Summary

An inkjet printer was used to manufacture polyvinyl alcohol multilayers. Polyvinyl alcohol water-based ink was formulated, and the main physical properties were investigated.

Abstract

Inkjet printing is a modern method for polymer processing, and in this work, we demonstrate that this technology is capable of producing polyvinyl alcohol (PVOH) multilayer structures. A polyvinyl alcohol aqueous solution was formulated. The intrinsic properties of the ink, such as surface tension, viscosity, pH, and time stability, were investigated. The PVOH-based ink was a neutral solution (pH 6.7) with a surface tension of 39.3 mN/m and a viscosity of 7.5 cP. The ink displayed pseudoplastic (non-Newtonian shear thinning) behavior at low shear rates, and overall, it demonstrated good time stability. The wettability of the ink on different substrates was investigated, and glass was identified as the most suitable substrate in this particular case. A proprietary 3D inkjet printer was employed to manufacture polymer multilayer structures. The morphology, surface profile, and thickness uniformity of inkjet-printed multilayers were evaluated via optical microscopy.

Introduction

Polyvinyl alcohol is semicrystalline, artificial, non-toxic, water-soluble, insoluble in most organic solvents, biodegradable, and biocompatible in human tissues and has excellent gas-barrier properties1. Furthermore, due to its many useful properties, PVOH is widely used in a large number of applications. Nowadays, PVOH is used in: the manufacture of cleaning and detergent products, the food packaging industry, water treatment, textile, agriculture, and construction (as additives)1. However, PVOH has recently attracted an increased amount of attention for pharmaceutical uses2 (i.e., drug delivery) and in medical applications3,4 (e.g., wound dressing, soft contact lenses, eye drops, and soft implants for cartilage replacement). PVOH films are produced either through a melt or solution form. Melt processing is compatible only with PVOH with low hydrolysis levels or heavily plasticized PVOH. Thus, when using this pathway, some properties can be sacrificed1. On the other hand, a PVOH layer can be deposited via the solution form by drop casting5, spin coating6, or electrospinning7. However, these methods have a number of limitations in terms of the waste of unwanted material. For example, in the case of spin coating, it has been reported8 that 95% of the material is wasted. Additionally, these methods are quite rigid in term of design/features (no patterning capability) and have high overall processing costs. In order to overcome the limitation of the conventional solution processing, we here explore the potential of inkjet printing technology to provide a novel platform to produce polyvinyl alcohol (PVOH) multi-layer structures that have a strong impact on both the material and application perspectives.

Recent developments in the manufacturing sector have focused on cheap, simple, eco-friendly, and energy-saving processes. Inkjet printing (IJP) is a modern fabrication process that fits perfectly within this framework. The major advantages of IJP technology are the efficiency of material use, the digital (mask-free) and additive patterning, the large area capability, the compatibility with rigid/flexible substrates, and the low cost.

IJP is a deposition method that uses polymeric materials dispersed in a solvent. To date, functional polymer-9, ceramic-10, conductive nanomaterial-11, 2D-12, biologically-, and pharmaceutically-based13 materials have been successfully deposited. Recently, it has been reported that IJP was involved in the deposition of components as part of electronic devices, such as transistors14, sensors15, solar cells16, and memory devices17, as well in electronic packaging18.

The ink, cartridge, and substrate are equally important components that are employed in the printing process. First, the physical properties of the ink, such as the surface tension and the rheological properties (i.e., shear viscosity), have a significant impact on the printability behavior. Also, the pH plays an important role on both the solution (e.g., drying, foaming, and viscosity) and on the lifetime of the IJP print cartridge. Second, for the cartridge (piezoelectric), the driving voltage waveform actually defines the drop formation and both the directionality and the uniformity of the liquid jet. Finally, it is imperative that the ink/substrate interaction is very well understood, as the resolution and accuracy of the printed object are strongly dependent upon this interface. Solvent evaporation, phase changes from liquid to solid, and chemical reactions are the main processes that occur between the fluid drop and the substrate. All aspects involved in the IJP, from ink properties to drop/substrate mechanisms, are highlighted in review papers by Hutchings19 and by Derby20.

In this study, we explore the capabilities of IJP to manufacture polyvinyl alcohol multilayers. First, a PVOH water-based ink was formulated, and the main physical properties, such as rheological behavior, surface tension, and pH, were investigated. In this work, a piezoelectric inkjet printer was employed, and the appropriate waveform parameters were then identified. PVOH multilayers were printed, and the quality and surface/thickness profiles were assessed by optical microscopy.

