Study of a Dot-patterning Process on Flexible Materials using Impact Print-Type Hot Embossing Technology

Summary

Impact print-type hot embossing technology uses an impact header to engrave dot patterns on flexible materials in real time. This technology has a control system for controlling the on-off motion and position of the impact header to create dot patterns with various widths and depths on different polymer films.

Abstract

Here we present our study on an impact print-type hot embossing process which can create dot patterns with various designs, widths, and depths in real time on polymer film. In addition, we implemented a control system for the on-off motion and position of the impact header to engrave different dot patterns. We performed dot patterning on various polymer films, such as polyester (PET) film, polymethyl methacrylate (PMMA) film, and polyvinyl chloride (PVC) film. The dot patterns were measured using a confocal microscope, and we confirmed that the impact print-type hot embossing process produces fewer errors during the dot patterning process. As a result, the impact print-type hot embossing process is found to be suitable for engraving dot patterns on different types of polymer films. In addition, unlike the conventional hot embossing process, this process does not use an embossing stamp. Therefore, the process is simple and can create dot patterns in real time, presenting unique advantages for mass production and small-quantity batch production.

Introduction

Researchers are actively attempting to miniaturize existing devices and displays and increase the flexibility of these devices1,2. To reduce the width and depth of electrical channels to the micro or nano scale, high-precision technology is necessary. In addition, to increase the flexibility of these devices, the patterns of the electrical channels must be located on a flexible material, such as a polymer film3,4. To meet these conditions, the study of ultrafine microprocessing technology is actively underway.

Ultrafine microfabrication technology has an advantage in that possible patterning materials include not only highly rigid materials such as iron or plastic but also soft materials such as polymer films. Due to these advantages, this technology is widely used as a core process in various fields, such as communications, chemistry, optics, aerospace, semiconductor, and sensors5,6,7. In the ultrafine microprocessing field, LIGA (lithography, electroplating, and molding) or micromachining methods are used8. However, these conventional methods are associated with several problems. LIGA methods require a considerable amount of time and several process steps to create ultrafine patterns and incur a high cost as well because they need many different types of equipment during the processes. In addition, LIGA methods use chemicals that can pollute the environment.

To address this issue, hot embossing process technology has been spotlighted among ultrafine microprocess technologies. Hot embossing is a technology that creates a pattern on a heated polymer film using a micro- or nanoscale embossing mold. Conventional hot embossing technology is divided into the plate type and roll-to-roll type depending on the shape of the mold. The two types of hot embossing technology are different in terms of the shape of the mold, but these two processes are similar in that the embossing mold presses the polymer film onto a heated plate to engrave a pattern onto the polymer film. To engrave the pattern using the hot embossing process, it is necessary to heat the polymer film above the glass transition temperature and to apply an adequate amount of pressure (~30–50 MPa)9. In addition, the width and depth of the pattern change depending on the temperature of the heated plate, the material, and the shape of the embossing mold. Moreover, the cooling method after the patterning process affects the shape of the pattern on the polymer film.

In the conventional hot embossing process, embossing stamps or rollers can be embossed with the desired pattern, and the embossing mold can be used to print the same pattern onto polymer film surfaces continuously. This feature makes this process suitable not only for mass production but also for fabricating devices with soft materials, such as polymer films10,11,12,13,14. However, the conventional hot embossing method can only create the single pattern engraved in the embossing mold. Therefore, when the user wants to make a new pattern or modify the pattern, they must make a new mold to modify the imprinting pattern. For this reason, conventional hot embossing is costly and time-consuming when creating new patterns or replacing existing designs.

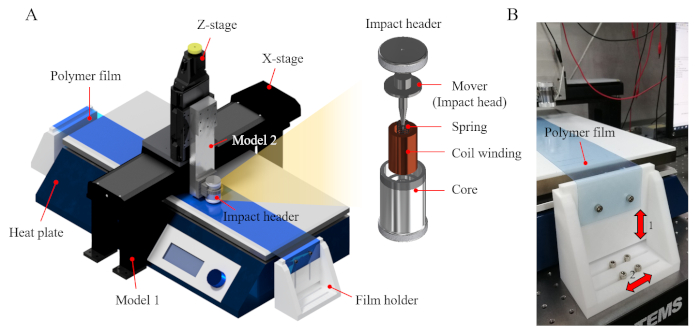

Earlier work introduced the impact-type hot embossing process for producing dot patterns with various widths and depths in real time15. Unlike the conventional hot embossing process, the impact print-type hot embossing method uses an impact header to create patterns on the polymer film. This technology moves the impact header to the desired position with a precision positioning system. A control signal is applied to print patterns at a desired width and depth and at an arbitrary position. The structure of the impact header consists of a mover, a spring, a coil winding, and a core (see Figure 1A)15. Earlier work confirmed through an analysis and experiment that such an impact header can produce the proper force for hot embossing16. The protocol of this paper covers the design of the hardware for the impact-type hot embossing process and the control environment for process control. In addition, we analyze the dot patterns on PET film, PMMA film, and PVC film, all of which are processed with the proposed protocol to verify that the impact print-type hot embossing process can create dot patterns with various widths and depths in real time. The results of these experiments are presented below in the results section, confirming that the embossing process can suitably produce ultrafine patterns.

