Shotgun Proteomics Sample Processing Automated by an Open-Source Lab Robot

Summary

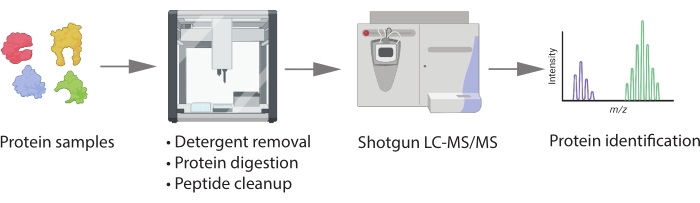

Detailed protocol and three Python scripts are provided for operating an open-source robotic liquid handling system to perform semi-automated protein sample preparation for mass spectrometry experiments, covering detergent removal, protein digestion, and peptide desalting steps.

Abstract

Mass spectrometry-based shotgun proteomics experiments require multiple sample preparation steps, including enzymatic protein digestion and clean-up, which can take up significant person-hours of bench labor and present a source of batch-to-batch variability. Lab automation with pipetting robots can reduce manual work, maximize throughput, and increase research reproducibility. Still, the steep starting prices of standard automation stations make them unaffordable for many academic laboratories. This article describes a proteomics sample preparation workflow using an affordable, open-source automation system (The Opentrons OT-2), including instructions for setting up semi-automated protein reduction, alkylation, digestion, and clean-up steps; as well as accompanying open-source Python scripts to program the OT-2 system through its application programming interface.

Introduction

Mass spectrometry-based shotgun proteomics is a powerful tool to measure the abundance of many proteins in biological samples simultaneously. Proteomics experiments with bioinformatics analysis are routinely employed to identify biomarkers and discover associated biological complexes and pathways underpinning pathological mechanisms. With its high analyte specificity and potential quantitative accuracy, shotgun proteomics also has excellent potential to be adopted by research facilities and diagnostic laboratories for clinical sample analysis without the need to rely on antibodies1,2.

To prepare protein samples for shotgun proteomics analysis, proteins extracted from biological samples (e.g., cells and tissues) typically first need to be processed using lengthy protocols, including measuring the sample protein concentration, protein reduction, and alkylation, and enzymatic digestion into peptides. Moreover, proteins extracted in common lysis buffers containing detergents often require additional steps of buffer exchange or detergent removal before analysis because detergent can interfere with trypsin digestion and significantly degrade the performance of downstream liquid chromatography-tandem mass spectrometry (LC-MS/MS) analysis3. Peptides are typically further desalted, dried, and reconstituted in LC-MS/MS compatible solvents following enzymatic digestion. These protein biochemistry procedures can be labor-intensive and time-consuming. Thus, they continue to limit the throughput of proteomics workflows and contribute to the variability of acquired data4,5. Human errors and biases have been recognized as crucial factors affecting data variance and reproducibility6,7. To minimize human errors in mass spectrometry sample preparation workflows, automated pipetting robotic systems have been utilized to improve the throughput and reproducibility of protein identification and quantification from shotgun proteomics and targeted mass spectrometry analysis, where such advances have been hailed as instrumental for continuing the push for widespread adoption of proteomics technologies in critical research and clinical settings8,9,10,11,12,13. However, most existing protocols utilize robotic liquid handling platforms that require substantial investment and training, limiting their utility in many laboratories in the academic environment or otherwise with a limited budget.

This article describes a protocol that utilizes a low-cost, open-source robotic liquid handling system, the OT-2, to semi-automate a typical shotgun proteomics sample preparation workflow. The OT-2 has a lower cost than many other robotic liquid handling systems, and at the time of writing, costs approximately $5,000 US dollars. When factoring in the prices of different modules and labware, the total cost to set up experiments in this protocol at the time of writing is around $10,000, which renders it more affordable to a considerably broader set of laboratories over more expensive options. The OT-2 is compatible with open-source programming through Python scripts and offers great flexibilities in user-defined DIY protocol design. Using three in-house developed scripts, the protocols below cover executing a typical shotgun proteomics sample preparation workflow on the OT-2 station with an archetypical protein standard (bovine serum albumin; BSA) and a complex protein sample of a normal human heart lysate (Figure 1). The procedures for processing (1) a BSA sample and (2) a complex cardiac lysate sample are detailed in Protocol sections 1, 2, 5, 6 and 3, 4, 5, 6, respectively. Sera-Mag carboxylate-modified magnetic beads are utilized in single-pot solid-phase-enhanced sample preparation (SP3) to remove detergents and salts in the protein and peptide samples. Tryptic digests from bovine serum albumin and human heart proteins are further cleaned by SP3 beads and submitted for LC-MS/MS analysis. Mass spectra are then analyzed using the MaxQuant software for peptide and protein identification. Representative results performed by us show that the protocol achieves excellent technical coefficients of variation (CV) while saving bench time and is non-inferior to hand digest.

Protocol

The developed Python scripts have been deposited on GitHub at: https://github.com/MaggieLam-Lab/StandardDigestion-Opentrons. A copy of the scripts is given in Supplementary File 1. Please refer to the GitHub repository for the latest versions.

1. Experimental preparations

- Check the required hardware before starting the protocol.

NOTE: The following hardware components are required: OT-2 pipettes, pipette tips, 4-in-1 tube rack set, aluminum block set, magnetic module, temperature module, 96-well 2 mL deep well plates (see Table of Materials).

2. Mass spectrometry (MS) sample preparation with a single protein bovine serum albumin (BSA)

- Open the NoSP3_digestion.py script in a text editor and specify the experiment-specific variables as needed in the CUSTOMIZE HERE ONLY section.

NOTE: The experiment-specific variables include the number of samples and replicate; the sample concentration; the volume of reagents dithiothreitol – DTT, iodoacetamide – IAA, and trypsin; the DTT and IAA incubation time, and the starting tip for pipette P20/P50 and P300).- Open the Opentrons App and upload the script to the PROTOCOL tab in the Opentrons App.

