Development of a Bio-Hybrid Mosquito Stinger-Based Atomic Force Microscopy Probe

Summary

Quantitative and controlled investigations into insect biting behaviors are crucial for devising effective strategies to combat vector-borne diseases. In this context, a method for fabricating a bio-hybrid atomic force microscopy (AFM) probe is introduced.

Abstract

Mosquitoes, notorious as the deadliest animals to humans due to their capacity to transmit diseases, pose a persistent challenge to public health. The primary prevention strategy currently in use involves chemical repellents, which often prove ineffective as mosquitoes rapidly develop resistance. Consequently, the invention of new preventive methods is crucial. Such development hinges on a thorough understanding of mosquito biting behaviors, necessitating an experimental setup that accurately replicates actual biting scenarios with controllable testing parameters and quantitative measurements. To bridge this gap, a bio-hybrid atomic force microscopy (AFM) probe was engineered, featuring a biological stinger – specifically, a mosquito labrum – as its tip. This bio-hybrid probe, compatible with standard AFM systems, enables a near-authentic simulation of mosquito penetration behaviors. This method marks a step forward in the quantitative study of biting mechanisms, potentially leading to the creation of effective barriers against vector-borne diseases (VBDs) and opening new avenues in the fight against mosquito-transmitted illnesses.

Introduction

World Health Organization (WHO) reported that vector-borne diseases (VBDs) account for over 17% of all infectious diseases, which cause more than 7,00,000 deaths per year globally. For example, as the deadliest animal in the world, mosquitoes spread numerous pathogens, such as dengue, malaria, and Zika, through blood-feeding arthropods, resulting in 700 million infections each year1. Explorations toward the development of effective measures to prevent VBDs are of crucial importance, including mimicking the penetration behaviors of mosquitoes to investigate their biting mechanisms and studies of potential barriers to prove their efficacy in preventing penetration. One key challenge is to develop proper approaches to perform such investigations. Efforts have been made in the literature, including the development of micro-scale needles that resemble the geometry of a mosquito stinger; however, many of the materials used to make these microneedles (i.e., viscoelastic materials2, silicon (Si), glass, ceramic3, etc.) have different mechanical properties than the biological material of the mosquito's proboscis. The engineered materials can be brittle and prone to fracture and buckling3,4, whereas the mosquito's proboscis can withstand fracture or buckling better4. The benefit of having a bio-hybrid probe using the labrum of a mosquito instead of engineered materials is that it can be a more accurate representation of the piercing mechanism of mosquitoes. Also, specialized tools must be integrated with micro needles to perform quantitative studies, such as the accurate measurement of force5, which is not easily achievable with customized setups using engineered microneedles.

Atomic force microscopy (AFM)-based approach is promising in that it operates by employing a cantilever with an ultra-fine tip that is carefully positioned close to a sample's surface. The tip can either scan across or be pressed towards/into a surface, experiencing varying attractive or repulsive forces due to its interactions with a sample6. These interactions lead to the cantilever's deflection, which is tracked by the reflection of a laser beam from the cantilever's top onto a photodetector6. The exceptional sensitivity to movement of the system enables AFM to conduct a diverse range of measurements, including but not limited to morphological mapping with picometer accuracy, force measurements ranging from piconewtons to micronewtons, and comprehensive multiphysics investigations7. For example, AFM indentations can be performed to precisely assess the response to the applied force of a sample and also to measure the hardness, elasticity, and other mechanical properties of a sample by coupling with appropriate analytical models8. The probe of the AFM is most commonly made of silicon (Si) or silicon nitride (Si3N4)8 with a length of 20-300 µm9 and a tip radius on the order of several to tens of nanometers10. The nanometer scale tip radius can be ideal for applications such as high-resolution imaging; however, it does not possess the characteristics of biological stingers for studies that try to mimic penetration behaviors in terms of stiffness, radius, shape, and aspect ratio. For example, the microneedle structure of a mosquito is the fascicle, which has an aspect ratio of ~6011 (length ~1.5 mm to 2 mm; diameter ~30 µm)12. While a conventional AFM probe can be assumed to resemble a biological stinger like a labrum, its distinct material properties and dimensions will not reflect the real situation during a bite.

