A Millimeter Scale Flexural Testing System for Measuring the Mechanical Properties of Marine Sponge Spicules

Summary

We present a protocol for performing three-point bending tests on sub-millimeter scale fibers using a custom-built mechanical testing device. The device can measure forces ranging from 20 µN up to 10 N and can therefore accommodate a variety of fiber sizes.

Abstract

Many load bearing biological structures (LBBSs)—such as feather rachises and spicules—are small (<1 mm) but not microscopic. Measuring the flexural behavior of these LBBSs is important for understanding the origins of their remarkable mechanical functions.

We describe a protocol for performing three-point bending tests using a custom-built mechanical testing device that can measure forces ranging from 10-5 to 101 N and displacements ranging from 10-7 to 10-2 m. The primary advantage of this mechanical testing device is that the force and displacement capacities can be easily adjusted for different LBBSs. The device's operating principle is similar to that of an atomic force microscope. Namely, force is applied to the LBBS by a load point that is attached to the end of a cantilever. The load point displacement is measured by a fiber optic displacement sensor and converted into a force using the measured cantilever stiffness. The device's force range can be adjusted by using cantilevers of different stiffnesses.

The device's capabilities are demonstrated by performing three-point bending tests on the skeletal elements of the marine sponge Euplectella aspergillum. The skeletal elements—known as spicules—are silica fibers that are approximately 50 µm in diameter. We describe the procedures for calibrating the mechanical testing device, mounting the spicules on a three-point bending fixture with a ≈1.3 mm span, and performing a bending test. The force applied to the spicule and its deflection at the location of the applied force are measured.

Introduction

By studying the architectures of load bearing biological structures (LBBSs), such as shell and bone, engineers have developed new composite materials that are both strong and tough 1. It has been shown that the remarkable mechanical properties of LBBSs and their bio-inspired counterparts are related to their intricate internal architectures 2. However, the relationships between LBBS architectures and mechanical properties are not fully understood. Measuring a LBBS's mechanical response is the first step toward understanding how its architecture enhances its mechanical properties.

However, it is important that the type of test used to measure a LBBS's mechanical response is consistent with its mechanical function. For example, since feathers must support aerodynamic loads, the primary function of a feather rachis is to provide flexural stiffness 3. Therefore, a bending test is preferred to a uniaxial tension test for measuring its mechanical response. In fact, many LBBSs—such as feather rachises 3, grass stems 4, and spicules 5,6,7,8—primarily deform by bending. This is because these LBBSs are slender—i.e., their length is much greater than their width or depth. However, performing bending tests on these LBBSs is challenging because the forces and displacements that they can withstand before failing range from 10-2 to 102 N and 10-4 to 10-3 m, respectively 3,4,5,7,8. Consequently, the device used to perform these mechanical tests should have force and displacement resolutions of ≈10-5 N and ≈10-7 m (i.e., 0.1% of the sensor's maximum measureable force and displacement), respectively.

Commercially available, large scale, mechanical testing systems typically cannot measure forces and displacements with this resolution. While atomic force microscope-based 9,10 or microelectromechanical systems-based 11 testing devices have adequate resolution, the maximum force (respective displacement) they can measure is smaller than the maximum force (respective displacement) that the LBBS can withstand. Therefore, to perform bending tests on these LBBSs, engineers and scientists must rely on custom-built mechanical testing devices 5,7,12,13. The primary advantage of these custom-built devices is that they can accommodate large ranges of forces and displacements. However, the construction and operation of these devices is not well documented in the literature.

