Design and Construction of an Urban Runoff Research Facility

Summary

This paper describes the design, construction, and function of a 1,000 m2 facility containing 24 individual 33.6 m2 field plots equipped for measuring total runoff volumes with time and collection of runoff subsamples at selected intervals for quantification of chemical constituents in the runoff water from simulated home lawns.

Abstract

As the urban population increases, so does the area of irrigated urban landscape. Summer water use in urban areas can be 2-3x winter base line water use due to increased demand for landscape irrigation. Improper irrigation practices and large rainfall events can result in runoff from urban landscapes which has potential to carry nutrients and sediments into local streams and lakes where they may contribute to eutrophication. A 1,000 m2 facility was constructed which consists of 24 individual 33.6 m2 field plots, each equipped for measuring total runoff volumes with time and collection of runoff subsamples at selected intervals for quantification of chemical constituents in the runoff water from simulated urban landscapes. Runoff volumes from the first and second trials had coefficient of variability (CV) values of 38.2 and 28.7%, respectively. CV values for runoff pH, EC, and Na concentration for both trials were all under 10%. Concentrations of DOC, TDN, DON, PO4-P, K+, Mg2+, and Ca2+ had CV values less than 50% in both trials. Overall, the results of testing performed after sod installation at the facility indicated good uniformity between plots for runoff volumes and chemical constituents. The large plot size is sufficient to include much of the natural variability and therefore provides better simulation of urban landscape ecosystems.

Introduction

Four of the most rapidly growing, highly populated metropolitan areas are located in the southern U.S. in subtropical climates1. In addition, the largest percent change in urbanized land between 1982 and 1997 occurred in southern USA1. With increased urban areas comes a concomitant demand for potable water, much of which is used for outdoor use during summer months2. With new construction, programmable in-ground irrigation systems are often installed. Unfortunately, these systems are often programmed to deliver irrigation to urban landscaping more frequently and/or in volumes that exceed evapotranspiration demands of the landscape2. This results in a significant volume of runoff from urban landscaping to receiving waters, which contributes to what has been termed urban stream syndrome3. Symptoms of the urban stream syndrome include increased frequency of overland flow and erosive flow, increased nitrogen (N), phosphorus (P), toxicants, and temperature in addition to changes in channel morphology, freshwater biology, and ecosystem processes3.

Losses of N and P from agricultural ecosystems have been extensively studied and found to be primarily dependent on four factors: nutrient source, application rate, application timing, and nutrient placement4. While fewer published data currently exist on off site movement of nutrients from urban landscapes, these principals can be directly applied to turfgrass culture, whether in home lawns, sod farms, parks, or other green spaces. Additionally, improper irrigation practices which result in runoff from the landscape can exacerbate these losses.

Nutrient losses can be further altered by irrigation water quality. Areas in the southwest US often utilize more saline or sodic water for irrigation of home lawns and urban landscapes5,6. The chemical composition of the irrigation water may significantly alter soil chemistry causing a release of carbon, nitrogen, calcium, and other cations to runoff water. Recent work showed that increased sodium absorption ratio (SAR) of the extracting water significantly increased the amounts of carbon (C) and nitrogen (N) leached from St. Augustinegrass clippings, ryegrass clippings, and other organic materials7. Furthermore, water extractable soil C, N, and P losses from recreational turfgrass soils were significantly correlated with irrigation water chemical constituents6.

Washbusch et al. studied urban runoff in Madison, WI and found that lawns were the largest contributors of total phosphorus8. In addition, they also found that 25% of the total P in “Street Dirt” originated from leaves and grass clippings. In a typical rural setting, leaf litter falls onto the ground and then decomposes slowly releasing nutrients back to the soil environment. However, in urban environments, significant quantities of nutrient-rich leaves and grass clippings may fall on or get washed or blown onto hardscapes such as driveways, sidewalks, and roadways, subsequently making their way into the streets where they contribute to “street dirt”, much of which gets washed directly into receiving waterways.

Urban landscape soils are often disturbed and highly compacted during construction, which can also increase amounts of runoff due to reduced infiltration rates9. Kelling and Peterson reported that both total runoff volume and the nutrient concentrations in runoff from home lawns are increased from lawns that are compacted or have severely disturbed soil profiles due to previous construction activities10. Edmondson et al. on the other hand, found that urban soils were less compacted compared to surrounding agricultural soils in the urban and suburban region of Leicester, UK11. They attributed this to heavy agricultural machinery used, but they also noted that lawns had a greater soil bulk density than soil under trees and shrubs which was attributed to grass mowing and greater human trampling.

It would appear that in many situations, urban and suburban stream syndromes are significantly impacted by runoff and point-source discharges3,12. While point-sources can be manipulated through permits and recycling, additional research is needed to develop and test best management procedures for home lawn establishment and management to minimize nutrient losses to runoff. Past research efforts in this regard have often been centered along coastal areas where there are high sand content soils, due to concerns related to the effects of leaching and runoff losses of nutrients to coastal waters. However, when working with very sandy soils, one must have steep slopes and high rainfall rates to be able to generate any runoff13,14. In contrast, many of the soils in the central United States are fine textured and have low infiltration rates that result in significant amounts of runoff from even small rainfall events. Thus, it was desired to design and construct a runoff facility on native soil and slope typical of those that may occur on residential landscapes.

This paper describes the design, construction and function of a 1,000 m2 facility containing 24 individual 33.6 m2 field plots for measuring total runoff volumes at relatively small temporal resolutions and simultaneous collection of runoff water subsamples at selected volumetric or temporal intervals for measurement and quantification of chemical constituents of the runoff water.