Protocol

1. Fabrication of the impact print-type hot embossing process

- Make model 1 and combine it with an X-stage (see Figure 1).

NOTE: It is recommended that Model 1 be made of aluminum to avoid heat being conducted onto the X-stage. Moreover, it is recommended that the length of Model 1 be the distance between the surface of the heat plate and the lowest height of the bearing plate of the Z-stage as the design of Model 1 varies with the size of the heat plate. - Combine the X-stage and Z-stage and assemble the Z-stage and Model 2.

NOTE: Ensure that Model 2 is made of a metal that can endure the heat from the heat plate (e.g., aluminum). Fixing Model 2 to the Z-stage tightly will ensure the capability of the Z-stage to hold the weight of Model 2 and the impact header. - Combine Model 2 and the impact header and place the heat plate below Model 1.

NOTE: Joining the impact header with the lowest position on Model 2 will ensure that the mover reaches the surface of the heat plate. It is recommended to install the heat plate after raising the Z-stage maximally to avoid any contact of the impact head with the surface of the heat plate. Use suitable software to control the stage. - Convert the STL files of the film holder (Supplementary File 1 and Supplementary File 2) to GCODE files using suitable software to print the film holder with a three-dimensional (3D) printer.

NOTE: The software may vary with the 3D printer used, and some environments may support 3D printer environments without GCODE conversion. - Use the 3D printer to print the film holder with the GCODE file.

NOTE: Using a filament (e.g., Z-HIPS) is recommended because less contraction will occur when printing large parts, such as the film holder. - Install two film holders onto the end of the heat plate and fix the polymer film onto the film holder, as shown in Figure 1. To ensure that the polymer film is flat on the heat plate, pull the polymer film as much as possible using motion 1 of the film holder (see Figure 1B). To move the polymer film to the side, move the film holder via motion 2 (see Figure 1B).

NOTE: To fix the polymer film onto the film holder, it is recommended to use a screw. Glue is insufficient to affix the polymer film onto the film holder, and it is best for the detachment of the polymer film after the patterning experiment.

2. Fabrication of the control circuit

NOTE: This process describes the process of constructing the control circuit of the impact header and the X–Z stage.

- Connect the control device that sends the signals (see Table of Materials) to the impact header to control it.

- After connecting the control device to the impact header, input -3 V and +10 V as control signals into the impact header.

NOTE: If a +10 V control signal is sent to the impact header (see Figure 1), the mover (impact head) goes down and enters the turn-on state. In this state, the mover hits the polymeric film and engraves the pattern on the polymer film.- Raise the mover to engrave the next pattern after engraving a pattern using the mover of the impact header. To raise the mover (impact head), apply the -3 V control signal.

NOTE: A negative voltage is input to the impact header to prevent the mover from becoming magnetized by the inner remnant flux of the impact header.

- Raise the mover to engrave the next pattern after engraving a pattern using the mover of the impact header. To raise the mover (impact head), apply the -3 V control signal.

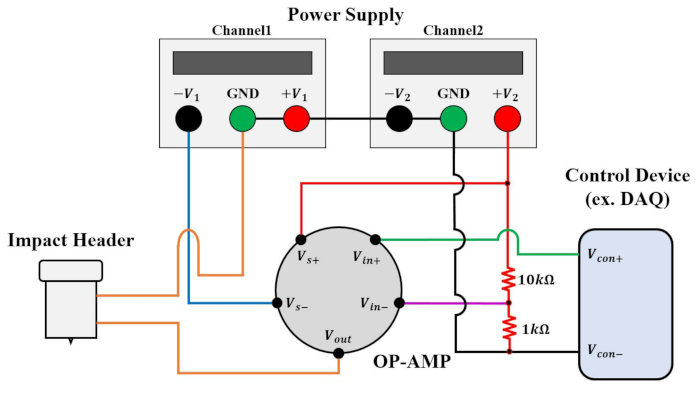

- If the control device cannot supply a sufficient control signal, use a high-power operation amplifier (e.g., OP-AMP) which amplifies the ~0 V–5 V control signal to ~-3 V–+10 V, as shown in Figure 2, to control the impact header.

- First, prepare a dual-channel DC power supply (see Table of Materials). After this step, connect four nodes to provide common ground (GND) nodes to all channels: a positive voltage terminal (V1+) and a ground (GND) terminal for channel 1 and a negative voltage terminal (V2-) and ground (GND) for channel 2. An overall connection diagram is shown in Figure 2.

