Measuring the Mechanical Properties of Glass Fiber Reinforcement Polymer Composite Laminates Obtained by Different Fabrication Processes

Summary

This paper describes a fabrication process for fiber-reinforced polymer matrix composite laminates obtained using the wet hand lay-up/vacuum bag method.

Abstract

The traditional wet hand lay-up process (WL) has been widely applied in the manufacturing of fiber composite laminates. However, due insufficiency in the forming pressure, the mass fraction of fiber is reduced and lots of air bubbles are trapped inside, resulting in low-quality laminates (low stiffness and strength). The wet hand lay-up/vacuum bag (WLVB) process for the fabrication of composite laminates is based on the traditional wet hand lay-up process, using a vacuum bag to remove air bubbles and provide pressure, and then carrying out the heating and curing process.

Compared with the traditional hand lay-up process, laminates manufactured by the WLVB process show superior mechanical properties, including better strength and stiffness, higher fiber volume fraction, and lower void volume fraction, which are all benefits for composite laminates. This process is completely manual, and it is greatly influenced by the skills of the preparation personnel. Therefore, the products are prone to defects such as voids and uneven thickness, leading to unstable qualities and mechanical properties of the laminate. Hence, it is necessary to finely describe the WLVB process, finely control steps, and quantify material ratios, in order to ensure the mechanical properties of laminates.

This paper describes the meticulous process of the WLVB process for preparing woven plain patterned glass fiber reinforcement composite laminates (GFRPs). The fiber volume content of laminates was calculated using the formula method, and the calculated results showed that the fiber volume content of WL laminates was 42.04%, while that of WLVB laminates was 57.82%, increasing by 15.78%. The mechanical properties of the laminates were characterized using tensile and impact tests. The experimental results revealed that with the WLVB process, the strength and modulus of the laminates were enhanced by 17.4% and 16.35%, respectively, and the specific absorbed energy was increased by 19.48%.

Introduction

Fiber reinforced polymer composite (FRP) is a type of high-strength material manufactured by mixing fiber reinforcement and polymer matrixes1,2,3. It is widely used in the aerospace4,5,6, construction7,8, automotive9, and marine10,11 industries due to its low density, high specific stiffness and strength, fatigue properties, and excellent corrosion resistance. Common synthetic fibers include carbon fibers, glass fibers, and aramid fibers12. Glass fiber was chosen for investigation in this paper. Compared to traditional steel, glass fiber reinforcement composite laminates (GFRPs) are lighter, with less than one-third of the density, but can achieve a higher specific strength than steel.

The preparation process of FRP includes vacuum-assisted resin transfer molding (VARTM)13, filament winding (FW)14, and prepreg molding, in addition to many other advanced fabrication processes15,16,17,18. Compared to other preparation processes, the wet hand lay-up/vacuum bag (WLVB) process has several advantages, including simple equipment requirements and uncomplicated process technology, and the products are not limited by size and shape. This process has a high degree of freedom and can be integrated with metal, wood, plastic, or foam.

The principle of the WLVB process is to apply greater forming pressure through vacuum bags to enhance the mechanical properties of the prepared laminates; the production technology of this process is easy to master, making it an economical and simple composite material preparation process. This process is completely manual, and it is greatly influenced by the skills of preparation personnel. Therefore, the products are prone to defects such as voids and uneven thickness, leading to unstable qualities and mechanical properties of the laminate. Hence, it is necessary to describe the WLVB process in detail, finely control steps, and quantify material proportion, in order to obtain a high stability of mechanical properties of laminates.

Most researchers have studied the quasi-static19,20,21,22,23 and dynamic behavior24,25,26,27,28, as well as the property modification29,30 of composite materials. The volume fraction ratio of fiber to matrix plays a crucial role in mechanical properties of FRP laminate. In an appropriate range, a higher volume fraction of fiber can improve the strength and stiffness of FRP laminate. Andrew et al.31 investigated the effect of fiber volume fraction on the mechanical properties of specimens prepared by the fused deposition modeling (FDM) additive manufacturing process. The results showed that when the fiber volume fraction was 22.5%, the tensile strength efficiency reached its maximum, and a slight improvement in strength was observed as the fiber volume fraction reached 33%. Khalid et al.32 studied the mechanical properties of continuous carbon fiber (CF)-reinforced 3D-printed composites with diverse fiber volume fractions, and the results showed that both tensile strength and stiffness were improved with the rise in fiber content. Uzay et al.33 investigated the effects of three fabrication methods-hand lay-up, compression molding, and vacuum bagging-on the mechanical properties of carbon fiber-reinforced polymer (CFRP). The fiber volume fraction and void of the laminates were measured, tensile and bending tests were conducted. The experiments showed that the higher the fiber volume fraction, the better the mechanical properties.

Voids are one of the most common defects in FRP laminate. Voids reduce the mechanical properties of composite materials, such as strength, stiffness, and fatigue resistance34. The stress concentration generated around the voids promotes the propagation of micro-cracks and reduces the interface strength between reinforcement and matrix. Internal voids also accelerate the moisture absorption of FRP laminate, resulting in interface debonding and performance degradation. Therefore, the existence of internal voids affects the reliability of composite and restricts their wide application. Zhu et al.35 investigated the influence of void content on the static interlaminar shear strength properties of CFRP composite laminates, and found that a 1% increase in void content ranging from 0.4% to 4.6% led to a 2.4% deterioration in interlaminar shear strength. Scott et al.36 presented the effect of voids on damage mechanism in CFRP composite laminates under hydrostatic loading using computed tomography (CT), and found that the number of voids is 2.6-5 times the number of randomly distributed cracks.

