A Method for Studying the Temperature Dependence of Dynamic Fracture and Fragmentation

Summary

Fracture and fragmentation are late stage phenomena in dynamic loading scenarios and are typically studied using explosives. We present a technique for driving expansion using a gas gun which uniquely enables control of both loading rate and sample temperature.

Abstract

The dynamic fracture of a body is a late-stage phenomenon typically studied under simplified conditions, in which a sample is deformed under uniform stress and strain rate. This can be produced by evenly loading the inner surface of a cylinder. Due to the axial symmetry, as the cylinder expands the wall is placed into a tensile hoop stress that is uniform around the circumference. While there are various techniques to generate this expansion such as explosives, electromagnetic drive, and existing gas gun techniques they are all limited in the fact that the sample cylinder must be at room temperature. We present a new method using a gas gun that facilitates experiments on cylinders from 150 K to 800 K with a consistent, repeatable loading. These highly diagnosed experiments are used to examine the effect of temperature on the fracture mechanisms responsible for failure, and their resulting influence on fragmentation statistics. The experimental geometry employs a steel ogive located inside the target cylinder, with the tip located about halfway in. A single stage light gas gun is then used to launch a polycarbonate projectile into the cylinder at 1,000 m/sec-1. The projectile impacts and flows around the rigid ogive, driving the sample cylinder from the inside. The use of a non-deforming ogive insert allows us to install temperature control hardware inside the rear of the cylinder. Liquid nitrogen (LN2) is used for cooling and a resistive high current load for heating. Multiple channels of upshifted photon Doppler velocimetry (PDV) track the expansion velocity along the cylinder enabling direct comparison to computer simulations, while High speed imaging is used to measure the strain to failure. The recovered cylinder fragments are also subject to optical and electron microscopy to ascertain the failure mechanism.

Introduction

The dynamic failure of a material is an important aspect of its overall mechanical behavior, and has relevance to numerous industries including automotive, aerospace, and military to name a few. While failure at low strain-rates is typically studied through conventional tension tests, in which a long thin sample is loaded in tension from the ends, at high strain rates such a geometry/configuration requires a sample to be very small in order to maintain a pseudo-mechanical equilibrium throughout the test. At the appearance of a single crack, the surrounding material will be relaxed, effectively arresting the development of any adjacent failure sites. This limits the number of fractures that can be simultaneously observed in any one experiment, and prevents important information regarding the statistics of failure to be determined.

The expanding cylinder test is a well-established technique for characterizing the manner in which materials fail and fragment under high speed loading. In the test, a cylinder made of the material of interest is uniformly loaded along its inner circumference, launching a stress wave through the wall and causing the cylinder to expand. Soon this radial wave dissipates and a uniform tensile hoop stress around the circumference dominates. As the stress and strain rate is the same around the cylinder the fracture and fragmentation behavior is governed solely by the material’s properties. The test alleviates the aforementioned problem as the typically large sample circumferences promote initiation of multiple failure sites under uniform stress 1.

The main aim in developing this experimental technique was to enable the study of the role of temperature in the fracture and fragmentation behavior of an expanding cylinder. The control of the sample temperature will allow for investigation of how the dynamic tensile strength, fracture mechanism, and fragmentation behavior of the material is affected. For example in metals, an increase in temperature can cause a shift from brittle to ductile fracture, accommodating more plastic work before ultimately failing. Some materials such as Ti-6Al-4V can also exhibit adiabatic shear localization 2. While the sample deforms, the plastic work generates heat. If the rate of softening as a result of this temperature increase is greater than the rate of work hardening from the deformation, an instability can form where a large amount of plastic deformation occurs in a very localized band (adiabatic shear band). This response is promoted in Ti-6Al-4V due to its poor thermal conductivity, and can potentially limit its effectiveness for applications such as lightweight armor.

