收敛抛光:高品质光学平面与球的一种简单,快速,全口径抛光工艺

Summary

A novel optical polishing process, called “Convergent Polishing”, which enables faster, lower cost polishing, is described. Unlike conventional polishing processes, Convergent Polishing allows a glass workpiece to be polished in a single iteration and with high surface quality to its final surface figure without requiring changes to polishing parameters.

Abstract

会聚抛光是一种新颖的抛光系统及方法用于精加工平面和球形玻璃光学其中一个工件,独立于它的初始形状( 即表面图),将收敛到最终表面的数字与下一个固定的,不变的一组良好的表面质量在单个抛光迭代抛光参数。与此相反,常规的全口径抛光方法需要多个常长,涉及抛光,计量和工艺变化以获得所需的表面图的迭代循环。的收敛抛光过程是基于工件 – 研具失配的高度造成的压力差,与去除并导致工件会聚到搭接的形状减小的概念。成功地执行收敛抛光处理的是若干的技术的结合的结果,以除去非均匀的空间的材料去除(所有来源除了工件 – 研具失配)为表面图形收敛性和减少在系统中为低刮密度和低粗糙度流氓颗粒的数目。的收敛抛光过程已被证明为单位和各种形状,尺寸的球体,以及各种玻璃材料的长宽比的制造。的实际影响是,高品质的光学元件,可以更快速地制造,更多次,以较少的计量,并以更少的劳动,从而降低了单位成本。在这项研究中,收敛抛光协议是专门用于制造26.5厘米正方形熔融二氧化硅单位从细地面表面到抛光〜λ/ 2的表面图抛光表面每4小时就A 81厘米直径的抛光后说明。

Introduction

在一个典型的光学制造工艺的主要步骤包括整形,打磨,全口径抛光,有时小工具抛光1-3。凭借高品质的光学元件的需求成像和激光系统不断增加,出现了光学加工显著的进步在过去的几十年。例如,精密,确定性材料去除现在可以塑造和打磨工艺,在计算机数字控制的进步(CNC)玻璃成型机中。同样地,小工具抛光技术( 例如 ,计算机控制光学表面(CCOS),离子辩别,而磁流变精加工(MRF)),导致确定性材料去除和表面形状控制,从而强烈地影响光学制造工业。然而,在整理过程中,全口径抛光的中间步骤,仍然缺乏确定性较高,通常需要熟练的opticiaNS开展多个,长常,迭代周期,多工艺变化,实现对所需的表面图1-3。

大量的研磨方法中,过程变量,以及复杂的化学和工件,搭接和浆料3-4之间的机械相互作用作出它具有挑战性的,从一个“艺术”到科学变换光学研磨。为了实现确定性全口径抛光,该材料去除速率,必须很好地理解。从历史上看,材料去除速率已经描述了广泛的应用普雷斯顿公式5

(1)

(1)

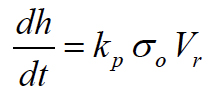

其中,DH / dt是平均厚度去除率,K p是普雷斯顿恒定的,σO被所施加的压力,而V r是在工件和研具之间的平均相对速度。 图1示意性地示出了如所描述的普雷斯顿公式,包括在速度的空间和时间的变化和压力,之间的差别影响的材料去除速率的物理概念施加的压力和压力分布工件经历,和摩擦效应6-8。具体地,经历了由工件的实际压力分布由一些现象强烈影响所得工件的表面图(在别处详细描述的6-8)的约束。另外,在普雷斯顿公式,微观和分子水平的影响在很大程度上折叠成宏观普雷斯顿常数(k p)的 ,这影响了整体材料去除率,微观粗糙度,甚至刮伤工件上。各种研究已扩大普雷斯顿的模型来解释对于微观粒子的浆垫,工件的相互作用来解释材料去除率和微粗糙度9-16。

