Wicking Tests for Unidirectional Fabrics: Measurements of Capillary Parameters to Evaluate Capillary Pressure in Liquid Composite Molding Processes

Summary

An experimental method to measure geometrical parameters and the apparent advancing contact angles describing capillary wicking in unidirectional synthetic and natural fabrics is proposed. These parameters are mandatory for the determination of the capillary pressures that must be taken into account for liquid composite molding (LCM) applications.

Abstract

During impregnation of a fibrous reinforcement in liquid composite molding (LCM) processes, capillary effects have to be understood in order to identify their influence on void formation in composite parts. Wicking in a fibrous medium described by the Washburn equation was considered equivalent to a flow under the effect of capillary pressure according to the Darcy law. Experimental tests for the characterization of wicking were conducted with both carbon and flax fiber reinforcement. Quasi-unidirectional fabrics were then tested by means of a tensiometer to determine the morphological and wetting parameters along the fiber direction. The procedure was shown to be promising when the morphology of the fabric is unchanged during capillary wicking. In the case of carbon fabrics, the capillary pressure can be calculated. Flax fibers are sensitive to moisture sorption and swell in water. This phenomenon has to be taken into account to assess the wetting parameters. In order to make fibers less sensitive to water sorption, a thermal treatment was carried out on flax reinforcements. This treatment enhances fiber morphological stability and prevents swelling in water. It was shown that treated fabrics have a linear wicking trend similar to those found in carbon fabrics, allowing for the determination of capillary pressure.

Introduction

During impregnation of fibrous reinforcements in liquid composite molding (LSM) processes, the resin flow is driven by a pressure gradient. Capillary effects have an additional effect that can compete with the pressure gradient, depending on the process parameters. Their influence on the process thus has to be evaluated1,2. This can be done by defining an apparent capillary pressure, Pcap, modifying the initial pressure gradient3. This parameter may subsequently be inserted into numerical models in order to simulate flows during processes and to accurately predict void formation4.

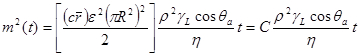

The spontaneous impregnation of a fabric by a liquid (wicking) can be described by the Washburn equation5. Originally, the Washburn equation described the capillary rise of a liquid in a tube. This equation was then extended for porous structures, such as fibrous reinforcements, that can be approximated to a capillary tube network. Considering a cylindrical sample holder with a radius, R, filled with a porous medium, the Washburn equation was modified in the form of squared mass gain (m²(t)) over time, as follows6:

(1)

(1)

where c is a parameter that accounts for tortuosity, ṝ is the mean pore radius, and ε = 1-Vf is the porosity (Vf being the fiber volume ratio). All parameters in the square brackets concern the morphology and configuration of the porous medium, and they can be consolidated into a constant, C, referred to as the "geometric porous medium factor." The other parameters express the dependence of wicking on the interactions between the medium and the liquid (through ρ, η, and γL, which are, respectively, the density, viscosity, and surface tension of the liquid, and through θa, an apparent advancing contact angle).

In parallel, the flow through a porous medium is usually modelled with the well-known Darcy law7, which relates an equivalent fluid velocity, vD, to the pressure drop through the permeability of the medium, K, and the liquid viscosity, η. This equation also allows for the expression of the mass gain over a square root of time and thus for the consideration of the equivalence between the two equations. From this equivalence between the Washburn equation and the Darcy law, the capillary pressure was then defined as follows8:

(2)

(2)