High-quality and reliable FRP laminates can be manufactured by using an autoclave. Abraham et al.37 manufactured low-porosity, high-fiber content laminates by placing a WLVB assembly in an autoclave with a pressure of 1.2 MPa for curing. Nevertheless, the autoclave is a large and expensive piece of equipment, resulting in considerable manufacturing costs. Although the vacuum-assisted resin transfer process (VARTM) has been in use for a long time, it has a limit in terms of the time cost, a more complicated preparation process, and more disposable consumables such as diversion tubes and diversion media. Compared with the WL process, the WLVB process compensates for insufficient molding pressure through a low-cost vacuum bag, absorbing excess resin from the system to increase the fiber volume fraction and reduce the internal pore content, thereby greatly improving the mechanical properties of the laminate.

This study explores the differences between the WL process and the WLVB process, and details the meticulous process of the WLVB process. The fiber volume content of laminates was calculated by the formula method, and the results showed that the fiber volume content of WL laminates was 42.04%, while that of WLVB laminates was 57.82%, increasing by 15.78%. The mechanical properties of laminates were characterized by tensile and impact tests. The experimental results revealed that with the WLVB process, the strength and modulus of the laminates were enhanced by 17.4% and 16.35%, respectively, and the specific absorbed energy was increased by 19.48%.

Protocol

1. Material preparation

- Cut eight pieces of 300 mm x 300 mm woven glass fiber fabric with scissors. Tape the cut first to prevent the fiber filaments from falling off.

NOTE: Wear a mask and gloves to prevent finger pricking and filament inhalation when cutting the fabric. Not only the woven glass fiber fabric, but unidirectional fabric and other types of fiber, such as carbon fiber and aramid fiber, are also available. - Weigh out 260 g of epoxy resin and 78 g of hardener according to the mass ratio of 10:3.

NOTE: The ratio of fiber fabric and resin system is recommended to be 360 g of epoxy resin system per square meter of single layer fiber fabric.

2. Fabrication process

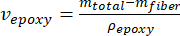

NOTE: Figure 1 shows the schematic of fabrication of composite laminate for the hand lay-up process, which is shown in section 2.

- WLVB

- Put the fabric in an oven at 60 °C for 8 h.

- Paste isolation film on the acrylic sheet to prevent the resin from bonding.

- Place the mold on the laying area.

- Mix the resin and hardener slowly for 5 min, and then put it into a vacuum chamber to draw out the air bubbles inside.

- Lay the non-porous release film on the mold and fix it with tape around it.

- Lay one peel ply on the non-porous release film.

- Pour in the epoxy resin and use a scraper to distribute the resin evenly throughout the film.

- Ply the first fiber fabric, roll with a naked roller to make sure the resin fully infiltrates the fabric and the bubbles are extruded, and then pour the resin, using a scraper to scrape the resin evenly.

- Repeat steps 2.1.7 and 2.1.8 until all the fabric has been used.

- Lay one peel ply on the fabric and squeeze out the air bubbles manually.

- Lay one perforated release film and one breather fabric successively.

- Place the suction channel and breathable pad on one side.

- Stick a circle of heat-resistant tape with an acrylic sheet outside the mold and attach the vacuum bag around with the tape to form a closed space.

- Turn on the vacuum pump to press 1 bar of pressure for 10 h at room temperature. Then, close the vacuum pump and maintain quiescence for 14 h.

- Put the laminates into the oven at 80 °C for 16 h to cure completely.

- Measure the fiber volume fraction using equations (1-3)38,39.

(1)

(1)

(2)

(2)

(3)

(3)

n is the number of layers of the laminate, ρfiber is the areal density of the fiber fabric from the manufacturer, Afiber is the area of the laminate, mfiber is the mass of fiber fabric, mtotal is the mass of the laminate, ρepoxy is the density of the epoxy, vepoxy and vtotal are the volumes of epoxy and laminate, respectively, and is the fiber volume fraction.

- WL

- Put the fabric in an oven at 60 °C for 8 h.

- Mix the resin and hardener slowly for 5 min and then put it into a vacuum chamber to draw out the air bubbles inside.

- Lay the non-porous release film on the mold and fix it with tape around it.

- Lay one peel ply on the non-porous release film.

- Pour in the epoxy resin and use a scraper to distribute the resin evenly throughout the film.

- Ply the first fiber fabric, roll with a naked roller to make sure the resin fully infiltrates the fabric and the bubbles are extruded, and then pour the resin, using a scraper to scrape the resin evenly.

- Repeat steps 2.2.5 and 2.2.6 until all the fabric has been used.

- Lay one peel ply on the fabric and squeeze out the air bubbles manually.

- Lay one perforated release film, one breather fabric, and one non-porous release film successively.

- Place one aluminum plate with the same size as the fiber fabric on top.

- Maintain quiescence at room temperature for 14 h.

- Put the laminates into the oven at 80 °C for 16 h to cure completely.

