Preparation of Sample Support Films in Transmission Electron Microscopy using a Support Floatation Block

Summary

Sample preparation for cryo-electron microscopy (cryo-EM) is a significant bottleneck in the structure determination workflow of this method. Here, we provide detailed methods for using an easy-to-use, three-dimensionally printed block for the preparation of support films to stabilize samples for transmission EM studies.

Abstract

Structure determination by cryo-electron microscopy (cryo-EM) has rapidly grown in the last decade; however, sample preparation remains a significant bottleneck. Macromolecular samples are ideally imaged directly from random orientations in a thin layer of vitreous ice. However, many samples are refractory to this, and protein denaturation at the air-water interface is a common problem. To overcome such issues, support films-including amorphous carbon, graphene, and graphene oxide-can be applied to the grid to provide a surface which samples can populate, reducing the probability of particles experiencing the deleterious effects of the air-water interface. The application of these delicate supports to grids, however, requires careful handling to prevent breakage, airborne contamination, or extensive washing and cleaning steps. A recent report describes the development of an easy-to-use floatation block that facilitates wetted transfer of support films directly to the sample. Use of the block minimizes the number of manual handling steps required, preserving the physical integrity of the support film, and the time over which hydrophobic contamination can accrue, ensuring that a thin film of ice can still be generated. This paper provides step-by-step protocols for the preparation of carbon, graphene, and graphene oxide supports for EM studies.

Introduction

Over the last decade, breakthroughs, principally in detector technology, but also in other technical fields, have facilitated a succession of substantial increases in the resolution at which biologically relevant systems can be imaged by transmission electron microscopy (TEM)1,2. Despite the fact that cryo-EM already allows the resolution of high-resolution structures from as little as 50 µg of protein through single-particle analysis (SPA), cryo-EM sample and grid preparation remain major bottlenecks3,4,5. SPA samples consist of macromolecules distributed approximately randomly within a layer of vitreous ice. The ice must be as thin as possible to maximize the contrast difference between the particles and the solvent. Biological macromolecules are more stable (i.e., less likely to lose their native structure) in thicker ice, because they remain better solvated. Moreover, particles are often found to be much better distributed over the field of view in ice much thicker than the particle size6 and frequently may not be found within holes in the carbon films at all.

Additionally, thicker layers of ice decrease the probability of molecules being close to the air-water interface due to the high surface-to-volume ratio, and it has been estimated that using standard plunge-freezing methods for cryo-EM studies results in the adsorption of ~90% of particles to the air-water interface7. Thicker ice results in undesirably high background due to increased scattering events within the solvent and concomitant attenuation of the signal6,7. It is therefore necessary to achieve as thin a layer of vitreous ice as possible; ideally, the layer would be only slightly thicker than the particle. The challenge for the researcher, which must be overcome for every different sample applied to a grid, is to prepare specimens thin enough for high-contrast imaging whilst maintaining the structural integrity of the particles within their sample. Protein adsorption to the air-water interface is accompanied by several, usually deleterious, effects.

First, binding of proteins to this hydrophobic interface often induces denaturation of the protein, which proceeds rapidly and is typically irreversible8,9. A study conducted using yeast fatty-acid synthase showed that up to 90% of adsorbed particles are denatured10. Second, evidence from a study comparing the orientation distribution of 80S ribosome datasets collected either on amorphous carbon11 or without support12 showed that the air-water interface can cause severe preferential orientation compromising 3D reconstruction of the volume13. Methods to reduce particle interaction with the air-water interface include supplementation of the freezing buffer with surfactants (such as detergents), the use of support films, affinity-capture or scaffolding of substrates, and accelerated plunging times. The use of surfactants is associated with its own problems, as some protein samples may behave non-ideally in their presence, whilst affinity-capturing and scaffolding substrates generally require engineering bespoke grid surfaces and capture strategies. Finally, although there is a lot of research on the development of rapid-plunging devices14,15,16, these require apparatus that is generally not widely available.

