Application of Design Aspects in Uniaxial Loading Machine Development

Summary

Here we present a protocol to develop a pure uniaxial loading machine. Critical design aspects are employed to ensure accurate and reproducible testing results.

Abstract

In terms of accurate and precise mechanical testing, machines run the continuum. Whereas commercial platforms offer excellent accuracy, they can be cost-prohibitive, often priced in the $100,000 – $200,000 price range. At the other extreme are stand-alone manual devices that often lack repeatability and accuracy (e.g., a manual crank device). However, if a single use is indicated, it is over-engineering to design and machine something overly elaborate. Nonetheless, there are occasions where machines are designed and built in-house to accomplish a motion not attainable with the existing machines in the laboratory. Described in detail here is one such device. It is a loading platform that enables pure uniaxial loading. Standard loading machines typically are biaxial in that linear loading occurs along the axis and rotary loading occurs about the axis. During testing with these machines, a load is applied to one end of the specimen while the other end remains fixed. These systems are not capable of conducting pure axial testing in which tension/compression is applied equally to the specimen ends. The platform developed in this paper enables the equal and opposite loading of specimens. While it can be used for compression, here the focus is on its use in pure tensile loading. The device incorporates commercial load cells and actuators (movers) and, as is the case with machines built in-house, a frame is machined to hold the commercial parts and fixtures for testing.

Introduction

Mechanical testing has an interesting history that can be traced back to hardness testing equipment developed by Stanley Rockwell in the early in the twentieth century. While technology has grown to the extent that standard, documented practices guide everything from the verification of machine performance to the guidelines for carrying out specific tests1,2,3,4. Today, mechanical tests are conducted on everything from building materials such as concrete, steel, and wood to food and textile products5,6,7,8,9. Given that the fields of biomedical engineering and, more specifically, biomechanics utilize mechanical testing, loading machines are commonplace in biomechanics labs.

Loading machines run the range of scale in biomechanics. As an example, larger loading machines can be used to conduct full-body impact studies or determine human femoral mechanical properties, while smaller loading machines can be used to test murine bones or stimulate cells10,11,12,13,14. Two types of loading machines are found in the testing laboratory; those that are purchased commercially and those that are built by the user. Loading machines developed in-house are often favored for their personalization and customization options15.

In testing, a specimen is secured in the machine so that a displacement can be applied, generating a measurable force. If the load is used as the driving feedback, the test is load-controlled; if the displacement is used as the driving feedback, the test is displacement-controlled. Loading machines, in general, are built upon a frame that connects a mover to a fixed support. As such, testing generally involves one end of the specimen being moved while the other end remains fixed.

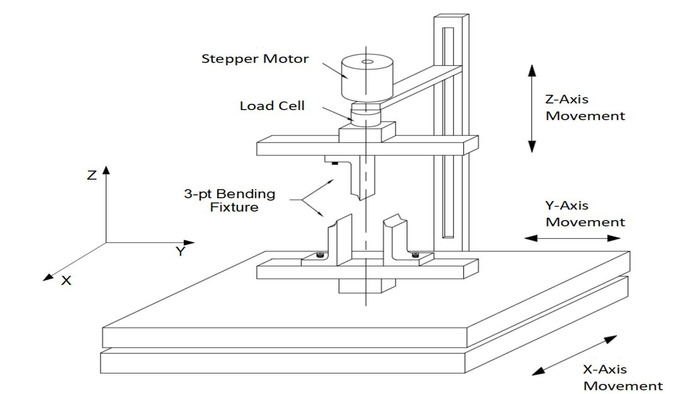

Shown in Figure 1 is a sketch of a simple loading machine demonstrating its basic components. Fundamental to all loading machines is a base or frame. Whereas the vast majority of commercial brands utilize a fixed base, the drawing depicts a platform that allows planar (XY) movement. The mover, in this case, is the upper arm that holds a load cell and is driven by a stepper motor. Attached to the frame are the fixtures which hold the specimen and dictate the type of test that is run. Shown in the drawing are three-point bend fixtures. The top fixture (the single contact) is mounted to the moving arm; the bottom fixture (the double contact) is mounted to the stationary base. During testing, the motor drives the upper fixture downward to where the center contact engages the specimen. As the contact engages the specimen, the load cell records the increase in resistance or the force placed upon the specimen.

