements. Synchronization allows all three measurement characteristics to be compared as a function of time and shear rate. This is made possible by the analogue triggering protocol that encodes transitions in shear rate in the neutron arrival time. This protocol exploits event mode acquisition of the SANS detector which generates a continuous list of the arrival time and pixel position of each neutron detected. The detector clock time can be reset using an analogue trigger, a 10 ms pulse with a 5 V amplitude. This resets the absolute arrival time of the neutrons within that list. The protocol outlined above allows this clock to be reset at the moment the motor is turned on and between each shear rate. This synchronization protocol allows the user to reconstitute the microstructural evolution of the sample to a time-resolution of 100 ms. An important limitation of this method is that currently there is no way to change detector position during the course of an acquisition. Therefore, only a single detector position can be acquired for a given experimental protocol. This will be improved by upcoming software changes in both the rheometer control protocols as well as the SANS instrument operations.

The results provided by this new instrument open up a new path to interrogate electrically active colloidal materials as they undergo deformation. In contrast to existing rheo-electric, rheo-SANS, and dielectric-SANS geometries, the dielectric RheoSANS geometry described here is capable of simultaneous dielectric-SANS measurement under arbitrary applied shear fields. This technique has relevance not only to electrochemical flow cells but the development of fuel cell electrodes and other electronic devices where materials are processed from the solutions state and subject to macroscopic shear.22,23,24 The instrument also has relevance to the study of materials whose mechanical properties can be actuated via an applied electric field. All these applications can potentially be studied by virtue of the flexible design of this instrument and the methodology for synchronizing the execution of each testing protocol.

Work is ongoing to improve the protocols for executing a dielectric RheoSANS experiment and creating new testing methodologies for a wider range of materials. Additionally, improved atmospheric control will be enabled with the improvement of the oven design and upcoming replacement of the window material within the oven environment. This will include an improved solvent trap design that will make long duration experiments on volatile fluids feasible. Upcoming oven designs promise access to the tangential plane of shear which has been demonstrated in operating RheoSANS instruments, but is not currently a tested and proven capability of the dielectric RheoSANS instrument.

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

The authors would like to acknowledge the NIST Center for Neutron Research CNS cooperative agreement number #70NANB12H239 grant for partial funding during this time period as well as the National Research Council for support. Certain commercial equipment, instruments, or materials are identified in this paper in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

Materials

| ARES G2 Rheometer | TA Instruments | 401000.501 | Rheometer |

| ARES G2-DETA ACCY Kit | TA Instruments | 402551.901 | BNC Connectors |

| Geometry ARES 25mm DETA | TA Instruments | 402553.901 | Dielectric Geometry |

| ARES G2 Forced Convection Oven | TA Instruments | 401892.901 | FCO |

| Agilent E4980A LCR Meter | TA Instruments | 613.04946 | LCR Meter |

| USB-6001 | National Instruments | NI USB-6001 | Data Acquisiton Card |

| Vulcan XC72R | Cabot | Vulcan XC72R | |

| Propylene Carbonate | Aldrich | 310328 | |

| LabVIEW System Design Software | National Instruments | 776671-35 | Control Software |

Referencias

- Macosko, C. Rheology: Principles, Measurements and Applications. Powder Technology. 86 (3), (1996).

- Barsoukov, E., Macdonald, J. R. . Impedance Spectroscopy Theory, Experiment, and Applications. , (2010).

- Pelster, R., Simon, U. Nanodispersions of conducting particles: Preparation, microstructure and dielectric properties. Colloid Polym. Sci. 277 (1), 2-14 (1999).

- Hollingsworth, A. D., Saville, D. A. Dielectric spectroscopy and electrophoretic mobility measurements interpreted with the standard electrokinetic model. J. Colloid Interface Sci. 272 (1), 235-245 (2004).

- Mewis, J., Spaull, A. J. B. Rheology of concentrated dispersions. Adv. Colloid Interface Sci. 6 (3), 173-200 (1976).