This new testing approach must satisfy two main criteria. Firstly, the method must produce a radial strain rate on the order of 104 sec-1, typically seen in ballistic and impact events, to allow comparison to previous studies employing more traditional loading schemes. Secondly, the drive mechanism needs to be unaffected by the sample temperature to ensure consistency between experiments. Initial cylinder expansion mechanisms used explosive charges, either simply filling the sample cylinder 3-5 directly or using an intermediate driver. In the latter case a buffer is used 6, where the sample is placed over a steel cylinder that in turn contains an explosive charge. The obvious limitation is that as the sample cylinder contains the drive material (in the form of the explosive) heating the cylinder will also heat the charge. While this may not directly cause initiation of the charge many types of explosive contain a polymeric binder material that will melt out from the sample cylinder. Likewise, some explosives become highly sensitive when cooled. This means that explosive drives are not suitable for temperature study. An alternative method uses the Lorentz force for expansion — the sample is placed over a driver coil 7, 8. A high current is injected into this driver coil (typically heavy gauge copper wire), inducing an opposite current in the sample. These opposing currents have associated magnetic fields which act against each other, the magnetic pressure driving the sample outwards from the inner face. Again, heating the material will adversely affect the copper drive coil inside the sample. Gas guns have been used for cylinder expansion since the late 1970s 9. In these experiments the material used for the insert in the cylinder is a polymer, the drive coming as a result of both the projectile and insert deforming at impact. This insert is typically a rubber or plastic 10, the strength and ductility of which will be severely affected by temperature. Heating will make the insert too soft, and cooling will make it behave in a brittle manner so it fails prematurely.

Unlike previous cylinder expansion techniques, the method described here is the first to provide a repeatable loading drive over a wide range of temperatures (100-1,000 K). Our technique is unique in the fact that the material used for driving the expansion (in our case the projectile) is separate from the cylinder until the point of impact. Consequently, it is unaffected by the initial temperature of the sample cylinder and provides a repeatable load.

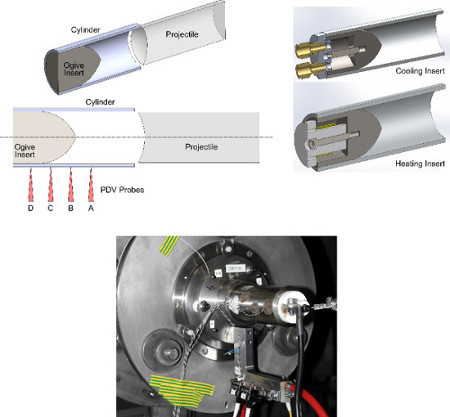

The experimental geometry consists of a steel ogive mounted inside the target cylinder, with the tip located about halfway along the length of the cylinder. A single stage light gas gun is then used to launch a polycarbonate projectile with a concave face into the cylinder at velocities up to 1,000 m/sec-1. The axis of the target is cylinder is carefully aligned to the axis of the gas-gun barrel to facilitate a repeatable and uniform load. The impact and subsequent flow of the polycarbonate projectile around the pseudo-rigid steel ogive, drives the cylinder into expansion from the inside wall. The geometry of the ogive insert and the concave face of the projectile were carefully optimized using hydro-code computer simulations to generate the desired expansion of the cylinder. Using 4340 alloy steel for the ogive enables experimentation with the cylinder at temperature as its strength is much higher than the polycarbonate projectile over the temperature range of interest, ensuring the drive mechanism remains consistent. Ogives recovered from heated and cooled experiments only exhibit minimal deformation as a result of the impact.

The heating and cooling of the sample cylinder is accomplished by the installation of temperature control hardware into a machined recess in the rear of the ogive insert. For cooling the sample to cryogenic temperatures (~100 K), the recess in the ogive is sealed with an aluminum cap and liquid nitrogen is flowed through the cavity. As the target cylinder has a large contact area with the ogive the sample is cooled through conduction. To heat the target cylinder to temperatures approaching 1,000 K, a ceramic and NiChrome resistive heater is placed in the ogive recess. A high current power supply provides up to 1 kW, heating the ogive and cylinder. The cylinder and ogive are thermally isolated from the target mount in the single stage gas-gun through the use of MACOR ceramic spacers. The tank is also held under moderate vacuum (<0.5 Torr) during the experiment which aids thermal manipulation.