There are occasions where machines are designed and built in-house to accomplish a motion not attainable with the existing machines in the laboratory. Here we describe in detail one such device. It is a loading platform that enables pure uniaxial specimen loading or equal and opposite motion at both ends. The device incorporates commercial load cells and actuators (movers); a frame is machined to hold the commercial parts and loading fixtures for specimen testing. Understanding the basic principles of testing machine construction can aid in the design of one's own machine. We have provided the drawing files we created as a starting point to assist researchers with their own machine development. The video will focus on the assembly of the device and the application of mechanical design principles to ensure alignment and reliable testing.

Protocol

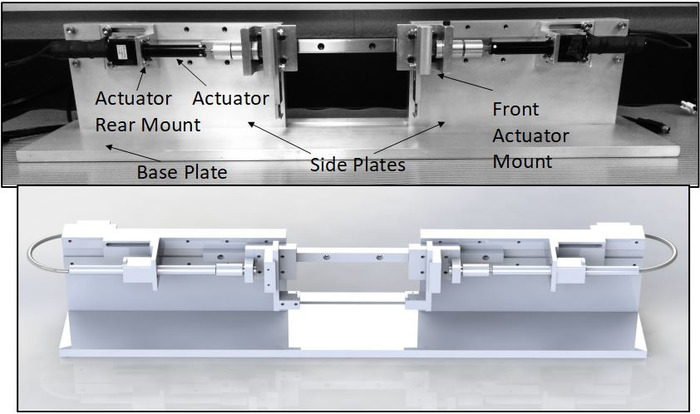

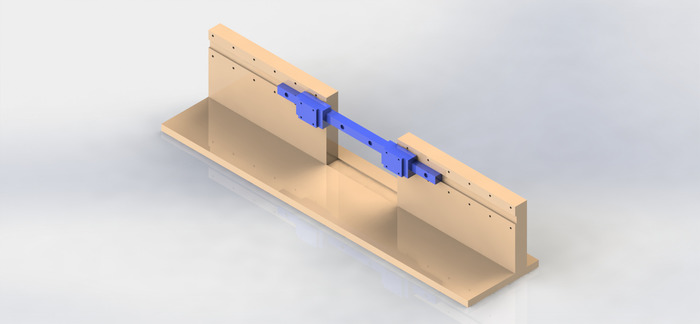

NOTE: The finished device is shown in Figure 2. The device enables pure uniaxial testing of specimens in a horizontal position.

1. Component Parts

- Prepare two programmable actuators with a 30 mm (1.2 in) travel per actuator capable of spanning 60 mm (2.3 in) when programmed to pull/push together. To accommodate a variety of potential uses, select actuators having a reasonable force capacity [67 N (15 lb)], peak thrust [58 N (13 lb)], speed resolution [0.9302 µm/s (0.00004 in/s)], and a unidirectional accuracy [25 µm (0.001 in)].

- Daisy-chain the actuators to sync them for an equal application of extension/retraction.

- Prepare a 24 V controller to provide the driving motion to the actuator; these systems enable a precise linear motion by the rotation of a screw, the leadscrew.

- Prepare two load cells with a maximum force capacity of 44.5 N (10 lb). Select a low profile or canister-style load which is ideal for confined spaces.

- Prepare the rail/carriage block system. Prepare one rail and two carriages; one to hold each actuator. Because steel will rust, select stainless-steel material if the device will be utilized for materials that require hydration; for all other purposes, steel is acceptable.