NOTE: The Opentrons App can be downloaded from Reference14 to a local computer. At the time of writing, the Opentrons P50 electronic pipette is unavailable for purchase in the Opentrons store. It has been replaced with the P20 single-channel electronic pipette compatible with the volumes specified in the protocol. Notes and instructions have been made in the script to replace the P50 pipette with the P20 pipette. Users may need to test and verify the particular pipette's compatibility with this protocol following Opentrons API instruction.

- Open the Opentrons App and upload the script to the PROTOCOL tab in the Opentrons App.

- Open the ROBOT tab and perform robot deck calibration Calibrate Deck in the ROBOT tab following the step-by-step on-screen instructions in the Opentrons App.

NOTE: This step is required only if it has not been previously implemented or the robot has recently been translocated. - Click on the MANAGE PIPETTES button to perform tip length calibration, followed by pipette offset calibration to calibrate the default tip and pipette combination position.

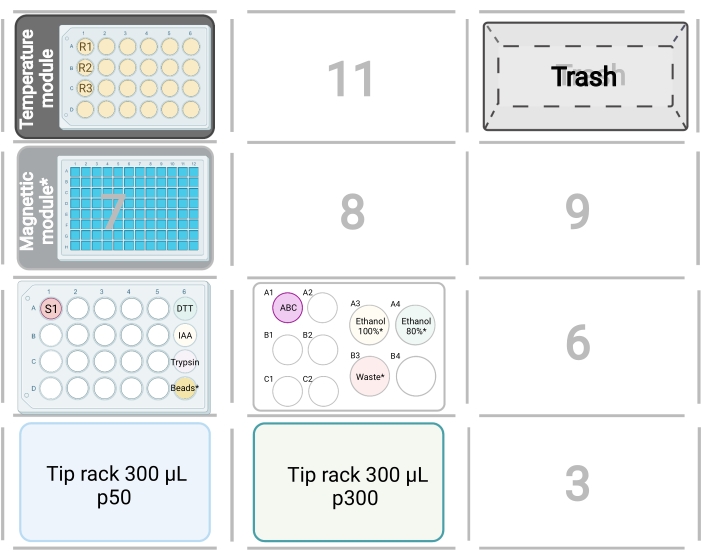

NOTE: This step is required if a pipette is used for the first time. - Place the required labware and pipettes in the corresponding location in the OT-2 deck specified in the Python script (Figure 2).

NOTE: Ensure that the temperature module is connected and powered on, and the aluminum block is placed on top of the temperature module. - Open the CALIBRATE tab and perform calibration for the combination of labware and pipettes required in this python script.

NOTE: The Opentrons App will record the calibration parameters, which is not necessary for future applications with the same labware and pipettes. - Prepare 5 mL of 100 mM ammonium bicarbonate (ABC) (pH ~8.0) solution by dissolving 39.53 mg of ABC in mass spectrometry-grade water to a total volume of 5 mL in a 15 mL conical tube. Place ammonium bicarbonate buffer in the A1 well of the 4-in-1 tube rack with the 15 mL + 50 mL tube holder top.

- Prepare 1 mL of bovine serum albumin (BSA) protein in a 2.0 mL protein low-bind tube (see Table of Materials). Place the sample in the A1 well of the 4-in-1 tube rack with 2 mL tube holder top.

- Manually place 2.0 mL protein low-bind tubes in the wells of A1, B1, C1, D1, E1, F1, A2, etc. in the aluminum block on top of the temperature module.

NOTE: The robotic pipette will dispense samples in the vertical order starting from A1 (first sample) until the last sample by default. Horizontal dispensing can be specified. Refer to15 for details. The total number of tubes that need to be prepared should equal the total number of samples (i.e., the number of biological samples multiplied by the number of technical replicates per sample). - Prepare 1 mL of 60 mM DTT by dissolving 9.26 mg of DTT solids in mass spectrometry grade water to a total volume of 1 mL. Place the DTT in the A6 well of the 4-in-1 tube rack with the 2 mL tube holder top.

CAUTION: DTT is harmful to human eyes, skin, and the respiratory system. Wear PPE and handle it under a chemical hood. Refer to the manufacturer's safety data sheet for proper procedures. - Observe while the robot transfers an appropriate volume of ABC buffer to the sample tubes in the aluminum block.

NOTE: The total volume of ABC and protein mix in each tube is 100 µL, and the volume of ABC buffer is calculated in the script (V = 100 µL minus the volume of 100 µg of protein sample). - Ensure that the robot transfers 100 µg of BSA protein to each tube with ABC buffer.

NOTE: A typical experiment may use up to 100 µg of proteins for protein digestion, i.e., 50 µL of 2.0 µg/µL for this BSA sample. - Manually verify that the robot program is paused and displays the message: Ensure DTT has been loaded into A6 of the 2 mL tube rack located in slot 4 before resuming protocol. Make sure a DTT tube is placed in the A6 well and open its cap. Click on the Resume button in the Opentrons app to continue. Ensure that the robot transfers 10 µL of DTT solution to each sample well, followed by five mixing rounds.

- Verify that the robot program is paused and displays the message: Ensure to close caps on sample tubes. Manually close the caps of the tubes and click on Resume to continue. Wait till the robot's temperature module starts to heat the aluminum block until the temperature reaches 55 °C, followed by a 5 min incubation to allow samples to get to 55 °C.

NOTE: The robot will hold the temperature at 55 °C for 30 min to allow protein reduction by DTT during incubation. - During the 30 min of DTT incubation, prepare 1 mL of 187.5 mM Iodoacetamide (IAA) by dissolving 34.68 mg of IAA in the ABC buffer to a total volume of 1 mL. Manually wrap the IAA solution with aluminum foil to avoid exposure to light.

CAUTION: IAA can cause severe eye and respiratory irritation. Handle it under a chemical hood wearing proper PPE. - Ensure that the robot's temperature module cools down upon completing the 30 min DTT incubation step.

NOTE: After the module's temperature reaches 22 °C, the module maintains the temperature for 5 min to allow the samples to cool down fully. - Uncap the sample tubes when the robot's program is paused and display the warning message: Ensure to open caps on sample tubes. Click on Resume to continue.