In order to diagnose the fragmentation process of the cylinder, the experimental design includes multiple channels of frequency-conversion PDV, to measure the expansion velocity at points along the cylinder. PDV is a relatively new 11, optical fiber based interferometry technique which enables the measurement of surface velocities during highly dynamic events. During a PDV measurement, Doppler shifted light reflected from a moving surface of interest using a fiber-optic probe is combined with un-shifted light, creating a beat frequency that is directly proportional to the velocity of the moving surface. Essentially, a PDV system is a fast Michelson interferometer using advances in near-infrared (1,550 nm) communications technology to record beat frequencies in the GHz range. The mounting system for the 100 mm focal length PDV probes used in the current study ensures that they are isolated from the temperature of the cylinder and provides easy alignment. An additional advantage of using the 100 mm focal length probes is that they provide sufficient optical access to enable high speed photography to measure the expansion profile of the whole cylinder. The arrangement and location of the four probes, A-D, along the cylinder is shown in Figure 1. Two high speed cameras are employed here; a high speed video camera Phantom V16.10 operating at 250,000 fps and an IVV UHSi 12/24 framing camera, capturing 24 images. The IVV camera is backlit such that the cylinder is illuminated in silhouette enabling the radially expanding edge of the cylinder to be accurately tracked. The Phantom camera is front illuminated imaging the failure initiation and fragmentation process. The high speed photography can then be correlated with the velocimetry to give strain and strain rate along the full sample. The high speed imaging also allows for an accurate measure of failure strain and the fracture patterns along the surface.

The experimental technique presented in the following protocol section provides a means of controlling the sample temperature in an expanding cylinder experiment, through which different fracture mechanisms may be activated or suppressed. This technique will lead to a more comprehensive understanding of the role of temperature in dynamic loading scenarios.

Protocol

1. Target Fabrication and Assembly

- Machine target cylinder to desired dimensions from solid stock.

- Prepare the cylinder surface by removing machining marks. A uniform diffuse surface is preferable for PDV reflection. Good results have been obtained with a light wet sanding with >1,200 grit.

- Characterize the target constituents, i.e., measure the following:

Cylinder length, diameter and wall thickness (at multiple locations)

Projectile length, diameter

Ogive length, diameter

Mass of all the above - Assemble the cylinder mounting ring and PDV arm.

- Mount the PDV probes in the kinematic mounts and onto the PDV arm.

- Insert the ogive in the target cylinder so that the rear of the ogive is flush with the rear of the cylinder (this should be done on a workshop flat). The three M3 screws are designed to hold the ogive in place while allowing the cylinder to ‘peel away’ during the expansion.

- Place the target cylinder in the mounting hardware so that the entrance of the cylinder is flush with the leading face of the mounting ring. Secure the cylinder in place with 6 M4 grub screws.

- Install heating/cooling apparatus and bond thermocouples along the length of the cylinder outer wall.

- Clean the FC/APC (ferrule connector, angled physical contact) connectors on the end of the PDV probe fibers with fiber cleaning cloth and check with a fiber scope. This is important to reduce back-reflection.

- Using a visible (660 nm) Class 3R laser roughly align the probes so that they are normal to the cylinder (i.e., the reflected light falls back on the probe).

- Assemble a basic reflectivity circuit using a circulator. Connect the Class 1 1,550 nm laser to input 1, the PDV probe to input 2 and a power meter to input 3. Align the PDV probes in turn so that the power returned is maximized.

2. Gas Gun Preparation

- Using the barrel plug and the depth micrometer align the target ring to the end of the barrel to minimize impact tilt.

- Install the fragment mitigation system and the door protection.

- Place the target alignment plug in the barrel.

- Install the target assembly and align to the plug.