3. Characterization of impact properties

NOTE: There are many methods for impact testing of composite laminates. Under low-velocity impact conditions, the commonly used method is the drop-weight impact test, while under high-velocity or ultra high-velocity impact conditions, the frequently used method is the bullet impact method. In this study, the drop-weight impact test was applied. The equipment is shown in Figure 2.

- Cut a set of 150 mm x 100 mm samples from GFRP for an impact test, according to ASTM D7136, using a high-precision cutting machine.

- Measure the weight and size of each sample.

- Fix the positions of the samples using positioning nails in the centers of the samples that the impactor can contact for every test.

- Fix the sample on the impact support fixture with four rubber tips.

- Conduct the impact test using a drop-weight impact tower at the 10 J energy level. Turn on the drop hammer testing machine and click Connect to connect the controller with the dropdown, then click Home | Before test. Set the impact energy to 10 J and the additional mass to 2 kg. Input the measurement thickness, 2.1 mm for the WLVB samples and 2.5 mm for the WL samples, to determine the height of the impactor, and click Start to start the experiment.

- Record the impact response data, including force, deflection, and energy history.

- Take out the sample. Record the morphology of the sample after impact.

- Repeat the impact test five times to ensure the repeatability of results.

- Calculate and compare the data of samples.

4. Characterization of tensile properties

- Cut a set of 250 mm x 25 mm samples from the laminates for a tensile test, according to ASTM D3039, using a high-precision cutting machine with a diamond cutter.

- Measure the size of each sample with a vernier caliper.

- Use epoxy adhesive to bond four 50 mm x 25 mm x 2 mm aluminum tabs on both ends of the sample to avoid stress concentration.

- Spray a thin layer of white paint on the front of the sample, then spray black speckles.

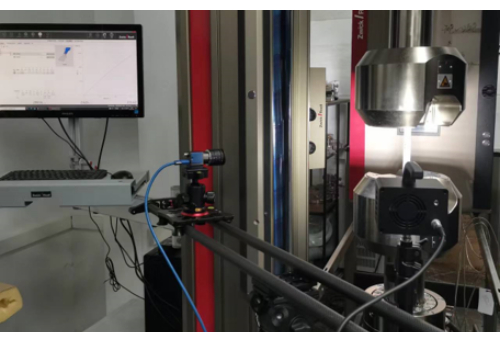

- Place the sample in the center of the clamps of the tensile testing machine and set up the image acquisition system, as shown in Figure 3.

- To ensure the accuracy of the strain data, vary the position of the sample so that it is in the middle of the camera shooting area and in a vertical position. Additionally, adjust the camera focal length and exposure rate to ensure that the spots on the sample are clearly recorded.

- Perform the tensile test. Click CONFIGURE TEST. Set the test speed a 0.5 mm/min. Click Specimen data. Input the measurement width and thickness of the samples. Click Start, then click Accept current position. Record the load-time data.

- Take out the sample. Record the morphology of the sample after the tensile test.

- Repeat the tensile test five times to ensure the repeatability of results.

- Use digital image correlation (DIC) software to measure the nominal strain of the sample during the tensile test.

- Click Length Scale Image to calibrate the length of the pixels, click Reference Image, and choose the first image as the reference image. Click Deformed Image and choose the remaining images as the deformed images. Click Drawing Tools | Select rectangle to select the measurement area. Click Extensometer and set the length of the extensometer to 100 mm, then click Processing | Start Correlation.

- Divide the load by the cross-sectional area to get the nominal stress.

- Combine the nominal strain from the DIC measurement and the nominal stress from the tensile testing machine.

- Choose the slope of the linear segment of the strain-stress curve as the elastic modulus. Choose the peak value of the tensile force-time curve as the strength.

- Compare the elastic modulus and the strength of samples.

Representative Results

Table 1 shows the fiber volume fraction, average thickness, and fabrication process of the samples. The G8-WLVB and G8-WL represent the laminates consisting of 8-ply glass fabric manufactured by wet hand lay-up with and without the vacuum bag process, respectively. Obviously, with the vacuum bag assistance, laminates have an increase of 15.78% in fiber volume fraction, as well as an reduction of 16.27% in average thickness.

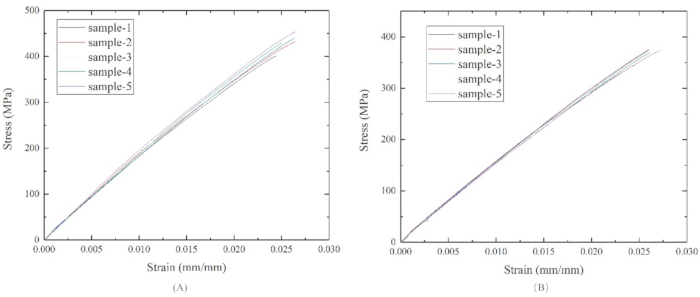

Strain-stress curves obtained by the tensile test of WLVB and WL samples are shown in Figure 4. The vertical axis shows the nominal stress, obtained from force divided by cross-section area, and the horizontal axis shows the nominal strain, calculated by DIC software. It can be seen that perfect repeatability is obtained in the experiment curve, whether they are WL samples or WLVB samples. The first two samples and the last three samples are not fabricated in the same laminate, but are in the same fabricated condition; therefore, it is important to finely control steps and quantify material proportion.