NOTE: According to the step described in 2.3.1, positive and negative voltage with different absolute values can be supplied to the operational amplifier (OP-AMP). - Connect the negative voltage terminal of channel 1 (V1-) of the power supply to the negative power supply voltage terminal (Vs-) of the OP-AMP, as indicated by the blue line in Figure 2. Subsequently, input 3 V Vcc voltage to channel 1.

NOTE: According to step 2.3.1, the 3 V Vcc voltage is supplied as -3 V negative voltage to the negative power supply voltage terminal (Vs-) of the OP-AMP. - Connect the positive voltage terminal of channel 2 (V2+) of the power supply to the positive power supply voltage terminal (Vs+) of the OP-AMP, as indicated by the red line in Figure 2. Subsequently, input 10 V Vcc voltage to channel 2.

NOTE: According to step 2.3.1, the 10 V Vcc voltage is supplied as +10 V positive voltage to the positive power supply voltage terminal (Vs+) of the OP-AMP. - Connect the +output channel of a control device (Vcon+) to the positive input channel (Vin+) of the OP-AMP, as shown by the green line in Figure 2.

- Connect the -output channel of a control device (Vcon-) to the ground (GND) of channel 2 of the power supply, as shown by the black line in Figure 2.

NOTE: When connecting the (Vcon-) to the ground (GND), it is possible to connect it to one of the terminals connected during step 2.3.1 in addition to the GND of channel 2. - Prepare electric resistance of 1 kΩ and 10 kΩ values in each case and connect them between the red line and black line, as shown in Figure 2.

- Connect the terminal between 1 kΩ and 10 kΩ to the negative input channel of the OP-AMP (Vin-), as shown by the purple line in Figure 2.

- Pull out the lines from the output channel of the OP-AMP (Vout) and one of the electrical terminals described in step 2.3.1. Connect the lines to the impact header, as shown by the orange line in Figure 2.

- Regarding the power supply, set the voltages of channel 1–3 Vcc and channel 2–10 Vcc. Subsequently, generate control signals of ~0 V–5 V from the control device.

NOTE: The generated ~0 V–5 V control signals will be amplified by the OP-AMP to ~-3 V–+10 V, which is necessary to control the impact header as described in steps 2.2.1 and 2.2.2.

- First, prepare a dual-channel DC power supply (see Table of Materials). After this step, connect four nodes to provide common ground (GND) nodes to all channels: a positive voltage terminal (V1+) and a ground (GND) terminal for channel 1 and a negative voltage terminal (V2-) and ground (GND) for channel 2. An overall connection diagram is shown in Figure 2.

3. Experiment design

NOTE: This section describes the processes of controlling the impact-type hot embossing device and engraving dot patterns onto the polymer film.

- Install a stage-control program (e.g., Micromove) to control the X-stage and Z-stage using a control computer (PC).

- Install DAQ driver software to detect the control device on the control PC that controls the impact header and install an operating program (e.g., MATLAB) to control the control device.

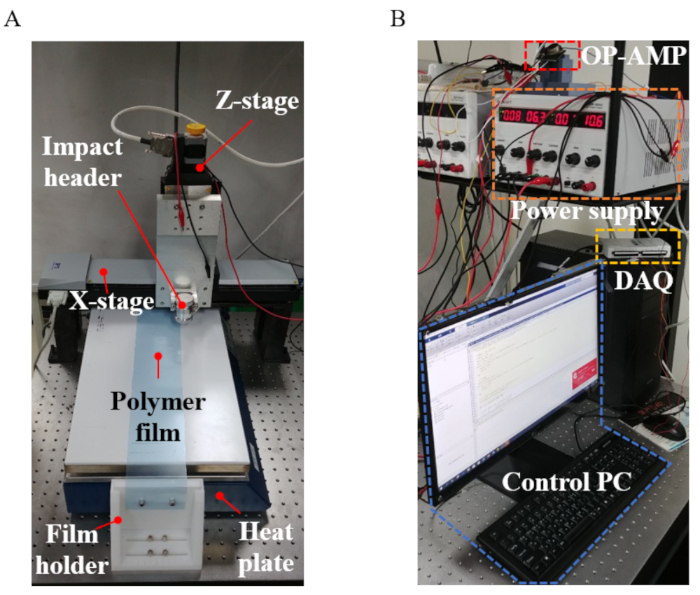

- After installing the software, construct the hardware environment as shown in Figure 3A to conduct the patterning experiment.

- Install the X stage, Z stage, impact header, film holder, and heat plate as shown in Figure 3A to construct the hardware environment.

- Fix the polymer film onto the film holder and adjust the position of the polymer film using motions 1 and 2 (see Figure 1B) to fix the film flatly.

NOTE: To keep the film flat while adjusting direction 2, the locations of the two film holders should be parallel. To make the film flat on the heat plate, it is recommended to adjust the film holder by lowering the position according to direction 1, as shown in Figure 1B. - After fixing the polymer film, adjust the temperature of the heat plate to heat the film above the glass transition temperature.