Protocol

1. Ink Formulation

- Prepare the solution for IJP by dissolving polyvinyl alcohol (8 wt.% PVOH in water) in purified water heated to 60 °C.

- Add 10 g of mono-propylene glycol (MPG) (10 wt.% mono-propylene glycol in water), as a humectant, to the solution.

NOTE: The role of the humectant is to prevent blockages in the printhead. - Stir the solution for several hours to ensure homogeneity and then filter it through a 5 µm filter to remove any particulates that might block the nozzles.

- Visually assess the ink for homogeneity, especially for any incidence of sedimentation. If sedimentation is observed, then either stir/ultra-sonicate the solution for a long time (days) or formulate a new water-based solution with a PVOH with low molecular weight.

NOTE: Store all fluids in sealed beakers at room temperature.

2. Ink Characterization

- Perform all the ink characterization tests at room temperature in a clean room environment.

- Measure the viscosity of the solution using a viscometer.

NOTE: This test is required in order to ensure that the formulated ink is compatible with the IJP hardware. The inkjet printing process requires a low-viscosity solution of 4-20 cP. Measure the viscosity of the ink as a function of the shear rate using a rotational viscometer. - Test the surface tension of the ink at room temperature using the pendant drop method. Use an appropriate measurement tool such as a tensiometer. Use the manufacturer's protocol.

NOTE: A typical solution for inkjet printing has a surface tension of 30-40 mN/m. - Test the pH using a pH meter. Use the manufacturer's protocol.

NOTE: The pH is an essential parameter in water-based inks, as it provides essential information about both the properties and the stability of the formulated solutions. A neutral solution pH of 7 guarantees a stable process and a good lifetime for the printhead. - Assess the wettability of the ink on different substrates by measuring the contact angle via a sessile drop experiment. Use a tensiometer to measure the surface energy of the possible substrates (e.g., glass, plastic, and paper). Measure the surface energy using the protocol supplied by the tensiometer manufacturer.

NOTE: The interaction between the drop and the substrate has a strong impact on the printing quality. To ensure the good adhesion of the ink to the substrate, the surface energy of the substrate should exceed the surface tension of the ink by 10-15 mN/m.

3. Inkjet Printing

NOTE: All the inkjet printing depositions were carried out at room temperature. The PVOH multilayers were deposited using a piezoelectric hybrid ink jet printing machine. A printhead with 512 nozzles (256 x 2 rows), a 30 µm nozzle diameter, and a 42-pL drop size was used in this work.

- Prior to printing, thoroughly clean the glass substrates with acetone/methanol/isopropanol and Di water. Dry the substrates with an N2 gun.

- Load the substrate onto the print-bed and secure it firmly.

- Prepare the cartridge by flushing the ink through the print head. Remove any air or cleaning solution from the reservoir and nozzles.

- Imbed the cartridge into the printer. Connect the printhead to the global inkjet systems (GIS) print manager via the head personality board.

- Load the solution into the 150 mL syringe situated above the cartridge and seal the syringe with an airtight cap.

- Purge the ink through the nozzle by pressing the purge button.

NOTE: The nozzle-substrate distance has a strong influence on the jet trajectory and hence on the quality of the printed pattern. Therefore, adjust the nozzle-substrate distance using the software of the printer to reduce jet spreading. - Set up the waveform and printing parameters using the GIS print software and Table 2.

NOTE: The GIS software interface allows control over both the draw and release amplitude and the width. - Load the desired image file for printing using the GIS print manager software.

- Start the digital process and print the image pattern onto the substrate.

4. Analysis of the Printed Pattern

- Investigate the quality of the printed patterns using an optical microscope. Check for the presence of defects within printed features and assess the improvement in the quality when more layers were printed.

- Evaluate the surface topology and thickness profile of the inkjet-printed multilayers using a non-contact 3D surface profilometer (based on white light interferometry) via a 3D optical microscope.

NOTE: More details about measurements and the instruments that were used to formulate/print and characterize the printed patterns are presented in reference21.

