Characterization of Anisotropic Leaky Mode Modulators for Holovideo

Summary

This work describes fabrication and characterization of anisotropic leaky mode modulators for holographic video.

Abstract

Holovideo displays are based on light-bending spatial light modulators. One such spatial light modulator is the anisotropic leaky mode modulator. This modulator is particularly well suited for holographic video experimentation as it is relatively simple and inexpensive to fabricate1-3. Some additional advantages of leaky mode devices include: large aggregate bandwidth, polarization separation of signal light from noise, large angular deflection and frequency control of color1. In order to realize these advantages, it is necessary to be able to adequately characterize these devices as their operation is strongly dependent on waveguide and transducer parameters4. To characterize the modulators, the authors use a commercial prism coupler as well as a custom characterization apparatus to identify guided modes, calculate waveguide thickness and finally to map the device’s frequency input and angular output of leaky mode modulators. This work gives a detailed description of the measurement and characterization of leaky mode modulators suitable for full-color holographic video.

Introduction

Most holographic display technologies, such as pixelated light valves as well as MEMs devices and bulk wave acousto-optic modulators, are too complex to allow for broad participation in their development. Pixelated modulators, especially those with filter layers and active back planes may require dozens of patterning steps to build5 and may be limited by fan-out6. The greater the number of patterning steps the higher the device complexity, and the tighter the fabrication protocol must be to achieve reasonable device yield7. Bulk-wave acousto-optic modulators do not lend themselves to wafer based processes8,9. Anisotropic leaky mode modulators, however, require only two patterning steps to fabricate and utilize relatively standard microfabrication techniques10,11. The accessibility of these processes make it possible for any institution with modest fabrication facilities to participate in the development of holographic video display technology12.

The simplicity of device fabrication can be beguiling, however, as the proper function of the devices is strongly dependent upon waveguides which must be carefully measured and adjusted to achieve the desired device characteristics. For example, if the waveguide is too deep, the device's operational bandwidth will be narrowed13. If the wave guide is too shallow, the device may not work for red illumination. If the waveguide is annealed too long, the shape of the waveguide's depth profile will be distorted, and the red, green and blue transitions may not sit adjacent in the frequency domain14. In this work the authors present the tools and techniques to perform this characterization.

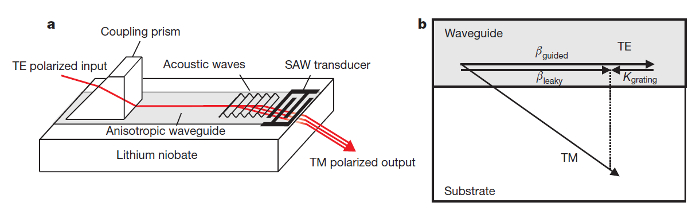

The leaky mode modulator consists of a proton exchanged waveguide indiffused on the surface of a piezoelectric, x-cut lithium niobate substrate15,16. At one end of the waveguide is an aluminum interdigital transducer, see Figure 1. Light is introduced into the waveguide using a prism coupler17. The transducer then launches surface acoustic waves which interact contralinearly with light in the waveguide along the y-axis. This interaction couples guided light into a leaky mode which leaks out of the waveguide into the bulk and finally exits the substrate from the edge face18,19. This interaction also rotates the polarization from TE polarized guided light to TM polarized leaky mode light. The surface acoustic wave pattern is the hologram, and it is capable of scanning and shaping the output light to form a holographic image.

The waveguide is created by proton exchange. First, aluminum is deposited on the substrate. Then the aluminum is patterned photo-lithographically and etched to expose regions of the substrate to become waveguide channels. The remaining aluminum acts as a hard mask. The substrate is immersed in a melt of benzoic acid which alters the surface index in the exposed regions. The device is removed, cleaned and annealed in a muffle furnace. The final depth of the waveguide determines the number of leaky mode transitions. The waveguide depth also determines the frequency of each guided-to-mode transitions for each color4.

The aluminum transducers are formed by liftoff. After waveguides are formed, an E-beam resist is spun onto the substrate. An interdigital transducer is patterned with an electron beam to form a chirped transducer designed to respond to the 200 MHz band responsible for controlling color in waveguide devices. The finger period is determined by Λƒ = v where, Λ, is the finger period, v, is the velocity of sound in the substrate and, ƒ, is the radio frequency (RF). The transducer will have an impedance that must be matched to 75 ohms for efficient operation20.

The guided to leaky mode interaction occurs at different frequencies for different wavelengths of illumination light and as a result red, green, and blue light can be controlled in the frequency domain. The surface acoustic wave pattern is generated by an RF signal sent to the interdigital transducer. The RF of the input signal translate to spatial frequencies on the surface acoustic wave pattern. The waveguide can be fabricated so that low frequency signals control the angular sweep and amplitude of red light, while middle frequencies control green light and high frequencies control blue light. The authors have identified a set of waveguide parameters that allow all three of these interactions to be separate and adjacent in the frequency domain so that all three colors can be controlled with a single 200 MHz signal which is the maximum bandwidth of commodity graphics processing units (GPUs).

By matching the bandwidth of a GPU channel to that of a leaky mode modulator, the system becomes fully parallel and highly scalable. By adding bandwidth matched pairs of GPUs and leaky mode modulator channels, one may construct holographic displays of arbitrary size.

After the device is created, it is carefully characterized to verify that the frequencies for guided-to-leaky mode transition are appropriate for frequency control of color. First, the location of the guided modes are determined by a commercial prism coupler to confirm that the waveguide has the appropriate depth and the correct number of guided modes. Then, after the devices are mounted and packaged, they are placed in a custom prism coupler which maps the input frequencies of the scanned output light. The resulting data gives the frequency input response and the angular output response for red, green, and blue light for the device to be tested. If the device has been fabricated correctly, the device input response will be separated in frequency and the output response will be overlapping in angle. When this is confirmed, the device is ready for use in a holographic video display.