Protocol

1. Site Selection

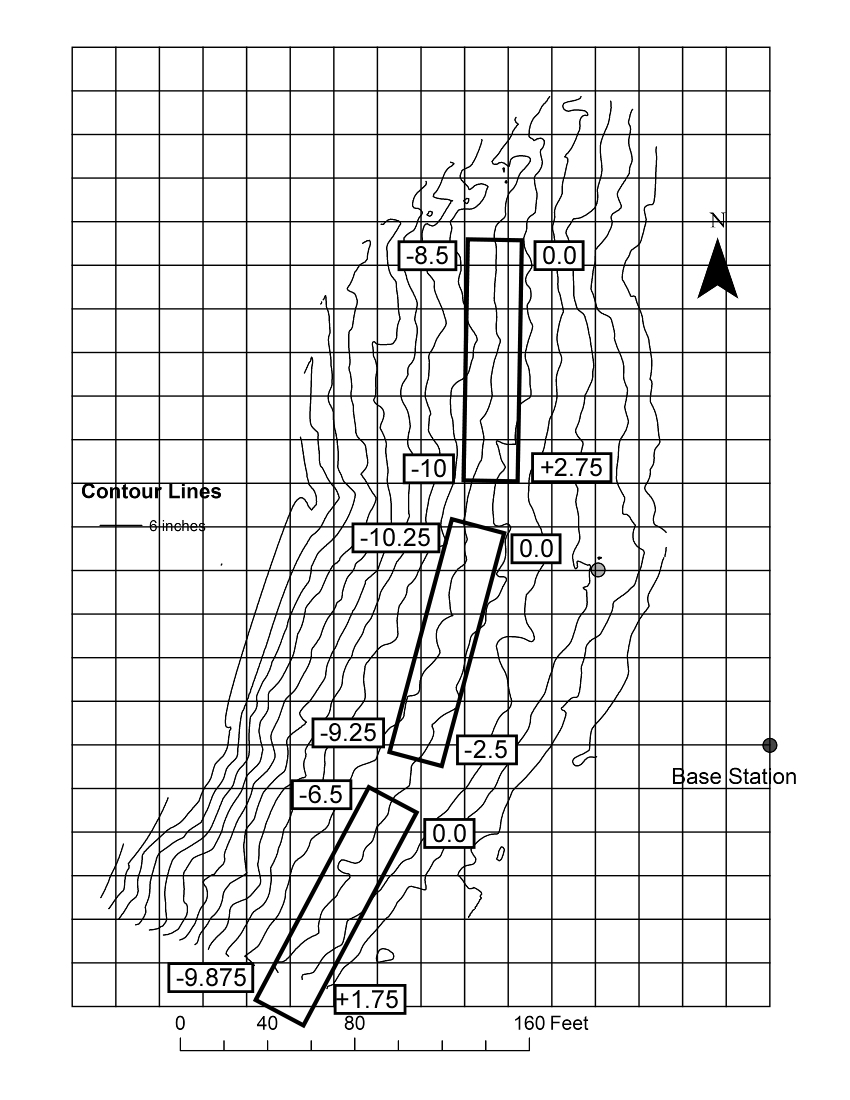

- Locate a suitably-sized area of undisturbed soil having a uniform 3-4% slope.

- Conduct a topographic survey and delineate an area approximately 10 m x 100 m having an average 3.7±0.5% slope.

- Divide the 10 m x 100 m area into three blocks, each approximately 10 m x 33.3 m (Figure 1).

- Subdivide each block into 8 field plots, each 4.1 m wide by 8.2 m long.

- Identify and document the soil series present in the study area. Note: this location had a Booneville series fine sandy loam but other soil series and textures may be used.

2. Retaining Wall Construction

- Cut a 30 cm wide by 30 cm deep trench at the low end of the plots.

- Cut a 20 cm wide by 1.2 m deep trench 10 cm from the plot edge to provide a smooth vertical edge that extends into the clay subsoil.

- Construct and install temporary wooden forms in the trench to hold it open.

- Remove soil adjacent to the downhill side of the form to a depth of 76 cm below the soil surface at the low end of the plots. Insure a minimum slope of 0.5% away from the plots for a distance of approximately 30 m to provide adequate drainage.

- Remove the temporary forms and construct a steel reinforced concrete retaining wall.

- Construct wooden forms for the outside of the wall and use the undisturbed soil below the plot areas as the inside wall.

- Be sure that the wall extends into undisturbed subsoil to help prevent future movement.

- Assemble two sections of trench drain for each plot with end caps at each end and a bottom discharge drain at the low end. Seal all joints with silicone and then screw the joints together as per manufacturer’s recommendations.

- Glue and screw a 10 cm diameter PVC 90° ell and 60 cm length of discharge pipe to the outlet. Place the assembled drain in the concrete form and attach it so that the top edge is level in both directions and 1.27 cm below the soil surface at the low end of the plot (Figure 2). Cover the drain with a temporary plastic cover to keep out wet concrete.

- Pour 4,000 lb. test ready mix concrete into the forms using appropriate amounts of vibration to remove voids.

- When forms are full, trowel the upper surface to form a smooth finish with rounded edges. Temporary plastic covers on the drains should be removed to allow final surface preparation.

- Ensure that the finished concrete surface is level with the soil surface at the bottom of the plot and has a 1.27 cm slope to the drain.

- Ensure that, on the downhill side of the drain, the concrete has a 1.27 cm slope away from the drain to prevent water from backing up into the drains.

- Form and pour steel reinforced concrete pads (1.2 m wide, 1.8 m long, and 15 cm thick) below each drain outflow. Pads must have 0.5% slope away from the wall and the top of the pad must be 30 cm below the bottom of the drain outlet.

- Provide a weatherproof electrical outlet (110/120 V) on the side of the retaining wall above each pad in preparation for instrumentation.