To enable quantitative investigations of penetration behaviors mimicking biological bites of insects or other animals with stingers, here, a process to fabricate bio-hybrid AFM cantilevers with a biological stinger as its tip is developed. As a case study, an AFM cantilever with a mosquito labrum's tip attached was successfully demonstrated. Harnessing existing information from literature on the typical insertion forces that a mosquito uses to pierce through a victim's skin12,13, this bio-hybrid AFM cantilever can potentially allow near-real mimicry of mosquito bites under a regular AFM. The protocol of leveraging micro biological stingers to fabricate bio-hybrid AFM cantilevers can also be applied to the development of other sharp stinger-based biohybrid AFM cantilevers for quantitative investigations of a variety of biting mechanisms.

Terminologies

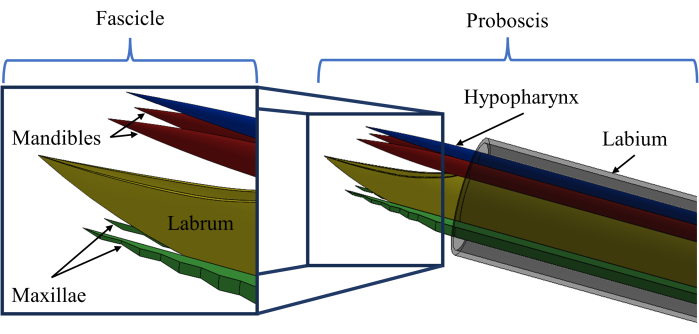

A schematic of a proboscis and its components of interest are shown in Figure 1, and their definitions are (1) Proboscis: a body part from the mouth of a mosquito that allows the mosquito to feed itself, with a core-shell structure composed of the fascicle(core) and the labium(shell), (2) Labium: the dark and blunt outer cover of a proboscis2, (3) Fascicle: a group of slender needles contained inside of the labium, including two maxillae, two mandibles, a hypopharynx, and a labrum2, (4) Hypopharynx: responsible for secreting saliva into the host's bloodstream2, (5) Maxillae: serrated member assisting in the feeding mechanism2, (5) Mandibles: similar to the maxilla, they help the mosquito in the feeding mechanism and have a sharp tip2, (6) Labrum: the main member for penetrating the skin of a victim, which is much bigger than the maxillae, mandibles and hypopharynx. It also has sensory structures that allow it to find blood vessels and internal channels under the skin2, (7) Manipulator: an assembly with three degrees of freedom and micron-scale accuracy for positioning, allowing movement in XYZ directions, (8) Clamp assembly: a custom-made 2-part clamp mounted to the manipulator used to clamp the tipless AFM cantilever during the experiment.

Protocol

The mosquito species used for this protocol is an uninfected adult female Aedes aegypti (A. aegypti), received frozen and stored in a -20 °C degree freezer. The species was provided by the NIH/NIAID Filariasis Research Reagent Resource Center for distribution through BEI Resources, NIAID, NIH: Uninfected Aedes aegypti, Strain Black Eye Liverpool (Frozen), NR-48920. The reagents and equipment used for the study are listed in the Table of Materials.

1. Dissecting the labium from the proboscis

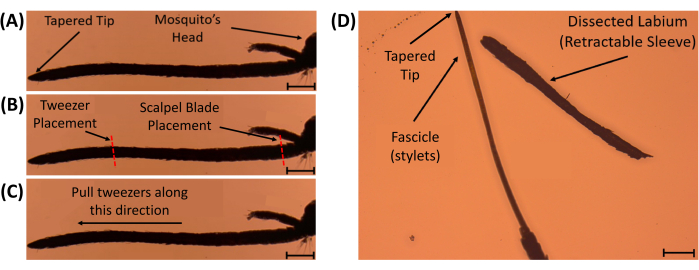

- Using tweezers, place a dead mosquito on a glass slide under the microscope and ensure there is a tapered tip at the end of the proboscis (Figure 2A).

- While keeping the mosquito on the glass slide, place a scalpel blade gently over the labium near the mosquito's head (Figure 2B).