NOTE: Each type of film has its own glass transition temperature. Therefore, it is recommended to adjust the temperature of the heat plate to its own glass transition temperature after checking the material properties of the film in the corresponding datasheet.

- After setting the hardware, put the control circuit together as shown in Figure 3B to control the stage and the impact header.

- Prepare the PC, control board, power supply, and OP-AMP to construct the control environment as shown in Figure 3B. Connect the devices as shown in Figure 2 and then connect the computer to the control board.

- Enter the 3 Vcc and 10 Vcc values into an OP-AMP through channels 1 and 2 of the power supply respectively, as described in step 2.3.9.

- Control the stage and impact header using the control computer.

- Adjust the initial position of impact header by controlling X and Z stages using the stage control program.

NOTE: While adjusting the initial position of the impact header, ensure that there is no collision between the impact header and the heat plate. If the position of the Z-stage is too low, the mover will collide with the heat plate, damaging both the mover and the heat plate. If there is damage to both devices, it will hinder the creation of fine patterns on a polymeric material. - Using the operating program, generate a 5 V control signal from the control device. According to steps 2.3.1–2.3.9, the OP-AMP will amplify the 5 V control signal to +10 V, turn the impact header on, and engrave the patterns on the polymer film.

- Now generate a 0 V control signal from the control device using the operating program. According to steps 2.3.1–2.3.9, the OP-AMP will amplify the 0 V control signal to -3 V and turn the impact header off.

NOTE: The mover of the impact header will be raised, waiting to engrave the new pattern. - Move the X-stage into position to engrave the next pattern.

- Engrave patterns 3x on the polymer film by repeating steps 3.5.1–3.5.4 sequentially.

- Lower the Z-stage 10 μm from the initial position and execute step 3.5.5, counting the number of Z-stage moves. When the number of Z-stage movements exceeds three, move the X-stage to the initial position and raise the impact header maximally by moving the Z-stage.

NOTE: Changing the height of the Z-stage will ensure adjustments in the depth and width of the dot pattern.

- Adjust the initial position of impact header by controlling X and Z stages using the stage control program.

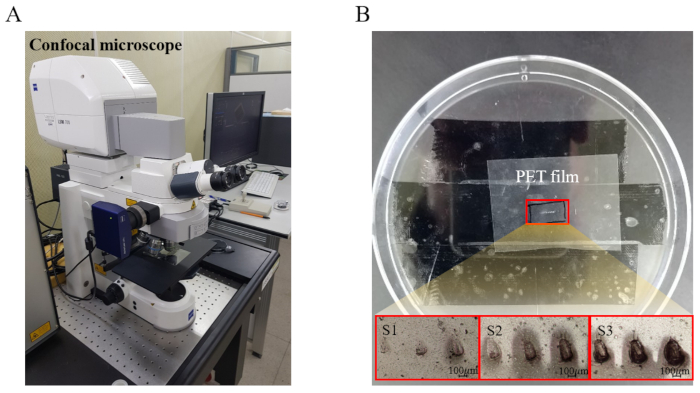

- Detach the polymer film from the film holder and measure the width and depth of each pattern using a confocal microscope (see Table of Materials), as shown in Figure 4A.

- Before starting the measurement process, select the magnification value of the microscope and use the direct observation mode initially to adjust the scanning position of the polymer film. After adjusting the position by means of direct observation, fix the polymer film and change the scanning mode to the laser scanning mode.

NOTE: When using the confocal microscope, using an acrylic panel is recommended to fix the sample, as shown in Figure 4B. - Using the laser scanning mode, measure the depth and width of the dot pattern.

- Before starting the measurement process, select the magnification value of the microscope and use the direct observation mode initially to adjust the scanning position of the polymer film. After adjusting the position by means of direct observation, fix the polymer film and change the scanning mode to the laser scanning mode.

- Repeat steps 3.3.2–3.6.2 after changing the type of film.

NOTE: Considering the glass transition temperature of each type of film, set the temperature of the heat plate before placing each film on the heat plate. In this study, the glass transition temperature of PVC film is 100 °C; for PMMA film it is 95 °C, and for PET film it is 75 °C.

Representative Results

The impact print-type hot embossing process is a process that can be used to engrave dot patterns onto a polymer film in real time, as shown in Figure 1. This process can resolve the issues of the high cost and long times for pattern replacement associated with the existing hot embossing process. A control circuit was constructed, as shown in Figure 2 (see steps 2.3–2.3.9), using the DAQ, OP-AMP, and power supply to carve patterns on various types of polymer films by the implementation of the impact header during the on-off operation. The implemented impact print-type hot embossing process is shown in Figure 3.