- Install the trigger make pair on the end of the barrel and connect to the timing hardware and diagnostics. Measure the distance from contact with the trigger to impact of the projectile on the ogive.

- Install the turning mirrors for high speed photography.

- Align the mirrors to give an orthogonal view of the cylinder through the target tank ports and lock in place.

- Align the high speed cameras and flash lamps outside the target tank. Looking down the barrel, place the high speed camera and one flash lamp at 3 o’clock relative to the cylinder. Place the IVV camera at 9 o’clock and another flash lamp at 12 o’clock. In this configuration the high speed camera will be front-lit for crack tracking and the IVV will provide silhouetted images for edge detection.

- Connect heating/cooling equipment to target and vacuum feed throughs.

- CAUTION: With the appropriate eyewear and other precautions turn on the Class IV lasers, oscilloscopes and PDV systems.

- Check the power levels being sent to the PDV probes. With the PDV system, typically use around 5 mW to each probe with 1 mW per channel for the reference.

- Check the alignment of the PDV probes with a power meter. Once satisfied with the alignment use IR card to measure where the PDV probes are looking on the cylinder surface.

- Turn on the reference laser and check the quality of the beat signals given by each probe. Adjust the wavelength of the laser(s) to set the desired zero velocity beat frequency (set this around 5 GHz).

- Once satisfied with the target alignment, trigger location, camera and mirror alignment, PDV probe alignment and location and the mitigation frame close the target tank.

- Remove the alignment plug; install the projectile.

- Setup cameras and lighting (frame rate, exposure, timings) and perform test imaging. Typical frame rates are around 250,000 frames/sec for both cameras, with an exposure of around 0.5 µsec. The first image is normally timed to coincide with the moment of impact.

3. Firing Preparation

- Install the breech diaphragms that are applicable to the firing pressure needed.

- Close the breech and begin evacuation of the target tanks. Aim for a vacuum level in the region of 50 mTorr.

- Perform final setup of all diagnostics (oscilloscope delays, triggers, camera settings etc.). Set oscilloscopes for PDV at 50 µsec per division, 25 psec per point and a pretrigger of 20% to give a 500 µsec window. Trigger the oscilloscopes and cameras such that zero time coincides with the time of impact.

- Final trigger test; check timings are accurate.

- Turn on lasers; arm cameras.

- Close room; ensuring laser and high pressure interlocks are in the correct position.

- Begin heating / cooling as required using the LabVIEW software.

- Charge the gun to the required firing pressure.

- When at pressure, do a final check that all diagnostic systems are armed.

- Isolate the heating or cooling apparatus.

- Countdown “3, 2, 1 FIRE.”

- Vent the target and capture tanks.

- Save all oscilloscope and camera data.

4. Post Shot

- Shut down lasers and wait for the gun to fully equalize at atmosphere.

- Open the target tank, collect all metal fragments and sort out the Ti-6Al-4V.

5. Data Analysis

- Perform STFT analysis on the PDV oscilloscope data to reduce the velocity history as per the analysis of Ao and Dolan 12.

- Process high speed imaging data with software such as mentioned in the equipment table. The high speed camera footage will provide time and strain at failure and enable analysis of crack formation and growth. The silhouetted images from the IVV provide a clear edge to examine the full deformation profile of the cylinder.

- Measure and weigh recovered fragments. Select fragments with interesting features such as arrested fractures and prepare them for microscopy.

- Section, mount, and polish the fragments; then analyze in the electron microscope. Electron backscatter diffraction provides information on texture and microstructure alongside secondary electron imaging to probe the fracture surfaces and identify the failure mode.