Representative Results

The physical properties of PVOH water-based ink, such as surface tension, viscosity/rheological behavior, pH, wetting, and time stability, were investigated. The viscosity of the ink used in this work was 7.5 cP, and the surface tension was 39.3 mN/m. Additionally, the formulated ink was neutral (pH 7), with the results summarized in Table 1.

| Ink | Surface tension (mN/m) | Viscosity (cP) 1 min/25 rpm | pH | ||||

| PVOH_ink | Mean val. = 39.5; SE = 0.2 | Mean val. = 7.6; SE = 0.17 | 6.75 ±0.05* | ||||

Table 1: Parameters of the ink. The key parameters of the formulated ink, such as surface tension, viscosity, and pH, are listed in this table.

A visual examination of the solution was performed in order to check the homogeneity and to identify any sedimentation or flocculation of the ink. As can be seen in Figure 1, the formulated solution is free from large particles and has a milky appearance.

Figure 1: PVOH water-based ink. This picture shows that after formulation, the solution is clearly free from visible large particles.

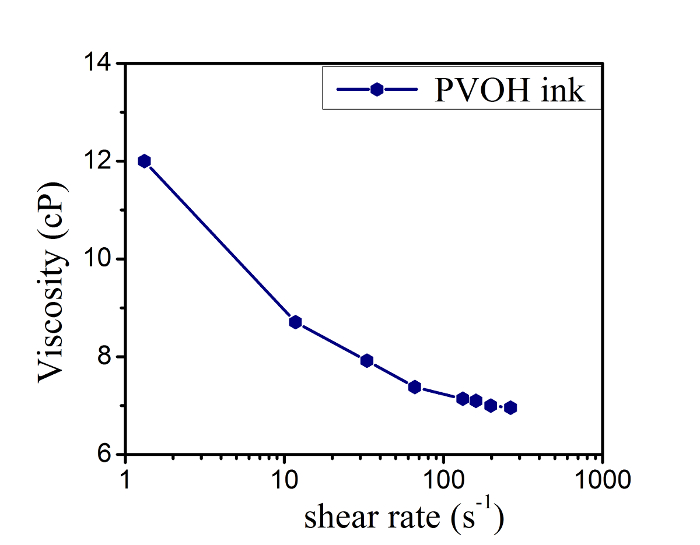

Moreover, it should be stressed that the rheological properties of the solution play a crucial role on the printability behavior; they are analyzed for this reason. The rheological behavior was examined by measuring the viscosity as a function of shear rate. As shown in Figure 2, the viscosity decreased with increasing shear rate, showing non-Newtonian shear thinning behavior over the range of shear rates from 1 to 100 s-1.

Figure 2: Viscosity as a function of shear rate. The formulated ink exhibits a pseudo-plastic/non-Newtonian shear thinning behavior at low shear rates. Please click here to view a larger version of this figure.

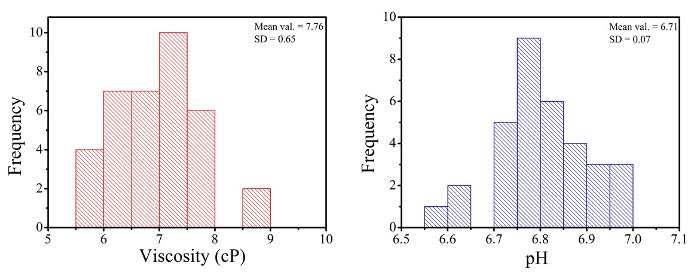

It is important to emphasize that the stability of the ink is crucial for maintaining quality during printing; thus, the stability of the ink at ambient conditions was assessed. The stability test was performed by measuring the viscosity and pH of the PVOH ink as a function of time via consecutive daily measurements over 30 days. Figure 3 illustrates the histograms of the collected data, which include both the mean and standard deviation values.

Figure 3: Histogram of the viscosity (left) and pH (right) of the PVOH water-based ink. In order to ensure a reliable and reproducible process, the stability of the ink was investigated, and the results are illustrated in this picture. Please click here to view a larger version of this figure.