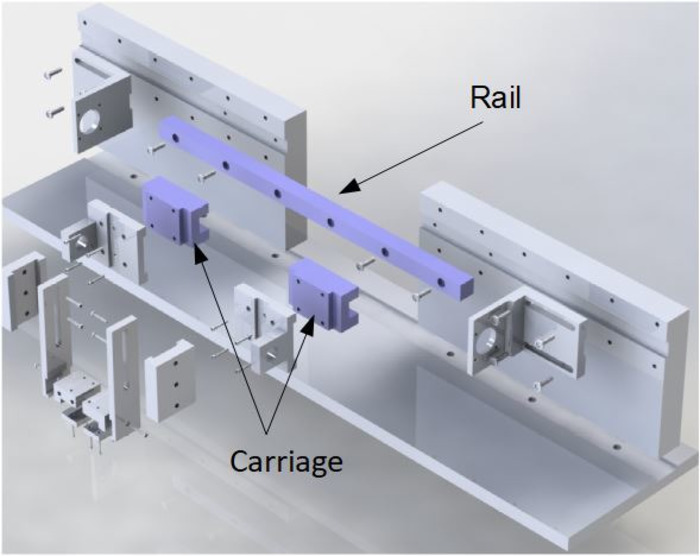

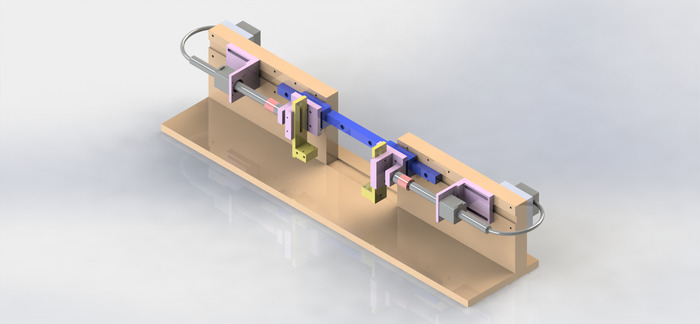

NOTE: An exploded view of the loading platform with the rail/carriage block shown in purple is provided in Figure 3.

2. Frame Construction

NOTE: For explanatory purposes, the platform is color-coded in the graphics.

- Prepare aluminum stock material. Select aluminum for its cost-effectiveness and ease of machining. Prepare both plate and 'L'-shaped angle stock.

- Prepare stock material to machine fixtures. Select plexiglass; it is strong while lightweight.

3. Metal Base and Side Plate (Frame) Assembly

- Cut the base plate from the aluminum stock, making sure it is approximately 64 x 15 x 1.3 cm (25 x 6 x 0.5 in). Clean up the edges in the mill and cut the base plate to its final dimensions.

- Machine the plate flat in the mill, according to the specifications provided in the supplemental files.

- Face it, ensuring the plane is level.

- Machine a track into the base plate to align the side plates with a tolerance of 0.0126 mm (0.0005 in).

- Machine the side plates according to specifications provided in the supplemental files.

- Drill and tap the side plates on their bottom face.

- Mount the side plates upright in the track.

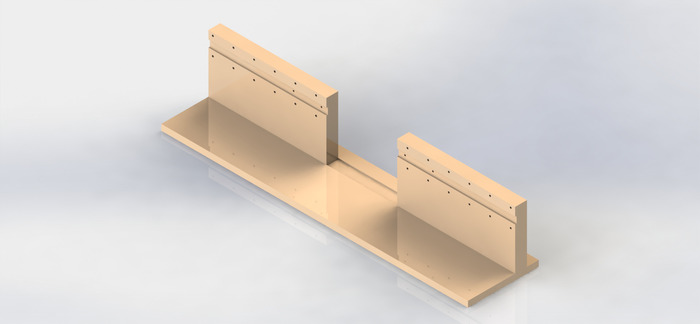

- Fasten the side plates to the base plate from underneath (Figure 4).

4. Attaching the Rail/Carriage Assembly to the Frame

- Machine tracks into the front face of each side plate to enable the mounting of the rail/carriage assembly according to the specifications provided in the drawing links (Figure 5).

- Fasten the rail to the track through the clearance holes in the rail via drilled and tapped holes (to accommodate #10-32 screws) in each side plate.

5. Rear Mount Attachment of the Actuators

- Machine rear mount attachments from the 'L'-shaped angle stock according to the specifications provided in the supplemental files.

- Machine a bar to attach to the bottom of the mount to serve as a keyway and ride it in the machined track on the face of the side plate according to the specifications provided in the supplemental files. Screw the bar into the bottom of the mount.

- Drill a through hole in the base of the rear mount for the actuator clearance.

- Attach the rear mount to the body of the actuator via the hole pattern in the commercial actuator.

NOTE: One reason for making a rear mount is to eliminate the need to repeatedly attach the actuator directly to the frame using the small #2 metric screws that come stock on the actuators. The mount eliminates the concern of stripping the internal threads of the actuator with repeated use. - Slot the base of the mount to attach the rear actuator mount to the frame via two screws.

- Drill and tap a series of holes (to accommodate #10-32 screws) flanking the track on the front face of the side plates to allow for an adjustable mount attachment if it is desirable to accommodate specimens of varying sizes.

