3D Printing – Evaluating Particle Emissions of a 3D Printing Pen

Summary

This protocol presents a method to analyze the emission of 3D printing pens. Particle concentration and particle size distribution of the released particle is measured. Released particles are further analyzed with transmission electron microscopy (TEM). Metal content in filaments is quantified by inductively coupled plasma mass spectrometry (ICP-MS).

Abstract

Three-dimensional (3D) printing as a type of additive manufacturing shows continuing increase in application and consumer popularity. The fused filament fabrication (FFF) is an inexpensive method used most frequently by consumers. Studies with 3D printers have shown that during the printing process particulate and volatile substances are released. Handheld 3D printing pens also use the FFF method but the consumer’s proximity to the 3D pens gives reason to higher exposure compared to a 3D printer. At the same time, 3D printing pens are often marketed for children who could be more sensitive to the printing emission. The aim of this study was to implement a low cost method to analyze the emissions of 3D printing pens. Polylactide (PLA) and acrylonitrile butadiene styrene (ABS) filaments of different colors were tested. In addition, filaments containing metal and carbon nanotubes (CNTs) were analyzed. An 18.5 L chamber and sampling close to the emission source was used to characterize emissions and concentrations near the breathing zone of the user.

Particle emissions and particle size distributions were measured and the potential release of metal particles and CNTs investigated. Particle number concentrations were found in a range of 105 – 106 particles/cm3, which is comparable to previous reports from 3D printers. Transmission electron microscopy (TEM) analysis showed nanoparticles of the different thermoplastic materials as well as of metal particles and CNTs. High contents of metal were observed by inductively coupled plasma mass spectrometry (ICP-MS).

These results call for a cautious use of 3D pens due to potential risk to the consumers.

Introduction

3D printing is a promising additive manufacturing method, which besides its industrial applications is also used in homes, schools and so-called maker spaces. 3D printers can now be purchased starting already from 200 €, thus making them attractive to consumers. These printers can be used to produce replacement parts, household items, gifts or other objects. Children can even make their own toys using 3D printers. Due to their easy handling and low price, printers based on fused filament fabrication (FFF) are the most widespread type in the hobby sector1. In this printing method a thermoplastic material, called filament, is melted, pushed through a nozzle and applied layer by layer using a movable print head until the three-dimensional object is finished. Digital computer-aided design (CAD) models needed for FFF printing are freely available online or can be designed in many different CAD drawing programs.

Initial studies have shown that during the printing process of the filament, ultrafine particles2,3,4,5,6,7,8 and volatile substances9,10,11,12,13,14,15,16,17,18 are released. Ultrafine particles can penetrate deeper into the respiratory system and might be harder to clear from the body19. In a study with employees regularly using 3D printers 59% have reported respiratory symptoms20. Most of the hobbyist's printers are not hermetically sealed and do not have exhaust fume extraction devices. Emissions are therefore released directly into the ambient air and could pose a risk to the user upon inhalation.

Previous studies have focused on emissions of the most commonly used filaments polylactide (PLA) and acrylonitrile butadiene styrene (ABS). Some studies have analyzed different filaments, such as nylon and high-impact polystyrene (HIPS)4,10,13. Furthermore, new filaments, which are provided with additives such as metal or wood, are constantly being launched to the market. Those filaments enable the consumer to print objects that look and feel like natural wood or metal. Other filaments allow to print conductive materials containing graphene or carbon nanotubes (CNTs)21. Metal nanoparticles22 and CNTs show cytotoxic effects and caused DNA damage23. So far, only little research was conducted regarding filaments containing additives. Floyed et al.13 analyzed PLA supplemented with bronze; Stabile et al.3 investigated PLA blended with copper, wood, bamboo and a filament with carbon fiber. Both studies measured particle concentration and size distribution however the morphology and composition of the released particles was not further investigated. Especially high aspect ratio nanoparticles (HARN) such as CNTs or asbestos fibers are known to cause hazardous health effects24. A recent study by Stefaniak et al.25 analyzed filaments with CNTs and observed emission of respirable polymer particles containing visible CNTs.

3D pens use the same FFF method as 3D printers, but so far only one study examining 3D pens has been published26. The authors used PLA and ABS filaments, but none with additives were analyzed. Due to their handheld use, 3D pens are even easier to use than 3D printers. They are more intuitive, have a small size and do not require the use of CAD models. 3D pens can be used to draw or create objects, and moreover to repair 3D printed parts and other plastic items. Prices start from as low as 30 €, different shapes and colors are available to target lower age groups. But particularly, children are more vulnerable to particle emissions. Their lung defense mechanisms against particulate and gaseous pollution are not fully evolved and they are breathing a higher volume of air per body weight27.