The tensile test results of WLVB samples and WL samples are indicated in Table 2 and Table 3, respectively. Nonlinearity was observed in the tensile curve. The slope of the linear segment of the tensile strain-stress curve represents the elastic modulus, and the maximum value point on the vertical axis of the tensile strain-stress curve represents the strength. As shown in Table 2, the average tensile strength and modulus of five WLVB samples are 431.79 MPa and 19.14 GPa, respectively. The standard deviations of the tensile strength and the tensile modulus are 17.81 and 0.52, respectively. As shown in Table 3, the average tensile strength and the average tensile modulus of five WL samples are 367.8 MPa and 16.45 GPa, respectively. The standard deviations of the tensile strength and the tensile modulus are 11.63 and 0.43, respectively.

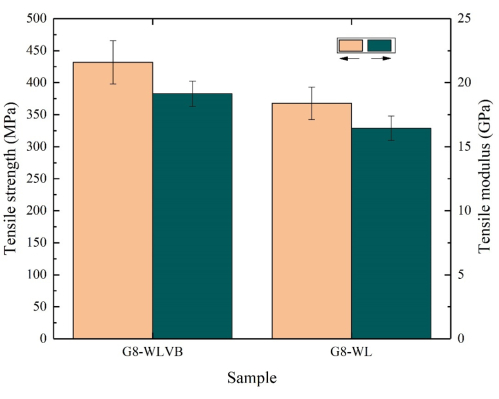

Table 4 shows the tensile strength and stiffness of laminates. The results indicate that the tensile strength and modulus of laminates are extremely improved by using the WLVB process. Laminates manufactured using the WLVB process have an increase of 17.4% and 16.35% in the tensile strength and modulus, respectively. Consequently, the WLVB process has an excellent effect on laminate fabrication, by enhancing the tensile properties of laminates.

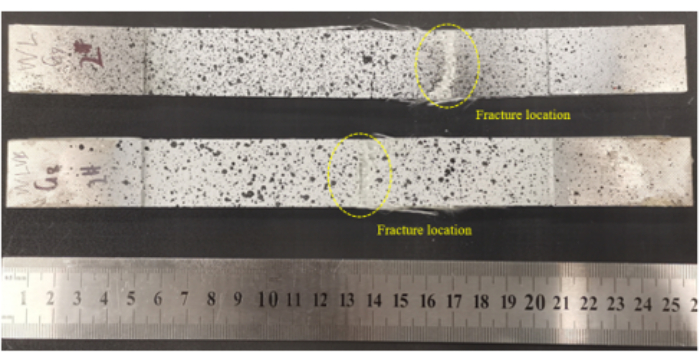

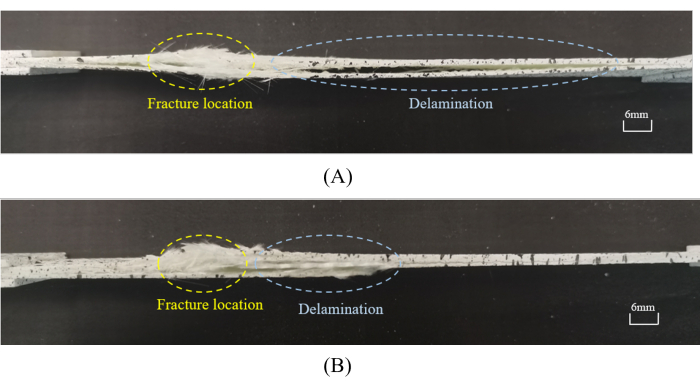

Figure 5 shows the tensile modulus and strength with the error bar of G8-WLVB and G8-WL samples. The tensile modulus and strength of laminates manufactured by the WLVB process are higher than those manufactured using the WL process. The smaller the error bar, the greater the stability of the process; in other words, the WLVB process is more stable than the WL process. Figure 6 shows the fracture of WLVB and WL samples after the tensile test; the fracture location of samples is near the middle, which is acceptable. Figure 7 shows the side view of WLVB and WL samples after the tensile test. Whether the samples are manufactured by the WLVB or WL fabrication processes, the tensile fracture modes of the samples include fiber breakage, matrix fracture, and delamination. As shown in Figure 7, the delamination length of the WL sample is longer than that of the WLVB sample. The WL samples have a higher resin volume fraction than the WLVB samples, resulting in thicker resin between layers. As a result, a longer delamination crack can be observed in the WL samples.

