High-throughput, Microscale Protocol for the Analysis of Processing Parameters and Nutritional Qualities in Maize (Zea mays L.)

Summary

Here, we present a microscale protocol for processing grain samples and for incorporating this microscale approach into a high-throughput analytical pipeline. This is a higher throughput adaptation of currently available protocols.

Abstract

Maize is an important grain crop in the United States and worldwide. However, maize grain must be processed prior to human consumption. Furthermore, whole grain composition and processing characteristics vary among maize hybrids and can impact the quality of the final processed product. Therefore, in order to produce healthier processed food products from maize, it is necessary to know how to optimize processing parameters for particular sets of germplasm to account for these differences in grain composition and processing characteristics. This includes a better understanding of how current processing techniques impact the nutritional quality of the final processed food product. Here, we describe a microscale protocol that both simulates the processing pipeline to produce cornflakes from large flaking grits and allows for the processing of multiple grain samples simultaneously. The flaking grits, the intermediate processed products, or final processed product, as well as the corn grain itself, can be analyzed for nutritional content as part of a high-throughput analytical pipeline. This procedure was developed specifically for incorporation into a maize breeding research program, and it can be modified for other grain crops. We provide an example of the analysis of insoluble-bound ferulic acid and p-coumaric acid content in maize. Samples were taken at five different processing stages. We demonstrate that sampling can take place at multiple stages during microscale processing, that the processing technique can be utilized in the context of a specialized maize breeding program, and that, in our example, most of the nutritional content was lost during food product processing.

Introduction

Maize (Zea mays L.) is the most widely cultivated grain crop in the United States1. In 2016, 71.12 billion kg (2.8 billion bushels) of maize were devoted to human consumption2, indicating the importance of maize in the American diet. One of the great benefits of maize grain is that it is a relatively inexpensive commodity, but it also contains beneficial phytochemicals such as phenolics, unsaturated fatty acids, and protein3. As such, maize-based food products may be relatively inexpensive sources of beneficial phytochemicals for humans.

However, maize must be processed prior to human consumption. As a result, processing activities often impact the nutritional value of the final processed food product4. For instance, during the production of snack foods and ready-to-eat breakfast cereals (i.e., cold cereals), maize kernels are dry milled to produce large flaking grits. During dry milling, the bran and germ are physically removed, leaving only endosperm material. Since many phytochemicals are predominantly located in either the bran or the germ (e.g., phenolics and unsaturated fatty acids, respectively), this may result in a significant decrease in the nutritional value of the processed food product4. Conversely, downstream processing steps may improve the nutritional value. For instance, many food product processing techniques include cooking, baking, or toasting. The thermal stresses encountered during these stages may improve the bioavailability of beneficial phytochemicals5.

From a food science and human nutrition perspective, it would be interesting to know how processing affects not only the nutritional value of processed food products but, foreseeably, also how adjustments to processing parameters may impact other sensory qualities, including color, texture, and taste. A protocol that allows such qualities to be monitored throughout processing could be used to select maize varieties for the improvement of the final processed maize food product. Two of the major obstacles to analyzing such characteristics in the past were the scale and throughput of available protocols. For instance, during the production of breakfast cereals for laboratory analysis, Fast and Caldwell6 suggested the use of 45.4 kg of large flaking grits. This mass of large flaking grits far exceeds the amount of large flaking grits or large flaking grit materials7 that can be produced from small plot field trials that are typical in plant breeding programs. Thus, the development of a microscale laboratory protocol for the production of processed food products could enable (1) plant breeders to improve maize varieties for nutritional and sensory traits that are of importance to food processors and (2) processors to efficiently design and test alternative processing strategies.

In this manuscript, we describe a high-throughput modification of the microscale processing protocol described in Kandohla8 that was used to produce toasted cornflakes from large flaking grit materials. We present the results of an example experiment that used this processing protocol to study the change in insoluble-bound ferulic acid and p-coumaric acid in maize. Our objectives in that specific study were to determine (1) how the phenolic acid content of maize changed during the production of ready-to-eat breakfast cereals, (2) at which processing stages those changes occurred, and (3) whether any of our experimental hybrids responded differently to processing stresses This protocol can be coupled with high-throughput analytical chemistry protocols for the efficient analysis of nutritional traits. This protocol can also be adjusted to mimic the production of other processed maize food products or processed food products that are produced from other grains.