For a better understanding of the release and the health risks of 3D pen emissions, we investigated different filaments consisting of the standard materials PLA and ABS in different colors. Furthermore, filaments with copper, aluminum, steel and CNT additives and a filament with glow-in-the-dark effect were investigated. To gain comprehensive insights into the 3D pen printing process and the particulate emissions analysis was conducted by online aerosol measurement of particle number concentrations and size distributions, by transmission electron microscopy (TEM) examination for the morphology and materials identification and by inductively coupled plasma mass spectrometry (ICP-MS) for quantitative metal assessment of the filaments.

Protocol

1. Protocol requirements

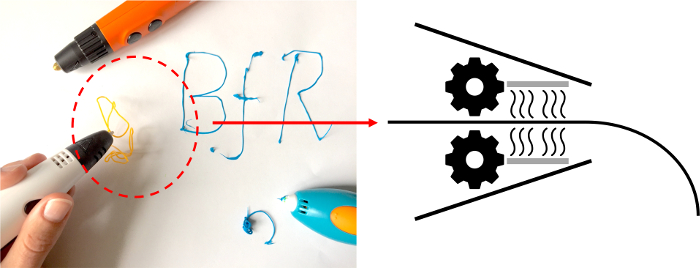

- Purchase a 3D printing pen capable of generating temperatures > 200 °C (Figure 1) to be able to print filaments with a higher print temperature (e.g., ABS or filaments with additives) to compare different filaments. Different 3D pens are available online.

- Purchase filaments with a diameter of 1.75 mm, suitable for the 3D pen. A variety of standard PLA and ABS filaments as well as filaments with additives are available online on different websites.

- For an easy setup, use a desiccator (18.5 L) as the emission chamber.

- Make sure the chamber is clean. Choose a desiccator with an inlet on one side to be able to insert the 3D printing pen and an outlet on the top to insert the sampling tube.

- Make sure that an air inlet at the connection to the 3D pen is established. Ambient air will used as background. The outlet tubing should be 10 cm away from the tip of the 3D printing pen to mimic the distance between the user’s head and the emission source.

- Use conductive tubing to minimize particle loss. The tubing length should be as short as possible and free of bends.

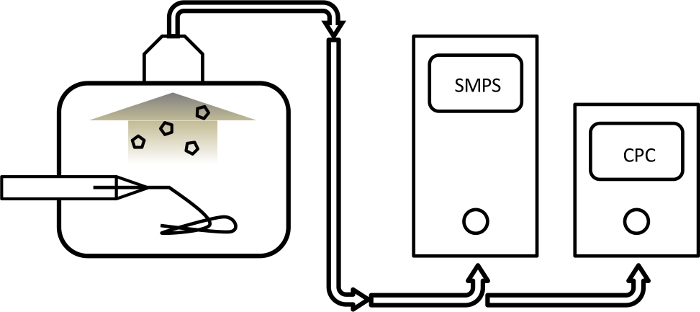

- Use Condensation Particle Counter (CPC) and Scanning Mobility Particle Sizer (SMPS) or other particle tracking devices for the online measurement of particle concentration and particle size distribution (Figure 2).

- Use a microwave and respective chemicals for digesting filament samples.

- Use an ICP-MS or another multi-element analysis instrument to quantify the metal content in the samples.

- Use an electron microscope to characterize the particle morphology.

2. Aerosol measurements of 3D Pen emissions

- Preparation before the experiment

- Switch on the respective online measurement instruments (SMPS, CPC). There is a button in the back of the machine. Warm up the instruments for around 10 min.

- Preload the 3D pen with a chosen filament (start with PLA as the most used material) and let the pen cool down.

- Attach a HEPA filter to the SMPS inlet and run a clean check measurement with the SMPS to ensure that the SMPS is not contaminated from previous measurements. Do not measure any particles if the SMPS is not clean.

- Connect the chamber outlet to the CPC inlet. Check the concentration inside the chamber with the CPC to ensure the chamber is clean (< 103 particles/m3) and experiments are running under the same conditions. Start a measurement.

- Experimental procedure

- Insert the preloaded and cooled down 3D pen into the chamber.

- Make sure the outlet tubing of the chamber is connected to the CPC.

- Start the computer connected to the CPC. Open a new file with a name suitable to the measurements. Make sure the CPC flow setting is set to 0.3 L/min and sampling time is set to at least 90 minutes. Start the CPC measurement to measure the background concentration for 10 minutes.

NOTE: Flow settings of 0.3 L/min and the chamber volume of 18.5 L will result in an air exchange rate (ACH) of 1.0 h-1. - After 10 min, switch on the 3D pen. Select the needed temperature for the chosen filament.

- After the needed temperature is reached, start the printing process. Let the 3D pen print for 15 minutes.

NOTE: No object, but a continuous string will be printed and collected on the bottom. - After 15 minutes, stop the 3D pen, connect the outlet tubing to the SMPS and start the size distribution measurements every 3 minutes for the next 1 hour.

- After the experiment is finished remove the printed filament and clean the chamber.

- Repeat every measurement three times.

3. Particle morphology using TEM

- To ensure that the measured signals originate from emitted particles and not from vapor molecules use transmission electron microscopy (TEM) to analyze the aerosol.