The first measurements take place before the device has been packaged. The waveguide depth is determined by a commercial prism coupler. This can be accomplished with just one illumination wavelength (typically 632 nm red) but authors have modified their commercial prism coupler to allow it to gather mode information for red, green and blue light. After packaging, the device undergoes a second measurement in a custom prism coupler which records deflected output light as a function of input RF. A detailed description of these measurements follows. Fabrication steps are also given.

Protocol

1. Initial Preparation

Note: Begin with a new X-cut lithium niobate wafer. It should be optical grade, 1 mm thick, clean, with nothing deposited on the surface, both sides polished, and the top side marked.

- Using an Electron Beam Evaporator or equivalent machine at a vacuum of 50 µTorr, evaporate 200 nm of aluminum on the wafer at 5 Å/sec. To replicate the presented results, position the wafer constellation 65 cm above the aluminum crucible.

- Spin on 30 drops of a positive photo resist, such as AZ3330, at 3,000 rpm for 60 sec. Softbake the resist at 90 °C for 60 sec. Note: For a detailed description of the mechanics of spinning polymer films see the work by C. J. Lawrence21.

- Using the proper mask, such as the "Mask 1. Proton Exchange Mask.dxf" file supplied in the appendix, expose the wafer using a mask aligner with a 350 W mercury bulb or its equivalent for 10 sec as per machine specifications. Ensure that the wafer is aligned so that the waveguides are parallel to the y-axis.

- Develop the resist in a positive photoresist developer for 60 sec. Hard bake the wafer for 60 sec at 110 °C. Etch away the exposed aluminum completely by submerging it for 2 min in a 1 L solution aluminum etch heated to 50 °C.

CAUTION: Aluminum etch is toxic, corrosive and harmful. See MSDS for proper handling and storage of this chemical. Use proper personal protective equipment for acid when handling this chemical. - Remove the photoresist mask with a rinse of acetone followed by isopropyl alcohol (IPA).

- Using a 0.016 in. thick diamond blade with an exposure depth of 0.165 in. on an automatic dicing saw, cut the wafer into 10 x 15 mm2 devices with the long dimension parallel to the y-axis.

Note: The blade will not cut all the way through the substrate. To separate each device, simply stress each cut made by the dicing saw. Each 10 x 15 mm2 device will individually go through the remaining steps of the protocol.

2. Proton Exchange

- Place an individual device in a test tube with a small hole ground into the bottom to allow interaction between the device and all liquid baths.

- Proton exchange the device by immersing it in a 1 L melt of 99% pure benzoic acid at 240 °C. Use an immersion time of 10 min and 10 sec in order to achieve the target depth of 0.4504 µm.

Note: The proton exchange immersion time is dictated by the diffusion coefficient, D, which for the authors' melt is currently D = 0.2993. The proton exchange immersion time is calculated using the relation T = d2 / (4D). In this equation, T is the exchange time in hours, d is the waveguide depth in microns, and D is the diffusion coefficient. For a detailed description of the mechanics of proton exchange see the work by J. L. Jackel15. - Remove the device and allow to cool for 5 min or until cool to the touch. Clean off any benzoic acid residue with a rinse of acetone then IPA.

3. Anneal

- Place device in a regular test tube and wrap the tube in aluminum foil. Place the tube in a muffle furnace for 45 min at 375 °C. Remove the device and allow to cool for 5 min or until cool to the touch.

4. Clean

- Clean the aluminum mask from the device using aluminum etch for roughly 2 min at 50 °C. Clean the device in acidic piranha etch to remove any organic residues.

CAUTION: Acidic piranha etch is toxic, corrosive and harmful. See MSDS for proper handling and storage of these chemicals. Use proper personal protective equipment for acid when handling these chemicals. - Rinse the device in acetone, then IPA, and dry with compressed nitrogen.

5. Waveguide Measurements

- Using any commercial waveguide analyzer measure the characteristics of the proton exchanged waveguide.

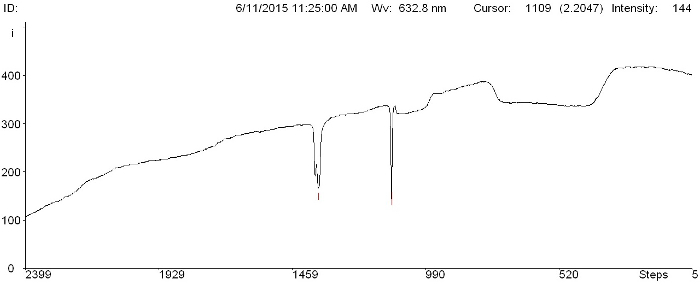

Note: A good device will have 2 guided modes using a 633 nm laser. See Figure 2 for an example of desired results. If the device shows more than two guided modes for red illumination then the exchange time in step 2.2 should be reduced. Likewise if the device shows less than two guided modes the exchange time should be increased.

6. Add Resist

- Spin on 4 drops of a Lift Off Resist (LOR) at 3,000 rpm for 60 sec and then bake at 200 °C for 1 hr. Remove and allow the device to cool for 5 min or until cool to the touch. Spin on 4 drops of a 3:1 solution of polymethyl methacrylate (PMMA) and Anisole at 3,000 rpm for 60 sec and then bake at 150 °C for 15 min.

- Remove and allow the device to cool for 5 min or until cool to the touch. Spin on 2 drops of a conductive polymer at 1,000 rpm for 60 sec, then spin at 6,000 rpm for 4 sec to remove any excess.

7. Pattern

- Use an electron microscope enhanced with a beam blanker to enable writing or an equivalent machine to expose the device.