Although the standard TEM grid for biological cryo-EM already features a perforated amorphous carbon foil17, there are a number of protocols available for the generation of additional support films and their transfer to TEM grids. The use of these films is a long-established method for sample stabilization18. Amorphous carbon supports are generated by evaporation and deposition on crystalline mica sheets19, from which the layers can be floated onto grids, with the utility of floatation supports as useful tools established in prior reports20. Graphene oxide flakes, typically prepared using a modified version of the Hummers method21, have been used as a preferable support structure to amorphous carbon for their decreased background signal as well as the ability to immobilize and stabilize macromolecules22. More recently, there has been a resurging interest in the use of graphene as a TEM support film due to its mechanical stability, high conductivity, extremely low contribution to background noise23, as well as the emergence of reproducible methods for generating macroscopically large areas of monolayer graphene24 and transferring it to TEM grids25. When compared to amorphous carbon, which undergoes beam-induced motions similarly to, or worse, than ice lacking a support film11,12,17, graphene showed a significant reduction in beam-induced motion of cryo-EM images12.

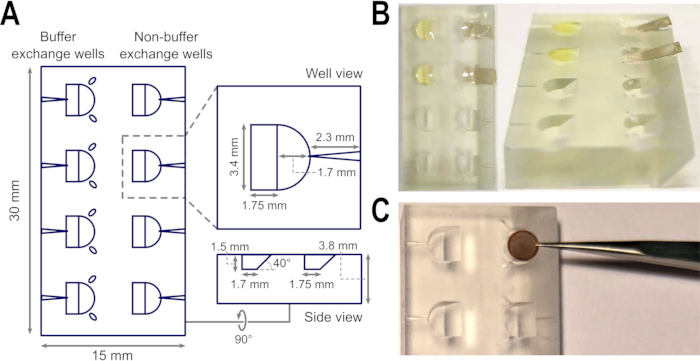

However, while hydrophilized graphene protected fatty acid synthase from air-water interfacial denaturation, the authors of this study noted that the graphene became contaminated during specimen preparation, likely due to a combination of atmospheric hydrocarbon contamination and from the reagent used to hydrophilize the grids10. Indeed, despite many of the superior qualities of graphene, its widespread use is still hindered by the derivatization required to decrease its hydrophobicity12, which ultimately is chemically difficult and requires specialist equipment. This paper reports protocols for the preparation of amorphous carbon, graphene oxide, and graphene sample supports using a three dimensionally (3D) printed sample floatation block27 to directly transfer support films from the substrates on which they were generated to TEM grids (Figure 1). A key advantage of using such a device is the wetted transfer of films, minimizing hydrophobic contamination of the supports and consequently the need for further treatment, and reducing the number of potentially damaging manual handling steps. These approaches are inexpensive to implement and therefore widely accessible and applicable for cryo-EM studies where sample supports are necessary.

Protocol

1. General preparation of TEM grids pre-support transfer

- Using a pair of clean, fine tweezers, lift and submerge TEM grids sequentially in double-distilled water (ddH2O) or ultrapure water for 10-15 s, followed by ethyl acetate, for 10-15 s.

NOTE: Here, negative-action, oblique-tip tweezers were used. - Place the tweezers, with grid still in grip, to one side to air-dry for ~5 min.

- Plasma-clean the grids to strip the surface of any contaminants accrued through the air or washing steps.

NOTE: Here, plasma-cleaning was done for 10-15 s in air with a radiofrequency power of 25 W.

2. General preparation of reagent solutions

- Uranyl acetate (UAc) solution (2% w/v)

- Wrap a 50 mL tube in foil, fill with 50 mL of ultrapure water, and add 1 g of UAc powder.

NOTE: UAc is light-sensitive and precipitates over time when exposed. As UAc is radioactive and toxic, maintain a high level of cleanliness. With the most serious hazard arising from inhalation or ingestion, extra care should be taken to prevent any possibility of inhaling fine particles. Gloves must always be worn when handling or weighing out the uranium salts. Masks and goggles highly recommended. Uranium salts must be disposed of according to the legal requirements set out for radioactive hazards within the state. - Leave the solution stirring for 1 h to allow for all the UAc to dissolve. Store at 4°C.

- Before use, filter 1 mL of the stain solution into a small vial using 0.22 µm filter to remove any remaining acetate crystals.

- Wrap a 50 mL tube in foil, fill with 50 mL of ultrapure water, and add 1 g of UAc powder.

- Graphene oxide (GrOx) suspension

- Pipette 2.5 µL of GrOx into a 1.5 mL tube (1% final concentration). Pipette 2.5 µL of 10% (w/v) n-dodecyl β-D-maltoside (DDM) detergent into the GrOx, and gently mix (0.1% (w/v) final concentration).