- TEM grid preparation

- Use 400 mesh 3.5 mm copper grids.

- Coat the grids with Collodion. Let the grids dry overnight and store them in a desiccation chamber until further use. Alternatively, use precoated grids (e.g., SF162-4 Formvar-Film on 400 mesh Cu-net).

- On the day of the experiment, the grids should be hydrophilized with 2% Alcian Blue in 0.3% acetic acid solution.

- Pipette 30 µL of the prepared Alcian blue solution on to a surface, for example a piece of parafilm. Let the grids float on the Alcian blue droplets for 5 to 10 minutes and dry them using a filter paper.

- Place the prepared TEM grids inside the chamber during the printing process and leave in place afterwards for 5 hours to allow particle sedimentation.

NOTE: For easier handling of the grids, place the grids on a platform coated with parafilm. - Examine at least four different areas of each grid with TEM and use diffraction patterns from published resources to identify material composition.

4. Quantitation of metal content before and after printing using ICP-MS

- Sample Preparation

- Print filament on a plastic surface to avoid contamination with metal.

- Weigh approximately 150 mg of bulk filament and printed filament. To avoid contamination with metal, use a ceramic knife to cut smaller pieces.

- Microwave digestion

- Transfer weighted filaments into microwave vessels.

- Add 1.5 mL of water (e.g., MilliQ), 3.5 mL of nitric acid and 1 mL of hydrogen peroxide to each sample.

CAUTION: Add water first and then acid! - Place the vessels into the microwave and start the digestion. Heat up to 200 °C and hold for 20 minutes.

- Determinate metal concentration with ICP-MS

- Dilute all samples of filaments where a high metal concentration is known or suspected to avoid contamination of the ICP-MS.

- Use a survey scan to determinate which metals are in the samples.

- Quantify the metal content of the specific metals using the appropriate calibrations standards.

Representative Results

Particle number concentration

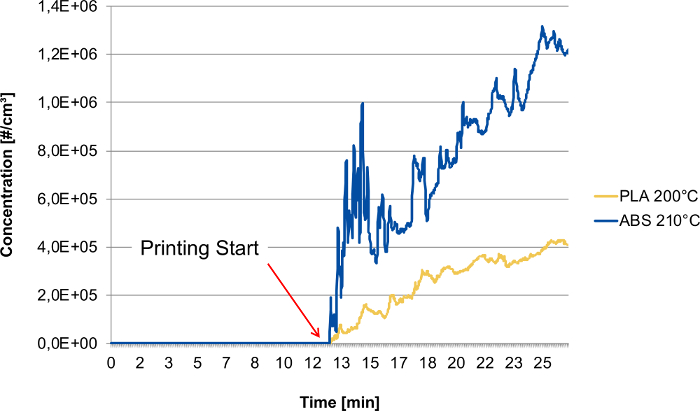

The highest peak particle number concentration was measured for PLA-copper with 4.8 x 106 #/cm3 and the lowest for PLA-black with 4.3 x 105 #/cm3. In general, a higher emission for ABS > 106 #/cm3 compared to PLA was observed. Nevertheless, some PLA filaments resulted in particle concentrations above 106 #/cm3 (PLA-white and PLA-blue). The different particle concentrations might be related to the use of additives. Zhang et al.28 have stated that particles might be formed by some additives as for example pigments, however not by the bulk material. Thus, the use of different pigments for different colors might influence the number of particles released.

In Figure 3 examples of particle emission increase during the printing process are shown for PLA-black and ABS-black. The results are in agreement with previous 3D printer studies, showing particle concentrations of 105-106 #/cm3 and higher values for ABS compared to PLA12,13. Floyd et al.13 measured peak concentration of 3.5 x 106 #/cm3 for ABS and 1.1 x 106 #/cm3 for PLA. It is important to mention, that ABS is generally printed at higher temperatures compared to PLA. To analyze the influence of the printing temperature on particle release, experiments using PLA-black were carried out at 210 °C (standard setting for ABS). Results were compared to the standard setting of 200 °C for PLA. With the higher temperature setting, particle concentration increased almost one order of magnitude. The average concentration during printing with PLA-black increased from 2.6 x 105 #/cm3 at 200°C to 1.3 x 106 #/cm3 at 210 °C. Higher emissions caused by a higher printing temperature were already observed in earlier studies with 3D printers3.