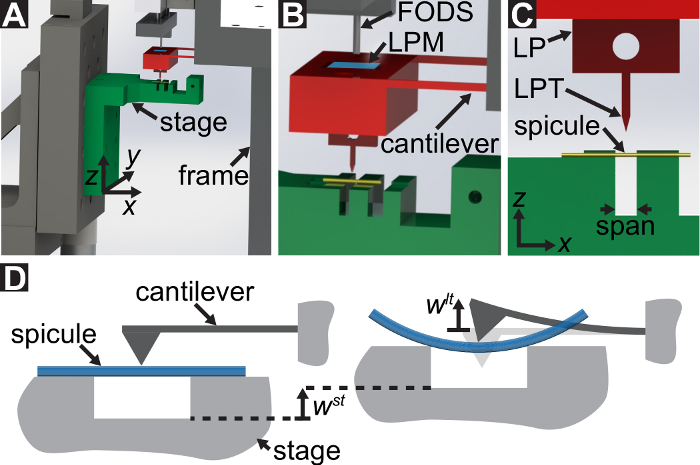

A protocol is described for performing three-point bending tests using a custom-built mechanical testing device that can measure forces ranging from 10-5 to 101 N and displacements ranging from 10-7 to 10-2 m. Technical drawings, including all dimensions, of the components of the mechanical testing device are provided in the Supplementary Material. The primary advantage of this mechanical testing device is that the force and displacement ranges can be easily adjusted to suit different LBBSs. The device's operating principle is similar to that of an atomic force microscope 9. In this device, a specimen is placed across a trench cut in a stainless steel plate (see Figure 1A-C). The span of the trench is measured from optical micrographs to be 1278 ± 3 µm (mean ± standard deviation; n = 10). The trench edges support the specimen during a bending test (see Figure 1C, and D). This sample stage is attached to a three-axis translation stage and positioned beneath an aluminum wedge so that the wedge is located midway across the trench's span (see Figure 1C). By moving the stage in the  direction (see Figure 1A, and C), the specimen is pushed into the wedge causing the specimen to bend.

direction (see Figure 1A, and C), the specimen is pushed into the wedge causing the specimen to bend.

We refer to the wedge as the load point tip (LPT) and the component of the device that contains the wedge as the load point (LP). The LP is attached to the end of a cantilever whose displacement is measured by a fiber optic displacement sensor (FODS). The FODS emits infrared light, which is reflected off of a mirror located on the top surface of the LP (see Figure 1B) and received by an optical fiber in the FODS. A ≈5 mm square piece of a polished silicon wafer is used as the LP mirror and is affixed to the LP using epoxy. The FODS measures displacements by comparing the intensities of the emitted and reflected light. The cantilever stiffness and displacement are used to compute the force,  , experienced by the wedge due to its interaction with the specimen. The cantilever displacement is also used to compute the displacement of the specimen's cross-section beneath the wedge,

, experienced by the wedge due to its interaction with the specimen. The cantilever displacement is also used to compute the displacement of the specimen's cross-section beneath the wedge,  . Cantilever-based force sensors have been used in a number of micro- and macro-scale mechanical testing studies 10,11,12,13,14. The specific design presented here is adapted from a mechanical testing device used for performing adhesive contact experiments 14. A similar design has also been used in a commercially available micro-tribometer 15,16.

. Cantilever-based force sensors have been used in a number of micro- and macro-scale mechanical testing studies 10,11,12,13,14. The specific design presented here is adapted from a mechanical testing device used for performing adhesive contact experiments 14. A similar design has also been used in a commercially available micro-tribometer 15,16.

Figure 1: Overview of the custom-built mechanical testing device. (A) A computer aided design rendering of the device. The stage components are highlighted in green. The force sensing subassembly (cantilever, load point (LP)) is highlighted in red. (B) A magnified view of (A). The LP mirror is shown in blue on the top surface of the LP beneath the FODS and is labeled LPM. (C) The coordinate system used to describe the motion of the translation stage. By leveling the stage in step 1.9 of the protocol, the  direction is made to coincide with the vector normal to the surface of the LP mirror. (D) A schematic of the three-point bending configuration showing the deformation of the spicule and the measured displacements

direction is made to coincide with the vector normal to the surface of the LP mirror. (D) A schematic of the three-point bending configuration showing the deformation of the spicule and the measured displacements  , and

, and  . Please click here to view a larger version of this figure.

. Please click here to view a larger version of this figure.