- Proceed to make an incision across the entire upper half of the labium (a cut of approximately 80 µm) with a shallow penetration depth through the thickness of the labium. Ensure to apply a light pressure on the blade as to cut only the labium but not the fascicle that lies beneath.

- With a pair of tweezers, firmly hold the head of the mosquito, and with another pair of precision tweezers, lightly pinch the labium at any position in between the tapered tip and the location of the incision (Figure 2B).

- Pull the tweezers holding the labium in the direction of the tapered tip (Figure 2C). Continue pulling the tweezers until the labium has ripped free and has been entirely removed from the fascicle.

- Place the mosquito under the microscope and verify if the labrum's tip is present. This can be identified by the presence of a tapered tip on the fascicle (Figure 2D).

2. Separating the labrum's tip from the other fascicle members

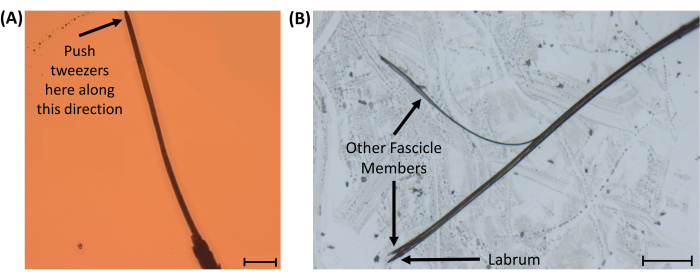

- Clamp and close the tips of a set of precision tweezers and place the tip of the tweezers right beside the labrum near its tip.

- Use the tweezer tip to apply a gentle force on the labrum in the direction perpendicular to the length of the fascicle (Figure 3A).

- Continue pushing the labrum across the glass slide until separation of the labrum from the other fascicle members is achieved.

- Inspect the sample under the microscope to verify proper separation between the labrum and other fascicle members has been achieved (Figure 3, left). If separation is unsuccessful, refer back to step 2.1.

3. Cutting the labrum's tip

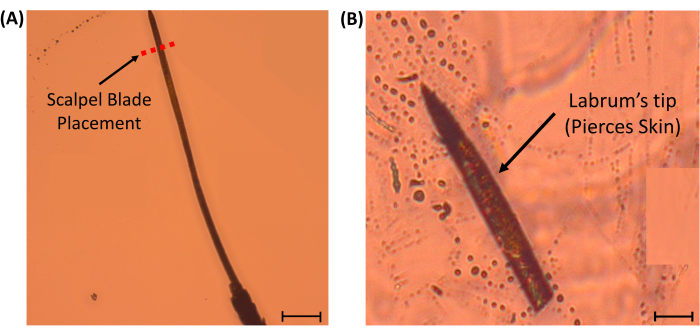

- While the labrum is still on the glass slide, place a scalpel blade over the labrum at approximately ~200 µm in distance from the labrum's tip (Figure 4A). Gently apply sufficient pressure and cut the tip of the labrum all the way through. While the labrum tip should ideally be as short as possible, ~200 µm is the best the current approach can handle.

- Measure the length of the cut labrum to ensure it is no longer than 300 µm (Figure 4B) using any digital measurement software. In this protocol, ImageJ was used14.

4. Grabbing the tip of the labrum

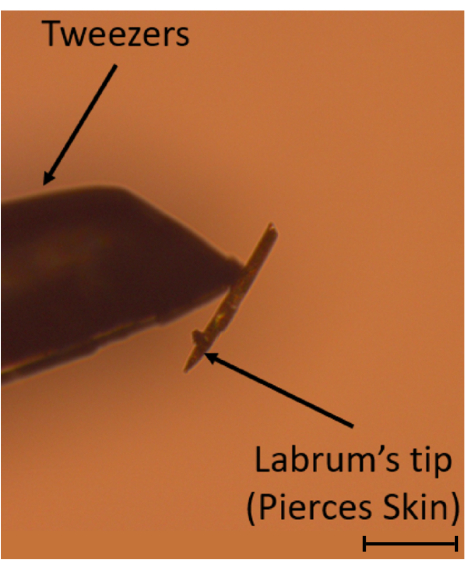

- With a pair of precision tweezers, locate and isolate the labrum's tip on the glass slide. Discard every part remaining on the glass slide other than the labrum's tip.