- Add 245 µL of ultrapure water to the GrOx-DDM mix, and immediately vortex vigorously for 5 min. Use GrOx suspension within 1 h of preparation, vortex vigorously for at least 1 min before immediate use.

- Iron(III) chloride (FeCl3) solution (10% w/v)

- Carefully weigh 5 g of FeCl3 in a weighing boat. Transfer to a 100 mL measuring cylinder containing 35 mL of ddH2O and a magnetic stir bar.

- Place on a magnetic stirring plate, and dissolve FeCl3, adding ddH2O to a final volume of 50 mL. Filter the FeCl3 solution through a 0.8 µm syringe filter into a clean bottle for storage.

NOTE: FeCl3 is corrosive and an irritant; wash hands and other exposed areas with mild soap and water before eating, drinking or smoking and when leaving work. Provide good ventilation in process area to prevent formation of vapor. Do not breathe mist, vapors, spray. Gloves must always be worn when handling or weighing out the salt. Masks and goggles highly recommended whenever in use.

3. Buffer exchange for carbon support films on mica to prepare negatively stained samples using the support floatation block

- Wash and plasma-clean TEM grids.

NOTE: Here, 300 mesh holey-carbon copper grids were used as outlined above in section 1. - Pipette 10-12 µL of sample into the buffer exchange well (with the small channels) of the floatation block and 10-12 µL of 2% UAc solution (see section 2.1) for negative staining into the adjacent non-buffer exchange well.

NOTE: The well has a volume of 10 µL; however, adjust the sample volume so that a convex meniscus is formed at the surface of the liquid to allow proper film floatation. A low volume of sample may cause film breakage. - Carefully cut two small pieces of mica with predeposited carbon film on top. Ensure that the mica fragments are wide enough to fit into the well (3.4 mm width) and longer than the well length (3.45 mm), such that the fragment will sit on the well while carbon is floating, and there is enough space to handle the fragment with the tweezers.

NOTE: To handle the carbon, use flat negative-action long-tip tweezers. When cutting the mica fragments, cut using single movements to maintain the integrity of the carbon film. - Immerse the mica into the well with an approximate angle of 45° until the mica sits on the ramp of the well and a layer of carbon is observed at the surface of the liquid sample.

- After the initial incubation on sample (typically 20 s to 20 min depending on the sample adherence; optimize this period based on experimental needs), withdraw the mica sheet very slowly to recover the carbon film and minimize residual viscous sample retention.

- Carefully blot the mica by tapping the lower surface (non-carbon side) with filter paper to remove excess liquid, and subsequently exchange the carbon bearing the sample into negative stain by application to the opposing well (i.e., immerse the mica as in step 3.4) containing the 2% UAc solution.

NOTE: A carbon layer should be observed floating on top of the stain solution at this point. - Recover the floating carbon layer with the holey carbon-covered side of a washed and plasma-cleaned EM grid. Leave the grids to air-dry until imaging on a TEM. Ideally, cover the grids during the drying process to avoid airborne contamination.

4. Application of the support floatation block to prepare graphene oxide-coated TEM grids

- Wash and plasma-clean TEM grids using 300 mesh holey-carbon copper grids as outlined above (section 1).

- Pipette 10-12 µL of GrOx suspension (see section 2.2) into the 4 non-buffer exchange wells along the floatation block. Pipette 10-12 µL ddH2O or ultrapure water into the remaining 4 buffer exchange wells of the block.

NOTE: This volume of water should be sufficient to form a slight convex meniscus rising above the height of the block. - Drop 4 grids gently onto the GrOx suspension of each well for 1 min, ensuring that the holey carbon-covered side makes contact with the solution. After 1 min, recover each grid carefully by sliding the tweezers into the tweezer groove of each non-buffer exchange well.

- Very gently and briefly touch the copper, non-carbon-covered side of each grid to the ddH2O in the adjacent well. Then, carefully and gently hold the grid, water droplet-side down, against a piece of filter paper.

NOTE: Blotting off the water will draw the GrOx suspension through the grid by capillary action. It is crucial to avoid submerging the grid in the ddH2O, so contact should be very brief. When the grid is lifted, a droplet of water should hold to the underside of the grid. Take care not to move the grid on the filter paper as this could upset the settling of the GrOx flakes. - Leave the grids in the tweezers to air-dry until preparation with sample. Ideally, cover the grids during the drying process to avoid airborne contamination.