- Manually verify that the robot's program is paused with a warning message: Ensure IAA has been loaded into B6 of the 2 mL tube rack located in slot 4 before resuming protocol. Confirm the rack location of the IAA tube and open the tube cap. Click on Resume to continue. Ensure that the robot transfers 10 µL of IAA to each sample tube followed by five mixing rounds.

- Cap the sample tubes when the robot's program is paused and display the message: Close caps on sample tubes and cover sample tubes with foil. Cover the entire aluminum block with a clean piece of foil. Click on Resume to continue. Wait till the samples are incubated at 22 °C for 30 min. Ensure that the robot's temperature module deactivates upon completion of IAA incubation.

- Prepare a mixture of trypsin solution during IAA incubation (step 2.19) at the final concentration of 0.2 µg/µL: dissolve 20 µg of mass spectrometry/sequencing-grade trypsin in 100 µL of MS-grade water.

- Place the trypsin solution in the C6 well of the 2 mL tube rack with the tube cap open when the robot's program is paused and displays the warning message: Ensure trypsin has been loaded into C6 of the 2 mL tube rack located in slot 4 prior to resuming protocol. Click on Resume to continue.

- Check that the robot's program is paused and displays the warning message: Open caps on sample tubes on the temperature module. Uncap the sample tubes and click on Resume to continue. Stand by while the robot transfers 10 µL of trypsin to each sample tube followed by five mixing rounds.

- Wrap the sample tube caps with paraffin film, transfer all samples to a temperature-controlled mixer, and incubate at 37 °C for 16-20 h with 600 rpm shaking.

NOTE: The trypsin digestion may also be performed directly on the temperature module at 37 °C.

3. Peptide clean-up using SP3 paramagnetic beads

- The next day after overnight trypsin digestion, briefly spin the samples using a benchtop microcentrifuge (≤2,000 x g) (see Table of Materials) and place the samples on a magnetic tube rack. Let the samples stand for 2 min.

- Transfer the supernatant carefully with a pipette to a new set of protein low-bind microcentrifuge tubes. Keep the samples in a refrigerator and proceed to steps 3.2-3.9.

NOTE: For long-term storage, store the samples at -80 °C.

- Transfer the supernatant carefully with a pipette to a new set of protein low-bind microcentrifuge tubes. Keep the samples in a refrigerator and proceed to steps 3.2-3.9.

- Open the SP3_peptide_cleanup.py Python script in a text editor and specify as needed in the CUSTOMIZE HERE ONLY section.

NOTE: The experiment-specific variables include the number of samples and replicates, the volume of peptides to be transferred, the volume of reagents (beads, acetonitrile, DMSO), the starting tip for P20/P50 and P300 pipettes, and starting well in the deep-well plate on the magnetic module. Each BSA digest sample contains about 120 µL of digestion volume, which will be aliquoted into two technical replicates with 55 µL in each replicate. To clean up half of the digest only, change the replicate number variable to 1. - Upload the script to the PROTOCOL tab in the Opentrons app.

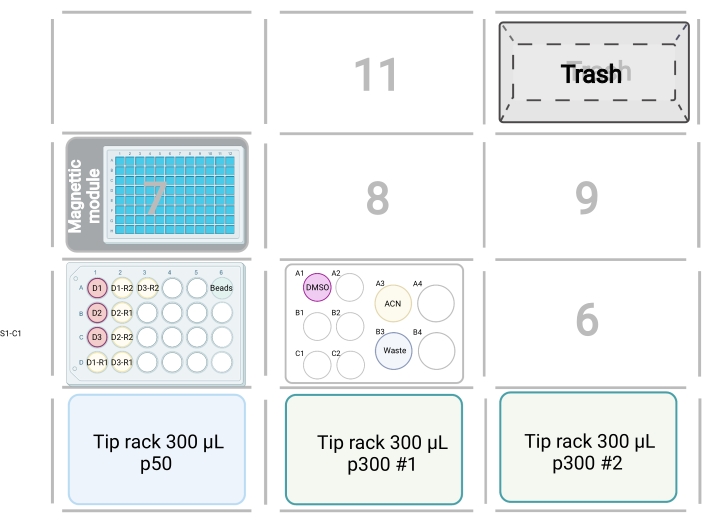

- Place the required labware and pipettes in the corresponding location in the OT-2 deck specified in the Python script (Figure 3). Make sure the magnetic module is powered on and connected to the robot. Place a new 2 mL 96-well deep well plate (see Table of Materials) on the top of the magnetic module.

- Open the CALIBRATE tab and perform calibration for the combination of labware and pipettes required in this Python script.

NOTE: Calibration for the same labware and pipette combinations only needs to be performed once, and the Opentrons App will record the calibration parameters. - Place the digested samples (supernatant collected at step 3.1) to the 2.0 mL tube rack in the vertical order in wells A1, B1….

- Prepare 15 mL of LC-MS/MS-compatible acetonitrile in a 50 mL conical tube and place the tube in the well A3 in the 4-in-1 tube rack with the 15 mL + 50 mL tube holder top.

- Prepare 5 mL of 2% DMSO by adding 100 µL DMSO with 4.9 mL mass spectrometry-grade water in a 15 mL conical tube. Place the tube in the well A1 in the 15mL + 50mL tube rack.

- Label an empty 50 mL conical tube as Waste and place it in the well B3 in the 15mL + 50mL tube rack.

- Prepare the SP3 beads following Reference16.

- Prepare an appropriate amount of mixed beads in a 2.0 mL microcentrifuge tube.

NOTE: Each peptide clean-up reaction requires 10 µL of mixed beads. For example, prepare a minimum of 40 µL of mixed beads for four clean-up reactions. - Let the bead mixture sit on the magnetic stand for 2 min. Remove the supernatant carefully with a pipette and measure the volume of the supernatant with a pipette.

- Calculate the remaining volume of beads and add 5-10 times the mass spectrometry grade water (e.g., 100-200 µL water for 20 µL of beads) and vortex (speed 10) for 10 s. Sit the beads on the magnetic stand for 2 min.

- Repeat water wash steps for a total of three washes.

