A Soft Tooling Process Chain for Injection Molding of a 3D Component with Micro Pillars

Summary

A protocol for fabricating injection molding inserts for complex geometry with micro features on surfaces employing Additive Manufacturing (AM) is presented.

Abstract

The purpose of this paper is to present the method of a soft tooling process chain employing Additive Manufacturing (AM) for fabrication of injection molding inserts with micro surface features. The Soft Tooling inserts are manufactured by Digital Light Processing (vat photo polymerization) using a photopolymer that can withstand relatively high temperaturea. The part manufactured here has four tines with an angle of 60°. Micro pillars (Ø200 µm, aspect ratio of 1) are arranged on the surfaces by two rows. Polyethylene (PE) injection molding with the soft tooling inserts is used to fabricate the final parts. This method demonstrates that it is feasible to obtain injection-molded parts with microstructures on complex geometry by additive manufactured inserts. The machining time and cost is reduced significantly compared to conventional tooling processes based on computer numerical control (CNC) machining. The dimensions of the micro features are influenced by the applied additive manufacturing process. The lifetime of the inserts determines that this process is more suitable for pilot production. The precision of the inserts production is limited by the additive manufacturing process as well.

Introduction

The presented method aims at manufacturing complex surface with micro features by a soft-tooling process, i.e., to use polymer additive manufacturing to produce inserts for polymer injection molding. In other words, polymer parts with functional surfaces are injection molded by polymer inserts.

Surface functionalities can be realized by micro features; for instance, Doan et al.1 and Luchetta et al.2 demonstrate functional surfaces in the field of cell biology, and Hu et al.3 shows an example of optical elements, etc. One type of surface feature, micro pillars, has been investigated intensively for promoting cell proliferation. They are able to enhance the bonding between the proliferated tissues and the surface if the micro pillars are patterned in certain ways4,5.

Polymer replications of micro features have been intensively studied, and precise molding can be achieved by many processes6. For instance, Metwally et al. has reported high fidelity between the molded parts and mold for replication of micro and sub-micro features on flat surfaces7.

There are many protocols for manufacturing micro pillars or features; however, most of them can only be applied on flat surfaces or surfaces with constant curvature. For instance, Nian et al.8 showed that micro features could be achieved by hot embossing on a curved surface. Those protocols are not suitable for complex shapes with three-dimensional surfaces, which are required by most real-life devices. Apparently, the fabrication of a three dimensional cavity with micro features on the surface challenges current protocols; meanwhile, ejection of the parts may fail for high aspect ratio pillars on a complex surface if they are non-perpendicular to the demolding direction. Bissacco et al.9 used 3D mold inserts and obtained sub-micro features by injection molding; in their study, specific sub-micro features with a low aspect ratio were generated by an aluminum anodizing process and successfully replicated by polymer on a complex component.

Researchers have attempted to involve additive manufacturing in the process chains for polymer replication in order to achieve the designed surface texture. Lantada et al. described a process chain that starts from AM prototypes, and then employs coating techniques for obtaining metallic mold inserts for injection molding10. Polymer parts produced by AM have been proved to be directly applicable as mold inserts11,12, which is the soft tooling process presented in this protocol.

In our previous work, we demonstrated that Ø4 µm PEEK pillars (2 µm high) were successfully demolded on a vertical wall by injection molding13. In this protocol, the investigated product is a ring with four tines, each characterized by having an angle of 60°. This product has been studied by Zhang et al.14, where micro features were introduced by implementing pre-fabricated nickel plates, and micro pillars (Ø4 µm) with aspect ratio of 0.5 were obtained by silicone rubber injection molding on the tines.

In the presented method, micro features can be obtained on complex surfaces created by a soft tooling process chain. Steel mold cavities are replaced by a set of inserts made by vat photo-polymerization-based AM. Compared to metal AM, photopolymer based AM technology is able to achieve higher precision15. Moreover, the machining time and cost is reduced significantly compared to conventional tooling processes based on CNC machining. According to a recent case study16, by using soft-tooling for thermoforming, the cost is reduced by 91%, while the consumed time is reduced by 93%. This protocol is suitable for products requiring a high design flexibility and intermediate production volume. It has been proved that inserts manufactured from carbon fiber reinforced photopolymers can withstand up to 2500 injection molding cycles for polyethylene before noticeable mold deterioration17. The choice of injection-molded material is limited by the thermal properties of the chosen photopolymer for inserts. Polymers with high melting temperatures may not be applied in a photopolymer cavity. In this study, polyethylene (PE) was chosen to conduct the injection molding test.