Protocol

1. Produce Cooked Grits

- Place a 15 L canning pressure cooker on an electric hotplate.

- Add 1 L of tap water into the canning pressure cooker and heat to 100 °C.

- While the water heats, place a 100 g sample of industrial flaking grits or flaking grit material (12% moisture content, wet basis)7 in a 1 quart canning jar.

NOTE: The representative results of this study are based on the flaking grit materials produced by Macke et al.9 using the laboratory scale dry milling protocol outlined by Rausch et al.7 - Add a sugar-salt solution consisting of 200 mL of distilled water, 2 g salt, 6 g granulated white sugar, and 2 g liquid malt extract.

NOTE: Multiple samples can be analyzed at once, although the exact number of samples will depend on the size of the canning pressure cooker. - Mix the solution with the flaking grit material using a glass stirring rod.

- After the water in the canning pressure cooker begins to boil, add 1 L of tap water to cool the water in the canning pressure cooker.

- Place the canning jars in the canning pressure cooker such that they are equidistant from each other and from the wall of the canning pressure cooker.

Figure 1: Placement of canning jars in canning pressure cooker. Canning jars should be placed equidistant from one another and from the sides of the canning pressure cooker to ensure even cooking and to avoid damage to canning jars. Please click here to view a larger version of this figure.

- Allow the water to reach a rolling boil. Place the lid on the canning pressure cooker.

- Cook the large flaking grits or flaking grit material at 15 psi for one h. Allow the canning pressure cooker to cool and depressurize completely before opening.

- Remove the lid from the canning pressure cooker using heat resistant gloves.

- Remove the canning jars from the canning pressure cooker using tongs. Place the jars on a heat resistant surface.

NOTE: The resulting intermediate product at this point is cooked grits. - If using flaking grit materials as produced using the protocol outlined by Rausch et al.7, remove non-endosperm material with a spatula after cooking. If using industrial flaking grits, skip this step.

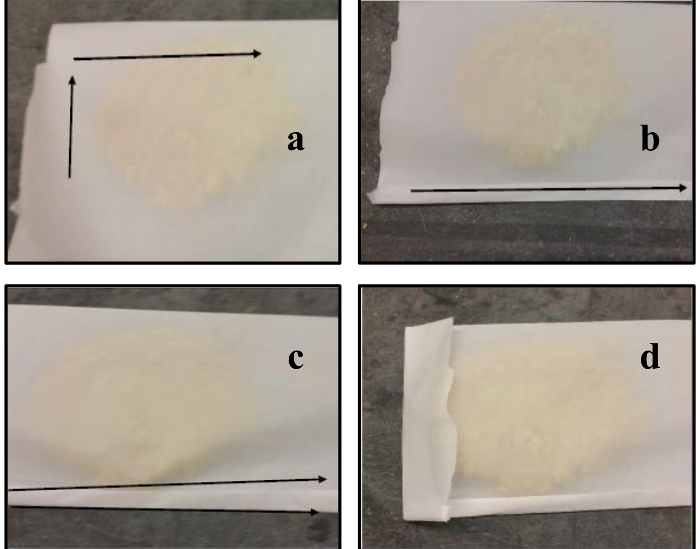

Figure 2: Removal of non-endosperm material. (a) Cooked grit sample prior to the removal of non-endosperm material that has risen to the top during cooking. (b) Cooked grit sample after the removal of non-endosperm material. Please click here to view a larger version of this figure.

- Place 30 g of cooked grits (per processed sample) in a weigh boat and dry in an oven at 65 °C for 12 h. After drying, grind the cooked grit sample to a fine powder using a coffee mill and store in a cool dry place for phenolics analysis.

2. Produce Baked Grits

- Place the remaining cooked grits on a foil-lined baking sheet.

- To improve throughput, bake two samples concurrently. To do this, create two foil boats on a baking sheet. This eliminates the possibility of cross-contamination between the samples.

Figure 3: Placement of cooked grits on baking sheet. Two different cooked grit samples are placed in individual foil boats on a baking tray prior to baking. The boats are labeled with green tape in the photo. This increased the throughput of the protocol while also ensuring cross-contamination did not take place. Please click here to view a larger version of this figure.

- Place the baking dish containing the two samples in a pre-heated convection oven at 107.2 °C (225°F) for 50 min.