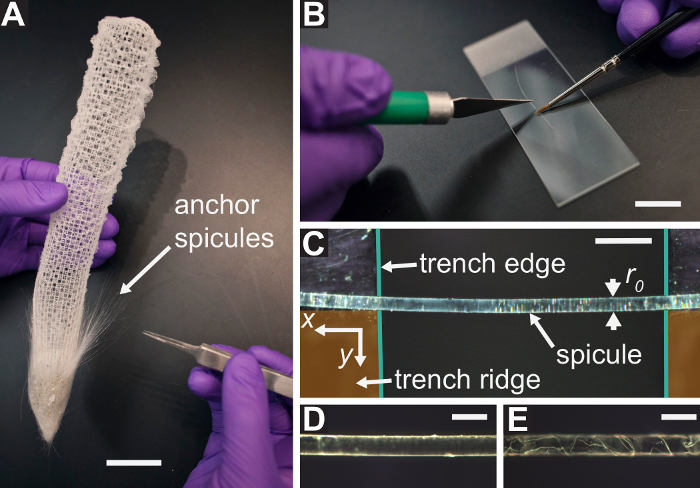

The device's capabilities are demonstrated by performing three-point bending tests on the skeletal elements of the marine sponge Euplectella aspergillum6,7. This sponge's skeleton is an assembly of filaments, called spicules (see Figure 2A). The spicules are ≈50 µm thick and are composed primarily of silica 6. Biosilica-based spicules are found in sponges belonging to the classes Demospongiae, Homoscleromorpha, and Hexactinellida. Sponges, such as E. aspergillum, that belong to the class Hexactinellida are also known as "glass sponges." While the spicules of glass sponges are composed primarily of silica, it has been shown that the silica often contains an organic matrix composed of either collagen 17,18 or chitin 19,20,21. This organic matrix plays an important role in silica biomineralization 18,20. Furthermore, in some spicules the organic matrix also serves as a template for the biomineralization of calcium 22. In addition to being distributed within the silica, the organic matrix can also form distinct layers that partition the spicule's silica into concentric, cylindrical lamellae 6,23. It has been shown that this concentric, lamellar architecture can affect the spicules' deformation behavior 6,7,8,24,25,26. Consequently, the spicules' mechanical properties are determined by a combination of their chemistry (i.e., the chemical structure of the silica-protein composite) and their architecture 27. Both the chemical structure and architecture of glass sponge spicules are still under investigation 24,28,29.

Most of the spicules in E. aspergillum are cemented together to form a stiff skeletal cage. However, at the base of the skeleton there is a tuft of very long (≈10 cm) spicules known as the anchor spicules (see Figure 2A). We describe the protocol for performing three-point bending tests on small sections of the anchor spicules.

In step 1 of the protocol, the procedure for assembling and aligning the components of the custom-built mechanical testing device is described. Steps 2 and 4 of the protocol provide instructions for generating calibration data used to compute forces and displacements in the bending test. The steps taken to prepare a section of a spicule and mount it to the test fixture are described in step 3. The procedure for conducting the bending test on the spicule section is described in step 5. Finally, in the Representative Results section the calibration data obtained in steps 2 and 4 are used along with the bending test data obtained in step 5 to compute  and

and  .

.

Figure 2: Procedure for sectioning and inspecting E. aspergillum spicules. (A) The skeleton of E. aspergillum. The tuft of free-standing anchor spicules is shown at the base of the skeleton. The scale bar is ~25 mm. (B) A single anchor spicule is held in place on a microscope slide using a #00000 red sable brush and sectioned using a razor blade. The scale bar is ~12 mm. (C) A section of an E. aspergillum spicule placed across the trench on the sample stage. The trench edges and trench ridge are highlighted in teal and orange, respectively. The spicule is pushed against the trench ridge to ensure that its axis is perpendicular to the trench edges. (D) A micrograph of a spicule that passes the inspection procedure described in step 3.4 of the protocol, which describes how to determine if a spicule section is damaged and should be discarded. (E) A micrograph of a spicule containing many cracks and missing large sections of silica layers that would fail the inspection procedure described in step 3.4 of the protocol. Scale bars = 250 µm (C), 100 µm (D), and 100 µm (E). Please click here to view a larger version of this figure.

Protocol

Representative Results

Discussion

Several steps of the protocol are particularly important for ensuring that forces and displacements are measured accurately. While some of these critical steps are universal to all three-point bending tests, others are unique to this mechanical testing device.