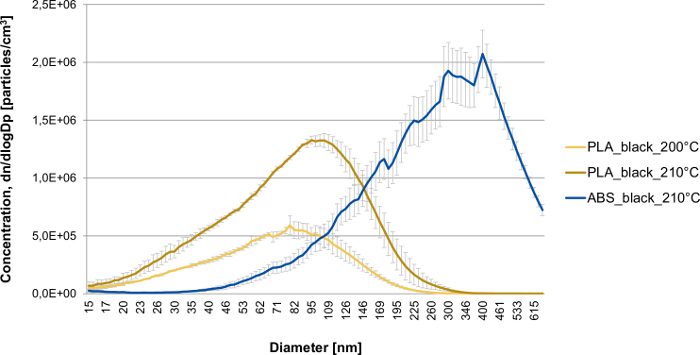

Particle size distribution in emissions of different filaments

Figure 4 shows particle size distributions for PLA at 200 and 210 °C and for ABS at 210 °C. Printing ABS resulted in a higher particle concentration and larger particles compared to PLA. The temperature increase during printing of PLA resulted in higher particle number concentrations but had no significant effect on the geometric mean diameter (GMD). This is in agreement with a previous study28.

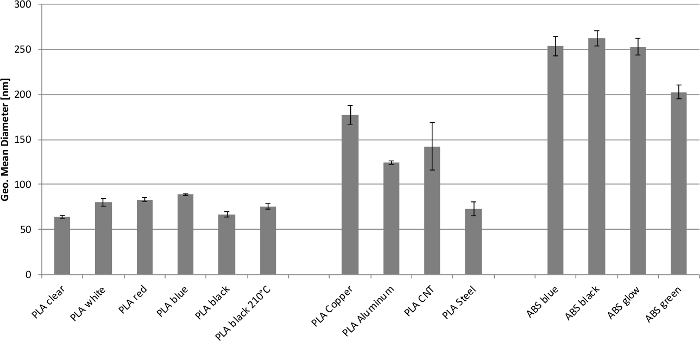

Figure 5 shows the GMD based on the number count for all measured filaments. There was a clear trend in difference observed between particles emitted during printing with ABS or PLA filaments. The ABS samples had the largest GMD ranging from 203.9 nm for ABS-green and up to 262.1 nm for ABS-blue. ABS-green is made by a different manufacturer than the other ABS filaments; this could be the reason of a slightly different particle size. PLA filaments emitted smaller particles with GMDs < 100 nm (63.8 nm for PLA-clear up to 88.3 nm PLA-blue). For the other filaments with additives, the GMD ranged from 73.1 nm for PLA-steel to 183.9 nm for PLA-copper. Reproducibility of measurements is evident from the low relative standard deviations (RSD) of particle size measurements. The range was mostly between 0.96 and 5.58%. Only in the case of PLA with steel (10.55%) and PLA with CNTs (18.52%) a higher range was observed. This could, however, be due to inhomogeneity in the filaments. Products with additives are a mixture of a thermoplastic (e.g., in this case PLA) and metal or other small particles. The particles might not be evenly distributed and could thereby cause a higher standard deviation. The geometric standard deviations ranged between 1.6 and 1.9, indicating a single modal distribution in the fine and ultrafine particle range, as observed in previous studies of 3D printers13.

The results show a significant difference in particle emissions between PLA and ABS filaments; this was not yet clear from previous publications as often only one or two filaments had been analyzed29. Some authors described larger particles for ABS5,12, some larger ones for PLA2,9. In further studies, no difference in size at all was observed4,13. Byrley et al.29 reviewed 13 publications and described mean particle diameters ranging from 14.0 nm to 108.1 nm for PLA and from 10.5 nm to 88.5 nm for ABS. The difference in particle sizes could be due to measurements at different time points. Some measured at the highest concentration12,13 and some reported the sizes for the whole printing process5,9. The only study of 3D pens available so far reports particles up to 60.4 nm for PLA and up to 173.8 nm for ABS26, which is similar to the findings here.

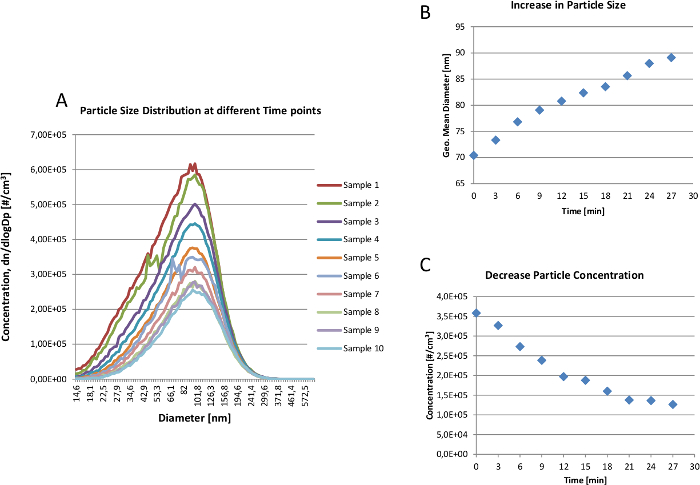

The size distribution measurement represents a one moment snapshot only. In order to observe time variability regarding the size of the emitted aerosol the particle size distribution for Filament PLA-black was measured 10 times every 3 minutes after the printing was stopped (Figure 6A). The measurements show an increase in GMD (Figure 6B) and a decrease in particle concentration (Figure 6C) with each consecutive measurement run. The increase in particle size could be due to agglomeration, which would also explain the decrease in particle concentration. Interestingly, this occurrence of particle size increase and concentration decrease was not only observed after the printing has stopped, but also during printing processes. This shows that the measurement time is an important factor.