- Stir the samples after 25 min of baking to ensure even baking.

- At the end of the 50 min time period, remove the baking dish containing the first two samples and allow to cool at room temperature for 30 min.

- At the end of the cooling period, take a 30 g sample from the baked grits intermediate product. Place this sample in a weigh boat in an oven at 65 °C for 12 h. After drying, grind the baked grit sample to a fine powder using a coffee mill and store for phytochemical analysis.

3. Produce Final Toasted Cornflake Product

- Roll the baked grits through a tortilla press.

- Remove the remaining baked grits from the foil-lined baking dish and place these on a piece of parchment paper approximately 1 m in length.

NOTE: To increase throughput, it is helpful to fold the parchment paper length-wise into a pouch. This minimizes the amount of sample lost during the rolling stage that follows. - Slowly feed the baked grit sample in the pouch through a tortilla press. Be careful to avoid pinching fingers in the press.

- Remove the remaining baked grits from the foil-lined baking dish and place these on a piece of parchment paper approximately 1 m in length.

Figure 4: Parchment paper pouch. (a) The parchment paper is folded lengthwise. (b) The long, open side of the pouch is folded over. (c) The long side is folded over again at a 10° angle. (d) The short, open side of the pouch is folded over. This will be the side of the pouch that is fed through the tortilla press. Please click here to view a larger version of this figure.

- Cut the rolled baked grits into 2.5 cm x 2.5 cm (1 in2) squares. Use a tool such as a pizza cutter to cut/score the rolled dough through the parchment paper.

Figure 5. Cutting rolled dough into flakes. The rolled dough is scored through the parchment paper. Please click here to view a larger version of this figure.

- Open the parchment paper and allow the rolled, cut, baked grits to dry at room temperature for 12 h.

- To increase throughput, store the dried sample in a foil-covered weight boat at room temperature until multiple samples (typically 24 or more) are ready for toasting.

- Pre-heat a convection oven to 204.4 °C (400 °F). Place the dried untoasted flake sample on a flat baking sheet. Spread the sample so that minimal overlapping of the sample occurs. This ensures even toasting.

- Place the sample in the oven for 60–90 s until it achieves the proper color (see Figure 6).

Figure 6: Correct color of final toasted cornflakes. The cornflakes on the left side of the picture were toasted for the appropriate amount of time. The cornflakes on the right side of the picture were toasted for too long. Please click here to view a larger version of this figure.

- Allow the sample to cool for approximately 5 min at room temperature. This yields the final toasted cornflake.

- Grind the toasted cornflake sample into a fine powder using a coffee mill.

4. Phytochemical and Statistical Analyses

NOTE: Depending upon the exact phytochemical of interest and the laboratory equipment available to researchers, these analytical protocols may change.

- Determine phytochemical content using a protocol such as that outlined in Butts-Wilmsmeyer et al.3 Follow all safety procedures provided in the protocols.

- Analyze the data using an appropriate statistical model.

NOTE: These example data were analyzed using a split-plot in an RCBD where the whole plot unit was the field plot from which grain was harvested, and the subplot unit was the processing stage. Analyses were conducted in PROC MIXED of SAS (version 9.3), and figures were produced in R.