3. Installation of Instrumentation

- Cut discharge pipes flush with the concrete wall.

- Install a 1.2 m long H flume immediately below the drain outflow.

- Anchor the flume to the wall using appropriate concrete anchors and screws being sure that the flume is level from side to side.

- Support the front of the flume with an adjustable stainless steel stand and use the adjustments to level the unit both side to side and front to back. Seal the joints between the flumes and concrete with Tub and Tile sealant.

- Install a flow meter on each pad. Locate the flow meter near the end of the flume to minimize the length of tubing needed.

- Install a portable sampler on each pad. Locate the sampler as needed to minimize the needed amount of tubing to reach the sampling tube. Note: It may be necessary to put the sampler on a stand to prevent depressions that may retain water in the sampling tubing.

- Design, fabricate, and install stainless steel covers over the wall and the flumes to prevent the entrance of precipitation into the trench drains or flumes.

4. Plot Area Preparation

- Fill and tamp any minor voids on the upslope side of the wall using native topsoil from adjacent field areas.

- Use a small walk behind trencher to cut a 10 cm wide, 30 cm deep trench on the remaining 3 sides of all plots.

- Insert 40 cm wide strips of 0.10 mm thick clear plastic vertically in the trenches to prevent lateral movement of water between plots.

- Install irrigation pipe and heads. Install six heads on 4.1 m2 spacing for each plot.

- Backfill and lightly tamp all trenches by hand. Mound the soil into a 5 cm tall by 30 cm wide berm over the trench area to prevent lateral movement of surface water between plots.

- Adjust irrigation heads to the top of the soil height in the berm areas.

- Construct a diversion ditch to prevent upslope water from getting on the plots

- Use a box blade to cut a V-shaped channel approximately 20 cm deep in the center and 2 m across. Note: The center of the channel should be approximately 1.25 m above the high side of the plot area and should extend across the upper side of all plots.

- Cut a sloped trench in the bottom of the channel. Note: To insure good drainage, the trench bottom should be 30 cm below the channel bottom at the high point in the center point above each block and have a minimum slope of 0.5% going to each end of each block. Trench bottoms must be hand smoothed and surveyed as necessary to ensure uniform slope.

- Add 5 cm of washed 6-9 mm pea gravel to the bottom of the trenches.

- Place a 15 cm diameter slotted drain line on the gravel surface and fill the trench with more 6-9 mm gravel.

- Cut trenches as needed at the ends and between the blocks of plots to route drainage water to discharge locations below the retaining wall. Use 15 cm diameter plain corrugated drain line and backfill these trenches with the excavated soil. Cover the trench and channel area with a layer of large 5-15 cm diameter bull rock.

5. Planting and Initial Runoff Event

- Hand rake the plots to ensure a smooth seedbed with uniform slope in preparation for sod installation.

- Measure and document the slope of each plot using standard survey equipment by taking elevation measurements at distances of 0, 1.5, 3.0, 4.6, 6.1, and 7.6 m from the wall along the mid-line of each plot.

- Measure the depth of topsoil at 4 locations in each plot by inserting a 2.54 cm diameter soil probe into the soil until clay textured subsoil is encountered.

- Plant sod grown on a similar texture soil. Note: For this facility, mature ‘Raleigh’ St. Augustinegrass (Stenotaphrum secundatum [Walt.] Kuntze) was used. However, other grasses may be used based on location, weather, and experimental design considerations. All plots may be sodded at one time or as in the present case, 12 plots (4 plots in each block) were planted on 08 August 2012, with the remaining 12 plots planted on 12 September 2012.

- Create a Runoff Event

- Take initial readings of water meters and measure the soil moisture content of all plots.

- Remove the lids from the valve boxes located at the head of each plot and record the initial water meter reading for each of the 24 plots.

- Using a portable hand held moisture probe, measure and record the soil moisture content of each plot. Note: For the initial characterization, 4 measurements were taken per plot (1 measurement in each quadrant of each plot) using 7.5 cm long probes. However, the number of measurements, length of probes, and type of instrument used may be varied based on the specific study objectives.

- Program flow meters and samplers to measure flow and collect samples as desired. Note: 750 ml samples were collected after every 20 L of flow but other sample volumes and intervals may be used as appropriate.

- Operate the irrigation system for a predetermined time to apply sufficient water to cause runoff. Note: 20-21 mm of precipitation applied at a rate of 4.04 cm/hr was sufficient for this facility, however, this amount may vary based on site specific conditions.

- Record the ending water meter readings for each of the 24 plots. Collect irrigation water samples from the spray heads during operation. Label and transport runoff samples to the laboratory for analysis.

- Take initial readings of water meters and measure the soil moisture content of all plots.

6. Sample Analysis

- Measure the electrical conductivity and pH of the water samples by dipping probes directly into the samples. Then filter a 50 ml subsample of each water sample through a 0.7 µm glass microfiber filter in preparation for chemical analysis.

- Measure dissolved organic carbon (DOC) and total dissolved nitrogen (TDN) using the USEPA method 415.115.

- Make a 1,000 mg/L standard solution by adding 2.125 g dried potassium acid phthalate (1-KOCOC6H4-2-COOH) to a 1 L volumetric flask. Add approximately 500 ml distilled water, swirl to dissolve the chemical and bring to volume with distilled water. Store solution under refrigeration in a brown bottle.

- Make a 1,000 mg/L standard solution by adding 6.0677 g dried sodium nitrate to a 1 L volumetric flask. Add approximately 500 ml distilled water, swirl to dissolve the chemical, and bring to volume with distilled water.

- Make intermediate C and N standards that encompass the anticipated range of concentrations in the samples to be run by diluting subsamples of the standard solutions from steps 6.3.1-6.3.2.