In step 1.2 of the protocol the LP mirror is cleaned and inspected for scratches, and in step 1.6 of the protocol the FODS gain is set. It is important for the gain and the LP mirror reflectance to be co…

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

This work was supported by National Science Foundation [Mechanics of Materials and Structures Program, grant number 1562656]; and the American Society of Mechanical Engineers [Haythornthwaite Young Investigator Award].

Materials

| TMC 36" x 48" isolation table with 4" CleanTop breadboard | TMC | 63-563 | Isolation Table |

| Diffeential Screw Adjuster | Thorlabs | DAS110 | For stage leveling plate |

| 1" Travel Micrometer Head with 0.001" Graduations | Thorlabs | 150-801ME | For stage leveling plate |

| Right-Angle Bracket for PT Series Translation Stages, 1/4"-20 Mounting Holes | Thorlabs | PT102 | For microscope mount |

| 1" Dovetail Translation Stage, 1/4"-20 Taps | Thorlabs | DT25 | For microscope mount |

| 1" Translation Stage with 1/4"-170 Adjustment Screw, 1/4"-20 Taps | Thorlabs | PT1B | For microscope mount |

| 12" Length, Dovetail Optical Rail | Edmund Optics | 54-401 | For microscope mount |

| 2.5" Width, Dovetail Carrier | Edmund Optics | 54-404 | For microscope mount |

| 0.5" Width, Dovetail Carrier | Edmund Optics | 54-403 | For microscope mount |

| InfiniTube Mounting C-Clamp with ¼-20 | Edmund Optics | 57-788 | Microscope component |

| Standard (with no In-Line Attachment), InfiniTube | Edmund Optics | 56-125 | Microscope component |

| Standard In-Line Attachment (Optimized at 2X-10X), InfiniTube | Edmund Optics | 56-126 | Microscope component |

| Mitutoyo/Achrovid Objective Adapter (M26 to M27) | Edmund Optics | 53-787 | Microscope component |

| 5X Infinity Achrovid Microscope Objective | Edmund Optics | 55-790 | Microscope component |

| 0.316" ID, Fiber Optic Adapter SX-6 | Edmund Optics | 38-944 | Microscope component |

| ¼" x 36", Flexible Fiber Optic Light Guide | Edmund Optics | 42-347 | Microscope component |

| 115V, MI-150 Fiber Optic Illuminator w/IR Filter and Holder | Edmund Optics | 55-718 | Microscope component |

| Allied Vision Manta G-223 2/3" Color CMOS Camera | Edmund Optics | 88-452 | Microscope component |

| Power Supply for Manta/ Guppy Pro/ Stingray/ Pike | Edmund Optics | 68-586 | Microscope component |

| 1/4" Travel Single Axis Translation Stage | Thorlabs | MS1S | FODS micrometer |

| Analog Reflectance Dependent Fiber Optic Displacement Sensor | Philtec | D20 | FODS |

| 30V, 3A DC Power Supply | Agilent | U8001A | Power supply for DAQ and FODS |

| 14-Bit, 48 kS/s Low-Cost Multifunction DAQ | National Instruments | USB-6009 | DAQ for FODS |

| Three Axis Motorized Translation Stage | Thorlabs | Thorlabs T25 XYZ-E/M | Translation stage |

| T-Cube DC Servo Motor Controller | Thorlabs | TDC001 | Motor controller for stage |

| T-Cube Power Supply | Thorlabs | TPS001 | Power supply for motor controller |

| National Instruments LabVIEW (2013 SP1) | National Instruments | Used for running software | |

| National Instruments LabVIEW Vision Acquisition Software (2016) | National Instruments | Used for running software | |

| Nikon Eclipse Ci-POL Main Body | MVI | MDA96000 | Polarized light microscope |

| Nikon Pi Intermediate Tube with Analyzer Slider | MVI | MDB45305 | Polarized light microscope |