- Under a vacuum of 50 µTorr, expose the conductive layer to an electron beam with an area dose of 30 µC/cm2 that scans the pattern of the interdigital transducers. To replicate the results use a measured beam current of 410 pA.

- Write the pattern from a .dxf or equivalent file on the electron microscope as per machine specifications.

Note: For a detailed description of the E-Beam lithography process see the work done by R. E. Fontana22.

8. Develop

- Remove the conductive layer by rinsing the device in a continuous stream of deionized water for 5sec. Remove the exposed PMMA by dipping the device into 1:3 solution of methyl isobutyl ketone (MIBK) and IPA for 45 sec.

- Remove from the 1:3 solution of MIBK:IPA and rinse with IPA for 5 sec. Dry the device with compressed nitrogen.

- Repeat steps 8.1-8.1.1 as necessary to fully develop the PMMA.

Note: However expose the device to the solution of MIBK:IPA in 5sec increments only. Complete development should reveal the LOR underneath the PMMA and can be identified by uniform coloration throughout the developed area surrounded by crisp edges and corners.

Note: Over development of PMMA leads to small feature blowout and can completely erase the interdigital transducer fingers leaving a single large developed block. Likewise under development leaves non-uniform residues that will decrease the effectiveness of the liftoff process that follows. - Remove LOR in exposed region by dipping the device into a 1:1 solution of an appropriate developer and deionized water for 25 sec. Remove from the 1:1 solution of an appropriate developer and deionized water. Rinse with IPA for 5 sec.

- Dry with compressed nitrogen. Repeat steps 8.3 as necessary to fully develop the LOR.

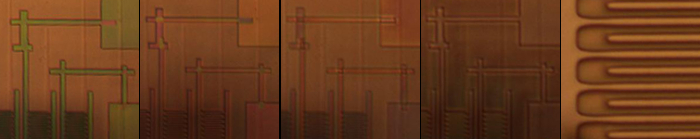

Note: However expose the device to the solution of an appropriate developer and deionized water in 2 sec increments only. Complete development should reveal the surface of the substrate underneath the LOR. It can be identified by uniform white coloration throughout the developed area while maintaining crisp edges and corners. Failure to develop the LOR properly also leads to the problems discussed in 8.2.3.1. See Figure 3 for an example LOR development process.

Note: Switching to a lower ratio of an appropriate developer to deionized water such as 1:2 or 1:3 is helpful as the device nears complete development to allow the fine features to develop without blowing out the device. However, it is not advantageous to start with these doses as total time increases and exceeds the optimal time in the developer.

- Dry with compressed nitrogen. Repeat steps 8.3 as necessary to fully develop the LOR.

9. Deposit Aluminum

- Using an Electron Beam Evaporator or equivalent machine at a vacuum of 50 µTorr, evaporate 200 nm of aluminum on the wafer at 5 Å/sec.

10. Liftoff Aluminum

- Fill a large glass dish with 750 ml of water on a hot plate at 90 °C. Insert a plastic buffer into the water dish. In a separate small glass container submerge the device in a 100 ml solution of N-methyl-2-pyrrolidone (NMP).

- Place the container of NMP solution containing the device onto the plastic buffer ensuring that the water level does not exceed the height of the container of NMP. Cover and let sit 3 to 4 hr or until aluminum liftoff is complete. Remove the device from NMP.

Note: It is advantageous to clean off large sections of aluminum from the device before removing it from the NMP bath. Do this by using a pipette filled with NMP to squirt the device and knock off any remaining large chunks of unwanted aluminum. - Rinse the device in IPA and dry with compressed nitrogen. Under a microscope, verify that liftoff is complete. If unwanted residual aluminum remains, wet the device with acetone and very gently brush with a cleanroom swab coated in acetone to remove.

- Rinse in IPA, dry with compressed nitrogen, and recheck under the microscope. Repeat 10.3 and 10.4 as needed.

11. Polish the End

- Coat the device in a protective film such as a layer of positive photoresist. Clamp the device so that the end with the transducers is exposed for polishing. Using proper polishing procedures23, slowly polish the end of the device to a surface roughness of less than 100 nm, so that no surface defects interfere with the light exiting the device.

- Remove the device from the clamp and clean off the protective film. If photoresist was used as a protective film, a generous rinse in acetone and then IPA will remove it. Dry the sample as necessary with compressed nitrogen.

12. Mount on a Breakout Board

- If any assembly is required for the RF breakout board, assemble the breakout board according to its specifications.

- Build, out of glass slides, a mounting platform to hold firmly both the RF breakout board and the device. Note: The mounting platform is built in a U shape out of three glass slides: one 75 x 50 x 1 mm3 and two 75 x 25 x 1 mm3.

- Place a generous bead of superglue over the leftmost fourth of the large slide. Place one of the smaller slides over the bead of superglue so that leftmost edge and the bottom edge align with the corresponding edges on the large slide.

- Apply firm and equal pressure to the two slides until the superglue sets, about 15 sec. Repeat the process for the rightmost fourth of the large slide.

- Mount the device to the top of the mounting platform with double-sided tape. Make sure the end of the device overhangs the end of the mounting platform so that the mounting platform does not interfere with light exiting the end of the device.

- Mount the RF breakout board to the mounting platform so that it is not in the beam path of the light exiting the device. A simple way to do this is to elevate the breakout board with thick tape so that the bottom of the breakout board is above the top of the device.

- Wire bond the pads on the device to their respective locations on the RF breakout board. Use a 27 nH series inductor to impedance match each transducer to the breakout board inputs.

13. Prism Coupling

- Select a rutile prism to couple light into the device. The polarization of the light (Transverse Electric) should be parallel to the optical axis of the rutile the optical axis (Z-axis) of the X-cut lithium niobate.