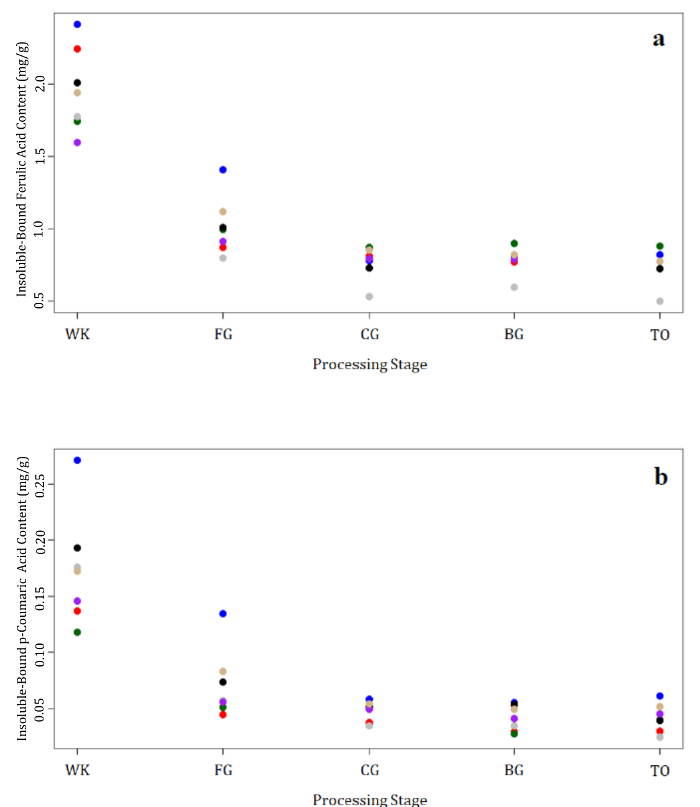

Representative Results

This protocol allowed for the sampling and nutritional analysis of a processed maize food product, cornflakes, beginning with large flaking grits and continuing through intermediate stages of processing to the final product. This protocol was coupled with the protocol outlined by Rausch et al.7 to produce flaking grit components from hybrid grain samples. Thus, information regarding the nutritional content of hybrid samples analyzed at the whole grain, large flaking grit, cooked grit, baked grit, and toasted cornflake processing stages are presented. Regardless of the hybrid cultivar under evaluation, most of the insoluble-bound ferulic acid and p-coumaric acid was removed during dry milling (Figure 7). Another decrease in the insoluble-bound ferulic acid and p-coumaric acid occurred during cooking. The decrease in the insoluble-bound ferulic acid and p-coumaric acid content observed during cooking may be due to the removal of the small amount of non-endosperm material that remained in the large flaking grit material. Multi-degree of freedom contrasts indicated that both the ferulic acid and p-coumaric acid content remained stable throughout the remainder of processing, regardless of the hybrid (Table 1).

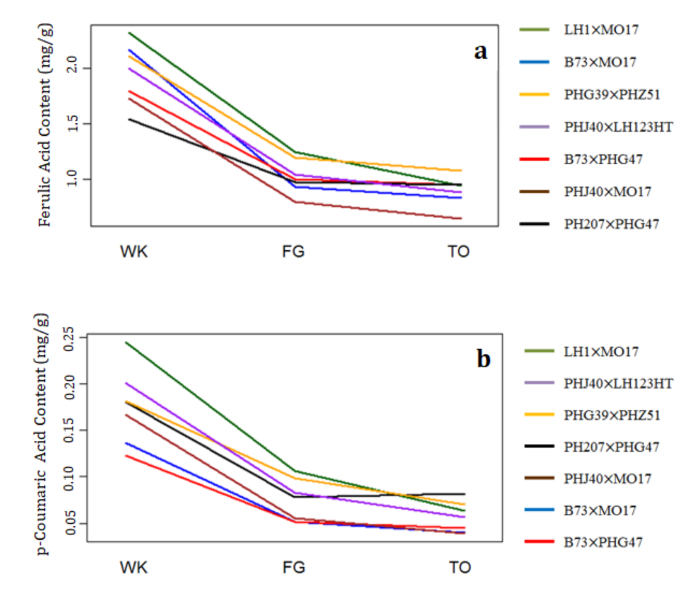

Furthermore, the initial ranking of the hybrid cultivars in terms of their insoluble-bound ferulic acid content and p-coumaric acid content were not indicative of the ranking of the hybrids at the final processing stage (Table 2 and Figure 8). In other words, the initial content in the whole kernel was not indicative of which hybrid would possess the most insoluble-bound ferulic acid or p-coumaric acid at the end of processing. Thus, in order to study the genetic traits underlying the nutritional characteristics of processed food products, microscale processes must be used to study maize grain.

Figure 7: Change in insoluble-bound phenolic acid content throughout processing. (a) Change in insoluble-bound ferulic acid content throughout processing. (b) Change in insoluble-bound p-coumaric acid content throughout processing. WK: Whole Kernel, FG: Flaking Grit, CG: Cooked Grit, BG: Baked Grit, TO: Toasted Cornflake. Different color points represent different hybrids. Figure originally published in the supplemental information of Butts-Wilmsmeyer et al.4 Please click here to view a larger version of this figure.