- Resuspend the final beads in MS-grade water to a final concentration of 50 µg/µL. Place the washed magnetic beads in the well A6 in the 2.0 mL tube rack.

NOTE: The beads are recommended to resuspend at a concentration of 10 µg/µL16. In the current optimization effort, the final concentration was modified to 50 µg/µL to minimize the total volume of the bead-peptide-acetonitrile mixture.

- Prepare an appropriate amount of mixed beads in a 2.0 mL microcentrifuge tube.

- Ensure that the robot transfers 55 µL of the digested samples to the wells in the deep-well plates on the magnetic module.

- Verify that the robot protocol is paused and displays the message: Ensure prepared beads have been loaded into A6 of the 2 mL tube rack located in slot 4 before resuming protocol. Vortex the beads, and then briefly spin down for 5 s on a mini benchtop centrifuge and place the beads in the A6 well of the 2 mL tube rack with the cap open. Stand by while the robot mixes the beads 10 times for five rounds by pipetting up and down.

NOTE: The robot transfers 10 µL of beads to each digested sample in the deep-well plates followed by five times of mixing. - Ensure that the robot transfers 1,292 µL of acetonitrile to each well and immediately mixes 10 times by pipetting up and down to facilitate peptides and beads binding.

NOTE: Each transfer is completed over several rounds because the P300 pipette can only transfer up to 300 µL at a time. - Ensure that the robot mixes all samples five times by pipetting up and down in the deep-well plate.

- Wait till the magnetic module is engaged and samples are incubated on the module for 2 min.

- Stand by while the pipetting aspiration and dispense speeds are set to slow at 25 µL/s from the default of 150 µL/s.

NOTE: The robot slowly removes the supernatant from each well and discards it in the Waste tube while the magnetic module is engaged. - Wait till the pipetting aspiration and dispense speeds are returned to the default setting. Observe that the magnetic module disengages.

- Verify that the robot's program is paused and displays the message: Make sure the ACN tube cap is off. Manually uncap the acetonitrile tube and place it back to the tube rack. Click on Resume to continue. Ensure that the robot transfers 1 mL of acetonitrile to wash each sample and immediately mixes 10 times.

- Ensure that the robot mixes all samples 10 times to wash the samples.

- Stand by while the magnetic module is engaged and incubates the samples for 2 min.

- Wait till the robot changes the pipetting aspiration speed to slow and slowly removes the supernatant and dispenses it in the Waste tube.

- Observe while the robot incubates the samples on the magnetic module for 60 s to allow residual acetonitrile to evaporate, then changes the pipetting aspiration speeds back to default. Observe that the magnetic module becomes disengaged.

- Verify that the robot's program is paused and displays the message: Vortex DMSO again and open caps. Manually vortex the 2% DMSO for 10 s and place it back in the A1 well in the 15 mL-50 mL tube rack. Click on Resume to continue.

- Ensure that the robot transfers 80 µL of 2% DMSO to each well and immediately mixes 10 times.

- Ensure that the robot mixes all samples 10 times for additional five rounds.

- Stand by while the magnetic module is engaged and incubates the samples for 2 min.

- Observe while the robot changes the pipette aspiration speed to slow (25 µL/s) and slowly transfers the supernatant to empty wells in the deep-well plate.

- Wait till the robot incubates samples on the magnetic module for 2 min to remove residual beads in the samples.

- Verify that the robot's program is paused and displays the message: Place new 2 mL tubes in the 2 mL tube rack and ensure the number of tubes matches the total number of samples.

- Place the first 2 mL microcentrifuge tube in the well directly after the final BSA digest sample. Click on Resume to continue.

NOTE: For example, the six BSA digest samples tested in this protocol are in the wells A1, B1, C1, D1, A2, and B2. Therefore, the new set of 2.0 mL tubes is placed in the wells B3, C3, D3, … and so on. - Observe while the robot transfers 88 µL of samples from the wells in the deep-well plate to the new set of 2.0 mL tubes.

NOTE: The transferred volume (1.1 x 80 µL) in the protocol is optimized to ensure the entire volume of the sample is aspirated into pipette tips. - Stand by while the robot changes the pipette aspiration speed to default and disengages the magnetic module.

- Manually dry the cleaned-up peptides in a vacuum evaporator (see Table of Materials) and proceed to section 5 or store dried samples at -20 °C.

4. MS sample preparation with protein lysate of the human heart (5 mg/mL) with SP3 paramagnetic beads

- Open the SP3_digestion.py Python script and specify values of variables in the CUSTOMIZE HERE ONLY section.

NOTE: The variables include the number of samples and replicate, the sample concentration, the volume of reagents (DTT, IAA, trypsin, beads, 100% and 80% ethanol), DTT and IAA incubation time, starting tip for pipettes P20/P50 and P300, and starting well in the deep-well plate on the magnetic module. - Follow steps 2.2-2.23 in section 2 for MS sample preparation with a single protein bovine serum albumin for DTT and IAA incubation. Refer to Figure 1 for the robot deck setup in those steps.

- Prepare a fresh SP3 beads mix (20 µL beads per clean-up reaction) for protein clean-up (as specified in step 3.10) during the DTT and IAA incubation steps (steps 2.15 and 2.19). Place the beads in the D6 well on the 2 mL tube rack.

- Verify that the robot's program is paused with the message: Open tube caps. Manually uncap the sample tubes in the aluminum block on top of the temperature module and click on Resume to continue.

- Ensure that the robot transfers all the samples from 2.0 mL tubes to a new deep-well plate on top of the magnetic module.

- Check that the robot's program is paused and displays the message: Ensure prepared beads have been loaded into D6 of the 2 mL tube rack located in slot 4 prior to resuming protocol. Open the beads tube cap and click on Resume to continue.

- Observe while the robot transfers 20 µL of beads to each well in the deep-well plate with five rounds of mixing of the beads and five rounds of mixing of the sample-beads mixture.

- Verify that the robot's program is paused and displays the message: Ensure 100 percent ethanol has been loaded into A3 of the 15 mL-50 mL tube rack located in slot 5 prior to resuming protocol. Prepare 10-20 mL of 100% ethanol (i.e., 200 proof ethanol, see Table of Materials) in a 50 mL conical tube and place it in the A3 well of the rack. Click on Resume to continue.