- Pour approximately 16 ml of the water samples to be analyzed into a 24 ml sample vials and cover each with a septa and cap.

- Place filled vials in the autosampler tray keeping a record of what sample is in what position. Note: for quality assurance purposes a blank, two standards and two certified reference standards should be run after every 12th unknown.

- Place the autosampler tray in the machine and operate the auto analyzer following manufacturer’s instructions.

- Measure phosphorus, nitrate and ammonia using the USEPA methods 365.1, 353.2, and 350.1, respectively, within 48 hr of sample collection16-18.

- Make the following reagents and standards for phosphorus analysis:

- Make a 5 N sulfuric acid stock solution by slowly adding 70 ml concentrated sulfuric acid to 400 ml distilled water in a 500 ml volumetric flask. Cool the solution to RT and dilute to volume using distilled water.

- Make a 0.3% potassium antimonyltartrate stock solution. Weigh 0.5 g antimony potassium tartrate, trihydrate C8H4K2O12Sb2•3H2O and dissolve it in about 50 ml distilled water in 100 ml volumetric flask. After it is dissolved, dilute to volume with distilled water and store at 4 °C in a brown, glass-stoppered bottle.

- Make a 4% solution of ammonium molybdate by dissolving 4 g ammonium molybdate tetrahydrate, (NH4)6Mo7O24•4H2O, in 100 ml reagent water. Store in an acid washed plastic bottle at 4 °C.

- Make a 15% w/w stock solution of sodium dodecyl sulfate (SDS). Dissolve 15 g of SDS CH3(CH2)11OSO3Na in 85 ml of distilled water. Note: This may require gentle stirring and heat to fully dissolve.

- Make a dilution SDS Solution (REAGENT 1) by adding 2 ml of 15% SDS stock solution to 98 ml distilled water. Cap flask and mix by inverting 5-6x.

- Make 100 ml of color reagent (REAGENT 2) by mixing the above reagents as follows: To 20 ml of distilled water add 50 ml of 5 N H2SO4 and mix. Add 5 ml of 0.3% antimony potassium tartrate solution and mix. Add 15 ml of 4% ammonium molybdate solution and mix. Add 10 ml of 15% w/w SDS solution and mix. Note: This solution can be stored in an acid washed bottle at RT for no more than one week.

- Make an ascorbic acid solution (REAGENT 3) by dissolving 0.88 g of ascorbic acid C6H8O6 in 50 ml of distilled water. Add 0.5 ml of 15% SDS and swirl gently. Note: This solution must be prepared fresh daily.

- Make a 100 mg P/L standard solution by adding 0.4393 g dried KH2PO4 to a 1 L volumetric flask. Add approximately 500 ml distilled water, swirl to dissolve the chemical and bring to volume with distilled water.

- Make the following reagents and standards for nitrate analysis

- Add 25 ml of concentrated phosphoric acid (H3PO4) to 150 ml distilled water in a 250 ml volumetric flask. Cool to RT and add 10.0 g sulfanilamide (4-NH2C6H4SO2NH2) and dissolve. Add 0.5 g N-(1-napthyl) ethylenediamine dihydrochloride (C10H7NHCH2CH2NH2•2HCl) and dissolve. Add 2 ml of concentrated rinse solution (from instrument manufacturer) and dilute to volume using distilled water. Note: Solution may be stored in a brown bottle for up to several weeks.

- Dissolve 85 g of ammonium chloride (NH4Cl) and 0.1 g disodium ethylenediamine tetraacetate (C10H14N2Na2O8•2H2O) in approximately 900 ml of distilled water in a 1 L volumetric flask. Adjust the pH to 8.5 by addition of concentrated ammonium hydroxide (NH4OH) and dilute to volume with distilled water.

- Put 200 ml of the solution from 6.4.2.2 in a 1 L volumetric and dilute to volume with distilled water. Adjust the pH to 8.5 by addition of concentrated ammonium hydroxide (NH4OH).

- Dissolve 7.218 g potassium nitrate (KNO3) in distilled water and dilute to 1 L. Add 1 ml chloroform (CHCl3) as a preservative.

- Make the following reagents and standards for ammonia analysis:

- Dissolve 8 g sodium hydroxide (NaOH) in 125 ml of distilled water in a 250 ml volumetric flask. Cool to RT, add 20.75 g phenol (C6H5OH) and dissolve. Dilute to volume with distilled water and store up to 2 weeks in a brown bottle in the dark.

- Add 25 ml of bleach solution containing 5.25% NaOCl plus 0.5 ml of concentrated Probe Rinse Solution to a 50 ml volumetric flask. Dilute to volume with distilled water and mix.

- Dissolve 25 g EDTA disodium salt dihydrate (C10H14N2Na2O8•2H2O) and 2.75 g sodium hydroxide (NaOH) in approximately 450 ml distilled water in a 500 ml volumetric flask. Add 3 ml of concentrated Probe Rinse Solution, mix, and bring to volume with distilled water.

- Dissolve 0.075 g sodium nitroprusside dihydrate (Na2Fe(CN)5NO•2H2O) in 100 ml distilled water. Add 0.5 ml concentrated Probe Rinse Solution, mix and store in a brown bottle for up to 1 week.

- Make a 1,000 mg/L ammonia stock solution by dissolving 3.819 g dried anhydrous ammonium chloride (NH4Cl) in 500 ml distilled water and diluting to 1 L.

- Place samples in 4 ml sample vials and cover each with a septa and cap.

- Place filled vials in the analyzer keeping a record of what sample is in what position. Note: for quality assurance purposes a certified reference standard should be run after every 12th unknown.

- Operate the analyzer following manufacturers instructions for the analyte of choice.

- Make the following reagents and standards for phosphorus analysis:

- Measure cations (sodium, calcium, magnesium, and potassium) using Ion Chromatography.