- Clean the contact surfaces of both the device and the prism thoroughly with IPA. Position the prism so that it is centered on the channel to be tested.

- Press the bottom of the prism firmly against the top of the device with a clamping mechanism. Note: Do not overtighten as excessive pressure will crack the substrate and damage the coupling prism.

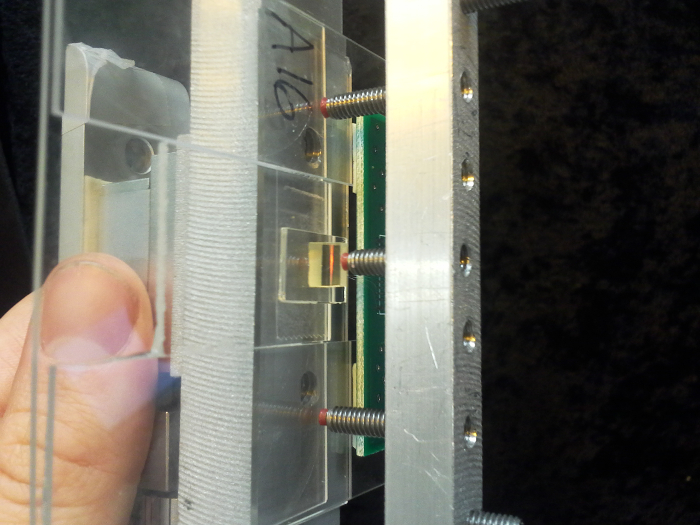

- If successful, observe a wet spot will appear.

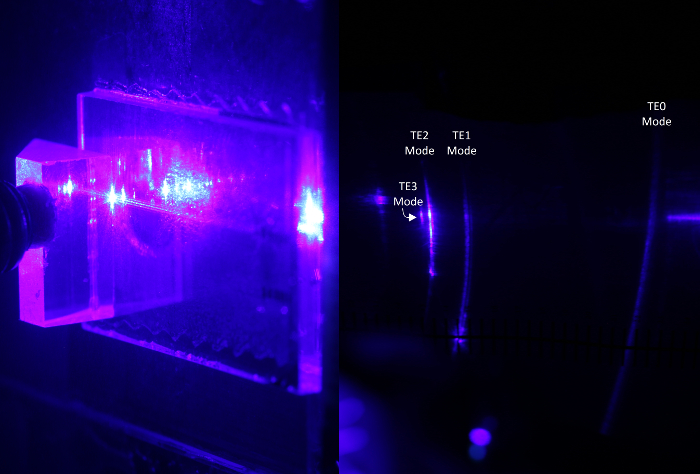

Note: A wet spot is a region of frustrated total internal reflection at the interface between the prism and the sample. For an example of proper prism coupling see Figure 4.

14. Mount in the Characterization Apparatus

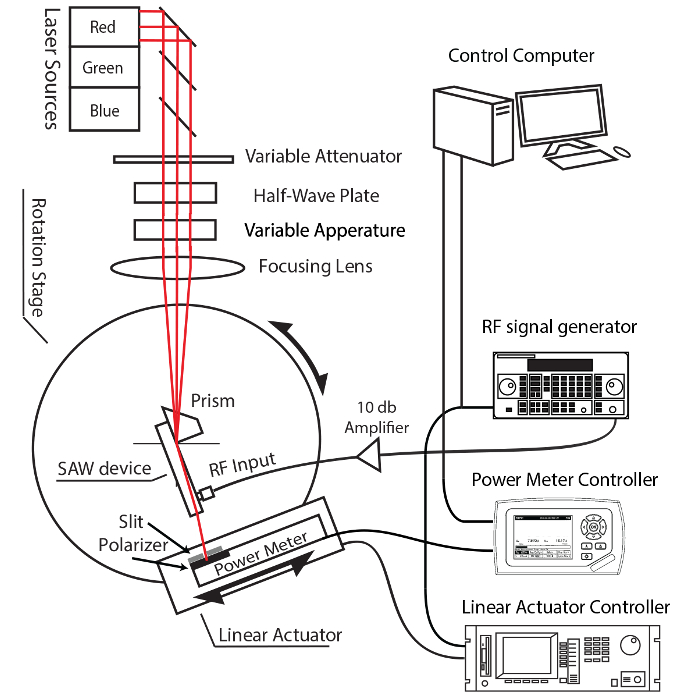

- Mount the device on the rotating platform of the Frequency division color characterization apparatus for anisotropic leaky mode light modulators discussed by A. Henrie4.

Note: A schematic of the Characterization Apparatus is supplied in Figure 5.

15. Align in the Characterization Apparatus

- Turn on the laser. To replicate the results presented in this paper use 5 V for 638 nm, 5.5 V for 532 nm, and 6.5 V for 445 nm.

- Attenuate the beam until the intensity of the scattered light is comfortable to the eye. Verify the laser polarization.

- Place a polarizer in the beam path after the half wave plate so that it blocks horizontally polarized light. Rotate the half wave plate to achieve maximum attenuation of the laser light. Remove the polarizer.

- Manually rotate the platform so that the angle between the laser and the top surface of the device is set to the proper entrance angle.

Note: The proper angle can be found in Table 1 according to the desired testing wavelength and mode. - Align prism using the linear translation stages when the focal point of the laser passes through the 90° corner of the prism. Note: Increased laser scatter caused by the corner of the prism can sometimes be seen.

- At this point, light should be coupling into the device which can be verified either by the characteristic streak of light caused by scattering in the waveguide or by the characteristic mode lines coming out of the end of the device24 (see Figure 6).