| Nikon Dia-Polarizer | MVI | MDN11920 | Polarized light microscope |

| Power Cord – 7'6" | MVI | 79035 | Polarized light microscope |

| Nikon P-Amh Mechanical Stage | MVI | MDC45000 | Polarized light microscope |

| Nikon Lwd Achromat Condenser | MVI | MBL16100 | Polarized light microscope |

| Nikon LV-NBD5BD-CH Manual Quint Nosepiece ESD | MVI | MBP60125 | Polarized light microscope |

| Nikon C-TF Trinocular Tube F | MVI | MBB93100 | Polarized light microscope |

| Nikon CFI 10X Eyepiece FN 22mm NC | MVI | MAK10110 | Polarized light microscope |

| Nikon TU Plan Flour BD 10x Objective | MVI | MUE42100 | Polarized light microscope |

| Venus Flower Basket Sponge | Denis Brand | N/A | Sponge skeleton |

| 3.5X Headband Flip-Up Magnifier | McMaster Carr | 1490T5 | Used for spicule sectioning |

| Ø1" Silicon Wafer, Type P / <100> | Ted Pella | 16011 | Used for load point mirror |

| Low Lint Tapered Tip Cotton Swab | McMaster Carr | 71035T31 | Used for cleaning LP mirror |

| Rubber grip precision knife | McMaster Carr | 35575A68 | Used for sectioning spicules |

| Microscope Slides, frosted end, 75 x 25 x 1mm | Ted Pella | 260409 | Used for sectioning spicules |

| Sable Brushes, #00000, 0.08mm W x 4.0mm L | Ted Pella | 11806 | Used for handling spicules |

| PELCO Pro High Precision Tweezers, extra fine tips, superior finish | Ted Pella | 5367-5NM | Used for handling spicules |

| Dual Axis Linear Scale Micrometer | Edmund Optics | 58-608 | Used for calibrating the microscopes |

| FLEX-A-TOP FT-38 CAS | ESD Plastic Containers | FT-38-CAS | Used for storing spicules |

| Plastic Vial Bullseye Level | McMaster Carr | 2147A11 | Used for leveling the stage |

| Analytical Balance | Mettler Toledo | MS105DU | Used to mass calibration weights |

Riferimenti

- Wegst, U. G., Bai, H., Saiz, E., Tomsia, A. P., Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14 (1), 23-36 (2015).

- Meyers, M. A., McKittrick, J., Chen, P. Y. Structural biological materials: critical mechanics-materials connections. Science. 339 (6121), 773-779 (2013).

- Bodde, S. G., Meyers, M. A., McKittrick, J. Correlation of the mechanical and structural properties of cortical rachis keratin of rectrices of the Toco Toucan (Ramphastos toco). J. Mech. Behav. Biomed. Mater. 4 (5), 723-732 (2011).

- Gibson, L. J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface. , (2012).

- Monn, M. A., Kesari, H. A new structure-property connection in the skeletal elements of the marine sponge Tethya aurantia that guards against buckling instability. Sci. Rep. 7, (2017).

- Monn, M. A., Weaver, J. C., Zhang, T., Aizenberg, J., Kesari, H. New functional insights into the internal architecture of the laminated anchor spicules of Euplectella aspergillum. Proc. Natl. Acad. Sci. U.S.A. 112 (16), 4976-4981 (2015).

- Monn, M. A., Kesari, H. Enhanced bending failure strain in biological glass fibers due to internal lamellar architecture. J. Mech. Behav. Biomed. Mater. , (2017).

- Levi, C., Barton, J. L., Guillemet, C., Bras, E., Lehuede, P. A remarkably strong natural glassy rod: the anchoring spicule of the Monorhaphis sponge. J. Mater. Sci. Letters. 8 (3), 337-339 (1989).

- Kesari, H., Doll, J. C., Pruitt, B. L., Cai, W., Lew, A. J. Role of surface roughness in hysteresis during adhesive elastic contact. Philos. Mag. Lett. 90 (12), 891-902 (2010).

- Croisier, F., et al. Mechanical testing of electrospun PCL fibers. Acta Biomater. 8 (1), 218-224 (2012).

- Haque, M. A., Saif, M. T. A review of MEMS-based microscale and nanoscale tensile and bending testing. Exp. Mech. 43 (3), 248-255 (2003).