- Prepare a 1,000 mg/L stock solution of Na by adding 2.542 g NaCl to a 1 L volumetric flask and bring to volume with distilled water.

- Prepare a 1,000 mg/L stock solution of K by adding 1.9070 g KCl to a 1 L volumetric flask and bring to volume with distilled water.

- Prepare a 1,000 mg/L stock solution of Mg by adding 8.3608 g MgCl2•6H2O to a 1 L volumetric flask and bring to volume with distilled water.

- Prepare a 1,000 mg/L stock solution of Ca by adding 3.6674 g CaCl•2H2O to a 1 L volumetric flask and bring to volume with distilled water.

- Prepare a 350 mg/L working solution of Na by adding 35 ml of stock solution to a 100 ml volumetric flask and bring to volume with distilled water.

- Prepare a 25 mg/L working solution of K by adding 2.5 ml of stock solution to a 100 ml volumetric flask and bring to volume with distilled water.

- Prepare a 25 mg/L working solution of Mg by adding 2.5 ml of stock solution to a 100 ml volumetric flask and bring to volume with distilled water.

- Prepare a 75 mg/L working solution of Ca by adding 7.5 ml of stock solution to a 100 ml volumetric flask and bring to volume with distilled water.

- Refilter runoff water samples through a 0.2 μm glass microfiber filter.

- Fill sample vial to fill line with sample or standard and seal with septa and cap.

- Place sample vials in the analyzer keeping track of sample locations. Note: for quality assurance purposes a blank and certified reference standard should be run after every 12th unknown.

- Operate the auto analyzer following manufacturer’s instructions.

Representative Results

Plot characteristics

The average slope for all 24 plots was 3.7% and ranged from a low of 3.2% for plot 17 to a high of 4.1% for plot 2 (Table 1). Average topsoil thickness was 36 cm and ranged from a low of 25.0 cm for plot 24 to a high of 51.5 cm for plot 10 (Table 1).

Runoff volumes

Runoff volumes from the first trial on 09 August 2012 had a mean of 213.5 L and ranged from a low of 95.6 L to a high of 391 L with a coefficient of variability (CV) of 38.2% (Table 2). It should be noted that prior to sodding, these plots had been well irrigated to ensure good function of the irrigation and runoff collection systems, measure irrigation distribution and similar activities. Thus, much of the applied irrigation was collected as runoff.

In contrast, the soil was much drier prior to the 13 September 2012 runoff event which resulted in lower average runoff volume of 52.6 L. Volumes ranged from a low of 27.5 L to a high of 70.8 L with a CV of 28.7%. In this case, much of the applied water infiltrated into the soil beneath the sod resulting in lower amounts of total runoff.

Chemical concentrations

Irrigation was done using the local potable water. A composite sample of the irrigation water was collected from the irrigation heads during the irrigation event and was analyzed for its chemical composition. The water had a pH of 8.5, an electrical conductivity (EC) of 1,030 dS/cm and contained 0.19 mg/L NO3-N, 0 mg/L NH4-N, 3.26 mg/L DOC, 0.38 mg/L TDN, 0.19 mg/L dissolved organic nitrogen (DON), 0.14 mg/L orthophosphate-P, 220.9 mg/L Na, 2.0 mg/L K, 0.87 mg/L Mg, and 4.27 mg/L Ca.

The pH values for all 49 water samples collected after the first runoff event the morning of 09 August 2012 after laying sod the previous day averaged 8.4 standard units with a minimum of 8.1 and a maximum of 8.9 units (Table 3), resulting in a very low CV of 1.5%. The EC and Na+ concentration of the runoff samples had fairly large means and CV values below 10% (Table 3). Concentrations of DOC, TDN, DON, PO4-P, K+, Mg2+, and Ca2+ had CV values in the range of 10.3-32.9%. Concentrations of NO3-N and NH4-N had means of 0.58 mg/L and 0.12 mg/L. However, these two parameters were the most variable and had the highest CV values of 85.0% and 63.5%, respectively.

The pH values for the 40 water samples collected on 13 September 2012 from the second group of plots averaged 8.5 standard units with a CV of 2.9% (Table 4). As with the first trial, pH, electrical conductivity (EC), and Na+ measurements for the first runoff event after laying sod on 12 September 2013 had the highest means and lowest CV values of 2.9, 4.9, and 6.5%, respectively. Concentrations of NO3-N, DOC, TDN, DON, PO4-P, K+, Mg2+, and Ca2+ had CV values in the range of 33.0-49.7%. Ammonium-nitrogen had the lowest mean value of 0.39 mg/L but was the most variable with the highest CV of 107.5%.

The above data for the first runoff event from newly sodded plots will serve as a baseline for future measurements. We expect the CV values between plots to decrease as the turfgrass becomes better established and there is less opportunity for channel flow of water between sod blocks and more uniform overland flow of water through the grass canopy. Plot size is adequate to allow for soil-water-chemical interactions to occur before runoff reaches the collection devices and thus, chemical concentrations in the runoff should be representative of what would be found in a similar urban landscape. We anticipate the facility to be of use in developing science based best management procedures for fertilization and irrigation of urban landscapes.

Figure 1. Contour map of hillside showing the locations for the three blocks of runoff plots. Please click here to view a larger version of this figure.