- With the same precision tweezers, slowly and lightly pinch the labrum so that the cut end is free and unobstructed by the tweezers. Also, ensure the orientation of the labrum is parallel to the direction of the tweezers' length and the cut end of the labrum is pointing away from the tweezers' body.

- Once the specimen is firmly pinched, remove the clamping force holding the tweezers' tips together. The labrum's tip will stick to one of the tweezers' tips.

- Under a microscope, inspect the tweezers' tips and ensure the labrum's tip is present on one of the tweezers' tips (Figure 5). If the labrum's tip is not on the tweezers, refer back to step 4.2, and if the labrum's tip is not on the tweezers nor on the glass slide, refer back to step 1.

5. Applying epoxy on the tipless cantilever beam

- Place a drop (~0.05 mL) of epoxy on the edge of a new glass slide by directly drop-casting the adhesive from its original bottle/container. Place the epoxy-containing glass slide under the probe station and focus on it.

- Mount the tipless AFM cantilever to the clamp assembly by securing the base (i.e., the larger end), leaving the cantilever end free and suspended in space. Ensure that the bottom of the AFM cantilever is facing downward.

- Mount the manipulator onto the probe station.

- Raise the Z-axis of the manipulator to a position where the tipless cantilever is a few millimeters above the epoxy-containing glass slide.

- Manually move the manipulator such that the tipless cantilever is visible in the field view of the camera on the probe station.

- Using the manipulator, move the AFM cantilever along the X and Y directions until the tip of the cantilever is resting directly above the epoxy on the edge of the glass slide.

- Using the manipulator again, slowly lower the tipless cantilever in the Z direction over the edge of the glass slide.

- As the cantilever is lowered and approaches the glass slide, keep lowering the cantilever very slowly until it first touches the epoxy. Do not lower the cantilever any further.

- Cautiously, engage the manipulator to slowly move the cantilever in the X or Y direction and remove the cantilever from the pool of epoxy by continuously moving the cantilever in the selected direction until the cantilever is entirely separated from the epoxy on the glass slide. The tipless cantilever should have a miniature bubble of epoxy at its tip, visible under the probe station.

- Raise the cantilever in the Z-direction using the manipulator.

6. Bonding the labrum's tip to the tipless cantilever beam

- Rotate the manipulator about the cantilever's long axis by 90 degrees and rest the manipulator on the probe station on its side. In this configuration, the thicknesses along the length of the AFM cantilever is in the vertical direction.

- Position the precision tweezers that contain the labrum's tip under the probe station camera so that the entire length of the labrum's tip is visible on the computer monitor.

- Position the manipulator assembly holding the clamp and the tipless cantilever under the probe station camera so that the entire length of the tipless cantilever is visible on the computer monitor.

- Focus the probe station microscope on the labrum's tip and the tipless cantilever.

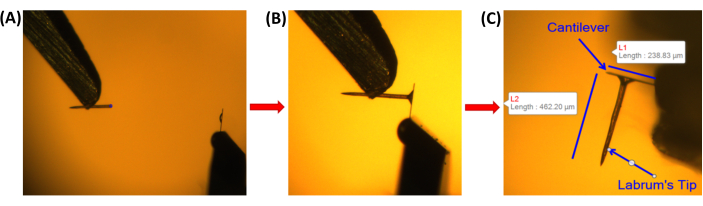

- Orient the cantilever perpendicularly to the labrum's tip by carefully and manually rotating the manipulator (Figure 6A).

- Using the degrees of freedom of the manipulator, slowly move the tipless cantilever in the XY directions such that the glue on the cantilever contacts the cut end of the labrum's tip (Figure 6B).

- Cure the epoxy, solidifying the intersection between the cantilever and mosquito labrum.

- Once the epoxy has cured, gently engage the manipulator in the XY directions and move the cantilever away from the tweezers, verifying that the labrum's tip is now standing on the tipless cantilever beam (Figure 6C).