Furthermore, during the IJP, the jetting process (i.e., pulling ink into the chamber and ejecting ink out through the nozzles) is fully controlled by the physical deformation of the piezoelectric membrane after the application of electric potential. It is very important to reiterate that the jetting reliability and consistency are completely defined by both the ink properties and the optimum waveform settings. The optimum waveform parameters, such as the draw voltage pulse (VD) and release pulse (VR), were identified and are included in Table 2.

| Ink | Draw pulse | Release pulse | |||

| Voltage (V) | Time (µs) | Voltage (V) | Time (µs) | ||

| PVOH_ink | 15 | 5 | 7.5 | 10 | |

Table 2: Printing (waveform) parameters applied to the piezoelectric printhead in the experiment. The amplitudes and widths of the draw and release pulses are crucial to the jetting performances. The appropriate values should be identified to ensure a high-quality printed layer.

As a starting point, the amplitudes/widths of the voltage pulses were selected accordingly, with the properties of the fluid including both surface tension and viscosity. Then, a pattern was printed, and the quality of the printed layers was assessed. Furthermore, the waveform settings were adjusted until the best quality was achieved.

Additionally, the drop-substrate interactions play a significant role on the printing quality. It is well known that a good adhesion of the ink to the substrate takes place if the surface energy of the substrate exceeds the surface tension22 of the ink by 10-15 mN/m. First, the surface energies of several potential substrates (i.e., glass, plastic, electronic paper, and photo paper) were tested, and the results are included in Table 3. In order to identify the best match of substrate to ink, the surface energy of the tested substrates and the surface tension of the formulated ink were compared, and the glass slide was selected for further work.

| Substrate | Surface energy (mN/m) | |

| Glass slide | 65 | |

| Plastic | 51.5 | |

| electronic paper | 50.8 | |

| Photo paper | 47.5 | |

Table 3: Surface free energies of four potential substrates. To secure the excellent adhesion of the ink to the substrate, the surface energies of four potential substrates were determined. Therefore, for the proper adhesion of the ink to the substrate, the surface tension of the ink must follow the 10-point rule (i.e., the surface tension should be lower by at least 10 mN/m than the surface energy of the substrate surface).

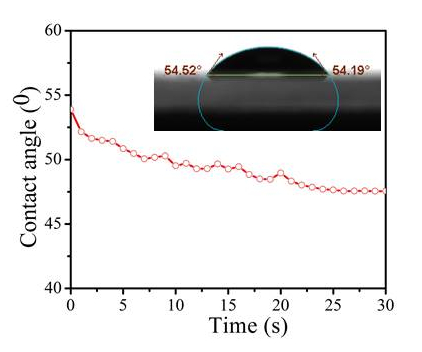

The wetting behavior of the PVOH ink was then investigated. As illustrated in Figure 4 (inset picture), the PVOH ink demonstrates a good level of wettability with the "first contact" contact angle of 54.5 ± 0.1° (the precision of the contact angle measurement is quoted as ± 0.1°). The evolution of the contact angle with time is presented in Figure 4; it can be observed that a slight decrease in contact angle occurs in the first 25 s, after which it is fairly constant.

Figure 4: Contact angle versus time for the PVOH ink/glass substrate. Inset: image of the ink droplet on the glass substrate.

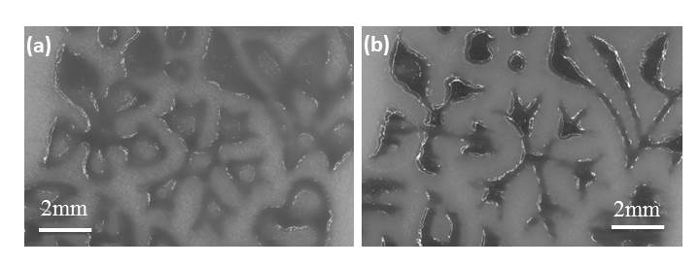

Optical micrographs of the IJP of PVOH with 10 and 75 layers are illustrated in Figure 5. A number of defects generated by a very well-known ring/coffee stain effect23,24 are revealed in the case when the pattern was made by 10 printing passes (Figure 5a). Nonetheless, it is interesting to observe that the quality is much improved after printing 75 layers. It is clear that the ring formation was suppressed effectively when 75 layers were printed (Figure 5b). The observed improvement in the quality of the printed pattern might be due to the change in the solvent evaporation rate/fluid flow and to the change in the interface interaction between a large number of overlapping layers. Additionally, heating the substrate during deposition and using a volatile co-solvent are two possible approaches to overcome these defects.

Figure 5: Optical micrographs of inkjet printing PVOH with (a) 10 and (b) 75 layers of printing passes. The quality of the printed layers was assessed via optical microscopy. This picture compares the quality of 10 and 75 printed layers. The picture reveals that the quality is much improved when 75 layers were printed. Please click here to view a larger version of this figure.