Figure 2. Schematic diagram of the retaining wall showing placement of the collection troughs and pads for measurement devices. Please click here to view a larger version of this figure.

| Plot Number | Topsoil Depth (cm) | Surface Slope (%) | pH (Std. Units) | NO3-N (mg/kg) | P (mg/kg) | K (mg/kg) |

| 1 | 34.8 | 4.0 | 4.7 | 43 | 215 | 334 |

| 2 | 35.3 | 4.1 | 5.0 | 40 | 204 | 273 |

| 3 | 39.5 | 4.0 | 5.1 | 44 | 190 | 302 |

| 4 | 35.3 | 3.8 | 5.0 | 59 | 184 | 300 |

| 5 | 30.5 | 3.7 | 4.9 | 56 | 205 | 325 |

| 6 | 31.5 | 3.6 | 5.0 | 26 | 223 | 271 |

| 7 | 33.5 | 3.8 | 5.1 | 30 | 224 | 243 |

| 8 | 40.5 | 3.9 | 4.8 | 13 | 218 | 208 |

| 9 | 36.0 | 3.4 | 5.1 | 26 | 263 | 343 |

| 10 | 51.5 | 3.6 | 5.4 | 49 | 229 | 348 |

| 11 | 32.5 | 3.5 | 5.6 | 34 | 262 | 352 |

| 12 | 50.5 | 3.6 | 5.4 | 32 | 235 | 339 |

| 13 | 48.5 | 4.0 | 5.0 | 54 | 261 | 318 |

| 14 | 26.0 | 3.3 | 5.6 | 23 | 252 | 322 |

| 15 | 36.5 | 3.4 | 5.1 | 37 | 247 | 292 |

| 16 | 28.0 | 3.6 | 5.4 | 20 | 279 | 291 |

| 17 | 38.1 | 3.2 | 5.5 | 13 | 319 | 256 |

| 18 | 36.4 | 3.3 | 5.3 | 15 | 316 | 220 |

| 19 | 40.8 | 3.9 | 5.3 | 31 | 329 | 223 |

| 20 | 33.5 | 4.0 | 5.1 | 40 | 321 | 271 |

| 21 | 39.0 | 3.6 | 5.0 | 24 | 283 | 269 |

| 22 | 31.0 | 3.3 | 5.0 | 30 | 311 | 314 |

| 23 | 31.0 | 3.4 | 5.0 | 30 | 287 | 259 |

| 24 | 25.0 | 3.8 | 5.2 | 13 | 301 | 292 |

Table 1. Mean depth of topsoil, surface slope, soil pH, nitrate-N, P, and K for the 24 runoff plots. Values for pH, NO3-N, P, and K reported by the Texas AgriLife Extension – Soil, Water and Forage Testing Laboratory. Soil pH was measured on a 2:1 soil:water extract, NO3-N by Cd reduction, P and K by Mehlich 3 extraction followed by ICP analysis.

| Date | Units | Mean | Minimum | Maximum | CV (%) |

| 9-Aug | L | 213.5 | 95.6 | 391.6 | 38.2 |

| 13-Sep | L | 52.6 | 27.5 | 70.8 | 28.7 |

Table 2. Mean, minimum, maximum, and coefficient of variation (CV) for the runoff volumes collected on 09 August 2012 and 13 September 2012 from 12 runoff plots one day after laying sod.

| Parameter | Units | Mean | Minimum | Maximum | CV (%) |

| pH | Std. Units | 8.4 | 8.1 | 8.9 | 1.5 |

| EC | µS/cm | 1,137 | 1,080 | 1,220 | 3.7 |

| NO3-N | mg/L | 0.58 | 0.08 | 2.93 | 85 |

| NH4-N | mg/L | 0.12 | 0.04 | 0.37 | 63.5 |

| DOC | mg/L | 22 | 16.3 | 30.1 | 13.4 |

| TDN | mg/L | 1.89 | 1.16 | 4.42 | 32.9 |

| DON | mg/L | 1.2 | 0.8 | 2.26 | 23.3 |

| PO4-P | mg/L | 1.05 | 0.59 | 1.76 | 31.9 |

| Na | mg/L | 213 | 201 | 222 | 2.3 |

| K | mg/L | 11.9 | 6.4 | 19.1 | 29.3 |

| Mg | mg/L | 4.65 | 2.64 | 5.69 | 13.2 |

| Ca | mg/L | 18.4 | 13 | 22.1 | 10.3 |

Table 3. Mean, minimum, maximum, and coefficient of variation (CV) for 49 measurements each of 12 parameters of water samples collected on 09 August 2012 from 12 runoff plots one day after laying sod with no fertilizer additions.

| Parameter | Units | Mean | Minimum | Maximum | CV (%) |

| pH | Std. Units | 8.5 | 8.1 | 9 | 2.9 |

| EC | µS/cm | 1,514 | 1,310 | 1,630 | 4.9 |

| NO3-N | mg/L | 1.68 | 0.28 | 3.95 | 49.7 |

| NH4-N | mg/L | 0.39 | 0.08 | 2.59 | 107.5 |

| DOC | mg/L | 27.6 | 7.08 | 54.6 | 33.7 |

| TDN | mg/L | 3.73 | 0.81 | 6.6 | 33.0 |

| DON | mg/L | 1.67 | 0 | 4.97 | 48.0 |

| PO4-P | mg/L | 1.34 | 0.33 | 2.32 | 40.5 |

| Na | mg/L | 206 | 188 | 241 | 6.5 |

| K | mg/L | 10.4 | 3.58 | 21.8 | 35.9 |

| Mg | mg/L | 3.17 | 1.02 | 5.02 | 41.3 |

| Ca | mg/L | 12.7 | 3.72 | 21 | 40.1 |

Table 4. Mean, minimum, maximum, and coefficient of variation (CV) for 40 measurements each of 12 parameters of water samples collected on 13 September 2012 from 12 runoff plots one day after laying sod with no fertilizer additions.