- Stand by while the robot transfers 140 µL of 100% ethanol to each well in the plate immediately followed by 10 rounds of mixing to facilitate peptides' binding to the beads.

- Ensure that the robot mixes each sample by pipetting up and down 10 times each round for a total of five rounds of mixing.

- Stand by while the magnetic module is engaged and incubates the samples on the module for 2 min.

- Observe while the robot changes the pipetting speed to slow (25 µL/s) and aspirates the supernatant from each well and dispenses it into the Waste tube.

- Wait till the robot changes the pipetting speed back to default and disengages the magnetic module.

- Verify that the robot's program is paused and displays the message: Ensure 80 percent ethanol has been loaded into A4 of the 15 mL-50 mL tube rack located in slot 5 prior to resuming protocol. Manually prepare 20 mL of 80% ethanol by mixing 4 mL of MS-grade water with 16 mL of 100% ethanol (i.e., 200 proof). Place the 80% ethanol in the A4 well in the tube rack. Click on Resume to continue. Ensure that the robot transfers 1 mL of 80% ethanol to each well and immediately mixes 10 times.

- Observe while the robot changes the pipetting speed to slow (25 µL/s), aspirates the supernatant from each well, and dispenses into the Waste tube. Wait till the robot changes the pipetting speed back to default and disengages the magnetic module.

- Open the cap of the ABC solution when the robot's program is paused and displays the message: Open cap on ABC tube. Click on Resume to continue. Stand by while the robot disengages the magnetic module, transfers 250 µL of ABC to each well, and immediately mixes for 10 times.

NOTE: This step is to wash the samples with ABC. - Ensure that the robot engages the magnetic module and incubates samples on the module for 2 min.

- Observe while the robot changes the pipetting speed to slow (25 µL/s) and transfers the supernatant from each well to the Waste tube. Wait till the robot transfers 100 µL of ABC buffer to each well and immediately mixes for 10 times.

- Verify that the robot's program is paused and displays the message: Ensure new collection tubes have been placed in 2.0 mL aluminum block prior to resuming protocol. Place a new set of low-protein-retention microcentrifuge tubes in the aluminum block immediately after the last sample tube initially in the block. Click on Resume to continue. Stand by while the robot transfers each sample in ABC buffer to the new 2.0 mL tubes.

NOTE: Examine the wells and manually transfer any residual sample to the tubes if needed. - Prepare an appropriate amount of MS-grade trypsin (10 µL per sample) by dissolving 20 µg of MS-grade trypsin in MS-grade water to a final concentration of 0.2 µg/µL when the robot's program is paused and displays the message: Ensure trypsin (0.2 µg/µL) has been loaded into C6 of the 2 mL tube rack located in slot 4 prior to resuming protocol. Ensure that the robot transfers 10 μL of trypsin to each sample tube, followed by five rounds of mixing.

- Wrap the sample tube caps with paraffin film, transfer all the samples to a temperature-controlled mixer, and incubate at 37 °C for 16-20 h with 1,000 rpm shaking.

NOTE: Performing the digestion with 1,000 rpm shaking is recommended to minimize beads' precipitation during the overnight incubation.

5. Peptide clean-up using SP3 paramagnetic beads

- Follow stepwise instructions in step 2, Peptide clean-up using SP3 paramagnetic beads.

6. Liquid chromatography and mass spectrometry

- Resuspend the BSA (steps 2-3) and heart lysate (step 4) peptides in 0.1% formic acid by adding 1 mL LC-MS grade 99% formic acid in MS water to a total volume of 1 L.

CAUTION: Formic acid is a strong acid. It is highly corrosive to the eyes, skin, and respiratory system. Handle with care under a chemical hood wearing PPE. - Quantify the post-digest peptide concentration using a quantitative peptide assay kit17 and inject 0.5 µg of BSA digest and 1.5 μg of heart digest for LC-MS/MS analysis.

- Set up the liquid chromatography program for LC-MS/MS analysis.

NOTE: In a typical setup, peptide digests may be loaded on a reversed-phase C18 column (3 µm particle; 100 Å pore; 75 µm x 150 mm; see Table of Materials) using the parameters provided in Supplementary File 2. - Acquire shotgun proteomics data using a mass spectrometer (see Table of Materials) using the parameters provided in Supplementary File 3.

- Search the protein database for protein identification.

- Download and install the required software, MaxQuant.

NOTE: MaxQuant software (v.1.6.10.43) was used here for the following steps (see Table of Materials). - Download the curated human proteome database from a high-quality protein sequence database (UniProt/SwissProt) (see Table of Materials). Click on the Download button and choose FASTA (canonical).

NOTE: Optionally, download FASTA (non-canonical) to include protein isoforms of each gene in the database, if desired. - In the MaxQuant software interface, specify the FASTA file to be used as a protein database by navigating to Global Parameters panel and click on the Sequences tab; then, click on the Add button to specify the file path to the FASTA file.

- In the MaxQuant software interface, specify the acquired raw mass spectrum files to be analyzed by going to the Raw Data panel and clicking on the Load button and select the raw file(s).

- Set up search parameters as shown in Table 1. Enable label-free quantification (LFQ) if needed.

- Wait for the search to complete, and locate the number of peptide-spectrum matches (PSMs) that pass the FDR 1% thresholds in the msms.txt file in the /combined/txt folder.