Figure 8: Interaction plot of the hybrid-by-processing stage interaction. (a) Interaction plot for insoluble-bound ferulic acid content. (b) Interaction plot for insoluble-bound p-coumaric acid content. The intersecting lines indicate a change-of-rank interaction, meaning that neither the insoluble-bound ferulic acid nor the insoluble-bound p-coumaric acid content of the final toasted cornflake can be predicted based upon the initial content of either of these phytochemicals in the whole kernel. WK: Whole Kernel, FG: Flaking Grit, TO: Toasted Cornflake. Figure originally published in the supplemental information of Butts-Wilmsmeyer et al.4 Please click here to view a larger version of this figure.

| Ferulic Acid | p-Coumaric Acid | |||

| Hybrid | F-value | p-value | F-value | p-value |

| B73xMO17 | 0.07 | 0.93 | 0.34 | 0.72 |

| B73xPHG47 | 0.02 | 0.98 | 0.61 | 0.55 |

| LH1xMO17 | 0.08 | 0.93 | 0.14 | 0.87 |

| PHJ40xLH123HT | 0.32 | 0.73 | 0.74 | 0.48 |

| PH207xPHG47 | 0.15 | 0.86 | 0.24 | 0.79 |

| PHJ40xMO17 | 0.01 | 0.99 | 0.31 | 0.74 |

| PHG39xPHZ51 | 0.06 | 0.94 | 0.07 | 0.93 |

Table 1: Multi-degree of freedom contrasts testing the difference in insoluble-bound phenolic acid content in the cooked grits, baked grits, and toasted cornflakes.

| Ferulic Acid | p-Coumaric Acid | |||

| F-value | p-value | F-value | p-value | |

| Hybrids | 7.15 | 0.001 | 8.7 | <0.001 |

| Inbreds | 4.07 | 0.007 | 6.57 | <0.001 |

| NOTE: All year-by-genotype-by-processing stage intereactions were non-significant at α = 0.05. | ||||

Table 2: Significance of genotype-by-processing stage interaction.

| Protocol Step | Critical Information | Troubleshooting | High-Throughput Recommendations |

| 1.2 and 1.6 | The coupling of these two steps enables water to be heated without breaking the canning jars. | NA | The heating of half the water prior to the addition of the canning jars increases throughput. |

| 1.4 | NA | NA | Pre-measure ingredients. The given amount is for one jar, so multiply the volume or mass of ingredients needed by the number of jars used in step 1.4.2. Divide the resulting mixture equally among the canning jars. |

| 1.4 note | Do not allow jars to touch edge of canning pressure cooker or each other. They will break, and sample will be lost. | NA | NA |

| 1.9 and 1.10 | Water should reach a rolling boil prior to cooking. | If grits are not thoroughly cooked after one h, then check to ensure the pressure weight was set to 15 psi and that water is reaching a full boil before the lid is placed on the canning pressure cooker and the timer is set. | NA |

| 1.13 | Remove the non-endosperm material that floats to the top during cooking. This will skew any phytochemical results if left in the sample. | If non-endosperm material does not rise to the top during cooking, then the grits did not cook thorougly. See information regarding steps 1.9 and 1.10. | NA |

| 1.15, 2.4, and 3.7 | Grind sample to a fine powder. | If phytochemical analyses do not appear to work, ensure that the sample has been ground to a fine powder such that there is a greater surface area exposed to solvents. | NA |

| 2.1 | Do not allow samples to touch one another. They will become cross-contaminated. | NA | Bake two samples concurrently by making individual foil boats for them on a cooking sheet. |

| 2.2.1 | Stir the sample after 25 min to ensure even baking. | If the sample does not appear to have baked evenly, stir at more frequent intervals (e.g. every 15 min). | NA |

| 3.1 | Place the baked grit dough in a parchment paper pouch. This ensures sample will not be lost during pressing. | If sample starts to come out of the end of the parchment paper pouch, make the pouch longer. We found that 1 m appeared to be sufficient. | NA |

| 3.2 | Leave the parchment paper pouch closed. | If the cutting tool cuts through the parchment paper, use a duller tool. | We found that a pizza cutter was the best tool for cutting the baked grits into squares. We did not cut through the parchment paper using this tool, but the baked grits still were able to be cut very quickly into squares. |

| 3.5 | Become very comfortable with the color and do not toast for too long. | If the sample becomes too dark, reduce the amount of time used to toast. | Store multiple dried baking grit samples in individual foil-covered weigh boats until multiple samples are ready for toasting. |

Table 3: Table of critical steps, troubleshooting steps, and recommendations.