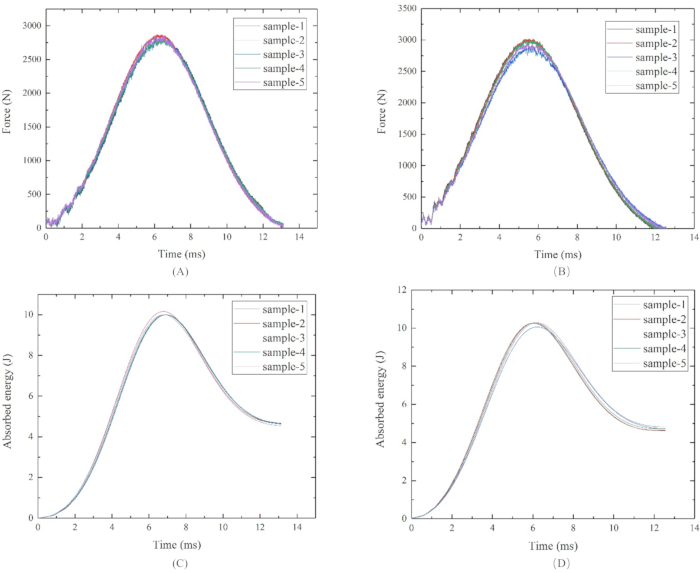

Force and absorbed energy history curves obtained by the impact test of WLVB and WL samples are shown in Figure 8. There is great repeatability shown in the impact test. The shape of the force-time curve of the WLVB and WL samples is similar to a sine wave, which is represented as a typical non-piercing curve. Figure 8C,D represents the real time energy absorption value. The absorbed energy value increased first and then decreased over time. In the initial rising stage, the laminate gradually absorbed all the kinetic energy of the impactor and converted it into its internal energy. Behind the maximum point, the laminate released elastic energy to rebound the impactor. The absorbed energy of the laminates was obtained by the final curve value.

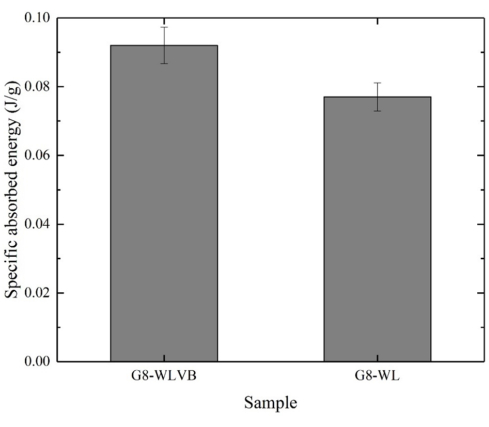

Statistical analysis was conducted on the experimental data40. The impact test results of the WLVB and WL samples are shown in Table 5 and Table 6, respectively. As shown in Table 5, the average specific absorbed energy and standard deviation of five WLVB samples are 0.092 J/g and 0.0024, respectively. As shown in Table 6, the average specific absorbed energy and standard deviation of five WL samples are 0.077 J/g and 0.0021, respectively.

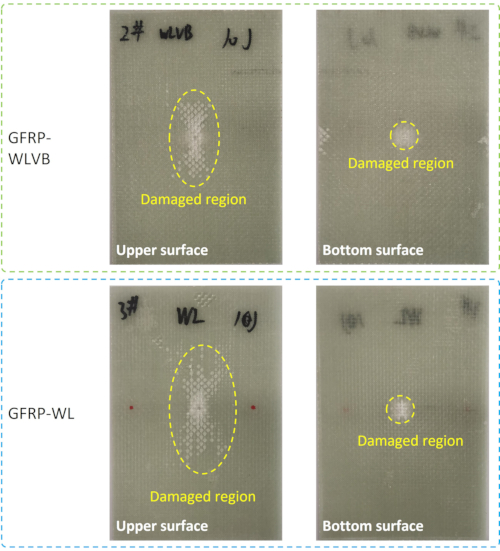

Table 7 shows the impact properties of laminates and the percentage increase in the specific energy absorption of laminates manufactured by the WLVB process. Under the same impact energy of 10 J, the same damage mode is observed for laminates manufactured by the WLVB and WL processes. The results show that laminates manufactured by the WLVB process have an increase of 19.48% in specific energy absorption. Thus, a marvelous effect in laminate fabrication by the WLVB process can be observed with the enhancement of impact properties of laminates.

Figure 9 shows the specific absorbed energy with error bars of the G8-WLVB and G8-WL samples. Due to the different thickness values of the laminates manufactured by the two processes, the specific energy absorption is used to characterize the energy absorption performance of the laminates. The results show that the specific absorbed energy of the WLVB sample is larger than that of the WL sample. The error bars of the WLVB sample and WL sample are similar in the impact test. Figure 10 shows the upper and bottom surface of the WLVB and WL samples after the impact test. It can be seen clearly that the damaged area of the WL sample is larger than the WLVB sample. It follows that the impact energy absorption capacity of samples manufactured by the WLVB process is greater than that of the samples manufactured by the WL process.

Figure 1: A simplified schematic of the WLVB process. (1) Vacuum film, (2) upper part of the vacuum valve, (3) peel piles, (4) non-porous release film, (5) heat-resistant tap, (6) acrylic plate, (7) bottom part of the vacuum valve, (8) breathable pad, (9) suction channel, (10) aluminum mold, (11) fabric, (12) perforated release film, (13) breather fabric. Abbreviation: WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 2: Drop hammer testing machine. Please click here to view a larger version of this figure.

Figure 3: Digital image correlation strain measuring system and Zwick tensile testing machine. Please click here to view a larger version of this figure.