In previous studies of impact print-type hot embossing, only experiments on PMMA films were validated, while no other polymer films were tested. In order to verify that impact print-type hot embossing can engrave patterns on other polymer films in real time, experiments were carried out using PMMA film, PVC film, and PET film. The height of the impact header was reduced by 10 μm for every three points using a Z-stage, and we tested whether nine dots could form a dot pattern with various heights on the three types of films. Using the equipment shown in Figure 3, a dot pattern was created on the three polymer films, and a confocal microscope was used to observe the pattern (see step 3.6).

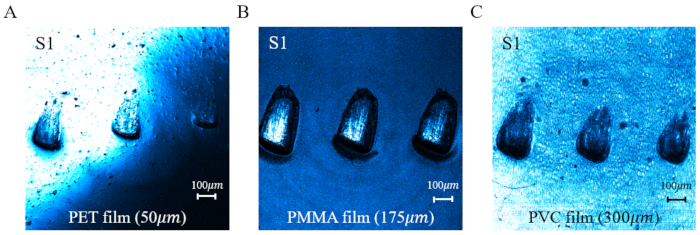

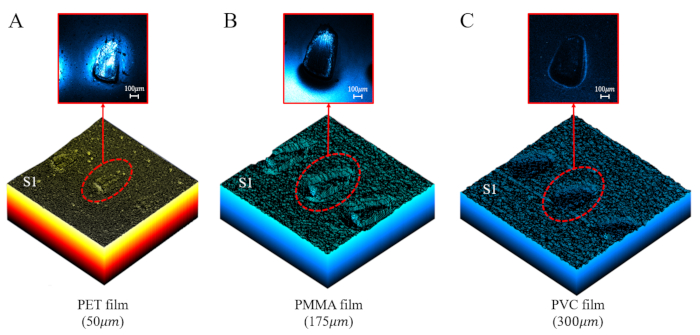

The dot pattern is shown in Figure 4B. As shown in Figure 4B, nine points were utilized, and the size of the pattern increased from Sample 1 (S1) to Sample 3 (S3) because the height of the Z-stage moved down by 10 μm. In this case, two-dimensional (2D) images by the confocal microscope of the three polymer films are shown in Figure 5. The 2D image in Figure 5 shows the S1 portion of each pattern. Figure 5A shows a PET film sample 50 μm thick, Figure 5B shows a PMMA film sample 175 μm thick, and Figure 5C shows a PVC film sample 300 μm thick. Figure 6 shows 2D micrographs of one dot pattern and 3D micrographs of S1 using the laser scanning mode (LSM) of the confocal microscope. As shown in Figure 6, we could measure the pattern width and depth of each dot pattern, and the pattern was clearly observable through the 2D image of one dot.

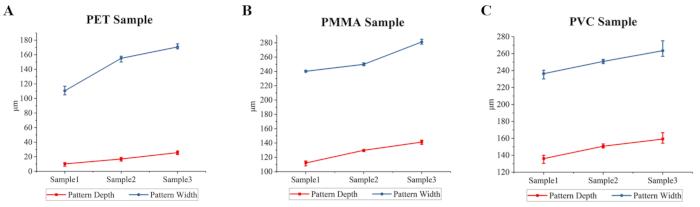

The width and depth results of the nine dot patterns on the three polymer films using the 3D function of the confocal microscope are shown in Table 1. The PET film is thinner than the other polymer films. Therefore, we created the sample carefully so that the impact header did not touch the heat plate when the Z-stage was adjusted. For PET, in S1 the average values of the pattern width and depth were 110.6 μm and 10.3 μm respectively, with corresponding errors of ~-5.6–6.2% and ~-3.3–1.7%. For S2, after the height of the Z-stage was decreased by 10 μm, the average values for the pattern width and depth changed to 155.2 μm and 17.0 μm respectively, with corresponding errors of ~-5.2–2.8% and ~-3.0–2.0%. For S3, after the height of the Z-stage was decreased by another 10 μm, the average values for the pattern width and depth changed to 170.8 μm and 25.7 μm respectively, with corresponding errors of ~-2.8–4.2% and ~-2.7–2.3%.

For PMMA, in S1 the average values of the pattern width and depth were 240.2 μm and 112.2 μm respectively, with corresponding errors of ~-1.2–1.3% and ~-4.1–2.8%. For S2, after the height of the Z-stage was decreased by 10 μm, the average values for the pattern width and depth changed to 250.0 μm and 129.8 μm respectively, with corresponding errors of ~-2.0–2.0% and ~-1.8–1.1%. For S3, after the height of the Z-stage was decreased by another 10 μm, the average values for the pattern width and depth changed to 281.2 μm and 141.3 μm, with corresponding errors of ~-3.1–3.8% and ~-3.3–2.6%.

For PVC, in S1 the average values of the pattern width and depth were 236.4 μm and 136.1 μm respectively, with corresponding errors of ~-6.3–4.0% and -~5.6–3.9%. For S2, after the height of the Z-stage was decreased by 10 μm, the average values of the pattern width and depth changed to 250.8 μm and 150.7 μm respectively, with corresponding errors of ~-2.5–2.4% and ~-2.1–2.8%. For S3, after the height of the Z-stage was decreased by another 10 μm, the average values of the pattern width and depth changed to 263.5 μm and 159.2 μm, with corresponding errors of ~-6.7–11.7% and ~-5.0–7.5%.