Discussion

Changes in the nutritional content of maize-based food products throughout processing are likely due to the removal of gain components and thermal stress5,10. However, exactly how processing affects various nutrients had been studied in relatively little detail prior to the development of this protocol4,8. Furthermore, due to the large scale of most laboratory processing protocols, it has often been impossible to study the genetic basis of sensory and nutritional characteristics in maize grain8. Here, we present a microscale laboratory method for studying nutritional and sensory traits in maize throughout food product processing.

This protocol allowed sampling to take place at the flaking grit stage, after cooking, after baking, and after the shearing forces encountered during rolling. Thus, with the additional analysis of harvested corn grain, the protocol facilitates the analysis of the initial stage substrate and well as the final food product and intermediary stages of processing to elucidate changes in composition related to nutrition. This key feature of the protocol enables nutritional and sensory traits to be analyzed throughout processing while also enabling the researcher to choose which analytical chemistry protocols to use for those specific analyses. Another key feature of this protocol is the efficiency of this microscale protocol. First, this protocol uses a small sample, which is appropriate in a plant breeding setting (Table 3). One kg of grain tended to produce approximately 0.3 kg of large flaking grit constituents, and roughly one third of the large flaking grit constituents produced were needed for processing. Secondly, this protocol allowed for the laboratory processing of approximately 16 samples per day, which is much more efficient than the previous protocol that required large sample sizes6.

This protocol could easily be modified to mimic the production of other processed maize food products. For instance, large flaking grits are used in the production of various snack foods in addition to ready-to-eat breakfast cereals9. The laboratory protocol for the production of these snack foods could foreseeably include adjustments to cooking times and cooking solutions or adjustments to baking times. It is also possible that an adapted version of this protocol could be used for the study of other grains and their respective processed products. Processed grain products often include cooking, baking, or toasting processing stages that could be mimicked using an adapted version of the protocol presented here.

An important limitation of this protocol is that it has very few stopping points, i.e. once a processing step begins, it and subsequent steps must be completed (Table 3). There is a single stopping point after the production of the cooked grits from the flaking grits. Only if necessary, the cooked grits could be placed in a sealed container (e.g. a sealed canning jar) and refrigerated for at most two days. However, storing the cooked grits for longer time periods appeared to alter the sample. Furthermore, once baking begins, there are no stopping points until after the baked grit dough has been rolled, cut, and dried.

Conclusion

Through these example results (see Butts-Wilmsmeyer et al.4 for more information), we demonstrated that nutritional content could be monitored throughout processing. Furthermore, key processing stages where nutritional changes occurred were identified. Additionally, the small sample size required for this processing protocol enabled the study of multiple hybrids within the context of a plant breeding program. Using these hybrids, we identified which set of hybrids maintained the highest concentrations of insoluble-bound ferulic acid and p-coumaric acid throughout processing. These traits are important indications of the final toasted cornflakes' prebiotic potential.11,12,13 These results could be used directly to help plant breeders establish breeding populations for improved prebiotic potential of processed maize products.

One of the major advantages of this processing protocol is that it does not limit the nutritional analyses that can be conducted. If a phytochemical protocol exists for analysis of the grain, then it can be used to study the processed products. Furthermore, because this processing protocol enables laboratory-scale food processing and nutritional analyses to be conducted independently, multiple phytochemicals can be studied. The analytical protocols for the study of phytochemical content should use small sample sizes, however, due to the small amount of intermediate and final processing products generated using the laboratory-scale processing protocol.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors would like to thank Tom Patterson and the Analytical Technologies Team at Dow AgroSciences for the use of their laboratory facilities and for their mentorship. This work was funded in part through gifts from the Kellogg Company and Dow AgroSciences and through USDA Hatch Grant, award ILLU-802-354. Student support for CJBW was provided by the Illinois Distinguished Fellowship and the William B. and Nancy L. Ambrose Fellowship in Crop Sciences.