6. Front Mount Attachment of the Actuators via Connectors

NOTE: The front mount is an 'L'-shaped piece that attaches the front of the actuator to the carriage. The actuator does not physically contact the mount; it attaches via a series of connectors that extend from the actuator tip.

- Machine front mount attachments from the 'L'-shaped angle stock according to the specifications provided in the supplemental files.

- Drill a hole in the base of the front mount to accommodate the tapered connector.

- Machine a track in the side of the front mount to accommodate a plate.

- Machine the plate with a track to accommodate the fixtures.

- Machine an aluminum, cylindrical connector according to the specifications provided in the drawing links. This adaptor connects the load cell to the actuator.

- Drill and tap the connector for a #2 metric screw on the actuator end and a #6 metric screw on the load cell end to support the axial mounting and alignment of the load cell and actuator.

- Repeat this process to machine two identical connectors, one for each load cell.

- Machine an aluminum, tapered, cylindrical connector according to specifications provided in the drawing links. This adaptor connects the load cell to the fixture and the carriage.

- Drill and tap the connector to the threaded load cell connection on one end.

- Pass the cylinder into the hole of the front actuator mount and use a set screw to anchor the cylinder end.

- Duplicate the system for the right and left actuators.

NOTE: As shown in Figure 6, once assembled, the base of the actuator is rigidly attached to the side plate. The front of the actuator is attached to the carriage and, as the actuator is extended and retracted, the carriage is pushed and pulled. This provides the framework for the fixture attachment and specimen loading.

7. Fixtures

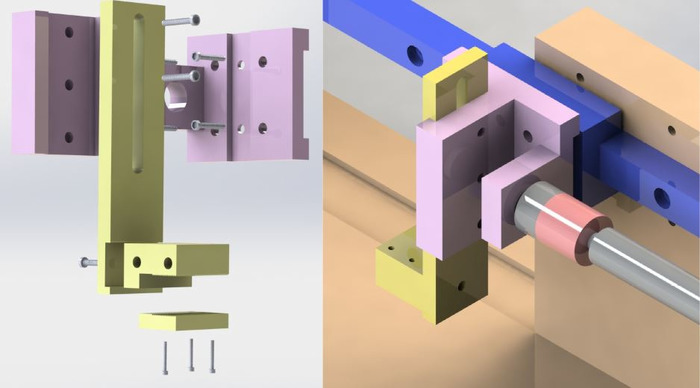

- Machine the fixtures according to the specifications provided in the supplemental files (Figure 7).

- Machine a central, vertical slot in the fixture holder to accommodate the height.

- Attach the actuator front mounts to the rectangular plate with three drilled and tapped holes (to accommodate #10-32 screws) vertically aligned in the center of the plate.

- Raise or lower the holder as necessary, for example, if a saline bath for hydrated testing is being used, and secure it with screws.

8. Operating Procedure:

- Download the actuator software to remotely control the device16.

- Create a link between the computer and the 24 V controller with a 6-pin mini-din male-to-female PS/2 extension cable; each actuator controller has two 6-pin mini-din connector cable links.

- Use a USB-to-6-pin mini-din converter to connect the actuators to a standard computer; the converter contains one female 6-pin mini-din connector end and a USB connection port.

- Daisy-chain the actuators so that a single computer cable is sufficient for the operation, or alternatively, use an HDMI adapter in place of the USB adapter.

- Connect the actuators to the 24 V power supply.

- Once connected and powered, select the devices and customize the actuator performance.

- Alternatively, control the actuators manually by the dial on each actuator, which is useful for the set-up.

NOTE: This software is applicable to any standard operating system. With this software, the actuators can be moved at varying speeds to any set distance, synced at a set distance or synced to each other to move in unison.

Representative Results

In order to verify the use of the system, actuator speed and performance tests were conducted17. These tests consisted of measuring the actuator speed and distance in comparison to the input values. To verify the sample travel distance accuracy, arbitrary travel distances along the shaft between 254 – 2540 µm (0.01 – 0.10 in) were selected. The device was run to these distances and compared to the actual distance measured using combinations of gauge blocks and feeler gauges. The distances chosen were representative of the 1% – 10% strain rate that is commonly used in cellular testing. The results for the distance test showed a < 4% deviation from the input.