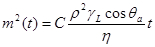

Here, the main focus is to describe the experimental procedure to measure the geometric factors and the apparent advancing contact angles for unidirectional fabrics, with the aim of determining the capillary pressure. This method relies on using a tensiometer to perform wicking tests (Figure 1). A tensiometer is a microbalance with a resolution of 10 µg that measures the liquid mass either forming a meniscus around a solid or ascending a fibrous medium. Wicking tests were carried out considering a one-dimensional characterization (direction along the fibers)8,9. Quasi-unidirectional fabrics used to validate the procedure were carbon uni-directional (UD) fabrics at a Vf = 40%. Once the method was validated, flax fabrics were submitted to a thermal treatment that modifies the wetting behavior of fibers6, and wicking tests were performed with different fiber volume ratios (from 30% to 40%) for both untreated and treated flax fabrics. To determine morphological and wetting parameters, at least two wicking tests are mandatory: the first one with a totally-wetting liquid, like n-hexane, to determine C (Equation 1), and the second one with the liquid of interest, to determine the apparent advancing contact angle once C is known. In the first approach, water was used to evaluate the procedure.

This method can be applied to different fabrics and liquids, allowing for the evaluation of the influence of material geometry (morphology of fabrics), porosity (different fiber volume ratios), and viscosity and surface tension of liquid on the capillary impregnation phenomena. It is obvious that the procedure according to the Washburn theory (Equation 1) can be adopted only if wicking curves (m²(t)) recorded by the tensiometer have a linear trend. This means that the parameters in Equation 1 must remain constant during the entire wicking process. If this is not the case, as for flax reinforcements in water, because fibers undergo swelling10,11, the Washburn equation should be modified to include the effect of swelling in order to describe the tests properly9. Treated fabrics were found to be less sensitive to water sorption9. Geometric factors and wetting parameters can be measured from linear fits, allowing for the calculation of the capillary pressure, Pcap.

Protocol

Caution: Consult all relevant material safety data sheets. Chemicals used for the tests are toxic and carcinogenic. Use personal protective equipment (safety glasses, gloves, lab coat, full-length pants, and closed-toe shoes).

1. Setup for Tests

- Preparation of samples

- Cut strips of fabric along the direction perpendicular to the fibers (in order to test wicking in the fiber direction).

NOTE: The lengths of the strips are calculated in order to obtain a defined fiber volume ratio. For carbon fabrics, to obtain Vf = 40%, the length of the strips was 150 mm. For untreated and treated flax, to achieve the same Vf, the length was 365 mm. The width of each strip will be equal to the height of sample holder, which is 20 mm (Figure 1). - Roll the strips tightly to allow their insertion into the cylindrical sample holder of R = 6 mm.

- Add a thin paper filter between the sample holder and the sample reinforcements (in order to suppress the effect of the sample holder on the wicking). The maximum thickness of the paper filter should be 0.1 mm.

- Insert the sample into the cylinder and screw the drilled cap at the bottom and the piston at the top in order to ensure compaction.

- Clamp the sample holder with the fabric to the tensiometer.

- Cut strips of fabric along the direction perpendicular to the fibers (in order to test wicking in the fiber direction).

- Preparation of liquids

- Fill a vessel with the liquid test and place it into the specific receptacle of the tensiometer. Use vessels made of borosilicate glass and with a diameter of 70 mm.

- For the first test (step 2.1), use n-hexane. For the second test (step 2.3), use water. Ensure that the liquid in the vessel reaches a height of at least 12 mm.

- Experimental parameters

- Set the surface detection threshold to 8 mg and the translation speed of the liquid vessel at 0.5 mm/s for detection of the liquid.

2. Wicking tests

NOTE: After the preparation of samples and the setup of the tensiometer parameters, the wicking tests can start. The liquid vessel moves up until the liquid is in contact with the sample holder. Then, liquid rises into the sample holder, and the tensiometer measures the squared liquid mass gain over time. Data are recorded by the software provided with the tensiometer. One curve of mass against time is then visualized for each wicking test.

- Initial test for determining the geometric factor:

- Use a totally-wetting liquid (for which the contact angle is 0°), such as n-hexane.

- Stop the wicking test when the visualized curve achieves a constant value. This indicates that the liquid has reached the top of the sample holder and thus that the wicking is complete.