Materials

| Canning pressure cooker | Wisconsin Aluminum Foundry Co. | Model 921 | Any can be used, but it should be large enough to accommodate multiple canning jars |

| Single burner or large hot plate | Waring Professional | Model SB30 | Any can be used, but it should be large enough so that canning pressure cooker can securely be placed on burner or hot plate |

| 1 quart wide mouth canning jars | Ball | 1440096258 | Any can be used, but they should be wide mouthed quart jars |

| 1 L Beaker | Fisher Scientific | 09-841-104 | |

| Stir plate | Corning | 6796420D | |

| Magnetic stir bar | Fisher Scientific | 14-513-67 | |

| 1 L Graduated cylinder | Kimble | 20027500 | |

| Spatula | Wal-Mart | 552145280 | |

| Hot pads | Wal-Mart | 556501140 | |

| Scale | Any | NA | Mettler Toledo Model MS105DU or Similar |

| Weigh boats | Fisher Scientific | 08-732-113 | |

| Sugar | Wal-Mart | 9259244 | |

| Salt | Morton (Purchased at Wal-Mart) | 9244849 | |

| Liquid malt extract | By the Cup (Purchased on Amazon) | NA | https://www.amazon.com/Barley-Malt-Extract-Syrup-Bottle/dp/B01N4SK72C |

| Labeling tape | Fisher Scientific | 15966 | |

| Permanent marker | Wal-Mart | 55529894 | |

| Convection oven | Wal-Mart | 1598495 | |

| Baking pan (usually included with oven) | Wal-Mart | 1598495 | |

| Cooking foil | Wal-Mart | 564264789 | |

| Tortilla press | E&A Hotel & Restaurant Equipment and Supplies | CTM-2000 | |

| Parchment paper | Reynolds (Purchased at Wal-Mart) | 551219672 | |

| Pizza cutter | Farberware (Purchased at Wal-Mart) | 553012200 | |

| Cooling racks | Flytt (Purchased on Amazon) | NA | https://www.amazon.com/dp/B075HQY627/ref=sspa_dk_detail_7?psc=1&pd_rd_i=B075HQY627&pd_rd_wg=WaJol&pd_rd_r=SF07KCHMP753WAPG6ED4&pd_rd_w=2BOwf |

| SAS Version 9.4 | SAS Institute | Version 9.4 | |

| R | R Foundation for Statistical Computing | Version 3.4.0 |

References

- United States Department of Agriculture. . National Agricultural Statistics Service. , (2017).

- USDA. . ERS. , (2017).

- Butts-Wilmsmeyer, C. J., Mumm, R. H., Bohn, M. O. Concentration of Beneficial Phytochemicals in Harvested Grain of U.S. Yellow Dent Maize (Zea mays L.) Germplasm. Journal of Agricultural and Food Chemistry. 65 (38), 8311-8318 (2017).

- Butts-Wilmsmeyer, C. J., et al. Changes in phenolic acid content in maize during food product processing. Journal of Agricultural and Food. , (2018).

- Dewanto, V., Wu, X. Z., Liu, R. H. Processed sweet corn has higher antioxidant activity. Journal of Agricultural and Food Chemistry. 50 (17), 4959-4964 (2002).

- Fast, R. B., Caldwell, E. F. Breakfast cereals and how they are made. Breakfast cereals and how they are made. , (2000).

- Rausch, K. D., et al. Laboratory measurement of yield and composition of dry-milled corn fractions using a shortened, single-stage tempering procedure. Cereal Chemistry. 86 (4), 434-438 (2009).

- Kandhola, G. . Processing and Genetic Effects on Resistant Starch in Corn Flakes. , (2015).

- Macke, J. A., Bohn, M. O., Rausch, K. D., Mumm, R. H. Genetic factors underlying dry-milling efficiency and flaking-grit yield examined in us maize germplasm. Crop Science. 56 (5), 2516-2526 (2016).

- Somavat, P., et al. A new lab scale corn dry milling protocol generating commercial sized flaking grits for quick estimation of coproduct yield and composition. Industrial Crops and Products. 109, 92-100 (2017).

- Adam, A., et al. The bioavailability of ferulic acid is governed primarily by the food matrix rather than its metabolism in intestine and liver in rats. Journal of Nutrition. 132 (7), 1962-1968 (2002).

- Rumpagapom, P. . Structural Features of Cereal Bran Arabinoxylans Related to Colon Fermentation Rate. , (2011).

- Wong, J. M. W., de Souza, R., Kendall, C. W. C., Emam, A., Jenkins, D. J. A. Colonic health: Fermentation and short chain fatty acids. Journal of Clinical Gastroenterology. 40 (3), 235-243 (2006).