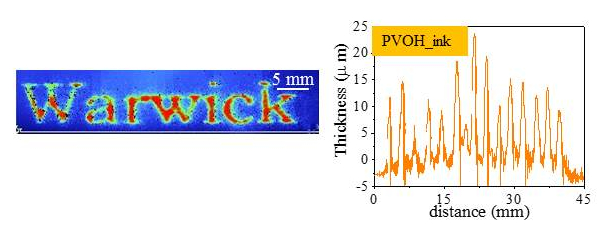

The "Warwick" logo was printed by 100 printing passes, and the surface profile and thickness uniformity were then investigated. As can be seen in Figure 6, the first part of the pattern is partially covered. However, the observed poorly-covered areas can be linked to the "first drop" effect25 in the printing process. As expected, this effect also reflects the thickness uniformity (i.e., the thickness is not uniform over the entire scanned area).

Figure 6: The "Warwick" logo printed with the PVOH water-based ink surface (left) and thickness (right) profiles. This picture shows that the first letter of the pattern is poorly covered; this is also reflected by the thickness uniformity. However, the rest of the printed pattern looks fairly good.

Discussion

In this work, we successfully demonstrated the ability of inkjet printing technology to deposit polymer multilayers. The rheological behavior was investigated, and the experimental results demonstrate that the formulated ink displays pseudoplastic shear thinning behavior. Also, the PVOH ink is a neutral solution (pH 7) and shows good stability over time. Notably, it was successfully demonstrated that IJP technology is capable of producing polyvinyl alcohol multilayer structures, but further improvements in printing coverage and overall quality are required.

Furthermore, in order to improve the accuracy of the printed patterns, a better understanding of the interaction between the ink and the substrate, as well as between adjacent layers, together with more effective control of the jetting behavior, are necessary.

Drop-on-demand (DOD) IJP is an modern method used to deposit materials, and it has recently captured the attention of the research community. DOD IJP technology has the ability to deposit a wide range of materials, from polymers to metals and even pharmaceuticals. However, there are a number of challenges, such as depositing defect-free printed layers; achieving a high-resolution pattern26; and producing thin (less than 1 µm), multilayered structures. Notably, the printed resolution is defined by the volume of the ejected drops, and currently, the maximum volume than can be dispersed is approximately 1 pL. However, further development in the near future is expected. Moreover, both the ink and the printhead are equally responsible in the DOD printing process. For example, for the ink, the key parameters, such as surface tension, viscosity, and pH, should be compatible with the IJP hardware. In order to control the evaporation rate and thus to improve the uniformity of the printed layer(s), a co-solvent can be used. On the other hand, for the printhead, the waveform design, the duration, and the amplitude of the applied pulses are the key parameters in the printing process.

A recent strategy in the electronics sector is to identify ways to make eco-friendly electronic devices. In this context, 3D IJP technology is without a doubt one of the most promising technologies to reduce the harmful radiation and heat generation caused by manufacturing and also to achieve cost reductions. IJP is capable of revolutionizing the whole system of manufacturing electronic devices, including material selection, design and fabrication, and device configuration and architecture. 3D IJP technology is a reliable alternative to the traditional manufacturing pathway, and most importantly, it is a proactive step to minimize the negative effects on the environment.

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

The authors would like to acknowledge Innovate UK for funding this research under the DIRECT (33417-239227) and PCAP (27508-196153) projects. The authors would also like to thank PVOH Polymers Ltd., for providing materials and professional guidance during this work, and Unilever, AkzoNobel, and Carclo Technical Plastics, for their support.

Materials

| Polyvinyl alcohol | PVOH Polymers Ltd, UK | Poval 4-88 | |

| Mono-propylene glycol | Sigma Aldrich, UK | W29004 | |

| DV2T viscometer | Brookfield, UK | ||

| Attension Theta Optical Tensiometer | Biolin Scientific, Sweden | ||

| HANNA pH meter | HANNA Instruments, UK | ||

| industrial Inkjet XYPrint100Z | Industrial Inkjet Ltd, UK | ||

| ContourGT-K 3D optical microscope | Bruker Corp, USA |

Riferimenti

- Goodship, V., Jacobs, D. Polyvinyl Alcohol: Materials, Processing and Applications. Rapta Review Reports. 16, (2008).