5. Application of the support floatation block for the preparation of samples on monolayer-graphene films

- Wash the TEM grids as outlined above (section 1), but omitting plasma-cleaning.

NOTE: Here, 300 mesh holey-carbon gold grids were used, but other non-copper grids or copper alloy grids are also practicable. - To deposit grids with graphene, directly transfer from graphene grown on copper (Cu-graphene) substrates to cryo-EM grids, as described previously25.

- Place four washed grids on top of a Cu-graphene sheet (10 mm × 10 mm) deposited onto a glass slide, and cover each grid with a drop of isopropanol (5-10 µL) to allow intimate contact between the monolayer graphene and the grid.

NOTE: Make sure to place the holey carbon-covered side of the grids in contact with the graphene sheet. - When the isopropanol is completely evaporated (typically 2 h), float the Cu-graphene sheet with grids onto 10% (w/v) FeCl3 solution (see section 2.3) in a glass Petri dish, and leave to etch at room temperature overnight. Cover the dish to avoid airborne contamination.

NOTE: After etching is complete, only the graphene monolayer will remain floating on the FeCl3 solution-this should be visible by eye with suitable lighting. - Use a loop with diameter larger than the TEM grid size to fish the grids floating on the graphene monolayer, and carefully transfer to a glass Petri dish containing ddH2O to wash.

NOTE: Be extremely cautious when fishing the grids to avoid hitting the walls of the Petri dish, which may cause graphene film breakage or bending. - Wash two more times in water by fishing grids and transferring to a clean Petri dish containing ddH2O to remove all residual FeCl3. Finally, transfer grids into a Petri dish containing sample buffer until sample preparation and plunge-freezing.

NOTE: The graphene-covered side of the grids must be kept wetted at all times to avoid their exposure to airborne contaminants.

- Place four washed grids on top of a Cu-graphene sheet (10 mm × 10 mm) deposited onto a glass slide, and cover each grid with a drop of isopropanol (5-10 µL) to allow intimate contact between the monolayer graphene and the grid.

- Pipette the sample (10-12 µL) into a non-buffer exchange well of the floatation block. When the sample is ready in the block, pick a graphene-coated grid from the buffer solution using a pair of clean tweezers, and place onto the surface of the sample-containing well.

- After an appropriate incubation period (1-5 min depending on the sample; optimize according to experimental needs), pick the grid with a pair of clean freezing tweezers, and proceed with blotting and vitrification.