Representative Results

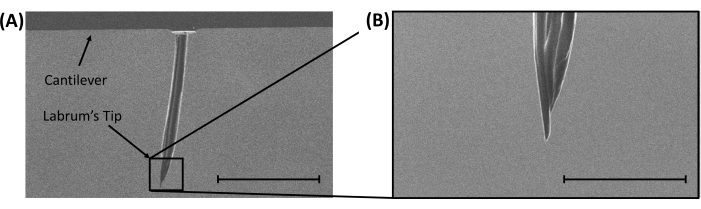

Scanning electron microscopy (SEM) images of the fabricated bio-hybrid AFM probe can be found in Figure 7. The end of the labrum was successfully glued to the tipless cantilever beam. Due to the natural curvature of mosquito stingers and the manual operation of the presented protocol, it is extremely difficult to obtain a cantilever with a stinger tip perfectly perpendicular to the cantilever. The off-center angle between the stinger and an imaginary center line perpendicular to the cantilever is usually ~10 degrees. While it seems a common problem when mounting a probe to an AFM cantilever15, the unintended inclination must be accounted for when performing force/stress analysis. It would be interesting for future studies to focus on improving the fabrication protocol and to perform studies using the bio-hybrid probe. This is the first attempt at making a bio-hybrid AFM probe using an insect's stinger.

Figure 1: Schematic of a mosquito's proboscis. Please click here to view a larger version of this figure.

Figure 2: Removal of the labium of a mosquito proboscis. (A) A mosquito with a full proboscis showing the presence of the intact tapered tip. (B) The location of the labium incision and tweezer placement on the labium during the labium removal process. (C) The direction of tweezer pulling during the removal of the labium. (D) The final dissected fascicle with an intact tip after labium removal, with the tapered labrum tip still present and intact. Scale bars: 200 µm. Please click here to view a larger version of this figure.

Figure 3: Separation of the labrum from unwanted fascicle members. (A) Location of tweezer placement and direction of tweezer pushing as a technique to separate the proboscis fascicle members. (B) Proboscis after being manipulated to separate the labrum from other fascicle members. Scale bars: 200 µm. Please click here to view a larger version of this figure.

Figure 4: Isolation of the desired labrum tip for mounting to the AFM cantilever. (A) The location of the labrum incision for the removal of the labrum's tip. Scale bar: 200 µm. (B) The labrum's tip, once cut from the body of the labrum, measures approximately 200-300 µm in length. Scale bar: 50 µm. Please click here to view a larger version of this figure.

Figure 5: Mounting the labrum tip to a tweezer before the gluing process. The labrum tip stuck to one of the tweezers' tip, with the uncut end of the labrum free and pointing away from the tweezers' body. Scale bar: 200 µm. Please click here to view a larger version of this figure.

Figure 6: Sequence for mounting the labrum's tip to the tipless cantilever. (A) Orienting the tipless cantilever in a perpendicular position with respect to the labrum. (B) Merging the tipless cantilever with the labrum and curing the epoxy adhesive used to solidify the joint between the two components. (C) The final cured bio-hybrid AFM probe without the labrum being supported by the tweezer. Please click here to view a larger version of this figure.

Figure 7: SEM images of the bio-hybrid AFM probe. (A) A global view of the labrum's tip and the tipless cantilever. Scale bar: 200 µm. (B) A magnified view of the labrum's tip. Scale bar: 50 µm. Please click here to view a larger version of this figure.

Discussion

Step 1 of the protocol is meant to clean the biological sample of the unwanted labium. To achieve this, an incision is made on the labium, but not on the fascicle, which rests directly beneath the labium (Figure 1). Because the fascicle and labium are not joined together at their interface (i.e., the labium is free to slide along the fascicle and is only kept in place by its attachment to the mosquito head), the performed incision is meant to separate part of the labium from the mosquito's head, thus facilitating the removal of the outer cover. As the labium is being pulled from the sample, the technician should experience a slight resistance caused by the bottom half of the labium still attached to the mosquito. It is expected for this resistive force to release relatively easily because the incision will promote crack propagation of the biological material, thus inducing the uncut segment of the labium to rip and causing the entire labium to slide off of the fascicle during the pulling action. If an insufficient incision is made, the technician may experience excessive resistance during pulling and is encouraged to attempt another incision before continuing with the protocol.