- Fit the linear trend of the wicking curve (m2(t)) with the Washburn equation:

(3)

(3)

Since the advancing contact angle is supposed 0° with n-hexane, from the slope of linear fit, determine the geometric constant, C (mm5).

NOTE: All tests were carried out under standard conditions at 20 °C. A change in temperature will modify the liquid surface tension and the results.

- Cleaning of sample holder for the following tests

NOTE: After removing the wet fabric, the sample holder has to be cleaned perfectly to prevent errors in the following measurements.- Immerse the sample holder in a vessel with sulfochromic acid (50% of a saturated solution of potassium dichromate and 50% of concentrated sulfuric acid) for 30 sec.

- Rinse it with distilled water and then dry it.

- Second test for determining the apparent advancing contact angle

- Use the liquid for which the advancing contact angle has to be measured with a new, identical, and dry fabric sample.

NOTE: Water was used in order to validate the method. - Stop the wicking test when the visualized curve achieves a constant value. This indicates that the liquid has reached the top of the sample holder and that the capillary rise is complete.

- Fit the linear part of the wicking curve (m2(t)) with the Washburn equation (Equation 3), since the constant, C, is already known due to the first test (step 2.1), with the slope of linear fit determining the advancing contact angle, θa (°).

NOTE: All tests were carried out under standard conditions at 20 °C. A change in temperature will modify the liquid surface tension and the results.

- Use the liquid for which the advancing contact angle has to be measured with a new, identical, and dry fabric sample.

- Evaluation of the liquid weight contribution due to the sample holder

NOTE: The tensiometer, as a microbalance, measures the total mass of liquid, including both the liquid ascending in the fabric and the contribution of the external meniscus on the sample holder and the wicking in the filter. Those contributions must be isolated.- Put the same amount of filter paper as used in step 1.1.3 into the sample holder and repeat steps 2.1.1-2.1.2.

- Subtract the constant value obtained (m2) from the data recorded in step 2.1.3 and shift the curve to assess the correct evaluation of the geometric constant, C.

- Fill the sample holder with only the filter paper and repeat steps 2.3.1-2.3.2.

- Subtract the constant value obtained (m2) from the data recorded in step 2.3.3 and shift the curve to assess the correct evaluation of the advancing contact angle, θa.

Representative Results

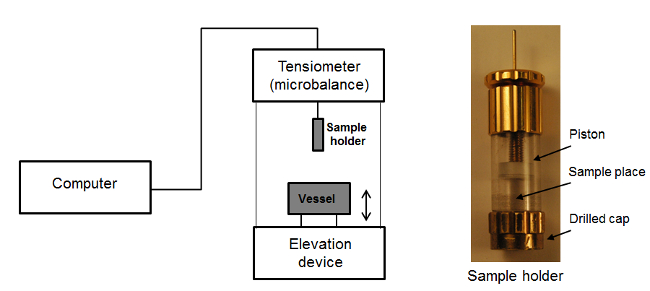

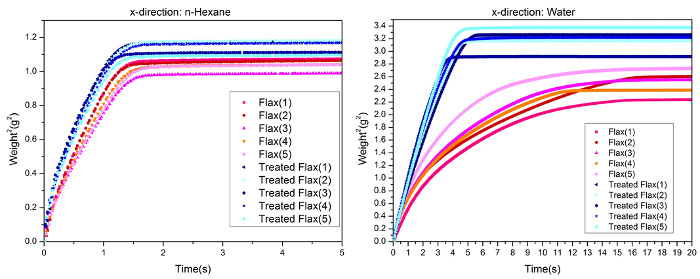

Curves of mass gain during wicking obtained with the tensiometer for carbon and untreated and treated flax fabrics are shown in Figures 2 and 3. All curves are shown after the subtraction of both weights of the external meniscus due to the sample holder and filter paper and are shifted to zero.