To test the actuator speed, random arbitrary speeds were chosen that span the actuator capabilities. The speed values ranged from 1 – 28,000 µm/s (0.00004 – 1.1 in/s). This speed was then compared to the calculated speed of the device by setting a distance and timing actuator motion. For the speed test, the actuator would complete one full cycle of extension and contraction. From this test, the actuator speed was found to be within a 10% deviation from the input. All test results had an r2 value of > 0.999. To verify the actuators did not overheat, each actuator was cycled with its maximum speed and distance. The temperature was then recorded every 5 min for 1 h and was found to never exceed 39.9 °C. All validation tests were performed at least 3x.

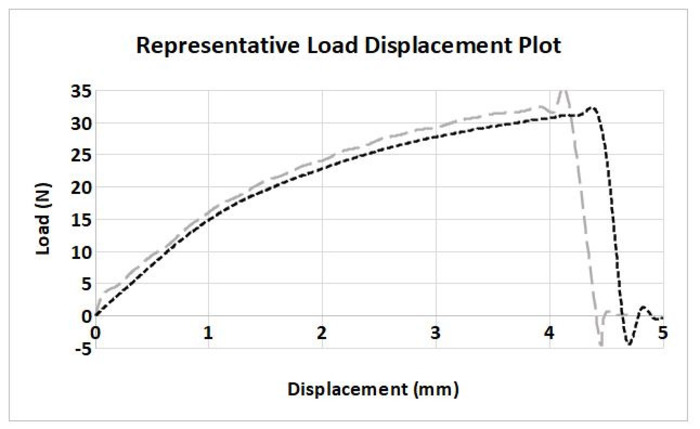

To test its performance, the pure uniaxial device in the fixed-end configuration was used and compared to the test results from our existing loading platform which was also developed in-house18. Ten 2-0 sutures were tested to failure in both machines. The sutures were knotted with three knots in order to create a stress riser in the middle of the sample and divert stress from the fixtures. A gauge length of 25.4 mm (1.0 in) was used with a loading rate of 0.61 mm/s (0.024 in/s). The same test was then performed with the existing loading machine, where the actuator speed was doubled to 1.22 mm/s (0.048 in/s) in order to compensate for the single actuator. All testing was completed using 44.5 N (10 lb) load cells. In addition, pure uniaxial testing was completed to verify no differences between the relative ends. A typical suture plot is provided in Figure 8. The gray dashed line represents results from the pure uniaxial device compared to the black dotted line from the existing fixed-end device.

In all tests, the sutures failed at the knot. The measurements consisting of stiffness, maximum load, and displacement at failure showed no statistical difference between the two machines for p < 0.05. Once it was determined the devices yielded statistically similar results, further testing was conducted. Suture material properties obtained using the pure uniaxial device in the pure and fixed-end configurations were not statistically different17.

Figure 1: Simple loading machine fitted with a three-point bending fixture. The design incorporates planar movement along the X- and Y-axes, adding to the versatility of the machine. Please click here to view a larger version of this figure.

Figure 2: Fabricated device shown (top) with its computer model counterpart (bottom). The uniaxial machine components are fabricated from aluminum. A solid model is utilized during the planning stages of the device. Please click here to view a larger version of this figure.

Figure 3: An exploded view of the loading platform with the rail/carriage block shown in purple. The commercial carriages and guide rail ensure the alignment and on-axis motion. The exploded view illustrates the use of screws in the assembly of the machine. Please click here to view a larger version of this figure.

Figure 4: The side plates mounted in the track of the base plate. The side plates fasten to the base plate through the bottom of the base. As seen in the figure, the front faces of the side plates have a machined track which accommodates the rail. Please click here to view a larger version of this figure.

Figure 5: Rail and carriage system highlighted in purple. The rail/carriage block consists of two ball-bearing carriages that enable smooth gliding along the rail. In assembly, the block mounts to the front of the side plates while the machined track ensures the alignment. Please click here to view a larger version of this figure.

Figure 6: Assembly drawing of the loading device. The actuator's front mount is attached to the rail and the extension/retraction of the actuator tip moves the specimen. The rail/carriage block is shown in purple; the actuator mounts (front and rear) are shown in pink; the connectors are shown in red; the fixtures are shown in yellow. Please click here to view a larger version of this figure.

Figure 7: Plexiglass friction clamps on a vertical, slotted track. The incorporation of a slotted track allows for the vertical alignment and use with an environmental bath (not shown). To allow for this adjustment, the set screws are used to raise and lower the track. The left image shows the exploded fixture assembly from the front; the right image shows the fixture assembly from the back. To grip the specimen, serrated teeth are machined into the clamps. Please click here to view a larger version of this figure.