Representative Results

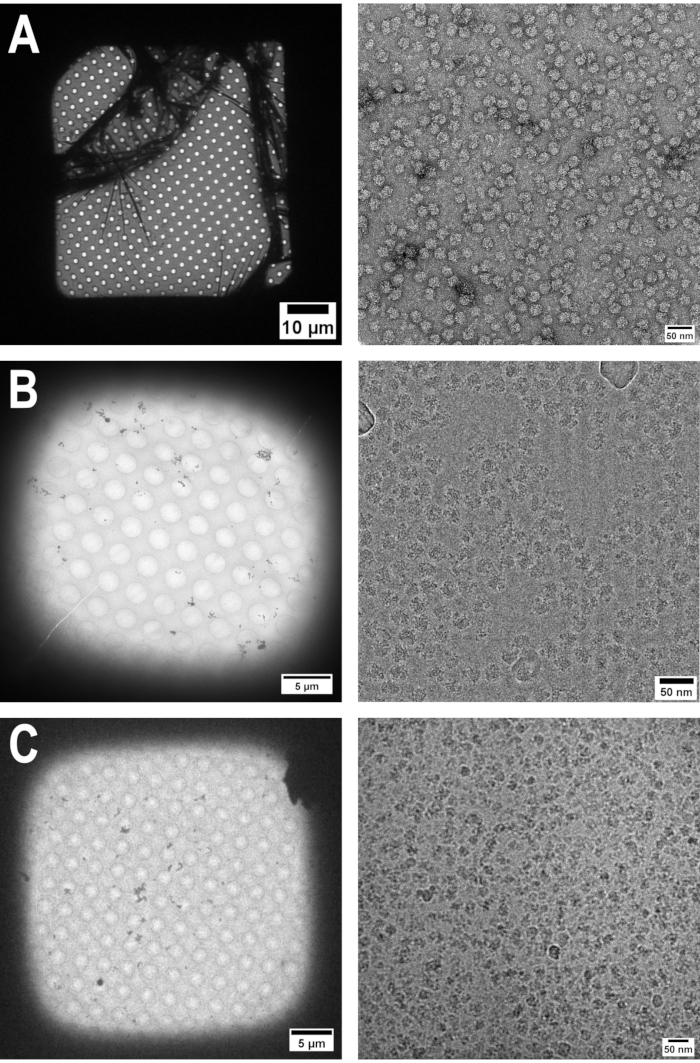

TEM grids prepared with amorphous carbon supports are typically covered across the entire grid surface. Although breakage of the carbon film occurs in some instances along with some ruffling (Figure 2A), a large number of grid squares are pristine and thus widely applicable for negative staining purposes. The major factor affecting the integrity of the support is the carbon thickness, which is determined during carbon evaporation. Similarly, with this GrOx protocol, good coverage is routinely achieved across the entire grid (Figure 2B). A single application of GrOx suspension for 1 min is sufficient to ensure few areas with multiple layers, which are easy to see due to flake edges. GrOx grids can be prepared quickly from raw materials and are highly protective of the sample. However, flake edges, incomplete coverage, and ruffling are more frequently visible with GrOx grids than for the other techniques because of the nature of the GrOx flakes.

Although the integrity of the graphene support film, like the amorphous carbon, depends on the deposition process, areas that are well-covered display the characteristic diffraction pattern of single-layer graphene. Importantly, by keeping graphene support films wetted, samples can be recovered from the floatation block after an incubation period and data collected in a manner amenable for single-particle analysis. This method does not require any other treatment of the graphene for wetting, thereby removing the requirement for expensive equipment to render graphene hydrophilic, and it is best to prepare support films shortly prior to sample preparation and grid freezing (Figure 2C).

Figure 1: Sample floatation block design and application during support film preparation. (A) Schematic of top, well, and side views of the floatation block including measurements of the shape, depth, and incline. The groove for tweezer tips to rest, as well as channels to insert needles, are indicated. (B) Amorphous carbon layers can easily be floated onto the surface of buffer contained within the wells of the floatation block using the ramp, i.e., during the preparation of negatively stained TEM grids. (C) The width of the wells is suited to accommodate one TEM grid, whilst the tweezer grooves reduce the need to release and pick up grids unnecessarily during preparation steps, but offer a defined path to recover grids without risk of bending if grids are released. Images in B are modified from 27. Abbreviation: TEM = transmission electron microscopy. Please click here to view a larger version of this figure.

Figure 2: Typical examples of sample support films prepared using the floatation block. Grid square (left) and image (right) views are shown for (A) amorphous carbon, (B) graphene oxide, and (C) graphene support films prepared using the floatation block. The amorphous carbon support was used in the preparation of 70S ribosomes for negative staining, whereas the graphene oxide and graphene supports were used in the preparation of 70S ribosomes for cryo-EM. Images in A and C are modified from 27. Scale bar for A grid square = 10 µm; scale bars for B and C grid squares = 5 µm; scale bars for A–C image views = 50 nm. Abbreviation: cryo-EM = cryo-electron microscopy. Please click here to view a larger version of this figure.

Discussion

This paper presents protocols for handling of both amorphous carbon and graphene films for cryo-EM sample preparation using a sample floatation block27. An STL file for the support block is freely available from the public Thingiverse repository [www.thingiverse.com/thing:3440684], and can be 3D-printed with any suitable stereolithography printer from a suitable resin. The use of carbon films covering a TEM grid usually involves the carbon floatation onto the sample28. This approach to preparing negative stain grids minimizes air exposure during support handling, thus reducing contamination and protein denaturation. The preparation of grids using floating carbon in small wells is advantageous to floating a larger surface area, i.e., in a water bath or Petri dish, in which case mechanical shearing of the carbon occurs much more readily.