It is possible to observe from the plots in Figure 2 that, with both n-hexane and water, a linear fit of Equation 1 with experimental wicking is well-achieved if the fabrics are inserted properly in the sample holder. The use of a filter paper is mandatory to ensure the repeatability of measurements. This makes it possible to set the constant, C, and then to calculate an apparent advancing contact angle, θa. Curves reach an asymptotic equilibrium that is given by the height of the sample itself, which is limited to 20 mm to ensure the capillary-driven flow. The equilibrium weight is due to the saturation of the porous medium by the test liquid. It is thus related to the fiber volume ratio and the sample holder inner volume (i.e., porosity, ε). With the derived constant, C, and the apparent advancing contact angle, θa (Table 1), it is possible to determine the capillary pressure, Pcap, along the fiber direction for unidirectional carbon fabrics.

Like the carbon fabrics, wicking tests for untreated and treated flax reinforcements were carried out. Figure 3 (left) shows experimental curves obtained on five tests for n-hexane. A linear trend was observed for both treated and untreated flax fabrics, allowing for the determination of the geometric factors. Only a slight difference was observed between untreated and treated fabrics, indicating an eventual decrease of tortuosity with treatment, but not demonstrating a significant modification of morphology. A significant effect of treatment on flax reinforcement is shown on Figure 3 (right). It is obvious that a linear fit is possible on treated fabrics, while untreated ones clearly show a non-linear trend. Average results over five tests for the three types of reinforcements are presented in Table 1. It will thus be possible, after measurements of fabrics permeabilities, to calculate with Equation 2 an equivalent capillary pressure for only treated fabrics. Differences in wicking are due to the sensitivity to water that induce the swelling of flax fibers. Swelling of natural fibers during wicking causes an increase in the fiber volume ratio, which causes the equilibrium weight to be reached more slowly. It also induces a smaller equilibrium weight due to the diminution in porosity. The capillary rise was already found to be faster for chopped, treated flax yarns; this result is thus coherent6. Treatment makes fibers less sensitive to water sorption9, and this can thus explain the differences in wicking for untreated and treated fabrics. A modified Washburn equation that includes the effect of swelling is then used to fit the experimental data of wicking in flax fabrics, allowing for the determination of the capillary pressure, Pcap9.

Figure 1: Scheme of the tensiometer (left) and the cylindrical sample holder (right)8. This scheme represents the tensiometer setup (left) and depicts the moving vessel and the weighing apparatus, which records the sample weight over time. The sample holder is shown on the right part of the scheme. The piston and the drilled cap ensuring the compaction of the fabrics can be seen. Please click here to view a larger version of this figure.

Figure 2: Washburn fit of two experimental tests in the x-direction, with n-Hexane (left) and water (right). The tests refer to carbon fabrics with Vf= 40%8. The aim of this figure is to show that the first part of the capillary wicking graph is linear, plotting the squared mass gain against time. It also shows that this is verified for each test liquid. Please click here to view a larger version of this figure.

Figure 3: Wicking curves obtained with n-Hexane (left) and water (right) for untreated and treated flax fabrics at Vf= 40%9. These graphs clearly show that there is a large difference between untreated and treated flax fabrics. While a linear fit can be achieved with n-Hexane for both fabrics, it is impossible for untreated flax with water. This is due to the swelling of the flax fibers. Please click here to view a larger version of this figure.

| Type of fabrics | cṝ (µm) | θa (°) |

| Carbon UD | 12.1 ± 1.5 | 74.8 ± 2.3 |

| Untreated flax UD | 12.2 ± 1.4 | ? |

| Treated flax UD | 15.3 ± 1.3 | 72.1 ± 1.8 |

Table 1: Average measured values of the geometric product and the apparent advancing contact angle on carbon and on untreated and treated flax fabrics. This table presents the average values over five tests for each fabric, derived from the linear fit of experimental graphs (m2(t)) with the Washburn equation.