Protocol

1. Insert Fabrication by Additive Manufacturing (AM)

- Design the needed cavities by computer-aided design software (see Supplemental Materials for files used in this work).

NOTE: Manufacture the inserts directly on the building stage without support to avoid warping the inserts during curing. The tolerance is 0.05 mm. - Choose a resin for photo polymerization, in particular one that can withstand pressure and heat during injection molding.

NOTE: The resin we chose (see Table of Materials) has a tensile strength of 56 MPa, elongation at break of 3.5%, a flexural strength of 115 MPa, a flexural modulus of 3350 MPa, and a heat deflection temperature of 140 °C18. - Mix the compounded photopolymer blend (proprietary methyl methacrylate and acrylamide blend, with a TiO2 based photo initiator) thoroughly for a minimum of 30 minutes by running the material canister on a wet-laboratory bottle roller, flask shaker or similar mixing device.

- Prepare the photo polymerization machine (voxel-size of 16 µm):

- For bottom-up AM machines, check that the vat coating is undamaged and thoroughly cleaned.

- For top-down machines, inspect the wiping system for any defects.

- Inspect the build stage and adjust the build plate using a 100 µm gauge foil to correctly offset the build plate to the vat.

- Pre-ignite the light source of the machine tool if possible to reach steady-state temperature before progressing. This temperature should be 65 °C in the light engine and 30 °C inside the vat.

- Import the geometry to the job preparation software. Follow the guidelines from the machine manufacturer19.

- Assign appropriate machine parameters to match the chosen photopolymer (light intensity and layer thickness for the utilized machine).

- Run the build at the highest vertical machine resolution (25 µm in this research).

- Clean the printed inserts.

- Rinse them in isopropanol exposed to ultrasonic bath for 3 min. Rinse thoroughly three times, and ensure that no photopolymer residue is left on the surface of the printed inserts.

- Allow the solvent to evaporate completely at room temperature and set the inserts in a desiccator to dry overnight at room temperature.

- Post cure the dried inserts using UV light flashes twice, each time by 2000 flashes with a frequency of 10 flashes per second (see Table of Materials).

2. Injection Molding (IM)

- Install the micro injection module on a conventional injection molding machine (see Table of Materials).

NOTE: In our case, the injection module had a screw mounted at an angle of 45°, the screw diameter was 8 mm, and the clamping force was 100 kN. - Mount the inserts on mold plates.

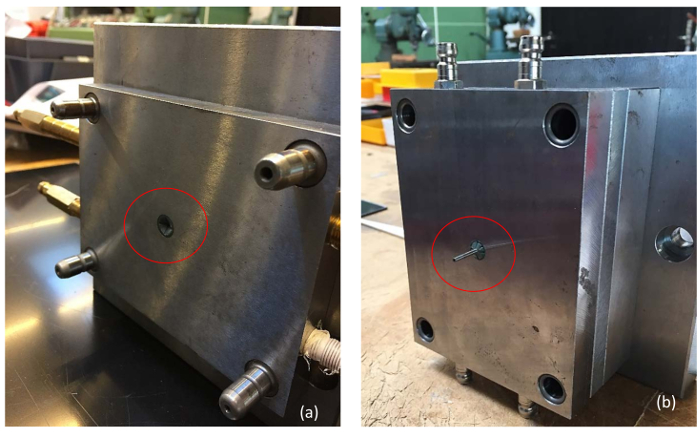

Figure 1: Injection machine with molds. (a) The injection side is assembled with the plates. The insert is highlighted by a red circle. (b) The movable side is assembled with the plates with ejection pin. The insert is highlighted by a red circle. Please click here to view a larger version of this figure.