Graphs of the pattern depth and width for the three polymer films are shown in Figure 7. The height of the Z-stage was decreased by 10 μm for every three dot patterns from S1 to S3, so that the width and depth of the film increased from S1 to S3. The maximum error was in the range of -6.7–11.7% for PVC and the minimum error ranged from -1.2–1.3% for PMMA. In conclusion, the errors in the dot patterns for the three types of films are minor. This shows that the impact print-type hot embossing process is suitable for engraving micropatterns onto polymer films in real time.

Figure 1: Design of the impact print-type hot embossing technology. (A) A 3D design of the impact print-type hot embossing process, (B) design of the film holder. The film holder can move in the Motion 1 and Motion 2 directions and can be used to fix the film or to move it to the side. Please click here to view a larger version of this figure.

Figure 2: Schematic design of the electricity amplifier circuit. In this picture, six devices are used to create the circuit: a power supply with two channels, a high-power operational amplifier (OP-AMP), a control device, an impact header, and two resistance components with different values. Each device is connected in the image, and the connection lines are shown in various colors. Please click here to view a larger version of this figure.

Figure 3: Implementation of the impact print-type hot embossing process and control circuit. (A) Implementation of the impact print-type hot embossing process, and (B) experimental settings of the control system Please click here to view a larger version of this figure.

Figure 4: Confocal microscope equipment and PET film with dot patterns. (A) Confocal microscope equipment to measure the pattern widths and depths of the dot patterns on the polymer film. (B) Dot patterns on the PET film. The nine patterns are divided into three sections from the lowest depth of the dot patterns (S1, S2, S3), and each section has three points. Micrographs are taken using the 2D function of the confocal microscope. Please click here to view a larger version of this figure.

Figure 5: Two-dimensional photomicrographs using confocal microscope. (A) A 2D photomicrograph of the 50 μm PET film, (B) 2D photomicrograph of the 175 PMMA film, and (C) 2D photomicrograph of the 300 PVC film Please click here to view a larger version of this figure.

Figure 6: Two-dimensional micrographs of one dot pattern and 3D micrographs of S1 using the LSM mode of the confocal microscope. (A) A 3D micrograph of three dot patterns and a 2D micrograph of one dot pattern on the 50-μm-thick PET film. (B) A 3D micrograph of three dot patterns and a 2D micrograph of one dot pattern on the 175-μm-thick PMMA film. (C) A 3D micrograph of three dot patterns and a 2D micrograph of one dot pattern on the 300-μm-thick PVC film Please click here to view a larger version of this figure.

Figure 7: Graphs of the pattern widths and depths for S1, S2, and S3 on three polymer films. The position of the Z-stage was increased by 10 µm for every three dot patterns from S1 to S3, and each graph is based on the data shown in Table 1. (A) The result of the pattern width and pattern depth for the PET film. (B) The result of the pattern width and pattern depth for the PMMA film. (C) The results of the pattern width and pattern depth for the PVC film. Please click here to view a larger version of this figure.

| Polymer Film | Sample Number | Average of Pattern Width (μm) | Average of Pattern Depth (μm) | Error rate Width (%) | Error rate Depth (%) |

| PVC Film | S1 | 236.4 | 136.1 | -6.3~4.0% | -5.6~3.9% |

| S2 | 250.8 | 150.7 | -2.5%~2.4% | -2.1~2.8% | |

| S3 | 263.5 | 159.2 | -6.7%~11.7% | -5.0~7.5% | |

| PMMA Film | S1 | 240.2 | 112.2 | -1.2~1.3% | -4.1~2.8% |

| S2 | 250 | 129.8 | -2.0~2.0% | -1.8~1.1% | |

| S3 | 281.2 | 141.3 | -3.1~3.8% | -3.3~2.6% | |

| PET Film | S1 | 110.6 | 10.3 | -5.6~6.2% | -3.3~1.7% |

| S2 | 155.2 | 17 | -5.2~2.8% | -3.0~2.0% | |

| S3 | 170.8 | 25.7 | -2.8~4.2% | -2.7~2.3% |

Table 1: Measurement results of nine dot patterns on three polymer films. The values in the table were measured using the 3D measurement function of the confocal microscope and represent the average values of the pattern widths and depths and the pattern errors for S1, S2, and S3.

Supplementary File 1. Please click here to download this file.

Supplementary File 2. Please click here to download this file.