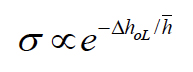

为了实现表面图的过程中充分孔径抛光确定性控制中,每个上述的现象,需要理解,量化,然后进行控制。后面收敛抛光的策略是消除或最小化的材料去除不均匀的不良的原因,无论是通过工程化抛光的设计或通过过程控制,使得去除仅驱动由工件-研具失配由于工件形状7,17- 18。 图2说明了如何根据工件-研具失配的概念工件形状可导致收敛。考虑一台一圈,并在左上方显示复杂形状的工件的假设。该接口高度不匹配(称为间隙,ΔHOL)影响界面压力分布(σ)为:

内容“FO:保持together.within页=”总是“> (2)

(2) 其中,h是常数,描述的速率将压力下降的增加间隙的ΔhOL 6。在这个例子中,工件具有在中心的最高局部压力(参见图2的左下角),因此这个位置将抛光期间观察的最高初始材料去除速率。作为材料被去除,横跨工件的压力差会减小,由于在工件 – 研具失配的降低,工件会收敛到搭接的形状。在收敛时,工件的压力分布,并且因此材料去除,将横跨该工件均匀(参照图2右侧的)。这个例子说明了一个平面搭接,howev呃同样的概念适用于一个球形棉卷(凹或凸)。同样,如果所有影响空间的材料的不均匀等现象已经消除了这种融合的过程才有效。在收敛抛光协议实施的具体程序和工程缓解在讨论中描述。

在以下研究中所描述的协议是收敛的抛光过程专门为26.5平方厘米的熔融石英玻璃工件从细地面开始。在8小时内抛光的(4小时/面),此工件可达到〜λ/ 2的抛光平坦度非常高的表面质量( 即低刮密度)。

Protocol

Representative Results

Discussion

正如引言中讨论,成功实现收敛相对于抛光表面图涉及消除或减少所有影响空间的材料的非均匀性,除了对工件 – 研具失配,由于工件形状的现象。如果这些现象的任何一个没有适当地减轻,无论是通过过程控制或通过抛光,然后将所需的会聚点不能达到或维持适当的工程;因此,每一个基本的缓解变得至关重要。为了说明这一点, 图6示出在工件上的收敛点的表面的图(表示为峰-谷?…

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

This work performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344 within the LDRD program.

Materials

| Name of Material/Equipment | Company | Catalog Number |

| MHN 50 mil Polyurethane Pad | Eminess Technologies | PF-MHN15A050L-56 |

| Cerium oxide polishing slurry | Universal Photonics | HASTILITE PO |

| Septum Glass (waterjet cut) | Borofloat ; Schott | NA |

| Diamond conditioner | Morgan Advanced Ceramics | CMP-25035-SFT |

| Ultrasonic Cleaner | Advanced Sonics Processing System | URC4 |

| Purification Optima Filter cartridge | 3M | CMP560P10FC |

| Blocking Pitch | Universal Photonics | BP1 |

| Blocking Tape | 3M | #4712 |

| Cleanroom Cloth | ITW Texwipe | AlphaWipe TX1013 |

| Single Particle Optical Sensing | Paritcle Sizing Systems | Accusizer 780 AD |

Riferimenti

- Anderson, D., Burge, J., Thompson, B., Malacara, D. Ch 28. Handbook of optical engineering. Optical fabrication. , (2001).

- Karow, H. . Fabrication Methods for Precision Optics. , (1993).

- Brown, N. J. A short course in optical fabrication technology. , (1981).

- Cook, L. Chemical processes in glass polishing. J. Non-Crystal. Solids. 120, 152-171 (1990).

- Preston, F. The Structure of Abraded Glass Surfaces. Trans. Opt. Soc. 23 (3), 141-14 (1922).

- Suratwala, T., Feit, M., Steele, R. Toward Deterministic Material Removal and Surface Figure During Fused Silica Pad Polishing. J. Am. Ceram. Soc. 93 (5), 1326-1340 (2010).