Figure 8: Load-displacement data from a suture test. The graph is a plot of a load-displacement curve of a suture tested to failure. Suture is a fiber and used here to demonstrate the typical shape of a failure curve. If fabricating a machine, twine or yarn could be substituted for a similar result. Please click here to view a larger version of this figure.

Actuator Front Mount: Please click here to download this file.

Actuator Mount: Please click here to download this file.

Base Plate: Please click here to download this file.

Bottom Clamp: Please click here to download this file.

Carriage: Please click here to download this file.

Load Cell Connector: Please click here to download this file.

Rail: Please click here to download this file.

Side Plates: Please click here to download this file.

Slider Arm: Please click here to download this file.

Top Clamp: Please click here to download this file.

Discussion

The goal of this work was to design and fabricate a cost-effective and reliable uniaxial loader for its use with small-scale specimens such as tissue and fibers. A device was constructed that met the requirements set forth while also being flexible enough in design to allow for new attachments to be fabricated as the user needs grow. For example, the device will allow for the testing of dry and wet specimens in a uniaxial or fixed-end configuration.

Critical steps in the design and fabrication of any loading device include the consideration of the material, the commercial components (maintenance), and the performance and flexibility of the system. All machining was completed on a standard mill. Aluminum and plexiglass provide the necessary rigidity for the frame and fixtures. The commercial components consist of actuators and the rail/carriage block system. The same actuators are used for both tension and compression. These actuators work well in mechanical testing platforms given that, when they are on but not in use, the power to the motor is halted so that the leadscrew does not generate a torque and the actuators do not overheat. Furthermore, the rail/carriage block system provides alignment and easy maintenance. The system uses two ball-bearing screw carriages that ride along the 15 mm (0.6 in)-wide track. One carriage is used per side plate to connect the actuator to the rail. The assembly has a 7800 N (1750 lb) dynamic load capacity and can accommodate a wide range of specimens. The carriages contain internal oil reservoirs to maintain lubrication. The fixtures hold the specimen to the platform during testing. In addition to holding the specimen, the fixtures attach to the actuator, so that the extension/retraction of the actuator applies load to the specimen. To accommodate a wide range of specimens that would require different environments, a vertically-adjustable design enables fixtures to be lowered into a water/media bath for testing. The serrations cut into the plexiglass using a double angle cutter (90°) create 'teeth' that enable an increased clamping and holding strength of the specimen during testing. At the base of the holder is a horizontal slot running along the width of the plate. The serrated clamp slides into the slot and is held in place with a screw. Because of the slot tolerance [+ 0.0127 mm (0.0005 in)], a single screw is sufficient to hold the fixture while the slot keeps it from twisting and maintains planar alignment.

If the basic mechanical principles of the design are followed, the machine is robust, and troubleshooting is minimal. All commercial components should be purchased after designing the device, but before fabricating it. Having the commercial parts on hand will aid with the decision-making and allows for the physical measurement of dimensions and threads which may vary from those specified here. If the device is to be used for standard testing, the device can be simplified by eliminating much of the flexibility in its design, such as eliminating the adjustability of the fixture height and track length.

This system provides for testing not currently available in our lab in a cost-effective manner. Moreover, pure uniaxial machines are not widely commercially available, so this device does not unnecessarily duplicate existing technologies. However, we have applied simple design techniques and there are several ways to accomplish pure uniaxial loading; only one is represented here. Commercial devices do exist for planar biaxial loading, but these are cost-prohibitive for uniaxial loading purposes.

The pure uniaxial loading machine came to a total cost of about $4,000. This price was a result of the commercial components (actuators, controllers, and load cells). Metal machining was completed in-house at no charge and the material cost was under $100. We estimate that the machining time was about 60 hours with a typical machining rate of about $75/h, essentially doubling the price. But, it is important to metal machine the device rather than three-dimensional (3-D) print it from plastic. The frame has to be stiff enough to support the loading. Given the frame is approximately 1.25 cm (0.5 in) thick, the frame would easily support specimens 2x – 3x as strong, adding to its future use. By comparison, commercial loading machines can easily exceed $100,000. However, it is important to note that these commercial machines incorporate feedback that enables load-control or displacement-control testing. This platform utilizes displacement control (actuator motion) and is not overly complicated. Researchers needing mechanical testing will find that, with a little effort, they can develop their own loading platforms.