Figure 4: Stress-strain curve obtained by the tensile test of the five samples. (A) WLVB; (B) WL. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 5: Tensile modulus and strength of the G8-WLVB and G8-WL sample. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 6: Front view of the WLVB and WL samples after the tensile test. The yellow dashed ovals show the fracture location. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 7: Side view of the WLVB and WL samples after the tensile test. (A) WL sample, (B) WLVB sample. Scale bars = 6 mm. The yellow dashed ovals show the fracture location and the blue ovals show delamination. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 8: Force and absorbed energy history curve by the impact test of the five samples. (A) Force history curve of the WLVB samples. (B) Force history curve of the WL samples. (C) Absorbed energy history curve of the WLVB samples. (D) Absorbed energy history curve of the WL samples. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 9: Specific absorbed energy of the G8-WLVB and G8-WL sample. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

Figure 10: Upper and bottom surfaces of the WLVB and WL samples after the impact test. Scale bars = 20 mm. The yellow dashed ovals show damaged regions. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag. Please click here to view a larger version of this figure.

| Sample | Fiber volume fraction (%) | Increase in fiber volume fraction (%) | Average thickness (mm) |

| G8-WLVB | 57.82 | 15.78 | 2.11 |

| G8-WL | 42.04 | – | 2.52 |

Table 1: Fiber volume fraction, increase in fiber volume fraction, and average thickness of laminates manufactured by the WLVB and WL processes. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag.

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | |||

| Tensile strength (MPa) | 400.68 | 432.61 | 440.1 | 430.41 | 455.15 | ||

| Average tensile strength (MPa) | 431.79 | ||||||

| Standard deviation for tensile strength (MPa) | 17.81 | ||||||

| Tensile modulus (GPa) | 19.64 | 18.95 | 18.47 | 18.79 | 19.85 | ||

| Average tensile modulus (GPa) | 19.14 | ||||||

| Standard deviation for tensile modulus (GPa) | 0.52 | ||||||

Table 2: Tensile test results of the WLVB samples. Abbreviation: WLVB: wet hand lay-up/vacuum bag.

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | |||

| Tensile strength (MPa) | 344.89 | 375.48 | 374.51 | 369.7 | 374.4 | ||

| Average tensile strength (MPa) | 367.8 | ||||||

| Standard deviation for tensile strength (MPa) | 11.63 | ||||||

| Tensile modulus (GPa) | 17.19 | 16.61 | 16.27 | 15.89 | 16.31 | ||

| Average tensile modulus (GPa) | 16.45 | ||||||

| Standard deviation for tensile modulus (GPa) | 0.43 | ||||||

Table 3: Tensile test results of the WL samples. Abbreviation: WL = wet hand lay-up.

| Sample | Tensile strength (MPa) | Increase in tensile strength (%) | Tensile modulus (GPa) | Increase in tensile modulus (%) |

| G8-WLVB | 431.79 | 17.4 | 19.14 | 16.35 |

| G8-WL | 367.8 | – | 16.45 | – |

Table 4: Average tensile strength and modulus of laminates manufactured by the WLVB and WL process esand the percentage increase in tensile properties. Abbreviation: WLVB: wet hand lay-up/vacuum bag.

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | |||

| Mass (g) | 49.52 | 49.34 | 49.52 | 49.05 | 49.88 | ||

| Peek Force (J) | 2847 | 2872 | 2854 | 2831 | 2866 | ||

| Absorbed energy (J) | 4.65 | 4.36 | 4.67 | 4.63 | 4.55 | ||

| Specific absorbed energy (J/g) | 0.094 | 0.088 | 0.094 | 0.094 | 0.091 | ||

| Average specific absorbed energy (J/g) | 0.092 | ||||||

| Standard deviation (J/g) | 0.0024 | ||||||

Table 5: Impact test results of the WLVB samples. Abbreviation: WLVB: wet hand lay-up/vacuum bag.

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | ||||

| Mass (g) | 62.83 | 62.02 | 60.07 | 61.82 | 61.4 | |||

| Peek Force (J) | 3018 | 3017 | 2905 | 2999 | 2949 | |||

| Absorbed energy (J) | 4.66 | 4.63 | 4.74 | 4.69 | 4.83 | |||

| Specific absorbed energy (J/g) | 0.074 | 0.075 | 0.079 | 0.076 | 0.079 | |||

| Average specific absorbed energy (J/g) | 0.077 | |||||||

| Standard deviation (J/g) | 0.0021 | |||||||

Table 6: Impact test result of the WL samples. Abbreviation: WL = wet hand lay-up.

| Sample | Impact energy (J) | Average peek Force (N) | Average specific absorbed energy (J/g) | Increase in average specific absorbed energy (%) |

| G8-WLVB | 10J | 2854 | 0.092 | 19.48 |

| G8-WL | 10J | 2978 | 0.077 | – |

Table 7: Average impact energy, peak force, and specific absorbed energy of laminates manufactured by the WLVB and WL processes, and percentage increase in impact properties. Abbreviations: WL = wet hand lay-up; WLVB: wet hand lay-up/vacuum bag.

Discussion

This paper focuses on the two different fabrication processes for the hand lay-up method with low cost. Therefore, two fabrication processes were selected to be carefully described in this paper, which are simpler, easier to master, lower in investment cost, and suitable for production with material modification in laboratories and small-scale factories. During the cure of laminates, high consolidation pressure plays an important role in manufacturing laminates with high quality. The adoption of the traditional WL process without enough external pressure can lead to a high resin volume fraction. High resin volume is one of the major factors that reduce the mechanical properties of laminates. In this work, a fabrication process based on the traditional WL process using a vacuum bag to remove air bubbles and provide pressure is described. In this fabrication process, it is important to control the proportion of materials and sequence of steps. The main factors that affect the mechanical properties of laminates are fiber volume fraction and voids; therefore, protocol steps to remove bubbles, as described in steps 2.1.4, 2.1.8, and 2.1.13, are critical.