UAc may be difficult to purchase due to current health and safety regulations at the time of publication. Many other commonly used, non-radioactive, negative staining reagents are available, and protocols for their preparation have been described previously29. Although alternative stains have not been used with this support floatation block, it is not likely that there would be any differences in these protocols besides the optimization of incubation time with sample (step 3.5), which is already inherently sample-dependent. The key step in this GrOx support preparation protocol is step 4.4, highlighted by the note to prevent the water and GrOx solution from making contact around the grid edge. Inappropriate mixing of the water and GrOx solutions prevents unidirectional settling of the GrOx flakes by capillary action. Having GrOx flakes on both sides of the carbon foil results in thick layers, thus negating the advantages of using GrOx as a near-single layer support, as well as trapping water between the flakes, which causes contamination of useable areas with additional layers of ice. Graphene oxide support preparation is relatively easy to achieve using droplets of solution on flexible polyolefin film. However, when performed in that way, it is easier to accidentally contaminate the copper side of the grid by mishandling errors; the use of the floatation block reduces the likelihood of this eventuality.

Finally, this paper presents a protocol to prepare graphene-covered grids that avoids any kind of graphene pretreatment to render it hydrophilic, thus reducing its cost and increasing its accessibility. Maintaining a wetted film throughout specimen preparation and applying the sample in situ in the block just before freezing is sufficient to allow the generation of suitable ice layers for cryo-EM with a homogeneous sample distribution. Overall, the protocols presented here minimize sample contact with the air-water interface, therefore reducing sample denaturation and support contamination. For the three support films used in these approaches, homogeneous sample distributions could be achieved across the grids along with imaging of intact, well-preserved single particles.

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

The authors would like to thank all the members of the Section for Structural & Synthetic Biology at Imperial College London who have helped test these techniques, as well as Harry Barnett at the Imperial College Advanced Hackspace, and Paul Simpson at the Centre for Structural Biology. CHSA is supported by a Sir Henry Dale Fellowship jointly funded by the Wellcome Trust and the Royal Society (206212/Z/17/Z).

Materials

| Basic Plasma Cleaner (230 V) | Harrick Plasma | PDC-32G-2 | |

| Dumont tweezers N5A INOX. | Dumont Swissmade | 0302-N5A-PO | |

| Dumont tweezers NGG INOX. | Dumont Swissmade | 0102-NGG-PO | |

| Ehtylacetate | Sigma-Aldrich | 270989-250ML | |

| Fishing Loops 10 μL | VWR | 612-9353 | |

| Graphene Oxide 2 mg/mL | Sigma-Aldrich | 763705-25ML | |

| Iron (III) chloride | Sigma-Aldrich | 31232-250MG | |

| Mica Sheets 75 mm x 25 mm x 0.15 mm | Agar Scientific | AGG250-1 | We usually coat mica with a target carbon film thickness of 2 nm |

| Monolayer Graphene on Cu | Graphenea | N/A | 10 mm x 10 mm, pack of 4 |

| n-dodecyl β-D-maltoside (DDM) | GLYCON Biochemicals GmbH | D97002-C | |

| Quantifoil R1.2/1.3 300 mesh copper grids | Enzo Life Sciences | JBS-X-101-Cu300 | |

| Quantifoil R2/1 300 mesh copper grids | Enzo Life Sciences | JBS-X-102-Cu300 | |

| Quantifoil R2/1 300 mesh gold grids | Electron Microscopy Sciences | Q350AR1 | |

| Scissors | Agar Scientific | AGT577 | |

| Uranyl Acetate | TAAB Laboratories Equipment | U001 | |

| Vitrobot Mark IV | FEI | N/A | |

| Whatman filter paper 55 mm | GE Healthcare Life Sciences | 1441-055 | |

| Whatman filter paper 70 mm | GE Healthcare Life Sciences | 1441-070 |

Riferimenti

- Frank, J. Advances in the field of single-particle cryo-electron microscopy over the last decade. Nature Protocols. 12 (2), 209-212 (2017).

- Lyumkis, D. Challenges and Opportunities in Cryo-EM Single-Particle Analysis. Journal of Biological Chemistry. 294 (13), 5181-5197 (2019).

- Elmlund, D., Elmlund, H. Cryogenic Electron Microscopy and Single-Particle Analysis. Annual Review of Biochemistry. 84 (1), 499-517 (2015).

- Thompson, R. F., Walker, M., Siebert, C. A., Muench, S. P., Ranson, N. A. An introduction to sample preparation and imaging by cryo-electron microscopy for structural biology. Methods. 100, 3-15 (2016).

- Arnold, S. A., et al. Miniaturizing EM Sample Preparation: Opportunities, Challenges, and “Visual Proteomics”. Proteomics. 18 (5-6), 1700176 (2018).