Discussion

Water flow over, into, and through soils is greatly affected by the topography, vegetative cover, and the soil physical properties. Excessively compacted soils and soils with high clay contents will exhibit reduced infiltration rates and increased amounts of runoff. Therefore, when building a facility of this nature, every effort should be made to use native soils with uniform slopes and minimize compaction from all types of traffic on the experimental areas during construction. In addition, compaction from post construction maintenance activities should be minimized. These factors also need to be considered when interpreting the data from a given experiment and comparing them to data from other sites where site conditions may be very different.

All natural soils have a high amount of inherent spatial variability. This may be a result of biological activity such as worm holes, insect activities, etc. or basic soil properties such as texture and shrink-swell potential of the clays. The large plot size used in this facility was selected to include as much of this spatial variability as possible and thereby minimize the total variability between plots.

The irrigation spray nozzles in this facility were selected for use to provide a high precipitation rate with improved drift reduction. An irrigation audit resulted in a mean precipitation rate of 4.04 cm/hr and a uniformity of 79.5%. Other nozzles may be used if lower precipitation rates are desired, however this may result in less uniform water distribution and increased spray drift due to wind. Forced runoff events in which the irrigation system was used as the water source were conducted between 7-9 a.m. to minimize wind effects.

Use and operation of the facility thus far has shown a need for careful observation of the spray nozzles and replacement of damaged ones. Damaged nozzles alter the amount and distribution of water which may bias data. Although not a problem in this initial work, it is evident that periodic cleaning of the channel drains and H flumes will be required to remove accumulated organic and inorganic sediments. Such sediments may affect flow rate measurements particularly at low flows as well as contribute chemical constituents to runoff water samples.

The mean NO3-N concentrations of 0.58 and 1.68 mg/L for the August and September trials are high compared to the 0.0-0.4 mg/L reported by Kelling and Peterson for unfertilized control lawns which served as check plots in their WI study10. A large part of this increase may be due to the fact that our study was conducted on freshly planted sod. This allowed water to come into direct contact with soil in seams between sod blocks and likely increased both soil erosion and N removal from the fertile soil. Effects of flow along seams will be diminished in future experiments as the turf matures and knits together into a tight, dense turf canopy. Furthermore, disturbance of the soil during construction and raking prior to sod installation did effectively aerate the soil which provided optimum conditions for nitrification in the soil. The measured NO3-N concentrations are similar to the mean of 1.54 mg/L reported by Gobel for rainfall runoff from gardens, grassed areas and cultivated land19.

Phosphorus losses from unfertilized turfgrass typically range from 0.5-5.5 mg/L 10,17,18. Mean phosphorus losses were 1.05 and 1.34 mg/L for the August and September trials, respectively, and were within the range of 0.5-1.7 mg/L reported by Kelling and Peterson10 and within the range of 0.5-5.5 mg/L reported by Vietor20. Higher P losses from unfertilized plots reported by Vietor were likely due to the higher slope of 8.5% and different grass species used in their study20. Mean P losses in the present study were higher than the mean P concentration of 0.09 mg/L reported by Gobel for rainfall runoff from gardens, grassed areas and cultivated land19. A large part of the P loss from the current study was likely due to soil erosion from the first runoff event on a newly planted site. It is also likely that the high sodium content of the irrigation water used in the present study may have affected the concentrations of P in the runoff water7.

In comparison to the first trial, the measured concentrations of parameters in the second trial were more variable. This increased variability was attributed to the drier initial soil moisture content prior to planting which resulted in fewer samples. The extra 30 days of hot, dry weather allowed more nitrification to occur. In addition, there was more dust at planting time which may have been on the vegetation and subsequently washed off in the runoff event. It is also possible that some of the increased variability may be due to differences in nutrient content of the purchased sod, although every effort was made to minimize this source of error.

Overall, the runoff facility has numerous benefits for future research concerning runoff from turf covered areas such as home lawns, sports fields, parks and similar green spaces. Primary among these is that the facility is large enough to be maintained on a long term basis using full sized equipment common to the turf industry. Mowing can be done using either walk behind or riding mowers. Fertilization can be done using commercially available drop spreaders. The large size of the individual plots should help include similar amounts of natural variability and microclimate effects in each. The facility was built on relatively undisturbed native soil so results are not biased by anthropogenic effects. The facility has individual plot control over irrigation using equipment that is typical of homeowner irrigation systems. Thus, the need for a rainfall simulator is eliminated thereby allowing up to all 24 plots to be run simultaneously if so desired. Runoff measurement and sampling is automated allowing data and sample collection from unscheduled storm events.

Future studies investigating the effects of irrigation volumes, ground cover, nutrient sources, application rates, and application timing are planned. As urban greenscape acreage continues to increase, facilities of this nature offer the potential for intensive studies of irrigation and nutrient movement from urban landscapes. Data of these type can be used for development of scientifically-based best management practices that minimize off-site movement of water and nutrients under various climatic regimes.

Divulgations

The authors have nothing to disclose.

Acknowledgements

The authors gratefully acknowledge financial support from The Scotts Miracle-Gro Company for this facility. We are also appreciative to the Toro Co. for assistance with providing the irrigation controller. The vision and planning by the late Dr. Chris Steigler in the early stages of this project is also gratefully acknowledged. The authors would also like to thank Ms. N. Stanley for her technical assistance with sample preparation and analysis.