To compare the mechanical properties of laminates manufactured by different fabrication processes, the tensile test and low-velocity impact tests are carried out. In this study, laminates manufactured by the WLVB process show better mechanical properties, including tensile strength, tensile modulus, and impact energy absorption. The results illustrate that laminates manufactured using the WLVB process have an increase of 18.3% in specific energy absorption, as well as an increase of 16.3% and 14.6% in tensile strength and modulus, respectively.

Compared with the WL process, the WLVB process compensates for the insufficient molding pressure through a low-cost vacuum bag, absorbing excess resin from the system to increase the fiber volume fraction and reduce the internal pore content, thereby greatly improving the mechanical properties of the laminate. The quality of laminates manufactured by the WLVB process is better. Due to the pressure exerted by vacuum bag being more uniform, the thickness of the laminate manufactured by the WLVB process is also more uniform. The thickness of the laminate prepared by the WL process using only the weight to provide pressure is uneven, resulting in unstable quality of laminates. The testing results show that the error bars of the tensile and impact properties of the WLVB samples are smaller. It is crucial for the stability of laminate quality to apply uniform pressure during curing.

The WLVB process has important driving significance for the composite material production field with small capital investment. Compared with other preparation processes, the WLVB process has several advantages, including simple equipment requirements and uncomplicated process technology, and the products are not limited by size and shape. This process has a high degree of freedom and can be integrated with metal, wood, plastic, or foam. However, the WLVB process also has some limitations, such as its low efficiency and long cycle. Of note, because it is mainly suitable for small batch production, and laminate performances are closely related to the skill level of operators and construction conditions, it is necessary to design and optimize the manufacturing process quantitatively to achieve a high yield.

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

The authors would like to thank the grants from the National Key Research and Development Program of China (No. 2022YFB3706503) and the Stable Support Plan Program of Shenzhen Natural Science Fund (No. 20220815133826001).

Materials

| breather fabric | Easy composites | BR180 | |

| drop-weight impact testing machine | Instron | 9340 | |

| Epoxy matrix | Axson Technologies | 5015/5015 | |

| glass fiber | Weihai Guangwei Composites | W-9311 | |

| non-porous release film | Easy composites | R240 | |

| Peel ply | Sino Composite | CVP200 | |

| perforated released film | Easy composites | R120-P3 | |

| test machine | ZwickRoell | 250kN | |

| vacuum film | Easy composites | GVB200 |

Riferimenti

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Progress in Materials Science. 102, 109-166 (2019).

- Singh, T. Optimum design based on fabricated natural fiber reinforced automotive brake friction composites using hybrid CRITIC-MEW approach. Journal of Materials Research and Technology. 14, 81-92 (2021).

- Li, Z. -. J., Dai, H. -. L., Liu, Z. -. G., Wang, Y. Micro-CT based parametric modeling and damage analysis of three-dimensional rotary-five-directional braided composites under tensile load. Composite Structures. 309, 116734 (2023).

- Rodríguez-García, V., de Villoria, R. G. Automated manufacturing of bio-inspired carbon-fibre reinforced polymers. Composites Part B: Engineering. 215, 108795 (2021).

- Atas, C., Akgun, Y., Dagdelen, O., Icten, B. M., Sarikanat, M. An experimental investigation on the low velocity impact response of composite plates repaired by VARIM and hand lay-up processes. Composite Structures. 93 (3), 1178-1186 (2011).

- Found, M. S., Friend, M. J. Evaluation of CFRP panels with scarf repair patches. Composite Structures. 32 (1-4), 115-122 (1995).

- Das, S. Urologic laparoscopy: The future is now. The Urologic Clinics of North America. 28 (1), 1-3 (2001).

- Zhang, J., Chaisombat, K., He, S., Wang, C. H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Materials & Design (1980-2015). 36, 75-80 (2012).

- Caltagirone, P. E., et al. Substitution of virgin carbon fiber with low-cost recycled fiber in automotive grade injection molding polyamide 66 for equivalent composite mechanical performance with improved sustainability. Composites Part B: Engineering. 221, 109007 (2021).

- Kini, M. V., Pai, D. The ageing effect on static and dynamic mechanical properties of fibre reinforced polymer composites under marine environment- a review. Materials Today: Proceedings. 52, 689-696 (2022).

- Kolat, K., Neşer, G., Özes, &. #. 1. 9. 9. ;. The effect of sea water exposure on the interfacial fracture of some sandwich systems in marine use. Composite Structures. 78 (1), 11-17 (2007).

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites. 18 (1), 13-23 (1987).

- Kim, J. -. H., Shin, P. -. S., Kwon, D. -. J., DeVries, K. L., Park, J. -. M. Evaluation of interfacial, dispersion, and thermal properties of carbon Fiber/ABC added epoxy composites manufactured by VARTM and RFI methods. Composites Part A: Applied Science and Manufacturing. 151, 106660 (2021).

- Vargas-Rojas, E. Prescriptive comprehensive approach for the engineering of products made with composites centered on the manufacturing process and structured design methods: Review study performed on filament winding. Composites Part B: Engineering. 243, 110093 (2022).

- Pishvar, M., Amirkhosravri, M., Altan, M. C. Magnet assisted composite manufacturing: a flexible new technique for achieving high consolidation pressure in vacuum bag/lay-up processes. Journal of Visualized Experiments. (135), e57254 (2018).