It is important to exercise a soft touch and patience in step 1 and step 4 when manipulating the labrum via pinching with tweezers. Though the labrum is relatively resilient, it may still experience damage if compressed by the tweezers too aggressively. The technician is guided to lightly pinch the labium/labrum, meaning they should execute the minimum amount of force needed on the tweezers to hold the labium/labrum. Evaluation of the presence of damage can be performed at the end of step 1 and step 4 when inspecting the sample under the microscope. It is advised to inspect the proboscis for any abnormalities along its length (i.e., dents, rips, separations in segments). If a sample is suspected to be damaged at the labrum's tip, discard it and restart the protocol.

Key process steps of the protocol, such as step 3 and step 6 require special care. To accomplish step 3, the labrum's tip must be cut manually with a scalpel. Cutting too short will make the rest of the experiment exponentially harder because it can be too small to manipulate. On the contrary, if the tip exceeds 300 µm in length, it becomes too long to be mounted to the AFM cantilever because of the excessive perpendicular offset that is introduced between the labrum tip and the AFM cantilever. This offset is driven by imperfections in the mounting process and/or a curvature that may be present in the sample, which both become problematic at greater labrum lengths. Also, cantilevers with very long tips will be very difficult to use under the AFM as well. During step 3, it is important to note that all fascicle stylets (labrum, maxillae, mandibles, and hypopharynx) will likely be cut in this procedure. The labrum will be easily located and isolated from the remaining stylets in step 4 because of the manual separation that was performed during step 2. In step 6, even though it is nearly impossible to ensure that the tip is perfectly normal to the cantilever under an optical microscope, it is still necessary to minimize the inclination angle to avoid unwanted loading conditions in future use.

It is also important to choose the right epoxy for the attachment of the stinger to the AFM cantilever. Various slow-curing two-part epoxies were tested, which were later proven to be not ideal because any small vibration of the laboratory floor during the curing process can cause the experiment to fail. Thus, a UV-curable epoxy was eventually adopted. The adhesive used is a low-viscosity, fast-curing epoxy that is capable of curing within 5 s of UV exposure. Upon solidification, the glue becomes very rigid and has excellent strength, causing the fabricated labrum-cantilever probe to behave as a single body and not fail or deform at the location of adhesion. This option provided enough time before curing to configure the setup in the proper position for adhering the stinger to the AFM cantilever (step 6.3) while eliminating any issues related to environmental vibrations due to its on-command curing behavior.

The remaining crucial equipment in this protocol is the probe station, the sharp tweezers, and the cantilever. The probe station used is equipped with a 5x lens mounted to the camera; however, it is not essential to use this exact probe station model for this protocol. When selecting the probe station, the only priority is to ensure clear and easy visibility of the AFM cantilever and the labrum. The sharp tweezers used were with a tip size of 0.5 mm by 0.1 mm. It is imperative to use tweezers of this tip dimension or similar because using forceps with a lower fineness may lead to difficulty during the manipulation of the labrum. The cantilever used in this protocol is obtained from a commercial source (see Table of Materials). This cantilever model was selected because of its high stiffness since a large force must be transferred to the tip of the mosquito probe in order to emulate real-life skin penetration. Generally, for all stinger-based probes, an AFM cantilever cannot be too soft because a lack of rigidity will lead to bending of the cantilever during AFM testing, in turn leading to a lack of pressure development at the stinger-probe tip. This will cause the probe to inaccurately mimic the stinging process, thus making highly rigid tipless AFM cantilevers a requirement for this protocol.