Note: If using mode lines to verify coupling, it is helpful to remove the power meter from the beam path. Instead insert a uniformly scattering object, such as a sheet of white paper, into the beam path. - If no coupling is detected, slowly rotate the device while maintaining the coupling edge of the prism in the focal point of the laser. If after five degrees rotation in either direction no coupling can be detected, remove the device from the rotating platform, remove the prism and return to step 13.

- At this point, light should be coupling into the device which can be verified either by the characteristic streak of light caused by scattering in the waveguide or by the characteristic mode lines coming out of the end of the device24 (see Figure 6).

- Once coupling is detected, fine tune the rotational platform and linear translation stages to maximize the coupling of the light.

16. Attach the RF Input and Enclose the Device

- Replace the power meter that was removed during alignment. Also remove any obstructions to the beam path used for alignment purposes.

- Attach the RF input to the device breakout board and turn on the RF signal generator. Make sure the amplifier is powered. Note: To protect the device from burnout, the electrical power of the signal reaching the device should not exceed 1 W.

- Remove any attenuation used for safety during alignment. The laser is now at the optical power levels used for testing. Enclose the entire system in an optically isolating box.

17. Run the Provided Testing Program

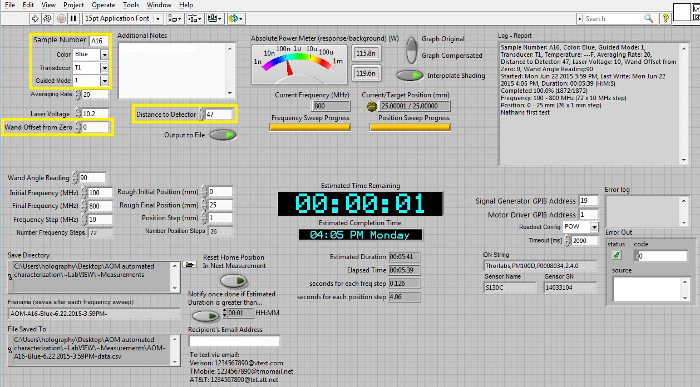

- Obtain a laboratory equipment manager to run the characterization device, such as the LabView file AutomatedDeviceCharacterization.vi provided in the appendix.

- Insert all user parameters into the testing software on the control computer. Note: Figure 7 is supplied for those using the provided experiment control file. It indicates with a yellow box the fields that must be updated before each automated test is run in order for the provided analytical program to run properly in step 19.

- To replicate the results presented in this paper use the following testing parameters: Initial Frequency: 100 MHz, Final Frequency: 800 MHz, Frequency Step: 10, Rough Initial Position: 0, Rough Final Position: 25, and Position Step: 1. Make sure the "Output to File" button is pressed.

- Run the testing program.

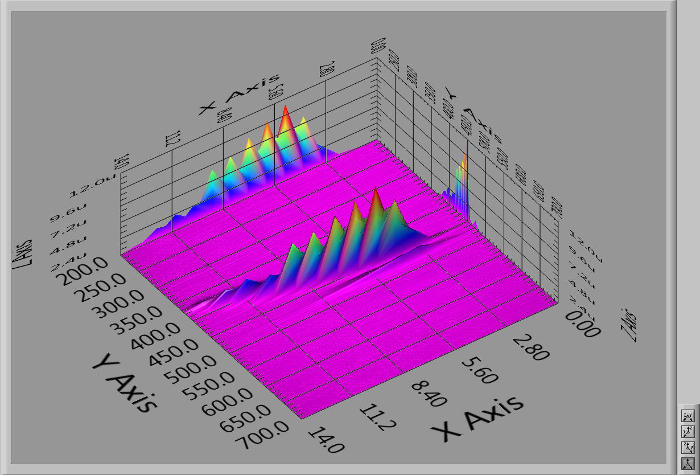

Note: The provided program drives a power meter along a linear track at user defined intervals. At each position the RF input signal is swept through a set of chosen frequencies and power measurements are made. A measurement is also made with the RF input at its lowest frequency setting and lowest output power which has been experimentally determined as equivalent to no input signal4. These measurements are then graphed in real time in a 3D interactive chart.- Observe the four output files: *config.csv describes the experiment, *data.csv contains the power reading at each frequency, *no_stim.csv contains the background noise reading, and *graph.jpeg contains a copy of the graph on the user interface of the program as it was when the program ended. See Figure 8.

- Repeat sections 15-17 for each wavelength and the TE1 mode described in Table 1.

18. Analyze the Frequency and Angular Output Profiles

- Obtain a statistical analysis program or download the CompareWDMmodes.m MATLab code provided in the appendix.

- In the folder (where the program is located), create a subfolder, "Sample Number" enter the "Sample Number" into the testing program. The sample number is the device identification number.

- In this folder, "Sample Number," create three subfolders. Name each folder as follows, "Sample Number"_ "Color"_M1_ "Transducer". The names in "bold and italics" are values entered into the testing program by the user. (e.g. A16_BLUE_M1_T1, C5_RED_M1_T13, or D35_GREEN_M1_T18).

- Into each subfolder, copy the four files created by the testing software that correspond with that particular wavelength, mode, and transducer.

- Open the analytical program and change the user defined variables at the top to reflect the user defined values input into the testing software.

Note: If using the provided analytical program and the user defined values in the testing program are "Sample Number"=A16, "Guided Mode"=1, "Transducer"=1 the analytical code would be modified to the following:

% User Defined Variables

series='A';

sample=16;

modes=[1];

transducer='T1'; - Run the analytical program.