- Marin, E., Rojas, J., Ciro, Y. A review of polyvinyl alcohol derivatives: Promising materials for pharmaceutical and biomedical applications. Afr J Pharm Pharmacol. 8 (24), 674-684 (2014).

- Baker, M. I., Walsh, S. P., Schwartz, Z., Boyan, B. D. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 100 (5), 1451-1457 (2012).

- Gaaz, T. S., et al. Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules. 20, 22833-22847 (2015).

- Birck, C., Degoutin, S., Tabary, N., Miri, V., Bacquet, M. New crosslinked cast films based on poly(vinyl alcohol): Preparation and physico-chemical properties. eXPRESS Poly Lett. 8 (12), 941-952 (2014).

- Kitsara, M., et al. Spin coating of hydrophilic polymeric films for enhanced centrifugal flow control by serial siphoning. Microfluid Nanofluid. 16, 691 (2014).

- Supaphol, P., Chuangchote, S. On the electrospinning of poly(vinyl alcohol) nanofiber mats: A revisit. J. Appl. Polym. Sci. 108 (2), 969-978 (2008).

- Hoath, S. D., et al. Links between Ink rheology, drop-on-demand jet formation, and printability. J Imaging Sci Technol. 53 (4), 1-8 (2009).

- Pan, Z., et al. Recent development on preparation of ceramic inks in ink-jet printing. Ceram Int. 41, 12515-12528 (2015).

- Kamyshny, A., Magdassi, S. Conductive nanomaterials for printed electronics. Small. 10 (17), 3515-3535 (2014).

- Li, J., Lemme, M. C., Östling, M. Inkjet Printing of 2D Layered Materials. ChemPhysChem. 15, 3427-3434 (2014).

- Choi, H. W., Zhou, T., Singh, M., Jabbour, G. E. Recent developments and directions in printed nanomaterials. Nanoscale. 7, 3338-3355 (2015).

- Basirico, L., Cosseddu, P., Fraboni, B., Bonfiglio, A. Inkjet printing of transparent, flexible, organic transistors. Thin Solid Films. 520 (4), 1291-1294 (2011).

- Komuro, N., Takaki, S., Suzuki, K., Citterio, D. Inkjet printed (bio)chemical sensing devices. Anal.Bioanal.Chem. 405 (17), 5785-5805 (2013).

- Cherrington, R., Wood, B. M., Salaoru, I., Goodship, V. Digital printing of titanium dioxide for dye sensitized solar cells. J. Vis. Exp. , (2016).

- Nelo, M., et al. Inkjet-printed memristor: Printing process development. Jpn. J. Appl. Phys. 52, 1-6 (2013).

- Jacot-Descombes, L., Gullo, R. M., Mastrangeli, M., Cadarso, V. J., Brugger, J. Inkjet-printed SU-8 Hemispherical Microcapsules and Silicon chip Embedding. IET Micro & Nano Letters. 8 (10), 633-636 (2013).

- Martin, G. D., Hoath, S. D., Hutchings, I. M. Inkjet printing – the physics of manipulating liquid jets and drops. J Phys Conf Series. 105, 012001 (2008).

- Derby, B. Inkjet printing of functional and structural materials: Fluid properties requirements, feature stability and resolution. Annu. Rev. Mater. Res. 40, 395-414 (2010).

- Salaoru, I., Zhou, Z., Morris, P., Gibbons, G. J. Inkjet printing of polyvinyl alcohol multilayers for additive manufacturing applications. J. Appl. Polym. Sci. 133, 43572 (2016).

- Deegan, R. D., et al. Capillary flow as the cause of the ring stains from dried liquid drops. Nature. 389, 827-829 (1997).

- Yunker, P. J., Still, T., Lohr, M. A., Yodh, A. G. Suppression of the coffee-ring effect by shape-dependent capillary interactions. Nature. 476, 308-311 (2011).

- Famili, A., Palkar, S. A., Baldy, W. J. First drop dissimilarity in drop-on-demand inkjet devices. Phys Fluids. 23, 1-6 (2011).

- Park, J., et al. Prediction of drop-on-demand (DOD) pattern size in pulse voltage-applied electrohydrodynamic (EHD) jet printing of Ag colloid ink. Appl. Phys. A. 117, 2225 (2014).