- To account for variations during the printing process, manually make any slight modifications to the inserts necessary in order to fit the mold.

- Screw the mold plates on the machine.

- Load PE granules onto the hopper.

- Set the machine parameter TMold at 60 °C, TBarrel at 175 °C, and Vinjection at 65 mm/s. Allow sufficient cooling time for the part to be demolded.

- Heat the screw at 31 °C, 155 °C, 165 °C, 170 °C, and 175 °C from the 1st to the 5th session. When the melt temperature is 175 °C, start accurate injection molding. Once the cavity is filled, maintain the packing pressure of 300 bar for 5 seconds to compensate for PE shrinkage.

- Open the mold and allow the ejection pin to push the PE part out of the moveable side of insert. If the PE part is clamped on the insert, take the part out by hand.

- Stop the machine at 100 cycles of injection molding (a cycle is defined from when the mold is closed until the part is ejected).

3. Quality Assessment

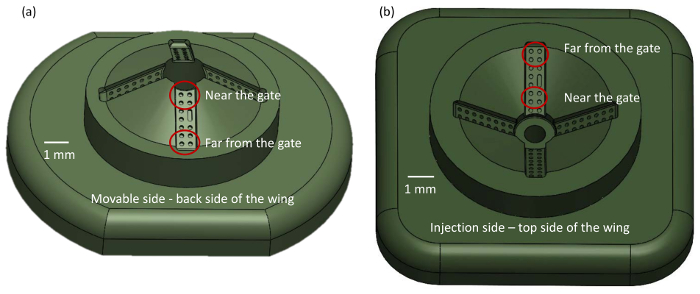

- Measure the diameter and depth of the holes on the inserts before injection molding by a laser scanning digital microscope20 . Measure on both inserts; on each insert, measure four holes on two areas with different distance to the gate "near the gate" and "far from the gate".

Figure 2: Measured areas highlighted on the CAD image of the inserts. (a) The movable side insert correspond to the backsides of the replica; (b) the injection side corresponds to the top sides of the replica. The injection gate locates at the center. Two areas with difference distance to the gate, "Far from the gate" and "Near the gate" are compared in the research. (This figure has been modified from Zhang et al. 201722) Please click here to view a larger version of this figure.

- Measure diameter and the height of the pillars on the tracked tines obtained from injection molding.

NOTE: Group the obtained PE parts into batches of 10 pieces; i.e., 1-10 is the 1st batch, 11-20 is the 2nd batch; until the last piece. Use one random sample in each batch and do the measurements on the top and back sides; on each side, measure four pillars on two areas with different distance to the gate ("near the gate" and "far from the gate"). - Analyze data with the assistance of image processing software21 in order to obtain the dimensions.