Representative Results

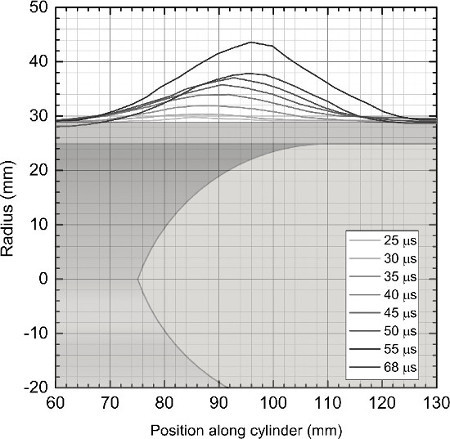

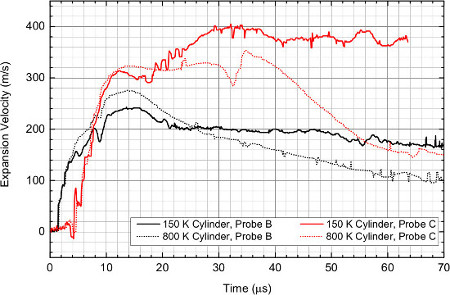

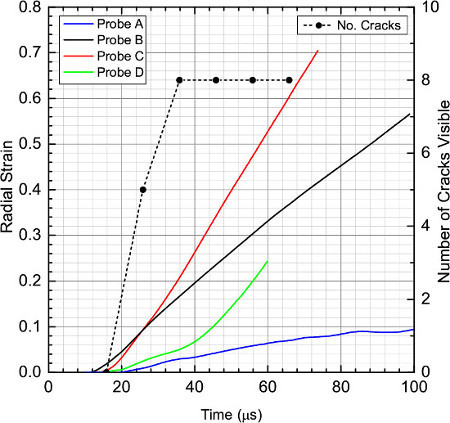

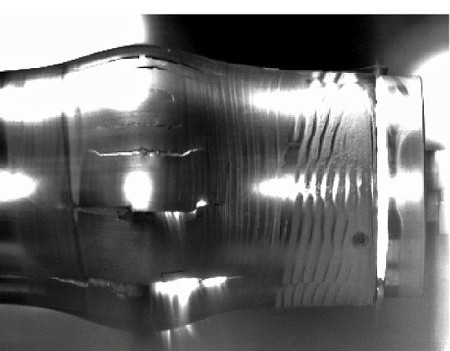

The quality of the data will firstly depend on the experimental timing. If the delays from trigger to impact are correct then the flash lamps will be producing enough light when the target cylinder begins to deform, enabling the high speed cameras to produce clear images. In this case the images from the framing camera will have a clear silhouetted edge that can be used to track the deformation of the whole cylinder. Software such as ImageJ can be used to extract lineout data for each frame, producing an image as in Figure 2. Ideally the PDV will be able to track the expansion velocity for ~100 µsec, this will depend on the surface finish of the cylinder and the alignment of the probe. For a given experiment the PDV and lineout data can be validated against one another using the four known points from the PDV in the image. With this combination an accurate measure of the radius or radial strain at any point along the cylinder length can be extracted. Figure 3 plots the radial expansion velocity at two points along the length of the cylinder, comparing experiments at 150 K and 800 K. We can see that the cooled cylinder has less deceleration after the peak velocity, suggesting fracture has initiated earlier leading to a loss of strength in the cylinder. The radial velocity is then integrated over time to reduce the radial displacement at the points observed by the probes. Figure 4 shows an example of this for the cooled cylinder. Images from the high speed video should be clear enough to discern fracture initiation and crack propagation, as seen in Figure 5. From this we extract the temporal activation of fracture and must extrapolate the number of cracks around the cylinder with time as the other side of the cylinder is not visible to the camera. Figure 5 is an example of a well-lit image, showing multiple longitudinal fractures along the cylinder.

The attached videos are examples of how the image quality is affected by the frame rate — a smaller interframe time produces more accurate time of fracture but the reduced resolution can make it difficult to accurately track crack propagation. The amount of compromise in this area will be determined by the camera hardware available, the lighting and lenses and the rate of deformation in the cylinder (i.e. the timescale that the fragmentation process occurs over).