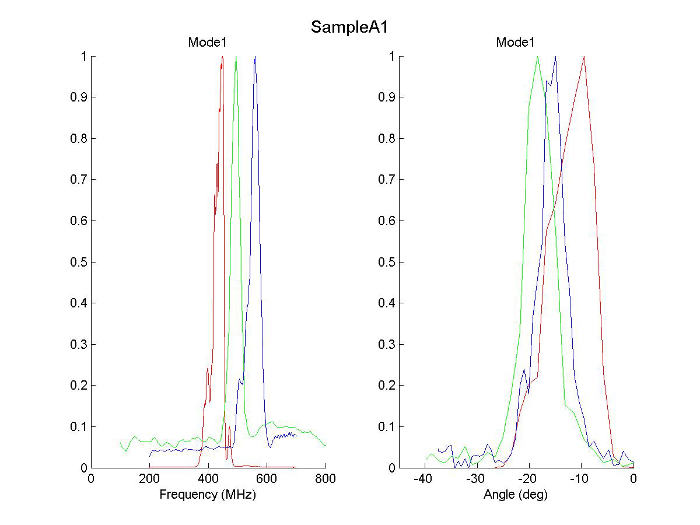

Note: If using the provided analytical code, among other things it creates a figure that compares the normalized frequency response and the angular output for red, green, and blue light. The file it creates is located in the "Sample Number" subfolder. See Figure 9 for an example of the output .

Representative Results

The principle results of the protocol above are the guided mode measurement from the commercial prism coupler shown in Figure 2, the single frequency, raw input/output data gathered from the customized prism coupler shown in Figure 8 and the multicolor curves shown in Figure 9. In the following paragraphs we discuss the actionable information produced by each of these outputs.

The guided mode information gleaned from the commercial prism coupler is used, primarily, to establish the waveguide depth, but the number of modes and their spacing contain other useful information relevant to leaky mode operation. For the leaky mode device to work as designed, it must have a guided-to-leaky mode transition for every color, and experimentation has shown this to be true when there exists at least two guided modes for each illumination wavelength. This is particularly relevant for red as it has the fewest guided modes of the three display colors. The proton exchange step 2 should be increased or decreased to make sure there are two red modes. In general, having two modes in red indicates that there are also at least two modes in green and blue. Devices optimized for frequency division multiplexing of color have shown two modes in red, three modes in green and four modes in blue. Fewer modes may appear for green and blue if the anneal time is too long. If fewer than the optimal number of modes appear for green and blue light, then the anneal time in step 3 may need to be extended. Long anneals, however, will also reduce the effective index of the guided modes.

The raw output of the custom prism coupler as shown in Figure 8 gives one a good qualitative sense for a number of important device parameters such as RF bandwidth, angular sweep, scan linearity, spot size, standing wave period and approximate diffraction efficiency. The projection of the data on the Y axis gives the frequency response of the device from which we can read the center frequency and the approximate bandwidth of operation. The projection of the data on the X axis gives span of the diffracted light output. This position information is nearly proportional to the angular sweep of the device output so the projection on this axis is a good indicator of the angular sweep of the device. The slope of the data on the XY plane of the graph gives us a sense of the linearity of the scan as well as the rate of scan with input frequency. If the X axis is sampled with sufficiently high resolution, then a cross section along the X axis will give the beam profile. If the Y axis is sampled with sufficiently high resolution, then surface acoustic standing wave patterns may become apparent- if they are prominent, it may be beneficial to add an acoustic absorber to the device to produce a smooth, even scan. Absolute diffraction efficiency is not measured but when comparing one device to another, the signal to noise ratio serves as a good indicator of relative diffraction efficiency. This raw data provides a significant amount of information, but it is relevant to only one illumination wavelength.

To determine if the device is capable of frequency control of color, raw data is processed for several experiments with all three wavelengths to form graphs like the one in Figure 9. The X and Y axis projections are first collected for the TE1 guided modes for all three colors. Then these projections are superimposed on the angle and frequency axes respectively to form a multicolor frequency and angular response like the one shown. If the response for each color is adjacent in frequency and overlapping in angle, then the device is appropriate for frequency control of color.

By using the characterization steps described in this work, one can both reproduce devices capable of frequency control of color as well as effectively modify their function to meet new optimization criteria such as maximized diffraction efficiency, high signal to noise ratio or high linearity.

Figure 1: Leaky Mode Modulator. As seen on the left, light enters the device through a rutile prism which evanescently couples light into a waveguide indiffused on the substrate's surface. As the guided light propagates toward the far end of the device it encounters surface acoustic waves which outcouple the light from the waveguide and rotate its polarization. The momentum diagram for this interaction is given on the right. Please click here to view a larger version of this figure.

Figure 2: Sample Waveguide Data. Light from the laser is coupled into the prism. It then reflects off the surface of the device and onto a power sensor. When a guided mode is present, instead of reflecting off the device the light is guided through the substrate and out the end of the device. Thus, it is guided away from the power sensor and a sharp "dip" occurs in the plot. There are two modes identified in this plot. The gradually increasing power reading from left to right can be explained by the gradually increasing transmission efficiency at the air to prism boundary. Please click here to view a larger version of this figure.

Figure 3: Sample LOR Development Process. Images of the same area of a device as the LOR is developed. The picture on the far left was taken under a microscope after the initial 25 sec development time. The pictures that follow are a sampling of the changes through the iterative process. The final picture is a close-up of the finer features on the device after LOR development to show the clean edges and the exposure of the underlying substrate. Please click here to view a larger version of this figure.

Figure 4: A Prism Coupled Device Mounted to a Breakout Board. A correctly coupled, completed device mounted to its breakout board. At the proper angle, as in this picture, the wet spot reflects a rainbow of color. Please click here to view a larger version of this figure.

Figure 5: Characterization Apparatus Schematic. Basic diagram of the characterization apparatus. The laser is sent through a series of optical components before being coupled into the device through a prism. Once inside a mode in the waveguide SAW waves produced by interdigital transducers and a RF signal knock the light into leaky modes which exit the device at a frequency controllable angle. A linear actuator drives the power meter through a range of positions while the signal generator runs through a range of frequencies creating multivariable graphs which describe the controllability and output of the device. Please click here to view a larger version of this figure.