- Suratwala, T., Steele, R., Feit, M., Desjardin, R., Mason, D. Convergent Pad Polishing of amorphous fused silica. International Journal of Applied Glass Science. 3 (1), 14-28 (2012).

- Suratwala, T., Feit, M., Steele, R., Wong, L. Influence of Temperature and Material Deposit on Material Removal Uniformity during Optical Pad Polishing. J. Am. Ceram. Soc. , (2014).

- Suratwala, T. Microscopic removal function and the relationship between slurry particle size distribution and workpiece roughness during pad polishing. J. Am. Ceram. Soc. 91 (1), 81-91 (2014).

- Terrell, E., Higgs, C. Hydrodynamics of Slurry Flow in Chemical Mechanical Polishing. J. Electrochem. Soc. 153 (6), 15-22 (2006).

- Runnels, S., Eyman, L. Tribology Analysis of Chemical MechanicalPolishing. J. Electrochem. Soc. 141 (6), 1698-1701 (1994).

- Park, S., Cho, C., Ahn, Y. Hydrodynamic Analysis of Chemical Mechanical Polishing Process. J. Tribology Int. 33, 723-730 (2000).

- Luo, J., Dornfeld, D. Effects of Abrasive Size Distribution in Chemical Mechanical Planarization: Modeling and Verification. IEEE T. Semicond. M. 16 (3), 469-476 (2003).

- Luo, J., Dornfeld, D. Material Removal Mechanism in Chemical Mechanical Polishing: Theory and Modeling. IEEE T. Semiconduct. M. 14, 112-133 (2001).

- Bastaninejad, M., Ahmadi, G. Modeling the Effects of Abrasive Size Distribution, Adhesion, and Surface Plastic Deformation on Chemical Mechanical Polishing. J. Electrochem. Soc. 152 (9), 720-730 (2005).

- Sampurno, Y., Sudargho, F., Zhuang, Y., Ashizawa, T., Morishima, H., Philipossian, A. Effect of Cerium Oxide Particles Sizes in Oxide Chemical Mechanical Planarization. Electrochem. Solid State. 12 (6), 191-194 (2009).

- Suratwala, T., et al. Method and system for Convergent Polishing. US Provisional Patent Application. , (2011).

- Suratwala, T., Feit, M., Steele, R. Apparatus and Method for Deterministic Control of Surface Figure During Full Aperture Polishing. US Patent Application. US. , (2010).

- Dylla-Spears, R., Feit, M., Miller, P., Steele, R., Suratwala, T., Wong, L. Method for preventing agglomeration of charged colloids without loss of surface activity. US Provisional Patent Application. , (2012).

- Dylla-Spears, R., Wong, L., Miller, P., Feit, M., Steele, R., Suratwala, T. Charged Micelle Halo Mechanism for Agglomeration Reduction in Metal Oxide Particle Based Polishing Slurries. Colloid Surface A. 447, 32-43 (2014).

- Wong, L., Suratwala, T., Feit, M., Miller, P., Steele, R. The Effect of HF/NH4F Etching on the Morphology of Surface Fractures on Fused Silica. J. Non-Crystal. Solids. 355, 797 (2009).

- Feit, M., DesJardin, R., Steele, R., Suratwala, T. Optimized pitch button blocking for polishing high-aspect-ratio optics. Appl. Opt. 51 (35), 8350-8359 (2013).

- Suratwala, T., et al. Sub-surface mechanical damage distributions during grinding of fused silica. J. Non-Crystal. Solids. 352, 5601 (2006).

- Miller, P., et al. The Distribution of Sub-surface Damage in Fused Silica. SPIE. 5991, (2005).

- Suratwala, T., et al. Effect of Rogue particles on the sub-surface damage of fused silica during grinding/polishing. J. Non-Crystal. Solids. 354, 2003 (2008).

- Suratwala, T., Miller, P., Ehrmann, P., Steele, R. Polishing slurry induced surface haze on phosphate laser glasses. J. Non-Crystal. Solids. 351, 2091-2101 (2004).