- Lee, D., Lee, D. G., Lim, J. W. Experimental implementation of a new composite fabrication method: exposing bare fibers on the composite surface by the soft layer method. Journal of Visualized Experiments. (128), e55815 (2017).

- Frey, M., et al. Fabrication and design of wood-based high-performance composites. Journal of Visualized Experiments. (153), e60327 (2019).

- Li, P. C., Zhang, X. M., Xie, W. F., Hoa, S. V. Operation of the collaborative composite manufacturing (CCM) system. Journal of Visualized Experiments. (152), e59969 (2019).

- Taheri-Behrooz, F., Esmkhani, M., Yaghoobi-Chatroodi, A., Ghoreishi, S. M. Out-of-plane shear properties of glass/epoxy composites enhanced with carbon-nanofibers. Polymer Testing. 55, 278-286 (2016).

- Taheri-Behrooz, F., Bakhshan, H. Characteristic length determination of notched woven composites. Advanced Composite Materials. 27 (1), 67-83 (2018).

- Uzay, C., Cetin, A., Geren, N., Bayramoglu, M., Tutuncu, N. Predicting the tensile stiffness and strength properties of plain woven carbon fiber/epoxy laminates: a practical analytical approach and experimental validations. Mechanics of Advanced Materials and Structures. , (2020).

- Cetin, A., Uzay, C., Geren, N., Bayramoglu, M., Tutuncu, N. A practical approach to predict the flexural properties of woven plain carbon fiber/epoxy laminates. Mechanics of Advanced Materials and Structures. 30 (9), 1801-1811 (2023).

- Villegas, I. F., Palardy, G. Ultrasonic welding of thermoplastic composite coupons for mechanical characterization of welded joints through single lap shear testing. Journal of Visualized Experiments. (108), e53592 (2016).

- Zhang, J., et al. Energy dissipation mechanism of fiber metal laminate under low-velocity impact. Thin-Walled Structures. 183, 110355 (2023).

- Fakhreddini-Najafabadi, S., Torabi, M., Taheri-Behrooz, F. An experimental investigation on the low-velocity impact performance of the CFRP filled with nanoclay. Aerospace Science and Technology. 116, 106858 (2021).

- Taheri-Behrooz, F., Shokrieh, M. M., Yahyapour, I. Effect of stacking sequence on failure mode of fiber metal laminates under low-velocity impact. Iranian Polymer Journal. 23 (2), 147-152 (2014).

- Zhang, X., et al. Rate dependent behaviors of nickel-based microcapsules. Applied Physics Letters. 112 (22), 221905 (2018).

- Li, X., Xu, R., Zhang, X., Zhang, H., Yang, J. Inner blast response of fiber reinforced aluminum tubes. International Journal of Impact Engineering. 172, 104416 (2023).

- Zhang, X., et al. Optimization of shear thickening fluid encapsulation technique and dynamic response of encapsulated capsules and polymeric composite. Composites Science and Technology. 170, 165-173 (2019).

- Wang, P. F., et al. Energy absorption mechanisms of modified double-aluminum layers under low-velocity impact. International Journal of Applied Mechanics. 7 (6), 1550086 (2015).

- Dickson, A. N., Barry, J. N., McDonnell, K. A., Dowling, D. P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Additive Manufacturing. 16, 146-152 (2017).

- Saeed, K., et al. Characterization of continuous carbon fibre reinforced 3D printed polymer composites with varying fibre volume fractions. Composite Structures. 282, 115033 (2022).

- Uzay, &. #. 1. 9. 9. ;., Çetin, A., Geren, N. Physical and mechanical properties of laminar composites depending on the production methods: an experimental investigation. Sādhanā. 47 (4), 262 (2022).

- Mehdikhani, M., Gorbatikh, L., Verpoest, I., Lomov, S. V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. Journal of Composite Materials. 53 (12), 1579-1669 (2019).

- Zhu, H., Wu, B., Zhang, D., Li, D., Chen, Y. Effect of void on the interlaminar shear fatigue of carbon fiber/epoxy composite laminates. Acta Materiae Compositae Sinica. 27 (6), 32-37 (2010).

- Scott, A. E., Sinclair, I., Spearing, S. M., Mavrogordato, M. N., Hepples, W. Influence of voids on damage mechanisms in carbon/epoxy composites determined via high resolution computed tomography. Composites Science and Technology. 90, 147-153 (2014).

- Abraham, D., Matthews, S., McIlhagger, R. A comparison of physical properties of glass fibre epoxy composites produced by wet lay-up with autoclave consolidation and resin transfer moulding. Composites Part A: Applied Science and Manufacturing. 29 (7), 795-801 (1998).

- Li, M., et al. Evaluation of through-thickness permeability and the capillary effect in vacuum assisted liquid molding process. Composites Science and Technology. 72 (8), 873-878 (2012).

- Bortz, D. R., Merino, C., Martin-Gullon, I. Mechanical characterization of hierarchical carbon fiber/nanofiber composite laminates. Composites Part A: Applied Science and Manufacturing. 42 (11), 1584-1591 (2011).

- Taheri-Behrooz, F., Moghaddam, H. S. Nonlinear numerical analysis of the V-notched rail shear test specimen. Polymer Testing. 65, 44-53 (2018).