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

This work was supported by the National Institutes Health NIDCR [DE022664].

Materials

| Power supply, 24 V DC 2.5 A out, 100-240 V AC in, plug for North America | Zaber Technologies inc | PS05-24V25 | |

| 6 pin mini din-male to female PS/2 extension cable | Zaber Technologies inc | T-DC06 | |

| Stepper motor controller, 2 phase | Zaber Technologies inc | A-MCA | |

| Linear actuator, NEMA size 11, 30 mm travel, 58 N maximum continuous thrust | Zaber Technologies inc | NA11B30 | |

| Corrosion resistant maintenance-Free Ball Bearing Carriages and Guide Rails | McMaster-Carr | 9184T31 | |

| 6061-t6 Aluminum Stock | McMaster-Carr | NA | |

| Plexiglas Stock | McMaster-Carr | NA | |

| Canister load cell, 4.5N | Honeywell Sensotec | NA | |

| USB to 6 pin mini-din | Universal | NA |

Riferimenti

- . ASTM E4-16. Standard practices for force verification of testing machines Available from: https://www.astm.org/Standard/standards-and-publications.html (2016)

- . ASTM E2309/E2309M-16. Standard practices for verification of displacement measuring systems and devices used in materials testing machines Available from: https://www.astm.org/Standard/standards-and-publications.html (2016)

- . ASTM E2428-15a. Standard practice for calibration and verification of torque transducers Available from: https://www.astm.org/Standard/standards-and-publications.html (2015)

- . ASTM E2624-17. Standard practice for torque calibration of testing machines Available from: https://www.astm.org/Standard/standards-and-publications.html (2017)

- . ASTM C39 – Standard test method for compressive strength of cylindrical concrete specimens Available from: https://www.astm.org/Standard/standards-and-publications.html (2018)

- . ASTM A370-17a. Standard test methods and definitions for mechanical testing of steel products Available from: https://www.astm.org/Standard/standards-and-publications.html (2017)

- . ASTM D4761-13. Standard test methods for mechanical properties of lumber and wood-base structural material Available from: https://www.astm.org/Standard/standards-and-publications.html (2013)

- Green, M. L., et al. Mechanical properties of cheese, cheese analogues and protein gels in relation to composition and microstructure. Food Structure. 5 (1), 169-192 (1986).

- . ASTM D76/D76M-11. Standard specification for tensile testing machines for textiles Available from: https://www.astm.org/Standard/standards-and-publications.html (2011)

- Papini, M., Zdero, R., Schemitsch, E. H., Zalzal, P. The biomechanics of human femurs in axial and torsional loading: comparison of finite element analysis, human cadaveric femurs, and synthetic femurs. Journal of Biomechanical Engineering. 129 (1), 12-19 (2007).

- Poulet, B., et al. Intermittent applied mechanical loading induces subchondral bone thickening that may be intensified locally by contiguous articular cartilage lesions. Osteoarthritis and Cartilage. 23 (6), 940-948 (2015).

- Li, J., et al. Osteoblasts subjected to mechanical strain inhibit osteoclastic differentiation and bone resorption in a co-culture system. Annals of Biomedical Engineering. 41 (10), 2056-2066 (2013).

- Huang, A. H., et al. Design and use of a novel bioreactor for regeneration of biaxially stretched tissue-engineered vessels. Tissue Engineering. Part C, Methods. 21 (8), 841-851 (2015).

- Keyes, J. T., Haskett, D. G., Utzinger, U., Azhar, M., Van de Geest, J. P. Adaptation of a planar microbiaxial optomechanical device for the tubular biaxial microstructural and macroscopic characterization of small vascular tissues. Journal of Biomechanical Engineering. 133 (7), 075001 (2011).

- Brown, T. D. Techniques for mechanical stimulation of cells in vitro: A review. Journal of Biomechanics. 33 (1), 3-14 (2000).

- . Zaber Console software download Available from: https://www.zaber.com/zaber-software (2018)

- King, J. D., York, S. L., Saunders, M. M. Design, fabrication and characterization of a pure uniaxial microloading system for biologic testing. Medical Engineering and Physics. 38 (4), 411-416 (2016).

- Saunders, M. M., Donahue, H. J. Development of a cost-effective loading machine for biomechanical evaluation of mouse transgenic models. Medical Engineering and Physics. 26 (7), 595-603 (2004).