Quantitation of metal content before and after printing using ICP-MS

A comparison of the filaments containing metal additives before and after the printing process revealed no difference in regard to their metal content. This unchanged metal-polymer ratio indicates that the released particles are not solely polymer, as this would lead to a higher metal concentration in the printed material due to the polymer loss. Released metal nanoparticles could imply higher health risk for the user22. In general, the high amount of metal in advanced filaments should be noted. Metals may cause adverse health effects and especially the release of nanoscale particles requires safety precautions in daily life scenarios30.

For the PLA-copper filament we measured a weight percentage of 70 for copper. For the steel filament we measured weight percentages of 30% Fe, 8% Cr and 6% Ni in the filament. Often the exact composition of the filaments is not declared, and possible risks are therefore not known to the user. Exposure to nickel may have adverse effects on human health and can cause skin allergies, lung fibrosis, cardiovascular and kidney diseases. The element is suspected human carcinogen31.

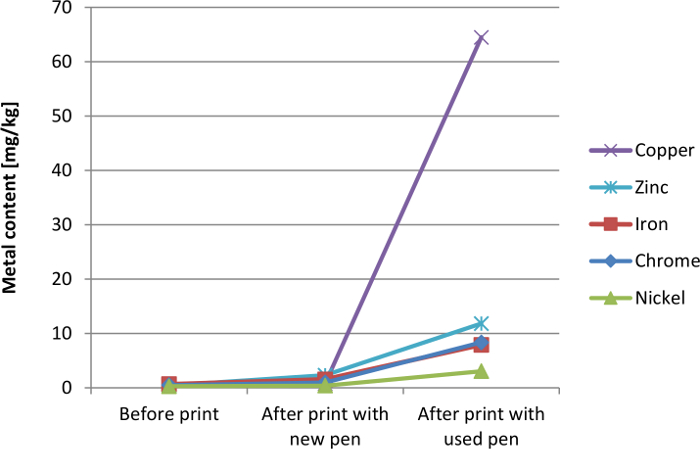

Besides the metal filaments, PLA clear was analyzed before and after printing. Here, an increase of Cu, Zn, Fe, Cr and Ni was measured after the printing process. This could be due to other materials having been extracted through the 3D pen before and resulting in a memory effect. Measurements were repeated with a newly purchased 3D pen and here no significant increase could be observed (Figure 7).

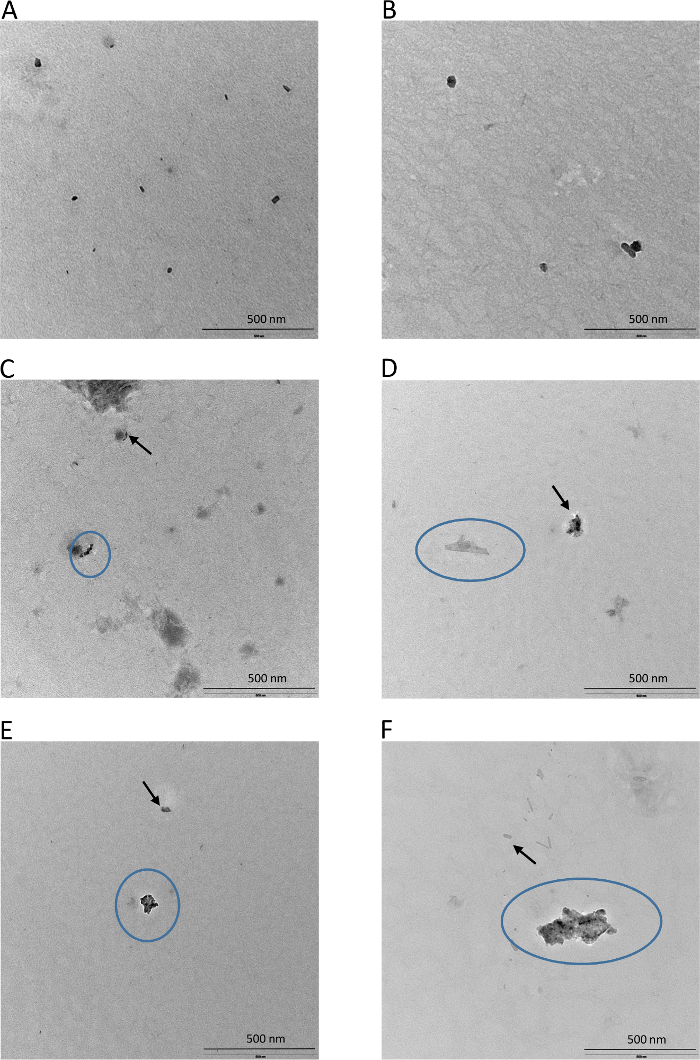

Particle morphology using TEM

The TEM images confirmed the presence of particles and verified the difference in particle size between ABS and PLA, measured with the SMPS. TEM images showed particle sizes mostly around 50 nm for PLA (Figure 8A). ABS black showed almost consistently larger particles up to 100 nm (Figure 8B). The difference of particle sizes between PLA and ABS, as seen with the SMPS, could be confirmed. However, smaller sizes were measured by TEM. The smaller sizes could be due to the SMPS measuring particle agglomerates, as described previously, and TEM images showing non agglomerated particles.