Figure 1: Experimental geometry. Top, left: Basic assembly, showing location of PDV probes along the cylinder. Top, right: Ogive modifications for cooling and heating the cylinder. Bottom: Heated cylinder experiment installed on the gas gun. Black cables are power for the heating coil. Thin black/white cables are thermocouples. PDV probes are visible at the bottom. Please click here to view a larger version of this figure.

Figure 2: Lineout data extracted from high speed imaging of a 300 K expanding cylinder experiment at a range of times after impact.

Figure 3: Radial expansion velocity measured with PDV at two points along the cylinder for a 150 K (solid) and 800 K (dotted) expanding cylinder. The cooled cylinder has less deceleration after the peak velocity suggesting fracture has initiated earlier.

Figure 4: 150 K expanding cylinder. Solid lines: radial strain accumulated at 4 points along the cylinder length. Dotted lines: number of visible fracture sites from the high speed camera data.

Figure 5: Extract from high speed video (Video 1) recorded. 150 K expanding cylinder.

Video 1: High speed video of an expanding 150 K cylinder experiment. Projectile velocity 1,000 m/sec. Framing: 1 image every 10 µsec, 0.7 µsec exposure. Please click here to view this video.

Video 2: High speed video of an expanding 650 K cylinder experiment. Projectile velocity 1,000 m/sec. Framing: 1 frame every 4.7 µsec, 0.7 µsec exposure. Please click here to view this video.

Discussion

This method enables investigation of materials at high rates of tensile loading over a wide range of temperatures, from cryogenic to ~1,000 K, unique to this design. However, this adds certain challenges to the experimental setup and execution. Firstly, to optimize the temperature control the ogive insert needs to be machined from a suitable material. 4340 steel is used here, although any high-temperature high-hardness steel should suffice. Likewise, as the entire expansion drive is now originating from the polymer projectile this needs to be made from a non-brittle plastic such as the machine-grade polycarbonate in this work.

It is important to have a close mechanical fit between the insert and the cylinder, to ensure good thermal contact. Care must be taken if the thermal expansion coefficient of the target cylinder is not close to the insert. For example, if the cylinder is brittle with a low thermal expansion (such as a ceramic) the expansion of the insert could damage or even crack the cylinder. For the same reason the epoxy used to bond the thermocouples on the cylinder must be able to resist the temperatures expected and the movement of the cylinder as it heats/cools. Finally, thermal isolation of the target from the mounting system is important, otherwise thermal soak makes temperature control difficult and can begin to adversely affect the PDV probes and target alignment.

The limitations of this technique are dependent on the projectile launching facilities available. The radial strain rates that can be attained are a function of the projectile velocity and the cylinder diameter. Smaller cylinders need lower projectile velocities but can then limit the number of fractures observed. Accurate measurement of the expansion velocity necessitates a quality laser based velocimetry system such as the upshifted PDV here or a multiple point VISAR.

Future applications are the study of the effects of temperature on the fracture mechanisms and resulting fragmentation behavior of materials at high rates of uniform tensile strain. While the experiment is especially suited to metals due to the reflective surface allowing PDV measurements it could be adapted to a range of materials if the surface is prepared correctly. This work at high and low temperatures is currently unavailable for other drive mechanisms for expanding cylinders, and will compliment other tensile test mechanisms allowing for further and more accurate population/calibration of material models and hydrocodes.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors gratefully acknowledge continued funding and support for the project from the Atomic Weapons Establishment, AWE Plc. (UK) and Imperial College London.