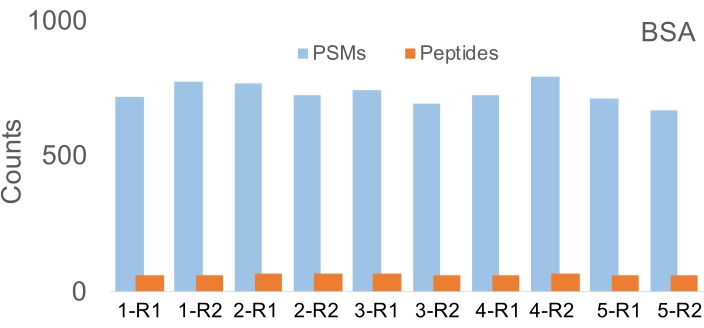

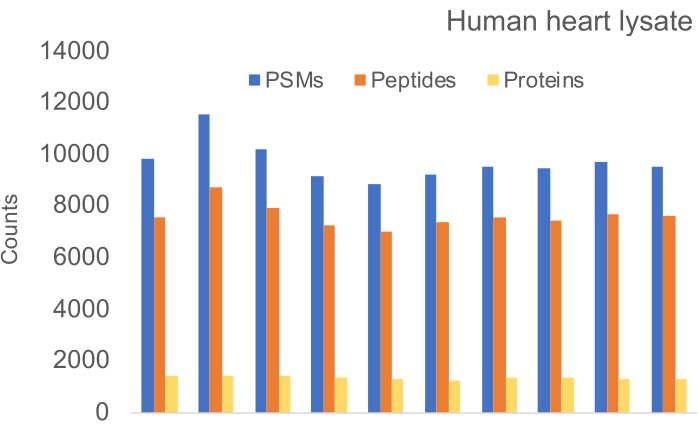

NOTE: In the comparisons performed here for the representative results section, PSMs mapped to multiple proteins were filtered out, and PSMs mapped to one unique protein were retained to count the number of PSMs, peptides, and proteins (Figure 4 and Figure 5).

- Download and install the required software, MaxQuant.

Representative Results

Three Python scripts are provided here that are compatible with the OT-2 robot, and that perform sample preparation for mass spectrometry proteomics with a single protein standard bovine serum albumin (technical replicates n = 5 digestions) and a detergent-containing human heart lysate sample (n = 5 digestions). Each digest product is partitioned into two peptide clean-up reactions. The number of identified peptide-spectrum matches (PSMs), peptides, and proteins in each run of the BSA and heart samples are shown in Figure 4 and Figure 5. A median of 728 PSMs and 65 peptides were identified with the BSA sample, with 5.2% and 3.2% coefficients of variation (CV), respectively. With the complex heart sample, a median of 9,526 PSMs, 7,558 peptides, and 1,336 proteins was identified in 10 runs with 7.6%, 5.9%, and 3.6% coefficient of variation. A total of 1,935 proteins were identified from 10 runs of the heart sample, and among those, 1,677 proteins were identified in two or more runs. To determine the variability in peptide quantification, the CV of the extracted ion chromatogram (XIC) intensities were calculated for 10 peptides that mapped to a unique protein (Table 2). The variabilities of human (hand-pipetted) vs. robot experimental results on measuring protein concentration were further compared using three protein standard samples with the BCA assay. The average CV (7.57%) of robot BCA assay was found to be lower than the human manual BCA assay (9.22%) (Supplementary Table 1).

The described protocol showed consistent performance over time when the BSA digestion protocol was performed 2 months apart and produced comparable results. The median number of unique PSMs and peptides in Figure 2 are 728 and 65, respectively. The same experiments performed on the OT-2 system 2 months before generated an average of 647 PSMs and 54 peptides (n = 2) (Supplementary Table 2). Longer-term stability may be estimated similarly.

The manual bench processing time (incubation time not included) is calculated between the robot protocol and human processing18 per sample preparation. With the digestion protocol without detergent removal followed by peptide desalting, the manual processing time is 41 min with the robotic system vs. 61 min by hand. With detergent removal, digestion, and peptide desalting protocol, the manual processing time is 54 min with the robotic system vs. 79 min by hand. Therefore, the semi-automated protocol reduces about 20-25 min of hands-on bench processing time per sample. This time reduction becomes considerable when many samples are processed and may be further improved when multiple OT-2 robots are used in parallel.

Figure 1: Schematic workflow. Proteins extracted with detergent aid will require processing with an extra step of detergent removal before digestion. Protein samples are digested, and peptides are desalted on the OT-2 robotic system. The peptide digests are injected into a Q-Exactive HF mass spectrometer coupled with a nano-LC. MS spectra are searched against a protein database for protein identification. Please click here to view a larger version of this figure.

Figure 2: Robot deck set up for protein digestion. The specified positions of tip racks, samples, trash, temperature module, and magnetic module are shown. Asterisks denote labware and reagents that are only required for the digestion protocol with detergent removal steps. Boxes with numbers denote unoccupied deck positions. Please click here to view a larger version of this figure.

Figure 3: Robot deck set up for the peptide clean-up script. The specified positions of tip racks, samples, trash, and magnetic module are shown. Boxes with numbers denote unoccupied deck positions. Please click here to view a larger version of this figure.

Figure 4: Number of peptide-spectrum matches (PSMs) and peptides detected in the digestions of BSA protein (n = 5). Each digest was split into two for technical replicate peptide clean-ups (R1 and R2). Coefficient of variations: 5.2% for PSMs; 3.2% for peptides. Please click here to view a larger version of this figure.

Figure 5: Number of PSMs, peptides, and proteins identified from a human heart lysate. Five digestions were performed with SP3 detergent removal. Each digest was split into two for peptide clean-ups (R1 and R2). Coefficients of variation: 7.6% for PSMs; 5.9% for peptides; 3.6% for proteins. Please click here to view a larger version of this figure.

| Digestion enzyme | Trypsin/P |

| Maximal missed cleavage | 2 |

| Fixed modification | Carbamidomethylation of cysteine |

| Variable modification | N-terminal protein acetylation; oxidation of methionine |

| Peptide length range | 7 – 25 aa |

| Precursor mass tolerance | ± 4.5 ppm |

| MS/MS ions mass tolerance | ± 20 ppm |

| Label-free quantification | LFQ |

| False discovery rate (FDR) for peptide-spectrum match (PSM) | 0.01 |

Table 1: The peptide database (MaxQuant) search parameters.