PLA-copper filament contained copper as well as PLA particles (Figure 8C). Copper was mostly in crystalline form with sizes around 150 nm. This fits the SMPS measurement of the copper filament, which resulted in mean GMD of 178 nm (Figure 5). Figure 8D possibly depicts a released CNT from the PLA-CNT filament. Furthermore, the release of small steel particles during the printing with PLA-steel filament was observed (Figure 8E). The aluminum filament was described as “PLA compound – with an incredibly high amount of silver aluminum-flakes added”32. Figure 8F shows possible an agglomeration of those flakes as the size is much bigger compared to the measured GMD of 124 nm using SMPS.

Figure 1: Picture of 3D printing pens and schematic construction of a 3D printing pen. The 3D printing pen heats the filament to the chosen temperature and extrudes the melted thermoplastic. Please click here to view a larger version of this figure.

Figure 2: Experimental setup for online aerosol measurement. The particle concentration is measured with a CPC and the particle size distribution with a SMPS. Please click here to view a larger version of this figure.

Figure 3: CPC measurement of particle concentrations. The measurements show an increase after print start and higher concentrations for ABS compared to PLA. Please click here to view a larger version of this figure.

Figure 4: Particle Size Distribution measured with SMPS with standard deviation (n=3). PLA printing results in smaller particle compare to ABS. Temperature increase results in higher concentration but shows no significant effect on the particle size. Please click here to view a larger version of this figure.

Figure 5: Average geometric mean diameter with standard deviation (n=3) for all filaments analyzed. Printing with PLA resulted in smaller particles compare to ABS. Please click here to view a larger version of this figure.

Figure 6: Particle size distribution measured just after print stop. (A) Particle size distribution measured every 3 minutes over a period of 30 minutes after a printing process with PLA-black. (B) Increase of GMD. (C) Decrease in concentration. Please click here to view a larger version of this figure.

Figure 7: Metal content in digested filaments measured with ICP-MS. Increase of metal content in PLA-clear filament after printing process. Please click here to view a larger version of this figure.

Figure 8: TEM-Images of samples from printing process: (A) PLA-black filament resulting in PLA particles around 50 nm. (B) ABS-black filament resulting in ABS particles up to 100 nm. (C) PLA-copper filament resulting in Copper crystals (120-150 nm) in addition to PLA. (D) PLA-CNT filament resulting in CNT release. (E) PLA-steel filament resulting in released steel fragments. (F) PLA-Aluminum filament resulting in big aluminum particles. (C) – (D): Arrows indicating PLA and circles metal or CNT respectively. Please click here to view a larger version of this figure.

Discussion

The protocol shows a fast, inexpensive and user-friendly method to analyze emissions of a 3D printing pen. Besides the comparison of PLA and ABS, filaments containing significant amounts of metals and CNTs can be investigated.

Critical steps are cleaning the chamber to avoid cross contamination and to ensure that the background concentration is low. We used a desiccator as an available chamber option, but other chambers might be used.

Particle concentrations and particle size distributions are measured online during and after the printing process. In this study, particle concentrations reaching values above 106 particles/cm3 were recorded, which might be of concern. In particular, when particles smaller than 100 nm were found. The aerosol measurements allowed particle concentration measurements with the CPC in the size range 4 nm to 3 µm. The SMPS measurements only allowed particle size distribution measurements between 14.4 nm and 673.2 nm. Smaller or larger particles might be missed in those measurements.

The method confirms particle presence in 3D pen emissions by offline TEM analysis. In the study nanoparticles of the different thermoplastic materials as well as of metal particles and CNTs were detected.

For the TEM analysis, we relied on the sedimentation of the particles over time as other sampling methods did not work, but improvement or modification of the sampling might be useful. The concentration of the ambient air was very low and insignificant to the emissions concentrations, but the use of an inlet filters might be valuable. In the future, other chamber volumes will be used to compare the result to 3D printer emissions. The protocol focused on the release of particles, but open questions remain, as for example, with regard to the emission of volatile organic compounds (VOCs). For 3D printers it was already shown that in addition to particles, VOCs are being released9,10,11,12,13,14,15,16,17,18,33. It can be assumed that 3D pens may cause similar emissions.