- Gudlavalleti, S. . Mechanical testing of solid materials at the micro-scale. , (2002).

- Tohmyoh, H., Ishihara, M., Akanda, M. S., Yamaki, S., Watanabe, T., Iwabuchi, T. Accurate determination of the structural elasticity of human hair by a small-scale bending test. J. Biomech. 44 (16), 2833-2837 (2011).

- Waters, J. F. . Contact mechanics of biologically-inspired interface geometries. , (2009).

- Dai, Z., Gorb, S. N., Schwarz, U. Roughness-dependent friction force of the tarsal claw system in the beetle Pachnoda marginata (Coleoptera, Scarabaeidae). J. Exp. Biol. 205 (16), 2479-2488 (2002).

- Tramacere, F., Kovalev, A., Kleinteich, T., Gorb, S. N., Mazzolai, B. Structure and mechanical properties of Octopus vulgaris suckers. J. R. Soc. Interface. 11 (91), (2014).

- Ehrlich, H., et al. Nanostructural organization of naturally occurring composites: Part I. Silica-Collagen-based biocomposites. J. Nanomater. 53, (2008).

- Ehrlich, H., et al. Mineralization of the meter-long biosilica structures of glass sponges is templated on hydroxylated collagen. Nat. Chem. 2, 1084-1088 (2010).

- Ehrlich, H., et al. First evidence of the presence of chitin in skeletons of marine sponges. Part II. Glass sponges (Hexactinellida: Porifera). J. Exp. Zoo. 308 (4), 473-483 (2007).

- Ehrlich, H. Chitin and collagen as universal and alternative templates in biomineralization. Int. Geol Rev. 52, 661-699 (2010).

- Ehrlich, H., et al. Supercontinuum generation in naturally occurring glass sponge spicules. Adv. Opt. Mater. 4 (10), 1608-1613 (2016).

- Ehrlich, H., et al. Calcite reinforced silica-silica joints in the biocomposite skeleton of deep-sea glass sponges. Adv. Funct. Mater. 21, 3473-3481 (2011).

- Werner, P., Blumtritt, H., Zlotnikov, I., Graff, A., Dauphin, Y., Fratzl, P. Electron microscope analyses of the bio-silica basal spicule from the Monorhaphis chuni sponge. J. Struct. Biol. 191 (2), 165-174 (2015).

- Kolednik, O., Predan, J., Fischer, F. D., Fratzl, P. Bioinspired Design Criteria for Damage-Resistant Materials with Periodically Varying Microstructure. Adv. Funct. Mater. 21 (19), 3634-3641 (2011).

- Weaver, J. C., et al. Unifying design strategies in demosponge and hexactinellid skeletal systems. J. Adhes. 86 (1), 72-95 (2010).

- Walter, S. L., Flinn, B. D., Mayer, G. Mechanisms of toughening of a natural rigid composite. Mater. Sci. Eng. C. 27 (3), 570-574 (2007).

- Ehrlich, H. Silica biomineralization in Sponges. Encyclopedia of Geobiology. , 796-808 (2011).

- Zlotnikov, I., Werner, P., Fratzl, P., Zolotoyabko, E. Eshelby Twist as a possible source of lattice rotation in a perfectly ordered protein/silica structure grown by a simple organism. Small. 11 (42), 5636-5641 (2015).

- Zlotnikov, I., et al. A perfectly periodic three-dimensional protein/silica mesoporous structure produced by an organism. Adv. Mater. 26 (11), 1682-1687 (2014).

- Gere, J. M., Timoshenko, S. P. Chapter 5: Stresses in Beams. Mechanics of materials. , 205-217 (1997).

- Baratta, F. I., Matthews, W. T., Quinn, G. D. . Errors associated with flexure testing of brittle materials. , (1987).

- Quinn, G. D., Sparenberg, B. T., Koshy, P., Ives, L. K., Jahanmir, S., Arola, D. D. Flexural strength of ceramic and glass rods. J. Test. Eval. 37 (3), 1-23 (2009).

- Tattersall, H. G., Tappin, G. The work of fracture and its measurement in metals, ceramics and other materials. J. Mater. Sci. 1 (3), 296-301 (1966).