Representative Results

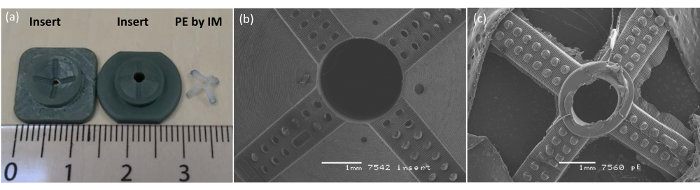

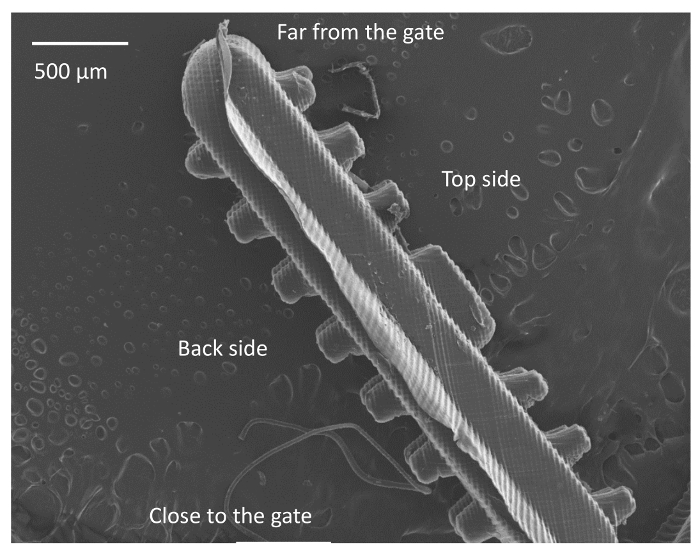

Figure 3 shows the inserts fabricated by AM and the PE parts produced by injection molding. Two rows of circular holes were vertical to the surface on the tines (Figure 3 (b)). The nominal dimension of the holes on the inserts is Ø200 µm and 200 µm in depth, with a center-to-center distance 400 µm. The layer structures due to the AM process are clearly visible. On the bottom left line there is a visible folding mark, which took place unintentionally during the preparation for SEM.

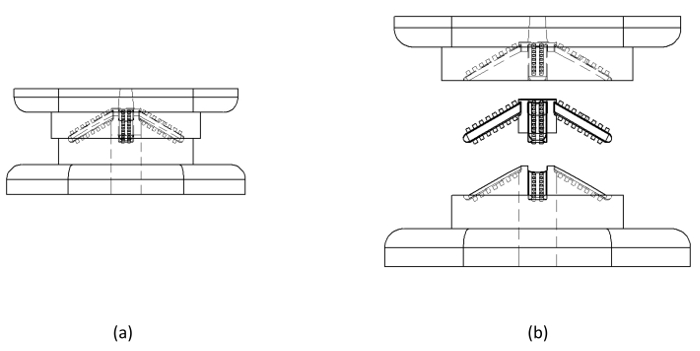

The demolding process is illustrated in Figure 4. Pillars are not parallel to the demolding direction. No pillar breaking was observed in all the studied samples (Figure 5). In this sense, the demolding was successful. It is already visible that the pillars on position of far-from-the-gate are notably lower than on the top side due the pressure drop. Regarding the diameter, the difference from positions are not as prominent as for the height.

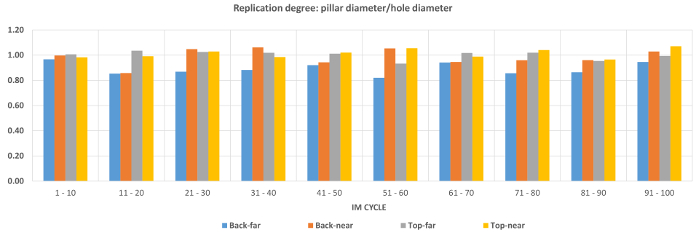

Figure 6 and Figure 7 illustrate how the replication propagated along the 100 cycles of injection molding. The degree of replication is defined by the ratio between the dimension of the pillars and the dimension of the inserts. Along the 100 cycles, stable process was achieved at each position regarding both vertical and lateral replication. The dimension of the holes on the inserts were unchanged after injection molding, which confirmed this conclusion. The height of the pillars positioned far from the gate were lower than those placed near the gate, because polymer flow increases its viscosity when the flow length increases.

The injection molding parameters were varied within the range allowed by the material datasheet. In the explored process window, most of the runs reached more than 80 cycles, confirming that the tool life of the AM inserts was not affected in the explored process window. However, cracking occurred to the inserts for the injection side in some tests when the injection pressure was high. This is due to the center part of the insert being much thinner.

Figure 3: Inserts and replicas. (a) Inserts produced by additive manufacturing process form the mold cavity; one polyethylene (PE) replica produced by injection molding is displayed. Markings on the reference ruler are millimeters; numbers mark centimeters. (b) Scanning electron microscope (SEM) image shows the surface of the insert; (c) SEM image shows the surface of the PE parts made by injection molding. ((a) and (b) have been modified from from Zhang et al. 201722) Please click here to view a larger version of this figure.

Figure 4: Successful demolding. The demolding was successful even though pillars are not parallel to the demolding direction. (a) Molds close and (b) molds open for demolding. (This figure has been modified from Zhang et al. 201722) Please click here to view a larger version of this figure.

Figure 5: SEM image of the side view of one random tine. The investigated four positions are labeled on the image. (This figure has been modified from Zhang et al. 201722) Please click here to view a larger version of this figure.