Discussion

The critical steps in the protocol relate to the preparation of the samples. Firstly, the rolled sampled have to be tight in order to make the assumption of a homogeneous fiber volume ratio. If there is a tightness gradient in the sample, the Washburn equation5,6 cannot be used to fit the wicking curves. In addition, the boundary conditions between the fabric and the sample holder are difficult to control. Thus, the filter paper (1.1.3) must also be carefully inserted into the sample holders8.

Some modifications of the technique can be made to analyze other directions of wicking in order to evaluate orthotropic effects in capillary pressure8. For instance, one can cut strips along the direction of fibers, in order to test the wicking in the direction perpendicular to the fibers (in the reinforcement plane); or one can cut discs of reinforcements of the cylindrical sample holder radius and stack them in order to test wicking in the transverse direction.

However, the procedure is limited by the Washburn hypothesis5. In addition, the method is limited in terms of sample size, as neither longer nor larger samples can be processed currently. This must be addressed for certain types of weaving, such as larger tows.

This method is currently the only one that allows the determination of capillary pressure during spontaneous impregnation. This parameter is of primary importance for the simulation of composite manufacturing and void formation in industrial composite parts manufactured by liquid composite molding processes.

Critical steps may have to be improved for further applications. Modifications of the sample holder will be made in order to move all of the actual boundaries. Another future application is to use the procedure to determine the capillary pressure with resin, which is the final purpose of the LCM processes.

Disclosures

The authors have nothing to disclose.

Materials

| Carbon UD fabrics | Hexcel | 48580 | |

| Flax UD fabrics | Libeco | FLAXDRY UD 180 | |

| n-Hexane | Sigma Aldrich | ||

| Sulfochromic acid | home made | toxic and corrosive | |

| Filter paper | Dataphysic | FP11 | |

| Tensiometer | Dataphysic | DCAT11 |

References

- Lawrence, J. M., Neacsu, V., Advani, S. G. Modeling the impact of capillary pressure and air entrapment on fiber tow saturation during resin infusion in lcm. Compos Part A: Appl Sci Manuf. 40 (8), 1053-1064 (2009).

- Ravey, C., Ruiz, E., Trochu, F. Determination of the optimal impregnation velocity in resin transfer molding by capillary rise experiments and infrared thermography. Compos Sci Technol. 99, 96-102 (2014).

- Verrey, J., Michaud, V., Månson, J. -. A. Dynamic capillary effects in liquid composite moulding with non-crimp fabrics. Compos Part A: Appl Sci Manuf. 37 (1), 92-102 (2006).

- Abouorm, L., Moulin, N., Bruchon, J., Drapier, S. Monolithic approach of Stokes- Darcy coupling for LCM process modelling. Key Eng Mater. 554, 447-455 (2013).

- Washburn, E. W. Note on a method of determining the distribution of pore sizes in a porous material. Proc Natl Acad Sci USA. , 115-116 (1921).

- Pucci, M. F., Liotier, P. -. J., Drapier, S. Capillary effects on flax fibers-modification and characterization of the wetting dynamics. Compos Part A: Appl Sci Manuf. 77, 257-265 (2015).

- Darcy, H., Dalmont, V. . Les fontaines publiques de la ville de Dijon: exposition et application. , (1856).

- Pucci, M. F., Liotier, P. -. J., Drapier, S. Capillary wicking in a fibrous reinforcement-orthotropic issues to determine the capillary pressure components. Compos Part A: Appl Sci Manuf. 77, 133-141 (2015).

- Pucci, M. F., Liotier, P. -. J., Drapier, S. Capillary wicking in flax fabrics – effects of swelling in water. Colloids Surf A: Physicochem Eng Aspects. 498, 176-184 (2016).

- Nguyen, V. H., Lagardère, M., Park, C. H., Panier, S. Permeability of natural fiber reinforcement for liquid composite molding processes. J Mater Sci. 49 (18), 6449-6458 (2014).

- Stuart, T., McCall, R., Sharma, H., Lyons, G. Modelling of wicking and moisture interactions of flax and viscose fibres. Carbohydr Polym. 123, 359-368 (2015).