3D printers can be started and then print without the user’s presence. 3D printing pens are, however, handheld devices and are mostly operated manually. Therefore, the user remains closer to the device during the entire printing process resulting in a potentially higher exposure. This should especially be noted as 3D pens are often advertised for being usable by children. In general, particle emissions from FFF 3D processes are comparable to laser printers, in terms of particle number concentrations34. Accordingly, precautions should be taken to reduce the level of exposure. It seems reasonable to advice that 3D pens should be used at low printing temperatures and only in well ventilated environments. Filaments with metal or other additives should be used with care, as the release of potentially harmful metal nanoparticles or fibers is likely.

In the future, this protocol can be used to compare more filaments and different 3D printing pens to gain a better understanding of the emissions of these devices and the possible risk for consumers. Furthermore, this protocol can be used to analyze other aerosol generating cases (e.g., spray products).

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

Thanks to Sebastian Malke and Nadine Dreiack for laboratory support.

Materials

| 3D printing pen | lovebay | bought on: www.amazon.de | |

| ABS black | Filamentworld | ABS175XBLK | bought on: www.filamentworld.de |

| ABS blue | Filamentworld | ABS175XSB | bought on: www.filamentworld.de |

| ABS glow in the dark | Formfutura | ABS175XGID | bought on: www.filamentworld.de |

| Alcian Blue | Sigma Aldrich, Germany | ||

| Collodion | Electron Microscopy Services GmbH, Germany | ||

| CPC | TSI Inc. | Model 3775 | other particle tracking measurement devices can be used |

| Hydrogen peroxide | Merck KGaA | 30%, suprapur | |

| Imaging camera | Olympus, Germany | Veleta G2 camera | |

| iTEM software | Olympus, Germany | ||

| MilliQ water | Merck KGaA | Milli-Q® System | |

| Nitric acid | 69%, In-house cleaned by distillation | ||

| PLA black | Filamentworld | PLA175XBLK | bought on: www.filamentworld.de |

| PLA blue | Filamentworld | PLA175XSBL | bought on: www.filamentworld.de |

| PLA clear | Filamentworld | PLA175XCLR | bought on: www.filamentworld.de |

| PLA red | Filamentworld | PLA175XRED | bought on: www.filamentworld.de |

| PLA white | Filamentworld | PLA175XWHT | bought on: www.filamentworld.de |

| PLA wiht Aluminium | Formfutura | GPLA175XTSI | bought on: www.filamentworld.de |

| PLA wiht CNTs | 3DXTech | 3DX175XPLAESD | bought on: www.filamentworld.de |

| PLA with Copper | Formfutura | MFL175XCOP | bought on: www.filamentworld.de |

| PLA with Steel | Proto-Pasta | PP175X500SST | bought on: www.filamentworld.de |

| SMPS | TSI Inc. | Model 3938 | other particle tracking measurement devices can be used |

| TEM | Jeol GmbH, Germany | Jeol 1400 Plus | |

| TEM grids alternative (plastic coated): Formvar-Film auf 400 mesh Cu-Netzchen | Plano GmbH, Germany | SF162-4 | |

| TEM grids: 400 mesh 3.5 mm copper grids | Plano GmbH, Germany |

Referencias

- Most used 3D printing technologies in 2019 [Graph]. Statista Available from: https://www.statista.com/statistics/560304/worldwide-survey-3d-printing-top-technnologies/ (2020)

- Stephens, B., Azimi, P., El Orch, Z., Ramos, T. J. A. E. Ultrafine particle emissions from desktop 3D printers. Atmospheric Environment. 79, 334-339 (2013).

- Stabile, L., Scungio, M., Buonanno, G., Arpino, F., Ficco, G. Airborne particle emission of a commercial 3D printer: the effect of filament material and printing temperature. Indoor Air. 27 (2), 398-408 (2017).

- Kwon, O., et al. Characterization and control of nanoparticle emission during 3D printing. Environmental Science & Technology. 51 (18), 10357-10368 (2017).

- Yi, J., et al. Emission of particulate matter from a desktop three-dimensional (3D) printer. Journal of Toxicology and Environmental Health, Part A. 79 (11), 453-465 (2016).

- Rao, C., et al. Capturing PM2. 5 emissions from 3D printing via nanofiber-based air filter. Scientific reports. 7 (1), 10366 (2017).

- Zontek, T. L., Ogle, B. R., Jankovic, J. T., Hollenbeck, S. M. An exposure assessment of desktop 3D printing. Journal of Chemical Health & Safety. 24 (2), 15-25 (2017).

- Zhang, Q., Wong, J. P., Davis, A. Y., Black, M. S., Weber, R. J. Characterization of particle emissions from consumer fused deposition modeling 3D printers. Aerosol Science Technology. 51 (11), 1275-1286 (2017).

- Kim, Y., et al. Emissions of Nanoparticles and Gaseous Material from 3D Printer Operation. Environmental Science & Technology. 49 (20), 12044-12053 (2015).

- Azimi, P., Zhao, D., Pouzet, C., Crain, N. E., Stephens, B. Emissions of ultrafine particles and volatile organic compounds from commercially available desktop three-dimensional printers with multiple filaments. Environmental Science & Technology. 50 (3), 1260-1268 (2016).