- Wu, S., Armache, J. P., Cheng, Y. Single-particle cryo-EM data acquisition by using direct electron detection camera. Microscopy. 65 (1), 35-41 (2016).

- Noble, A. J., et al. Routine single particle CryoEM sample and grid characterization by tomography. eLife. 7, 34257 (2018).

- Grimm, R., Typke, D., Bärmann, M., Baumeister, W. Determination of the inelastic mean free path in ice by examination of tilted vesicles and automated most probable loss imaging. Ultramicroscopy. 63 (3-4), 169-179 (1996).

- Glaeser, R. M. Proteins, interfaces, and cryo-EM grids. Current Opinion in Colloid and Interface Science. 34, 1-8 (2018).

- D’Imprima, E., Floris, D., Joppe, M., Sánchez, R., Grininger, M., Kühlbrandt, W. Protein denaturation at the water-air interface and how to prevent it. eLife. 8, 400432 (2019).

- Bai, X. C., Fernandez, I. S., McMullan, G., Scheres, S. H. W. Ribosome structures to near-atomic resolution from thirty thousand cryo-EM particles. eLife. 2013 (2), 00461 (2013).

- Russo, C. J., Passmore, L. A. Controlling protein adsorption on graphene for cryo-EM using low-energy hydrogen plasmas. Nature Methods. 11 (6), 649-652 (2014).

- Naydenova, K., Russo, C. J. Measuring the effects of particle orientation to improve the efficiency of electron cryomicroscopy. Nature Communications. 8 (1), 8-12 (2017).

- Jain, T., Sheehan, P., Crum, J., Carragher, B., Potter, C. S. Spotiton: A prototype for an integrated inkjet dispense and vitrification system for cryo-TEM. Journal of Structural Biology. 179 (1), 68-75 (2012).

- Razinkov, I., et al. A new method for vitrifying samples for cryoEM. Journal of Structural Biology. 195 (2), 190-198 (2016).

- Feng, X., et al. A Fast and Effective Microfluidic Spraying-Plunging Method for High-Resolution Single-Particle Cryo-EM. Structure. 25 (4), 663-670 (2017).

- Ermantraut, E., Wohlfart, K., Tichelaar, W. Perforated support foils with pre-defined hole size, shape and arrangement. Ultramicroscopy. 74 (1-2), 75-81 (1998).

- Adrian, M., Dubochet, J., Lepault, J., McDowall, A. W. Cryo-electron microscopy of viruses. Nature. 308 (5954), 32-36 (1984).

- Fujiyoshi, Y. The structural study of membrane proteins by electron crystallography. Advances in Biophysics. 35, 25-80 (1998).

- Koning, R. I., Oostergetel, G. T., Brisson, A. Preparation of flat carbon support films. Ultramicroscopy. 94 (34), 183 (2003).

- Hummers, W. S., Offeman, R. E. Preparation of Graphitic Oxide. Journal of the American Chemical Society. 80 (6), 1339 (1958).

- Pantelic, R. S., Meyer, J. C., Kaiser, U., Baumeister, W., Plitzko, J. M. Graphene oxide: A substrate for optimizing preparations of frozen-hydrated samples. Journal of Structural Biology. 170 (1), 152-156 (2010).

- Pantelic, R. S., et al. Graphene: Substrate preparation and introduction. Journal of Structural Biology. 174 (1), 234-238 (2011).

- Li, X., et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science. 324 (5932), 1312-1314 (2009).

- Regan, W., et al. A direct transfer of layer-area graphene. Applied Physics Letters. 96 (11), 2008-2011 (2010).

- Brilot, A. F., et al. Beam-induced motion of vitrified specimen on holey carbon film. Journal of Structural Biology. 177 (3), 630-637 (2012).

- de Martín Garrido, N., et al. Direct transfer of electron microscopy samples to wetted carbon and graphene films via a support floatation block. Journal of Structural Biology. 213 (1), 107677 (2021).

- Valentine, R. C., Shapiro, B. M., Stadtman, E. R. Regulation of Glutamine Synthetase. XII. Electron Microscopy of the Enzyme from Escherichia coli. Biochimica. 7 (6), 2143-2152 (1968).

- Scarff, C. A., Fuller, M. J. G., Thompson, R. F., Iadaza, M. G. Variations on negative stain electron microscopy methods: Tools for tackling challenging systems. Journal of Visualized Experiments. (132), e57199 (2018).