Materials

| Flow meter | Teledyne Isco | Model 4230 | Bubbling flow meter that measures and records water flow through flume |

| Portable Sampler | Teledyne Isco | Model 6712 | Works in conjunction with the flow meter to collect water samples at predetermined intervals. |

| Flow Link Software to collect data | Teledyne Isco | Ver 5.0 | Allows communication between flow meter and computer |

| Pre-sloped trench drain | Zurn Industries, LLC | Z-886 | |

| Irrigation Controller | Toro Company | VP Satellite | Controls irrigation to each plot individually |

| Electric Valves | Hunter | 2.5 cm PGV | Opens or closes water flow to individual plots based on signal from irrigation controller |

| Spray nozzles | RainBird | HE-Van 12 | Sprays irrigation water in predetermined pattern and rate |

| Irrigation heads | Hunter | Pro Spray 4 | 4 inch pop up spray heads |

| 6 inch slotted drain pipe | Advanced Drainage Systems | 6410100 | single wall corregated HDPE – slotted |

| 6 inch plain drain pipe | Advanced Drainage Systems | 6400100 | single wall corregated HDPE – plain |

| Filter Paper | Whatman GF/F | 1825-047 | 47mm diameter, binder-free, glass microfiber filter |

| pH Meter | Fisher | Accumet XL20 | |

| Combination pH probe | Fisher | 13-620-130 | |

| Automatic Temperature Compensating Probe | Fisher | 13-602-19 | |

| Electrical conductivity probe | Fisher | 13-620-100 | Cell constant of 1.0 |

| TOC-VCSH with total nitrogen unit TMN-1 | Shimadzu Corp | TOC-VCSH with TMN-1 | dissolved C and N analyzer |

| Smartchem 200 | Unity Scientific | 200 | Discrete Analyzer for P measurement |

| ICS 1000 | Dionex | ICS 1000 | Ion Chromatography for Ca, Mg, K and Na measurment |

| Portable Soil Moisture Meter | Spectrum | FieldScout TDR 300 | 7.5 cm long probes |

| Totallizing Water Meters | Badger | 3/4 inch water meters | standard homeowner water meters |

References

- Fulton, W., Pendall, R., Nguyen, M., Harrison, A. Who sprawls most? How growth patterns differ across the U.S. The Brookings Institution Survey Series. http://www.brookings.edu/~/media/research/files/reports/2001/7/metropolitanpolicy%20fulton/fulton. , (2001).

- White, R. H., et al. How much water is ‘enough’? Using PET to develop water budgets for residential landscapes. Proc. Texas Sec. Amer. Water Works Assoc. 7, 7 (2004).

- Walsh, C. J., Roy, A. H., Feminella, J. W., Cottingham, P. D., Groffman, P. M., Morgan, R. P. The urban stream syndrome: current knowledge and the search for a cure. J. North Am. Benthol. Soc. 24, 706-723 (2005).

- . 4R Plant Nutrition: A Manual for Improving the Management of Plant Nutrition. International Plant Nutrition Institute. , (2012).

- Miyomoto, S., Chacon, A. Soil salinity of urban turf area irrigated with saline water II. Soil factors. Landsc. Urban Plan. 77, 28-38 (2006).

- Steele, M. K., Aitkenhead-Peterson, J. A. Urban soils of Texas: Relating irrigation sodicity to water-extractable carbon and nutrients. Soil Sci. Soc. Am. J. 76, 972-982 (2012).

- Steele, M. K., Aitkenhead-Peterson, J. A. Salt impacts on organic carbon and nitrogen leaching from senesced vegetation. Biogeochem. 112, 245-259 (2013).

- Washbusch, R. J., Selbig, W. R., Bannerman, R. T. Sources of phosphorus in stormwater and street dirt from two urban residential basins. National Conference on Tools for Urban Water Resource Management and Protection Proceedings. , (2000).

- Pitt, R., Chen, S., Clark, S. E., Swenson, J., Ong, C. K. Compaction’s impacts on urban storm-water infiltration. J. Irrigation Drainage Eng. 134, 652-658 (2008).

- Kelling, K. A., Peterson, A. E. Urban lawn infiltration rates and fertilizer runoff losses under simulated rainfall. Soil Sci. Soc. Am. J. 39, 349-352 (1975).

- Edmondson, J. L., Davies, Z. G., McCormack, S. A., Gaston, K. J., Leake, J. R. Are soils in urban ecosystems compacted? A citywide analysis. Biol. Lett. 7, 771-774 (2011).

- Cunningham, M. A., et al. The suburban stream syndrome: Evaluating land use and stream impairments in the suburbs. Phys. Geogr. 30, 269-284 (2009).

- Erickson, J. E., Cisar, J. L., Volin, J. C., Snyder, G. H. Comparing nitrogen runoff and leaching between newly established St. Augustinegrass turf and an alternative residential landscape. Crop Sci. 41, 1889-1895 (2001).

- Morton, T. G., Gold, A. J., Sullivan, W. M. Influence of overwatering and fertilization on nitrogen losses from home lawns. J. Environ. Qual. 17, 124-130 (1988).

- O’Dell, J. W. Method 415.1 Organic carbon, total (combustion or oxidation). Methods for Chemical Analysis of Water and Wastes. , 415.1-415.3 (1983).

- O’Dell, J. W. Determination of phosphorus by semi automated colorimetry. Environmental monitoring systems laboratory, Office of research and development. U.S. Environmental Protection Agency. , (1993).

- O’Dell, J. W. Determination of nitrate nitrogen by semi automated colorimetry. Revision 2.0 Edited by JW O’Dell, Environmental monitoring systems laboratory. Office of research and development, U.S. Environmental Protection Agency. , (1993).

- O’Dell, J. W. Determination of ammonia nitrogen by semi automated colorimetry. Revision 2.0 Edited by JW O’Dell, Environmental monitoring systems laboratory. Office of research and development, U.S. Environmental Protection Agency. , (1993).

- Gobel, P., Dierkes, C., Coldewey, W. G. Storm water runoff concentration matrix for urban areas. J. Contam. Hydrol. 91, 26-42 (2007).

- Vietor, D. M., Provin, T. L., White, R. H., Munster, C. L. Runoff losses of phosphorus and nitrogen imported in sod or composted manure for turf establishment. J. Env. Qual. 33, 358-366 (2004).