Discussion

In this study, we implemented the impact print-type hot embossing process and engraved dot patterns with various widths and depths onto a range of polymer films in real time. Among the protocol steps, two steps should be critically considered among all steps. The first is the setting of the temperature of the heat plate (step 3.3.3), and the second is the setting of the initial position of the impact header (step 3.5.1). In step 3.3.3, if the temperature of the heat plate is too high, it becomes difficult to form a pattern because the viscosity of the film hinders the creation of a fine pattern. On the other hand, if the temperature of the heat plate is too low, the pattern is not engraved smoothly. The factor of the initial position of the impact header is important because the position of the impact header is related to the depth and width of the pattern. Moreover, if the height of the impact header is too low, the mover of the impact header will collide with the heat plate, causing damage to both the mover and the heat plate. This damage not only wears down the tip of the mover but also has an adverse effect on the height and width of the pattern engraved in the next step. For these reasons, during steps 3.3.3 and 3.5.1, the heating temperature and ignition condition should be carefully considered.

In earlier work on impact-type hot embossing, a dot patterning process was utilized with PMMA film, with deviation errors occurring due to a fixation problem associated with the polymer film15,16. To solve this problem, fixing the polymer film using film holders on both sides of the heat plate was considered, and this strategy reduced the error compared to the earlier values. It was also shown that dot patterns with various widths and depths can be engraved onto various polymer films, such as PET film and PVC films, in real time. Comparing the error rate of PMMA with those of previous hot embossing processes, the results of each film sample showed that the errors in the pattern widths and depths were significantly reduced.

However, there remained some error in the dot patterns. We considered two causes for these errors. The first is related to the change of the surface due to the glass transition temperature of the polymer film. When each film is heated above its glass transition temperature, the surface of the polymer film becomes soft, and the film surface rises slightly even if it remains fixed while using the film holder, causing an error. To prevent this, if the temperature of the heat plate is lower than the glass transfer temperature, the combination of the molecular structure of the polymer film is stronger, but the pattern on the polymer film is not engraved as well. Therefore, it is cumbersome to find the optimum value for each corresponding polymer film through repeated experiments. The second cause is the imbalance problem of the heat plate. The surface of the heat plate that heats the film during the hot embossing process should be entirely horizontal to engrave the height of the dot patterns uniformly. However, if the heat plate is slightly inclined, errors in the pattern width or pattern height will occur when the pattern uses a different position. To solve this problem, we consider that a device that can scan the height of a surface in real time should be attached to the impact header. More research should be done on scanning devices to measure the surface height properly.

The precision of the patterns produced by the suggested process also has limitations. The width and depth of each pattern depend on the diameter of the tip of the mover (impact head) and the depth at which the mover engraves on the polymer film. The diameter of the tip of the mover used in this process is 9 µm, and the precision of the engraved pattern has a minimum pattern width of 9 µm. However, the existing plate-to-plate type and roll-to-roll type hot embossing processes offer pattern precision levels in the nm range. This lack of precision of a pattern can be solved by reducing the diameter of the tip of the mover in the impact header. There is insufficient research thus far on mechanical or chemical processes for processing mover tips into nm units. If studies of mechanical or chemical processes are conducted so that the mover tip can be processed in nm units, it is expected that these limitations will be overcome. Still, unlike the conventional methods, the proposed process allows changes to the engraving pattern in real time using the impact header, and this offers the advantage of changing the new pattern or replacing the pattern if an erroneous process is found.

Next, we compared the processing speed of the proposed process with that of the existing roll-to-roll type hot embossing process. For the conventional roll-to-roll type, the process speed is 10 mm/s12. The proposed impact print-type hot embossing process offers a performance frequency of 6 Hz–10 Hz. If ten points are assumed on a 10 mm polymer film, the processing speed is 6 mm/sec and the maximum is 10 mm/s. As a result, the processing speed will vary depending on the pattern required by the user. Therefore, the process can be applied to mass production and to various product and small-volume production processes as well.

If we continue to develop our current technology, it will be able to engrave continuous patterns in addition to point patterns. Engraving continuous patterns can be useful in a variety of ways. For example, by placing electrical elements or by applying conductive ink onto the engraved pattern, a microelectrical circuit can be manufactured. Notably, because this process is linked to work on engraving micro- or nanopatterns on polymer films, it can be applied to manufacture flexible devices. Moreover, as our method is like existing hot embossing processes, this work can be used to manufacture flexible copper clad laminates (FCCLs) or flexible printed circuit boards (FPCBs). In addition, in order to apply the impact print-type hot embossing process to a wider range of materials, such as wearable devices or sensors, it is necessary to change the dot pattern by using various widths and depths depending on the device. The impact print-type hot embossing process investigated here has the advantage of being able to engrave various patterns while adjusting the widths and depths of the patterns in real time. Moreover, the technology mentioned in the protocol uses a simpler process than the conventional patterning process. Therefore, we are convinced that impact print-type hot embossing technology can be extended not only to mass production but also to the small-quantity batch production industry in the future.

Divulgations

The authors have nothing to disclose.