Materials

| Item | Company / Manufacturer | Part Number | Comments / Description |

| 1550 nm CW Laser | NKT Photonics | Koheras Adjustik | x 2 |

| 1550 nm Power Amplifier | NKT Photonics | Koheras Boostik HPA | |

| Delay Generators | Quantum Composers | 9500+ Digital Delay Pulse Generator | 8 output version |

| Stanford Research Systems | DG535 Digital Delay Generator | ||

| 16 Channel Digitiser | Agilent Technologies | U1056B Chassis + 4 X U1063A Digitiser | |

| High Bandwidth Oscilloscopes | Teledyne LeCroy | WaveMaster 816Zi-A | Expansion Velocity, Gen 3 PDV |

| Tektronix | DPO71604C | Projectile Velocity, Gen 1 PDV | |

| High Speed Imaging Systems | Vision Research | Phantom v16.10 | |

| Invisible Vision | IVV UHSi-24 | ||

| Zeiss Optics | Planar T* 1,4/85 | 85mm Prime Lens | |

| Nikon | AF-S Nikkor 70-200mm f/2.8 ED VR II | 70-200mm Telephoto Lens | |

| Flash Lamp | Bowens | Gemini Pro 1500W | x 2 |

| PDV Probe | Laser 2000 | LPF-04-1550-9/125-S-21.5-100-4.5AS-60-3A-3-3 | x 4 (Custom order) |

| PDV System | Built in-house by the Institute of Shock Physics | Custom Build | 3rd Generation (Upshifted) 8 Channel Portable PDV System |

| Control Software | National Instruments | LabVIEW 2013 | |

| Control Hardware for heating | National Instruments | NI-DAQ 6009 USB | |

| Heating Power Supply | BK Precision | BK1900 | |

| Thermocouple Logger | Pico Technology | TC-08 | |

| 100 mm Single Stage Light Gas Gun | Physics Applications, Inc. (PAI) | Custom Build | Capable of at least 1000 meters per second with ~ 2 kg projectile |

| Image analysis software | National Institutes of Health | ImageJ | Open source, free |

| Image analysis software | Mathworks | MATLAB r2014a | With image processing toolboxes |

| Material sectioning saw | Struers | Accutom-50 | |

| Electron Microscope | Zeiss | Auriga | |

| Electron Backscatter Diffraction | Bruker | e-Flash 1000 | |

| EBSD software | Bruker | eSprit |

References

- Jones, D. R., Chapman, D. J., Eakins, D. E. A gas gun based technique for studying the role of temperature in dynamic fracture and fragmentation. J. Appl. Phys. 114, 173508 (2013).

- Liao, S. C., Duffy, J. Adiabatic shear bands in a Ti-6Al-4V titanium alloy. J. Mech. Phys. Solids. 46 (11), 2201-2231 (1998).

- Mott, N. F. Fragmentation of shell cases. Proc. R. Soc. Lond. A. 189 (1018), 300-308 (1947).

- Hoggatt, C. R., Recht, R. F. Fracture behavior of tubular bombs. J. Appl. Phys. 39 (3), 1856-1862 (1968).

- Banks, E. E. The fragmentation behavior of thin-walled metal cylinders. J. Appl. Phys. 40 (1), 437-438 (1969).

- Warnes, R. H., Duffey, T. A., Karpp, R. R., Carden, A. E. Improved technique for determining dynamic metal properties using the expanding ring. Los Alamos Scientific Laboratory Report. , (1980).

- Niordson, F. I. A unit for testing materials at high strain rates. Exp. Mech. 5 (1), 29-32 (1965).

- Grady, D. E., Benson, D. A. Fragmentation of metal rings by electromagnetic loading. Exp. Mech. 23 (4), 393-400 (1983).

- Winter, R. E., Prestidge, H. G. A technique for the measurement of the high strain rate ductility of metals. J. Mat. Sci. 13 (8), 1835-1837 (1978).

- Vogler, T. J., et al. Fragmentation of materials in expanding tube experiments. Int. J. Imp. Eng. 29, 735-746 (2003).

- Strand, O. T., Goosman, D. R., Martinez, C., Whitworth, T. L., Kuhlow, W. W. Compact system for high-speed velocimetry using heterodyne techniques. Rev. Sci. Inst. 77, 083108 (2006).

- Ao, T., Dolan, D. H. SIRHEN: A data reduction program for photonic Doppler velocimetry measurements. Sandia National Laboratories Report. , (2010).