In summary, it has unique benefits to use a stinger-based bio-hybrid AFM probe for quantitative mechanical penetration/biting studies compared to other methods that require living mosquitoes and human volunteers4,11,12to perform similar studies. The ultrahigh sensing resolution of AFM can enable measurement with unprecedented accuracy, and the bio-hybrid probe enables a close-to-realistic emulation of actual biting scenarios, incorporating a statistically significant number of measurements without requiring human volunteers4,11,12. In addition, the materials used for fabricating engineered microneedles are typically prone to fracture or buckling3,4, which is not representative of the mosquito's proboscis. Using the mosquito's parts themselves better resembles the real biting scenario. This protocol can be potentially further developed and automated for high-throughput production. Finally, the developed protocol could be potentially used to produce other bio-hybrid AFM probes using stingers of different animals for quantitative studies of various biting/penetration behaviors.

Divulgations

The authors have nothing to disclose.

Acknowledgements

The authors acknowledge the funding support from Canada's New Frontiers in Research Fund (NFRF), Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery program, and Fonds de Recherche du Québec Nature et Technologies (FRQNT) master's training scholarships. The authors also would like to thank Prof. Yaoyao Zhao's group at McGill for their technical support on 3D printing of some components.

Materials

| 5-SA-SE Straight Tapered Ultra Fine-Pointed Tweezers | Excelta | N/A | For manipulating/dissecting the proboscis. |

| C-4D Probe station | Everbeing Int’l Corp | N/A | Used for AFM assembly. |

| Tipless Tapping Mode Cantilever | NanoAndMore USA | TL-NCH | AFM cantilever used for mounting the labrum. Specs are shown here: Shape: Beam Force Constant: 42 N/m (10 – 130 N/m) Resonance Frequency: 330 kHz (204 – 497 kHz) Length: 125 µm (115 – 135 µm) Largeur: 30 µm (22.5 – 37.5 µm) Thickness: 4 µm ( 3 – 5 µm) |

| UV Expoxy | Let's resin | ALR00146 | For stinger attachment. |

References

- World Health Organization. Global vector control response 2017–2030. World Health Organization. , (2017).

- Gurera, D., Bhushan, B., Kumar, N. Lessons from mosquitoes’ painless piercing. J Mech Behav Biomed Mater. 84, 178-187 (2018).

- Ma, G., Wu, C. Microneedle, bio-microneedle and bio-inspired microneedle: A review. Journ of Contr Relea. 251, 11-23 (2017).

- Kong, X., Wu, C. Micronano structure and mechanics behavior of mosquito’s proboscis biomaterials with applications to microneedle design. Advan Mater Res. 299-300, 376-379 (2011).

- Li, A. D. R., Putra, K. B., Chen, L., Montgomery, J. S., Shih, A. Mosquito proboscis-inspired needle insertion to reduce tissue deformation and organ displacement. Sci Rep. 10 (1), 12248 (2020).

- Meyer, E., Hug, H. J., Bennewitz, R. Introduction to Scanning Probe Microscopy. Scanning Probe Microscopy. 1, 1-13 (2004).

- García, R., Peréz, R. Dynamic atomic force microscopy methods. Surf Sci Rep. 47 (6), 197-301 (2002).

- Thurner, P. J. Atomic force microscopy and indentation force measurement of bone. WIREs Nanomed and Nanobio. 1 (6), 624-649 (2009).

- Müller, D. J., Dufrêne, Y. F. Atomic force microscopy as a multifunctional molecular toolbox in nanobiotechnology. Nat Nanotech. 3 (5), 261-269 (2008).

- Hussain, D., Ahmad, K., Song, J., Xie, H. Advances in the atomic force microscopy for -critical dimension metrology. Meas Sci Technol. 28 (1), 012001 (2017).

- Kong, X. Q., Wu, C. W. Mosquito proboscis: An elegant biomicroelectromechanical system. Phys Rev E. 82 (1), 011910 (2010).

- Kong, X. Q., Wu, C. W. Measurement and prediction of insertion force for the mosquito. J Bionic Eng. 6 (2), 143-152 (2009).

- Ramasubramanian, M. K., Barham, O. M., Swaminathan, V. Mechanics of a mosquito bite with applications to microneedle design. Bioinspir Biomim. 3 (4), 046001 (2008).

- Dai, G., et al. Nanoscale surface measurements at sidewalls of nano- and micro-structures. Measur Sci and Technol. 18 (2), 334-341 (2007).