Acknowledgements

This research is supported by the project entitled “Development of impact print-type hot embossing technology for a conductive layer using conductive nano-composite materials” through the Ministry of Trade, Industry and Energy (MOTIE) of Korea (N046100024, 2016).

Materials

| 0.3mm High Quality Clear Rigid Packaging PVC Film Roll For Vacuum Forming | Sunyo | SY1023 | PVC film / Thickness : 300µm |

| Acryl(PMMA) film | SEJIN TS | C200 | PMMA film / Thickness : 175µm |

| Confocal Laser Scanning Microscope: 3D-Topography for Materials Analysis and Testing | Carl Zeiss | LSM 700 | 3D confocal microscope / Supporting Mode : 2D, 2.5D, 3D topography |

| DAQ board | NATIONAL INSTRUMENTS | USB-6211 | Control board for two stage and impact header / 16 inputs, 16-bit, 250kS/s, Multifunction I/O |

| DC Power Supply | SMART | RDP-305AU | 3 channel power supply / output voltage : 0~30V, Output current : 0~5A |

| L511 stage | PI | L511.20SD00 | Z-stage / Travel range : 52mm |

| Large Digital Hotplate | DAIHAN Scientific | HPLP-C-P | Heatplate / Max Temp : 350ºC |

| M531 stage | PI | M531.2S1 | X-stage / Travel range : 306mm |

| Mylar Polyester PET films | CSHyde | 48-2F-36 | PET film / Thickness : 50µm |

| OPA2541 | BURR-BROWN | OPA2541BM | OP-AMP / Output currents : 5A, output voltage : ±40V |

References

- Lee, S. Y., et al. 2018 Optical Fiber Communications Conference and Exposition (OFC). IEEE. , 1-3 (2019).

- Yang, D., Pan, L., Mu, T., Zhou, X., Zheng, F. The fabrication of electrochemical geophone based on FPCB process technology. Journal of Measurements in Engineering. 5 (4), 235-239 (2017).

- Fukuda, K., et al. Fully printed high-performance organic thin-film transistors and circuitry on one-micron-thick polymer films. Nature Communications. 5, 4147 (2014).

- Sekitani, T., Zschieschang, U., Klauk, H., Someya, T. Flexible organic transistors and circuits with extreme bending stability. Nature Materials. 9 (12), 1015 (2010).

- Zamkotsian, F., Dohlen, K., Burgarella, D., Ferrari, M., Buat, V. International Conference on Space Optics-ICSO 2000. International Society for Optics and Photonics. , 105692A (2019).

- Zhang, X., Li, Z., Zhang, G. High performance ultra-precision turning of large-aspect-ratio rectangular freeform optics. CIRP Annals. 67 (1), 543-546 (2018).

- Ziaie, B., Baldi, A., Lei, M., Gu, Y., Siegel, R. A. Hard and soft micromachining for BioMEMS: review of techniques and examples of applications in microfluidics and drug delivery. Advanced Drug Delivery Reviews. 56 (2), 145-172 (2004).

- Mishra, S., Yadava, V. Laser beam micromachining (LBMM)-a review. Optics and Lasers in Engineering. 73, 89-122 (2015).

- Yun, D., et al. Development of roll-to-roll hot embossing system with induction heater for micro fabrication. Review of Scientific Instruments. 83 (1), 015108 (2012).

- Keränen, K., et al. Roll-to-roll printed and assembled large area LED lighting element. The International Journal of Advanced Manufacturing Technology. 81 (1-4), 529-536 (2015).

- Park, J., Lee, J., Park, S., Shin, K. H., Lee, D. Development of hybrid process for double-side flexible printed circuit boards using roll-to-roll gravure printing, via-hole printing, and electroless plating. The International Journal of Advanced Manufacturing Technology. 82 (9-12), 1921-1931 (2016).

- Rank, A., Lang, V., Lasagni, A. F. High-Speed Roll-to-Roll Hot Embossing of Micrometer and Sub Micrometer Structures Using Seamless Direct Laser Interference Patterning Treated Sleeves. Advanced Engineering Materials. 19 (11), 1700201 (2017).

- Shan, X., Liu, T., Mohaime, M., Salam, B., Liu, Y. Large format cylindrical lens films formed by roll-to-roll ultraviolet embossing and applications as diffusion films. Journal of Micromechanics and Microengineering. 25 (3), 035029 (2015).

- Wang, X., Liedert, C., Liedert, R., Papautsky, I. A disposable, roll-to-roll hot-embossed inertial microfluidic device for size-based sorting of microbeads and cells. Lab on a Chip. 16 (10), 1821-1830 (2016).

- Yun, D., et al. Impact Print-Type Hot Embossing Process Technology. Advanced Engineering Materials. 20 (9), 1800386 (2018).

- Ahn, J., Yun, D. Analyzing Electromagnetic Actuator based on Force Analysis. 2019 IEEE International Conference on Robotics and Automation (ICRA). , (2019).