- Mijović, J., Lee, H., Kenny, J., Mays, J. Dynamics in Polymer-Silicate Nanocomposites As Studied by Dielectric Relaxation Spectroscopy and Dynamic Mechanical Spectroscopy. Macromolecules. 39 (6), 2172-2182 (2006).

- Newbloom, G. M., Weigandt, K. M., Pozzo, D. C. Electrical, Mechanical, and Structural Characterization of Self-Assembly in Poly(3-hexylthiophene) Organogel Networks. Macromolecules. 45 (8), 3452-3462 (2012).

- Fowler, J. N., Kirkwood, J., Wagner, N. J. Rheology and microstructure of shear thickening fluid suspoemulsions. Appl. Rheol. 24 (4), 23049 (2014).

- Wagner, N. J. Rheo-optics. Curr. Opin. Colloid Interface Sci. 3 (4), 391-400 (1998).

- Callaghan, P. T., et al. Rheo-NMR: nuclear magnetic resonance and the rheology of complex fluids. Reports Prog. Phys. 62 (4), 599-670 (1999).

- Gurnon, A. K., et al. Measuring Material Microstructure Under Flow Using 1-2 Plane Flow-Small Angle Neutron Scattering. J. Vis. Exp. (84), e51068 (2014).

- Calabrese, M. A., Rogers, S. A., Murphy, R. P., Wagner, N. J. The rheology and microstructure of branched micelles under shear. J. Rheol. 59 (5), 1299-1328 (2015).

- Helgeson, M. E., Vasquez, P. A., Kaler, E. W., Wagner, N. J. Rheology and spatially resolved structure of cetyltrimethylammonium bromide wormlike micelles through the shear banding transition. J. Rheol. 53 (3), 727 (2009).

- Calabrese, M. A., et al. An optimized protocol for the analysis of time-resolved elastic scattering experiments. Soft Matter. 12 (8), 2301-2308 (2016).

- Eberle, A. P. R., Porcar, L. Flow-SANS and Rheo-SANS applied to soft matter. Curr. Opin. Colloid Interface Sci. 17 (1), 33-43 (2012).

- Campos, J. W., et al. Investigation of carbon materials for use as a flowable electrode in electrochemical flow capacitors. Electrochim. Acta. 98, 123-130 (2013).

- Duduta, M., et al. Semi-solid lithium rechargeable flow battery. Adv. Energy Mater. 1 (4), 511-516 (2011).

- Mewis, J., de Groot, L. M., Helsen, J. A. Dielectric Behaviour of Flowing Thixotropic Suspensions. Colloids Surf. 22, (1987).

- Richards, J. J., Wagner, N. J., Butler, P. D. A Strain-Controlled RheoSANS Instrument for the Measurement of the Microstructural, Electrical and Mechanical Properties of Soft Materials. Rev. Sci. Instr. , (2016).

- Youssry, M., et al. Non-aqueous carbon black suspensions for lithium-based redox flow batteries: rheology and simultaneous rheo-electrical behavior. Phys. Chem. Chem. Phys. PCCP. 15 (34), 14476-14486 (2013).

- Cho, B. -. K., Jain, A., Gruner, S. M., Wiesner, U. Mesophase structure-mechanical and ionic transport correlations in extended amphiphilic dendrons. Sci. 305 (5690), 1598-1601 (2004).

- Kiel, J. W., MacKay, M. E., Kirby, B. J., Maranville, B. B., Majkrzak, C. F. Phase-sensitive neutron reflectometry measurements applied in the study of photovoltaic films. J. Chem. Phys. 133 (7), 1-7 (2010).

- López-Barròn, C. R., Chen, R., Wagner, N. J., Beltramo, P. J. Self-Assembly of Pluronic F127 Diacrylate in Ethylammonium Nitrate: Structure, Rheology, and Ionic Conductivity before and after Photo-Cross-Linking. Macromolecules. 49 (14), 5179-5189 (2016).