Figure 6: Pillar height replication degree. The replication degree of the pillar height is defined by height of the pillar/depth of the hole. The mean value of the replication degree at the four positions was displayed in each batch. One randomly selected sample was measured in each batch. The four positions are "Back-far" for the position far from the gate at the back side, "Back-near" for the position near the gate at the back side, "Top-far" for the position far from the gate at the topside, and "Top-near" for the position near the gate on the top side. (This figure has been modified from Zhang et al. 2017 22) Please click here to view a larger version of this figure.

Figure 7: Pillar diameter replication degree. The replication degree of the pillars diameter is defined by diameter of the pillar/diameter of the hole. The mean value of the replication degree at the four positions was displayed in each batch. One randomly selected sample was measured in each batch. The four positions are "Back-far" for the position far from the gate at the back side, "Back-near" for the position near the gate at the back side, "Top-far" for the position far from the gate at the topside, and "Top-near" for position near the gate on the top side. (This figure has been modified from Zhang et al. 2017 22). Please click here to view a larger version of this figure.

Discussion

This method is suitable for fabrication of inserts for polymer parts with complex shapes. It replaces the tool steel mold cavity in the injection molding machine with a set of soft tool inserts made from polymers. the machining time and cost is reduced compared to conventional metal machining; therefore, the cycle of production is shortened. This process chain is suitable for products in intermediate scale (from 1000 – 10,000 cycles by injection molding or similar) production, but high variation in design. Moreover, for 3D printed inserts, no special mold plates are required. Standard commercial injection molding plates were purchased and machined to fit the inserts.

At the current technology state, soft tooling fails by a distinct mechanism17. The failure mechanism has been identified to be linked the heat deflection temperature of the soft tooling insert and the decomposition has been identified to be due to outgassing. Therefore, the most critical step is to choose the right resin for the inserts produced by additive manufacturing. The thermal and mechanical property determines the life of the inserts, i.e., how many cycles it can withstand during injection molding. It also determines the range of molded polymer; the mold temperature of the molded polymer should not be higher than the deflection temperature of the insert material.

The second critical step in the protocol is the design of the insert. General rules of mold design should be followed and mechanically weak parts should be avoided on a 3D printed polymer insert; otherwise, the tool life will be affected due to failures like cracks.

The surface quality of the obtained injection-molded parts is limited by the applied additive manufacturing process. Post processing such as chemical etching is a possible solution to improve the surface quality. Precision of the surface features is another issue due to the additive manufacturing process.

This method will create the possibility for creating micro features on real free-form surface on a new production platform meeting industrial demands. Therefore, this method has the potential to be applied and investigated for applications in connection with next generation medical devices that require micro features on complex shapes, for example in connection with medical devices or implanting devices14. This method will facilitate value creation through significantly reduced expenses for small-to-medium volume series productions, and positively affect the timescale for production in the gap between 1 – 10 individual devices and real mass production. It will open up new high-value products and design solutions.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This paper reports work undertaken in the context of the project "Advanced surface treatment for implantable medical devices" funded by Innovation Fund Denmark. The author gratefully acknowledge the support from European Innovative Training Network MICROMAN "Process Fingerprint for Zero-defect Net-shape MICROMANufacturing" funded by the Horizon 2020 Framework Programme for Research and Innovation of the European Union.

Materials

| Photopolymer resin | EnvisionTec | HTM140 V2 | |

| Resin mixing device | IKA | Vortex Genius 3 | |

| 3d printer | Envisiontec | Perfactory 3 | |

| UV light flash unit | EnvisionTec | Otoflash unit | |

| Polyethylene | lyondellbasell | PE Purell 1840 | |

| Injection moulding machine | Arburg | Allrounder 370A | |

| Image processing | SPIP | 6.2.8 |

References

- Doan, N., et al. Low-Cost Photolithographic Fabrication of Nanowires and Microfilters for Advanced Bioassay Devices. Sensors. 15 (3), 6091-6104 (2015).

- Lucchetta, G., et al. Effect of injection molded micro-structured polystyrene surfaces on proliferation of MC3T3-E1 cells. Express Polymer Letters. 9 (4), 354-361 (2015).