| Peptide | Protein ID | PEP | Median XIC Intensity | CV | |

| LSTSQIPQSQIR | Q92523 | 7.72E-08 | 1.96E+07 | 6.70% | |

| SEDFSLPAYMDR | P13073 | 9.64E-17 | 8.05E+08 | 7.30% | |

| YLQEIYNSNNQK | P02679 | 2.76E-23 | 9.69E+08 | 7.60% | |

| TDDCHPWVLPVVK | P17174 | 4.51E-14 | 4.60E+08 | 8.60% | |

| VIVVGNPANTNCLTASK | P40925 | 7.90E-29 | 1.17E+09 | 8.70% | |

| DYIWNTLNSGR | O75390 | 1.63E-15 | 1.38E+08 | 8.80% | |

| VSVPTHPEAVGDASLTVVK | P13611 | 1.86E-09 | 6.77E+07 | 9.10% | |

| QVAEQFLNMR | P22695 | 3.25E-08 | 1.09E+08 | 9.30% | |

| NTFWDVDGSMVPPEWHR | Q9UI09 | 2.05E-11 | 4.00E+07 | 9.60% | |

| SASDLTWDNLK | P02787 | 5.29E-11 | 1.92E+09 | 9.80% | |

Table 2: Extracted ion chromatogram (XIC) intensity quantification of 10 peptides.

Supplementary Table 1: Comparison of manual and automated BCA assays. Please click here to download this Table.

Supplementary Table 2: BSA digestion performed 2 months apart from the samples processed in Figure 4. Please click here to download this Table.

Supplementary File 1: A copy of the developed Python scripts. Please click here to download this File.

Supplementary File 2: Method parameters for the liquid chromatography program for LC-MS/MS analysis. Please click here to download this File.

Supplementary File 3: Method parameters for acquiring shotgun proteomics data using a mass spectrometer. Please click here to download this File.

Discussion

Critical steps within the protocol

For the best performance, Opentrons-verified labware, modules, and consumables compatible with OT-2 should be used. Custom labware can be created following Opentrons' instruction at Reference14. Make sure to calibrate the OT-2 deck, pipettes, and labware when used for the first time. It is also critical to follow guidelines from SP3 beads' manufacturer to prepare beads for peptide and protein clean-up. Notably, during the bead and peptide binding reaction, the volume of acetonitrile in the binding reaction needs to be ≥95%, and the bead concentration needs to be ≥0.1 µg/µL. Keep the peptide concentration in the range of 10 µg/mL-5 mg/mL. With the optimized parameters in the peptide clean-up script here, the acetonitrile volume ratio is 95%, the bead concentration is 0.37 µg/µL, and the peptide concentration is in the range of 14-37 µg/mL. The peptides mass is estimated to be 40-100 µg in 100 µL of digestion reaction from our experience. For SP3 protein clean-up, 5-10 µg of beads to 1 µg of protein was used and ensured that the minimal beads concentration is 0.5 µg/µL during protein binding. The recommended protein concentration is in the range of 10 µg/mL-5 mg/mL. With the default parameter in the provided script, 1 mg of beads is used for 100 µg protein, and the bead concentration during binding is 3.75 µg/µL, whereas the protein concentration is 0.35 mg/mL.

Modifications and troubleshooting

The default variables in the Python scripts are optimized for standard workflows in our laboratory. Users need to adjust the variables to make the scripts compatible with their applications if required. If low MS intensity is observed, check for protein or peptide loss after each significant protocol section with the protein BCA assay and quantitative peptide assay. When using the protocol on OT-2 for the first time, observe robot handling for each step to ensure the robot performs procedures as expected. At the time of writing, the P50 electronic pipette is no longer available in the Opentrons store. The current script has been modified to indicate where the P20 pipette may be used in its place. Users may refer to the Opentrons API to modify the scripts to use other pipettes, if necessary.

Limitations of the technique

Despite the advantages of using a robotic liquid handling system, caution should be exercised at the performance of fluid transfer between technical replicates. Monitoring the robot during the initial setup and liquid handling steps is highly recommended. After the robotic liquid transfer, manual recovery of residual volumes may be required to avoid sample loss and reduce variabilities.

Significance with respect to existing methods

This protocol describes a semi-automated mass spectrometry-based sample preparation method using the low-cost and open-source OT-2 liquid handling robot. Very recently, other works have also begun to use OT-2 toward proteomics applications11. Compared to existing methods, distinguishing features of this protocol include the use of a relatively low-cost, Python-programmable robot; the incorporation of semi-automated SP3 beads in two steps in the sample preparation protocols, namely, the protein sample detergent removal step and the peptide desalting/clean-up step; as well as the availability of open-source Python scripts to support further development. SP3 Paramagnetic beads bind proteins and peptides efficiently and have been coupled with automated liquid handling systems toward applications in protein clean-up/detergent removal before enzymatic digestion in MS sample preparation11,13.

Three open-source Python scripts are provided along with this protocol to researchers. The scripts are customizable for individual experimental conditions (e.g., sample number, replicate number, incubation temperature and time, etc.) and allow further development for modified workflows. The protocols afforded an excellent 3%-6% technical CVs in the number of peptides and/or protein identification between MS runs in our laboratory, comparable with previous work on other liquid handling systems (<20%)9,11.

Future applications

This protocol demonstrates the utility of a low-cost programmable liquid handling system in conjunction with SP3 beads for semi-automated proteomics sample preparation, which can be potentially applicable to mass spectrometry laboratories and core facilities to improve the efficiency of sample processing.

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

This work was supported in part by NIH awards F32-HL149191 to YH; R00-HL144829 to EL; R21-HL150456, R00-HL127302, R01-HL141278 to MPL. Figure 1, Figure 2, Figure 3 are created with the aid of a web-based science illustration tool, BioRender.com.