- Steinle, P. Characterization of emissions from a desktop 3D printer and indoor air measurements in office settings. Journal of Occupational and Environmental Hygiene. 13 (2), 121-132 (2016).

- Vance, M. E., et al. Aerosol emissions from fuse-deposition modeling 3D printers in a chamber and in real indoor environments. Environmental Science & Technology. 51 (17), 9516-9523 (2017).

- Floyd, E. L., Wang, J., Regens, J. L. Fume emissions from a low-cost 3-D printer with various filaments. Journal of Occupational and Environmental Hygiene. 14 (7), 523-533 (2017).

- Stefaniak, A. B., et al. Characterization of chemical contaminants generated by a desktop fused deposition modeling 3-dimensional Printer. Journal of Occupational and Environmental Hygiene. 14 (7), 540-550 (2017).

- Azimi, P., Fazli, T., Stephens, B. Predicting concentrations of ultrafine particles and volatile organic compounds resulting from desktop 3D printer operation and the impact of potential control strategies. Journal of Industrial Ecology. 21, 107-119 (2017).

- Gu, J., Wensing, M., Uhde, E., Salthammer, T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environment International. 123, 476-485 (2019).

- Davis, A. Y., Zhang, Q., Wong, J. P., Weber, R. J., Black, M. S. Characterization of volatile organic compound emissions from consumer level material extrusion 3D printers. Building and Environment. 160, 106209 (2019).

- Wojtyła, S., Klama, P., Śpiewak, K., Baran, T. 3D printer as a potential source of indoor air pollution. International Journal of Environmental Science and Technology. 17 (1), 207-218 (2020).

- Bierkandt, F. S., Leibrock, L., Wagener, S., Laux, P., Luch, A. The impact of nanomaterial characteristics on inhalation toxicity. Toxicology Research. 7 (3), 321-346 (2018).

- Chan, F., et al. Health survey of employees regularly using 3D printers. Occupational Medicine. 68 (3), 211-214 (2018).

- Acquah, S. F., Berber, M. A., Hafez, I. H., et al. Carbon nanotubes and graphene as additives in 3D printing. Nanotubes-current progress of their polymer composites. , 227-253 (2016).

- Schrand, A. M., et al. Metal-based nanoparticles and their toxicity assessment. Wiley interdisciplinary reviews: Nanomedicine and Nanobiotechnology. 2 (5), 544-568 (2010).

- Karlsson, H. L., Cronholm, P., Gustafsson, J., Moller, L. Copper oxide nanoparticles are highly toxic: a comparison between metal oxide nanoparticles and carbon nanotubes. Chemical Research In Toxicology. 21 (9), 1726-1732 (2008).

- Donaldson, K., Murphy, F. A., Duffin, R., Poland, C. A. Asbestos, carbon nanotubes and the pleural mesothelium: a review of the hypothesis regarding the role of long fibre retention in the parietal pleura, inflammation and mesothelioma. Particle and Fibre Toxicology. 7 (1), 5 (2010).

- Stefaniak, A. B., et al. Three-dimensional printing with nano-enabled filaments releases polymer particles containing carbon nanotubes into air. Indoor Air. 28 (6), 840-851 (2018).

- Yi, J., et al. Particle and organic vapor emissions from children’s 3-D pen and 3-D printer toys. Inhalation Toxicology. , 1-14 (2019).

- Salvi, S. Health effects of ambient air pollution in children. Paediatric Respiratory Reviews. 8 (4), 275-280 (2007).

- Zhang, Q., et al. Investigating particle emissions and aerosol dynamics from a consumer fused deposition modeling 3D printer with a lognormal moment aerosol model. Aerosol Science and Technology. 52 (10), 1099-1111 (2018).

- Byrley, P., George, B. J., Boyes, W. K., Rogers, K. Particle emissions from fused deposition modeling 3D printers: Evaluation and meta-analysis. Science of The Total Environment. 655, 395-407 (2019).

- Singh, A. V., et al. Review of emerging concepts in nanotoxicology: opportunities and challenges for safer nanomaterial design. Toxicology Mechanisms and Methods. 29 (5), 378-387 (2019).

- Denkhaus, E., Salnikow, K. Nickel essentiality, toxicity, and carcinogenicity. Critical Reviews In Oncology/Hematology. 42 (1), 35-56 (2002).

- Technical Data Sheet, Galaxy PLA. Formfutura Available from: https://bit.ly/31Bco0O (2020)

- Stefaniak, A., et al. Particle and vapor emissions from vat polymerization desktop-scale 3-dimensional printers. Journal of Occupational and Environmental Hygiene. 16 (8), 519-531 (2019).

- Uhde, E., He, C., Wensing, M. Characterization of ultra-fine particle emissions from a laser printer. Proc. Int. Conf. Healthy Building. 2, 479-482 (2006).