- Hu, H., Tian, H., Shao, J., Ding, Y., Jiang, C., Liu, H. Fabrication of bifocal microlens arrays based on controlled electrohydrodynamic reflowing of pre-patterned polymer. Journal of Micromechanics and Microengineering. 24 (9), 095027 (2014).

- Kolind, K., Dolatshahi-Pirouz, A., Lovmand, J., Pedersen, F. S., Foss, M., Besenbacher, F. A combinatorial screening of human fibroblast responses on micro-structured surfaces. Biomaterials. 31 (35), (2010).

- Wilkinson, C. D., Riehle, M., Wood, M., Gallagher, J., Curtis, A. S. G. The use of materials patterned on a nano- and micro-metric scale in cellular engineering. Materials Science and Engineering C. 19 (1-2), 263-269 (2002).

- Hansen, H. N., Hocken, R. J., Tosello, G. Replication of micro and nano surface geometries. CIRP Annals. 60 (2), 695-714 (2011).

- Metwally, K., Barriere, T., Khan-Malek, C. Replication of micrometric and sub-micrometric structured surfaces using micro-injection and micro-injection compression moulding. International Journal of Advanced Manufacturing Technology. 83 (5-8), 779-789 (2016).

- Nian, S. -. C. Novel embossing system for replicating micro-structures on curved surfaces. International Polymer Processing. 29 (3), 364-370 (2014).

- Bissacco, G., et al. Application of functional nano-patterning to polymer medical micro implants. Proceedings of the 4m/icomm2015 Conference. , (2015).

- Diaz Lantada, A., Piotter, V., Plewa, K., Barie, N., Guttmann, M., Wissmann, M. Toward mass production of microtextured microdevices: Linking rapid prototyping with microinjection molding. International Journal of Advanced Manufacturing Technology. 76 (5-8), 1011-1020 (2015).

- Volpato, N., Solis, D. M., Costa, C. A. An analysis of Digital ABS as a rapid tooling material for polymer injection moulding. International Journal of Materials and Product Technology. 52 (1-2), 3-16 (2016).

- Mischkot, M., Hansen, H. N., Pedersen, D. B. Additive manufacturing for the production of inserts for micro injection moulding. Proceedings of Euspen’s 15th International Conference & Exhibition. , (2015).

- Zhang, Y., Hansen, H. N., Sørensen, S. Injection molding of micro pillars on vertical side walls using polyether-ether-ketone (PEEK). Proceeding of 11th International Conference on Micro Manufacturing. , (2016).

- Zhang, Y., Mischkot, M., Hansen, H. N., Hansen, P. Replication of microstructures on three-dimensional geometries by injection moulding of liquid silicone rubber. Proceedings of the 15th International Conference on Metrology and Properties of Engineering Surfaces, ASPE, March 2015. , (2015).

- . . Envisiontec Perfactory MML with ERM. Technical Specifications Document no. MK-MCS-P3MiniMulti-V01-FN-EN. , (2018).

- Hofstätter, T., Mischkot, M., Pedersen, D. B., Tosello, G., Hansen, H. N. Evolution of surface texture and cracks during injection molding of fiber-reinforced, additively-manufactured, injection molding inserts. Proceedings of ASPE Summer Topical Meeting 2016: Dimensional Accuracy and Surface Finish in Additive Manufacturing. , (2016).

- . Perfactory® Material Available from: https://envisiontec.com/wp-content/uploads/2016/09/MK-MTS-HTM140IndustrialIV-V01-FN-EN.pdf (2017)

- . Software Manual, 2010 Available from: https://digfablab.wikispaces.com/file/view/Getting+started.pdf (2010)

- . . Olympus LEXT OLS4100 laser scanning digital microscope Manual. , (2018).

- . SPIP™ – Analytical Software for Microscopy Available from: https://www.imagemet.com/products/spip/ (2017)

- Zhang, Y., Pedersen, D. B., Gøtje, A. S., Mischkot, M., Tosello, G. A soft tooling process chain employing additive manufacturing for injection molding of a 3d component with micro pillars. Journal of Manufacturing Processes. 27, 138-144 (2017).