Materials

| 300 µL pipette tips | Opentrons | ||

| 4-in-1 tube rack set | Opentrons | Each set includes 2 base stands and 4 tube holder tops 1.5mL, 2mL, 15mL + 50mL, 15mL, and 50mL. We use 2mL and 15 mL + 50 mL tops in this study. | |

| Acclaim PepMap 100 C18 HPLC Column | Thermo Scientific | #164568 | 3 μm particle; 100 Å pore; 75 μm x 150 mm |

| Acetonitrile LC-MS grade | VWR | #JT9829 | |

| Aluminum block set | Opentrons | This block set includes 3 tops that are compatible with 96-well, 2.0 mL tubes and a PCR strip to use with the OT-2 temperature module. We use the 2.0mL tube holder in this manuscript. | |

| Ammonium Bicarbonate | Sigma-Aldrich | # A6141 | |

| Bovine Serum Albumin Standard, 2 mg/mL | Thermo Scientific | #23210 | |

| Dimethylsulfoxide (DMSO) LC-MS grade | Thermo Scientific | #85190 | |

| Dithiothreitol | Sigma-Aldrich | #D5545 | |

| EASY-Spray HPLC Columns | Thermo Scientific | #ES800A | |

| EasynLC 1200 Nano LC | Thermo Scientific | #LC140 | |

| Ethanol Proof 195-200 | Fisher | #04-355-720 | |

| Formic Acid LC-MS grade | Thermo Scientific | #85178 | |

| Human heart lysate | Novus Biologicals | NB820-59217 | |

| Iodoacetamide | Sigma-Aldrich | #I1149 | |

| Magnetic tube rack | Thermo Scientific | #MR02 | |

| MAXQuant v.1.6.10.43 | Tyanova et al., 2016 (https://www.maxquant.org/) | ||

| mySPIN 6 Mini Centrifuge | Thermo Scientific | #75004061 | benchtop mini centrifuge for quick spin |

| NEST 2 mL 96-Well Deep Well Plate, V Bottom | Opentrons | ||

| OT-2 magnetic module | Opentrons | GEN1 | |

| OT-2 P300 single channel pipette | Opentrons | GEN1 | |

| OT-2 P50 single channel pipette | Opentrons | GEN1 | |

| OT-2 robot pipetting robot | Opentrons | OT-2 | |

| OT-2 temperature module | Opentrons | GEN1 | |

| Pierce Quantitative Colorimetric Peptide Assay | Thermo Scientific | #23275 | |

| Protein LoBind tubes 2.0 mL | Eppendorf | #022431102 | |

| Protein Sequence Database | UniProt/SwissProt | https://www.uniprot.org/uniprot/?query=proteome:UP000005640% 20reviewed:yes |

|

| Sera-Mag SpeedBead Carboxylate-Modified Magnetic Particles, Hydrophobic | Cytiva | #65152105050250 | |

| Sera-Mag SpeedBead Carboxylate-Modified Magnetic Particles, Hydrophylic | Cytiva | #45152105050250 | |

| SpeedVac | Thermo Scientific | Vacuum evaporator | |

| Thermo Q Exactive HF Mass Spectrometer | Thermo Scientific | #IQLAAEGAAPFALGMBFZ | |

| Trypsin MS Grade | Thermo Scientific | #90057 | |

| Water LC-MS grade | VWR | #BDH83645.400 |

Referencias

- Geyer, P. E., et al. Revisiting biomarker discovery by plasma proteomics. Molecular Systems Biology. 13 (9), 942 (2017).

- Coscia, F., et al. A streamlined mass spectrometry-based proteomics workflow for large-scale FFPE tissue analysis. The Journal of Pathology. 251 (1), 100-112 (2020).

- Yeung, Y. -. G., Neives, E., Angeletti, R., Stanley, E. R., et al. Removal of detergents from protein digests for mass spectrometry analysis. Analytical Biochemistry. 382 (2), 135-137 (2008).

- Addona, T. A., et al. Multi-site assessment of the precision and reproducibility of multiple reaction monitoring-based measurements of proteins in plasma. Nature Biotechnology. 27 (7), 633-641 (2009).

- Lowenthal, M. S., Liang, Y., Phinney, K. W., Stein, S. E. Quantitative bottom-up proteomics depends on digestion conditions. Analytical Chemistry. 86 (1), 551-558 (2014).

- Elliott, K. C., Resnik, D. B. Scientific reproducibility, human error, and public policy. Bioscience. 65 (1), 5-6 (2015).

- Brown, A. W., Kaiser, K. A., Allison, D. B. Issues with data and analyses: Errors, underlying themes, and potential solutions. Proceedings of the National Academy of Sciences of the United States of America. 115 (11), 2563-2570 (2018).

- van den Broek, I., et al. Automated multiplex LC-MS/MS assay for quantifying serum apolipoproteins A-I, B, C-I, C-II, C-III, and E with qualitative apolipoprotein E phenotypic. Clinical Chemistry. 62 (1), 188-197 (2016).

- Müller, T., et al. Automated sample preparation with SP3 for low-input clinical proteomics. Molecular Systems Biology. 16 (1), 9111 (2020).

- Fu, Q., et al. Highly reproducible automated proteomics sample preparation workflow for quantitative mass spectrometry. Journal of Proteome Research. 17 (1), 420-428 (2018).

- Liu, X., Gygi, S. P., Paulo, J. A. A semiautomated paramagnetic bead-based platform for isobaric tag sample preparation. Journal of the American Society for Mass Spectrometry. 32 (6), 1519-1529 (2021).

- Poulsen, K. M., Pho, T., Champion, J. A., Payne, C. K. Automation and low-cost proteomics for characterization of the protein corona: experimental methods for big data. Analytical and Bioanalytical Chemistry. 412 (24), 6543-6551 (2020).

- Liang, Y., et al. Fully automated sample processing and analysis workflow for low-input proteome profiling. Analytical Chemistry. 93 (3), 1658-1666 (2021).

- . Web URL Available from: https://opentrons.com/ot-app/ (2021)

- . Web URL Available from: https://docs.opentrons.com/v2/ (2021)

- . Web URL Available from: https://www.cytivalifesciences.com/en/us/solutions/genomics/knowledge-center/cleanup-for-mass-spectrometry (2021)

- . Web URL Available from: https://www.thermofisher.com/order/catalog/product/23275#/23275 (2021)

- Han, Y., Wright, J. M., Lau, E., Lam, M. P. Y. Determining alternative protein isoform expression using RNA sequencing and mass spectrometry. STAR Protocols. 1 (3), 100138 (2020).