Figure 6: Identification Techniques of Proper Light Coupling. Proper coupling can be identified by either the presence of the characteristic streak of light caused by scattering in the waveguide, as shown on the left, or by the characteristic mode lines out of the end of the device, as show on the right. Please click here to view a larger version of this figure.

Figure 7: User Interface for LabView Testing Software. The user interface including all user defined variables. Items boxed in yellow must be updated before each automated test is run in order for the analytical program to run properly. Please click here to view a larger version of this figure.

Figure 8: Sample Frequency vs Position Graph. While the RF input and power meter location are scanned linearly, the experiment software builds and displays this interactive 3D graph of the collected data. Upon completion the current view is saved for quick reference. Please click here to view a larger version of this figure.

Figure 9: Sample Mode Comparison Data. The frequency response of the three wavelengths is shown on the left. The device has a bandwidth of 200 MHz with individual control for each wavelength. On the right is the output angle response for each device. There is good angular overlap for 5-7°. Please click here to view a larger version of this figure.

| Wavelength | Mode | Angle |

| 638 nm | TE0 | 23° |

| TE1 | 28° | |

| 532 nm | TE0 | 26° |

| TE1 | 31° | |

| TE2 | 32° | |

| 445 nm | TE0 | 31° |

| TE1 | 36° | |

| TE2 | 38° | |

| TE3 | 39° |

Table 1: Mode Excitation Parameters. Angle and wavelength parameters for desired the TE1 mode excitations for the devices discussed in this document.

Discussion

The design of each device has two critical steps, proton exchange and development of the LOR. Of the two, proton exchange time determines the depth of the waveguide, which in turn determines the number of guided to leaky mode transitions, the controllable frequency bandwidth, and every key design parameter for each color of light. Two guided modes in red is desired. If more exist then bandwidth is sacrificed. If less exist then no guided to leaky mode transition is guaranteed. Follow the note in step 2.2.1 to correct proton exchange times to achieve the desired result.

Proper LOR development is required for proper liftoff and thereby proper function of the interdigital transducers. It is a step best mastered through experience. A non-dilute solution of developer will blow out the fingers of the transducers in 7 sec while a 50% solution will do the same in about 35 sec. The exact time varies from device to device which creates the need to develop the device for 25 sec in a 50% solution followed by repeated quick exposures to more dilute solutions. If blowout occurs decrease development time or solution concentration to achieve desired results.

In the characterization process prism coupling and alignment are the critical steps. If the device is poorly prism coupled or poorly aligned no light will enter the waveguide making it impossible to measure results. Alignment is best achieved with small adjustments. Variations in the scattered light can indicate the approach to a mode line or show the proximity of the interdigital transducer. Experience is the best teacher.

This protocol is designed for the manufacture of a single device. As such scalability is limited and small variations will be present from device to device. However the authors are actively pursuing the development of a wafer driven manufacture process that will overcome this challenge. Another limitation of this characterization protocol is the reliance on an active testing process. The interdigital transducers must have a large bandwidth to accommodate the changes in the waveguide depth and mode transitions. Once the transition frequencies are determined a narrower bandwidth transducer can be designed. A good model for the process would eliminate the need for this step. Finally, the testing protocol is not completely automatic, requiring human adjustments between changes in wavelength and devices.

Once a device shows both good angular overlap and frequency control, then it is able to be used in such applications as the 3D holovideo display1. These devices require only 2 patterning steps to fabricate which is a large improvement on the common display technologies of today, such as pixelated light valves, MEMs devices, and bulk wave acousto-optic modulators. It is the authors' hope that having access to this manufacture, measurement, and characterization protocol will encourage broader participation in electroholographic display research.

Divulgations

The authors have nothing to disclose.

Acknowledgements

The authors gratefully acknowledge financial support from Air Force Research Laboratory contract FA8650-14-C-6571 and from DAQRI LLC.

Materials

| X-Cut Lithium Niobate | Gooch and Housego | 99-00630-01 | Lithium Niobate 3″ Diameter X-CUT Wafer 1mm Polish/Polish |

| Positive Photo Resist 1 | EMD Performance Materials | AZ 3330 F Photoresist | Used in the creation of the proton exchange mask. |

| Photoresist Developer | EMD Performance Materials | AZ MIF 300 | Develops AZ3330 and LOR 3A |

| Aluminium | International Advanced Materials | AL13 | 99.999% Pure |

| Aluminium Etch | Transene | Type A Aluminum Etchant | |

| Benzoic Acid | Sigma Aldrich | 109479-500G | 99% Pure |

| Acetone | Fisher Chemical | UN1009 | |

| IPA | Fisher Chemical | UN1219 | 99.5% pure Isopropyl Alcohol |

| Acidic Piranha etch | Cyantek Corperation | Nanostrip | |

| Under Layer Resist | Micro Chem | LOR 3A | Bottom layer used for liftoff. |

| Positive Photo Resist | Micro Chem | 950 PMMA A9 | Top layer used for liftoff |

| Anisole | Micro Chem | A Thinner | |

| Conductive polymer aqueous solution | Mitsubishi Rayon Company | AquaSAVE | |

| MIBK (4-Methyl-2-pentanone) | Sigma Aldrich | 360511 | Develops PMMA |

| NMP (1-methyl-2-pyrrolidone) | Sigma Aldrich | 328634 | Used for liftoff |

| Name of the Equipment | Company | Catalog Number | Comments/ Description |

| E-beam Evaporator | Denton Vacuum | Integrity 20 | Any equivalent equipment would suffice. |

| Thin Film Spinner | Laurell Technologies Corporation | WS-400A-6NPP-LITE | Any equivalent equipment would suffice. |

| Mask Aligner | Karl Suss America Inc. | MA 150 CC | Any equivalent equipment would suffice. |

| Automatic Dicing Saw | Disco Corperation | Disco Dad 320 | Any equivalent equipment would suffice. |

| Muffle Furnace | Thermo Scientific | FB1415M | Any equivalent equipment would suffice. |

| Electron Microscope | FEI | XL30 ESEM | Any equivalent equipment would suffice. |

| Dehydration Oven | Lab-Line Instruments | Ultra-Clean 100 (3497M-3) | Any equivalent equipment would suffice. |

| Hot Plate | Thermo Scientific | SP131325 | Any equivalent equipment would suffice. |

| Polisher | Ultra Tec Mfg., Inc. | Ultrapol End & Edge Polisher | Any equivalent equipment would suffice. |

| Class IIIb 12V RBG Lasers: Wavelengths(nm): 638, 532, and 445 | Bought second-hand. Probably pulled from a laser projector. Any equivalent equipment would suffice. | ||

| Signal Generator | Agilent | 8648D | Now found at Keysight. Obsolete. Any equivalent equipment would suffice. Needed Frequency sweep 9 KHz-1000 MHz. |

| Signal Amplifier | Mini-Circuits | TB-17 | Necessary only to overcome the limitations of the signal generator. |

| Power Meter Controller | ThorLabs | PM100D | With power meter model S130C. Any equivalent equipment would suffice. Needed sensitivity 500pW |

| Linear Actuator Controller | Newport | ESP7000 | With linear actuator model MFN25PP. Any equivalent equipment would suffice. Needs 0.1mm accuracy. |

| AutomatedDeviceCharacterization.vi | LabView | Experimental Control Software by BYU | Found in the appendix |

| CompareWDMmodes.m | MATLab | Analytical Software by BYU | Found in the appendix |

References

- Smalley, D., Smithwick, Q., Bove, V., Barabas, J., Jolly, S. Anisotropic leaky-mode modulator for holographic video displays. Nature. 498 (7454), 313-317 (2013).

- Smalley, D., Smithwick, Q., Bove, V. Holographic video display based on guided-wave acousto-optic devices. Proc. SPIE. 6488, 64880L-64880L-7 (2007).

- Smalley, D. . Holovideo on a stick: integrated optics for holographic video displays. , (2013).

- Henrie, A., Haymore, B., Smalley, D. Frequency division color characterization apparatus for anisotropic leaky mode light modulators. Rev Sci Instrum. 86 (2), (2015).

- Lawes, R. . MEMS Cost Analysis: Basic Fabrication Processes. , (2014).

- Pearson, E. . Mems spatial light modulator for holographic displays. , (2001).

- Tabata, M. Risk and Mobility: A Case Study of the Thin-Film Transistor Liquid-Crystal Display Industry in East Asia. East Asian Science, Technology and Society. 9 (2), 151-166 (2015).

- Pape, D., Goutzoulis, A., Kulakov, S. . Design and fabrication of acousto-optic devices. , (1994).

- Chang, I., Lee, S. Efficient Wideband Acuosto-Optic Bragg Cells. Ultrasonics Symposium. , 427-430 (1983).

- Proklov, V., Korablev, E. Multichannel waveguide devices using collinear acousto-optic interaction. Proc. SPIE. 1932, 298-311 (1993).

- Ito, K., Kawamoto, K. An optical deflector using collinear acoustooptic coupling fabricated on proton-exchanged LiNbO 3. Jpn. J. Appl. Phys. 37 (9R), 4858 (1998).

- Smalley, D., Smithwick, Q., Barabas, J., Jolly, S., DellaSilva, C. Holovideo for everyone: a low-cost holovideo monitor. J Phys Conf Ser. 415 (1), 012055 (2013).

- McClaughlin, S., Leach, C., Henrie, A., Smalley, D., Jolly, S., Bove, V. Frequency Division of Color for Holovideo Displays using Anisotropic Leaky Mode Couplers. Optical Society of America, 2015. , (2015).

- McLaughlin, S., Leach, C., Henrie, A., Smalley, D. Optimized guided-to-leaky-mode device for graphics processing unit controlled frequency division of color. Appl. Opt. 54 (12), 3732-3736 (2015).

- Jackel, J., Rice, C., Veselka, J. Proton exchange for high-index waveguides in LiNbO3. Appl. Phys. Lett. 41 (7), 607-608 (1982).

- Wong, K. . Properties of lithium niobate. , (2002).

- Tien, P., Ulrich, R. Theory of prism-film coupler and thin-film light guides. JOSA. 60 (10), 1325-1337 (1970).

- Tsai, C. . Guided-wave acousto-optics: interactions, devices, and applications. , (1990).

- Proklov, V., Korablev, E. Multichannel waveguide devices using collinear acousto-optic interaction. Proc. SPIE. 1932, 298-311 (1993).

- Li, R. . Circuit Design. , (2012).

- Lawrence, C. The mechanics of spin coating of polymer films. Phys. Fluids. 31 (10), 2786-2795 (1988).

- Fontana, R., Katine, J., Rooks, M., Viswanathan, R., Lille, J., MacDonald, S., et al. E-beam writing: a next-generation lithography approach for thin-film head critical features. IEEE Trans. Magn. 38 (1), 95-100 (2002).

- Robertson, M. . Substrate Surface Preparation Handbook. , (2011).

- Monneret, S., Flory, F., et al. M-lines technique: prism coupling measurement and discussion of accuracy for homogeneous waveguides. J Opt A-Pure Appl Op. 2 (3), 188 (2000).