Measurement of Dynamic Force Acted on Water Strider Leg Jumping Upward by the PVDF Film Sensor

Summary

The protocol here is dedicated to investigating the free and quick maneuvering of water strider on water surface. The protocol includes observing the microstructure of legs and measuring the adhesion force when departing from water surface at different speeds.

Abstract

This study aimed to make an explanation for the phenomenon in nature that water strider usually jumps or glides on the water surface easily but quickly, with its peak locomotion speed reaching 150 cm/s. First of all, we observed the microstructure and hierarchy of water strider legs using the scanning electron microscope. On the basis of the observed morphology of the legs, a theoretical model of the detachment from water surface was established, which explained water striders’ capability to slide on water surface effortlessly in terms of energy reduction. Secondly, a dynamic force measurement system was devised using the PVDF film sensor with excellent sensitivity, which could detect the whole interaction process. Subsequently, a single leg in contact with water was pulled upward at different speeds, and the adhesion force was measured at the same time. The results of the departing experiment suggested a deep understanding of the fast jumping of water striders.

Introduction

In nature, water striders possess remarkable ability to jump or glide easily and rapidly on the water surface with the help of the slender and nonwetting legs1,2,3,4,5, but seldom move slowly, which is unlike the terrestrial insects. The hierarchical structure of water strider stabilizes the superhydrophobic state, which renders dramatic reduction in contact area and adhesion force between water and the leg6,7,8,9. However, the hydrodynamic advantages of the quick disengagement of water striders from water surface remain poorly interpreted10,11,12.

The process of jumping from the water surface is mainly divided into three stages13,14,15,16. At first, water striders push the water surface downward with the middle and rear legs to convert the biological energy into the surface energy of the water until sinking to the maximum depth, which enable the insect to initialize the jumping direction and determine the detaching velocity. Followed by the ascending stage, the insect is pushed upward by the capillary force of the curved water surface until reaching the maximum velocity. In the final disengagement stage, the water strider continues to rise up by inertia until breaking away from the water surface, but the velocity is largely reduced due to the adhesion force with the water, which has principal influence on the energy consumption of the water strider. Hence, this protocol is proposed to measure the adhesion force at different take-off velocities in the disengagement stage and explain the distinct characteristic of fast moving.

There have been many studies to explore the adhesion force of water striders when propelling from water surface. Lee & Kim theoretically and experimentally confirmed that the adhesion force and energy required lifting the water strider's legs decreased dramatically when the contact angle increased to 160 degrees17. Pan Jen Wei designed a hydrostatic experiment to measure the adhesion force by the TriboScope System, which was found to be 1/5 of its weight 18. Kehchih Hwang analyzed the quasi-static process of the legs detaching from the water with a 2D model and found the superhydrophobicity of the legs played a significant role in reducing the adhesion force and energy dissipation19. However, the measurement of the adhesion force in previous studies was just in condition of a quasi-static process, which was unable to monitor the adhesion force changes during the fast jumping.

In this study, we designed a dynamic force measurement system using polyvinylidene fluoride (PVDF) film sensor and other adjuvant instrument. Compared with other piezoelectric materials, PVDF is more suitable for measuring the dynamic microforce with higher sensitivity20,21,22. By integrating the PVDF film sensor into the system, the real-time adhesion force could be detected and processed when the leg was pulling up from water surface23,24,25.

Protocol

1. Observation of the Surface Structure on Water Strider Leg

- Collect water striders from local freshwater ponds using fishing landing net.

- Cut off at least 5 pairs of middle legs as experimental samples using scissors. Touch the bottom of the legs carefully, to prevent the surface contamination and the disrupting of microstructure in the front of legs.

- Dry the legs out in the air naturally.

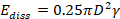

- Observe the surface microstructure of legs using a scanning electron microscope with micro-level resolution as shown in Figure 1a.

- Observe the microsetae of the legs using a scanning electric microscope with nano-level resolution as shown inFigure 1b.

2. Prepare the Component of the Dynamic Force Measurement System

- Purchase a PVDF film sensor with a dimension of 14.9 X 10.2 mm2 X 28 μm, which produces more than 10 mV per micro-strain.

NOTE: The PVDF film sensor is used to sense the dynamic contact force with high sensitivity. - Purchase a charge amplifier with maximum 1000 mV/pC charge gain and low noise less than 5 μV.

NOTE: The charge amplifier is used to enlarge the signal from the PVDF film sensor, in which the charge output from the transducer is converted to into a voltage. - Purchase a data acquisition device, in which the analog input has the sample rates in a range from 1 S/s to 102.4 kS/s.

NOTE: The data acquisition device is used to read the voltage data of the charge amplifier and send them to the computer for further processing and display. - Purchase several high-precise displacement stages and a servomotor.

NOTE: The legs depart from water at different speed driven by the servomotor. - Purchase a CCD camera, whose focus length is in a range from 5 mm to 30 mm and frame rate is 30 fps.

NOTE: This camera is used to record and monitor the deformation of water surface and the distance between legs and water surface. - Prepare a high-performance computer.

3. Assembly of all Parts of the Dynamic Force Measurement System

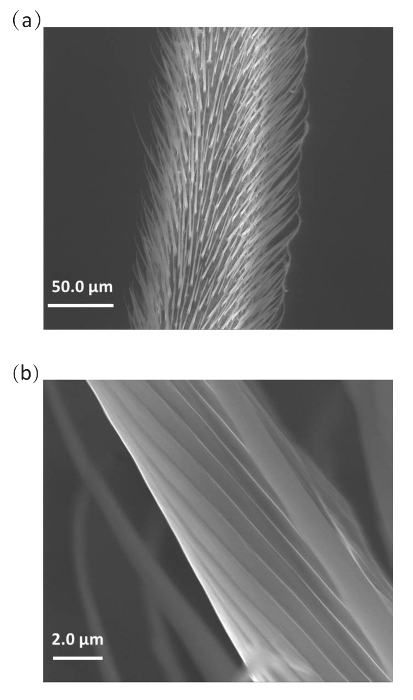

- Assemble the dynamic force measurement system according to the schematic illustration shown in Figure 2a and the real experiment instrument shown in Figure 2b.

- Fix one side of the PVDF film sensor with the electrodes to the high-precise displacement stage, which is placed on the horizontal frame, as other side is hanging. This installation method of PVDF film sensor helps improve the resolution of the measurement for the dynamic micro force.

- Connect the PVDF film sensor to the charge amplifier, the charge amplifier to the data acquisition device and the data acquisition device to the computer.

- Fix the camera to the high-precise displacement stage, which is placed on the left side of PVDF film sensor.

- To roughly adjust the distance between the legs and water quickly, fix a high-precise displacement stage to the frame above the PVDF film sensor, whose separation from the PVDF film sensor is about 10 cm.

- To lift the leg away from water surface at a precise speed, fix the servomotor below the high-precise displacement stage.

4. Calibration of the Dynamic Force Measurement System

- Use the electrostatic force system26 to generate a micro-constant force acted on the free end of PVDF film sensor, whose magnitude should be less than 0.5 µN. Control the electrostatic force of the system by a voltage applied to the inner and outer electrodes of the paralleled cylindrical capacitor.

Caution: The force should act in a direction normal to the PVDF film surface and the point of application is supposed to be as close as possible to the tip of the PVDF film sensor to increase sensitivity. - Release the force in a short time to generate a step input.

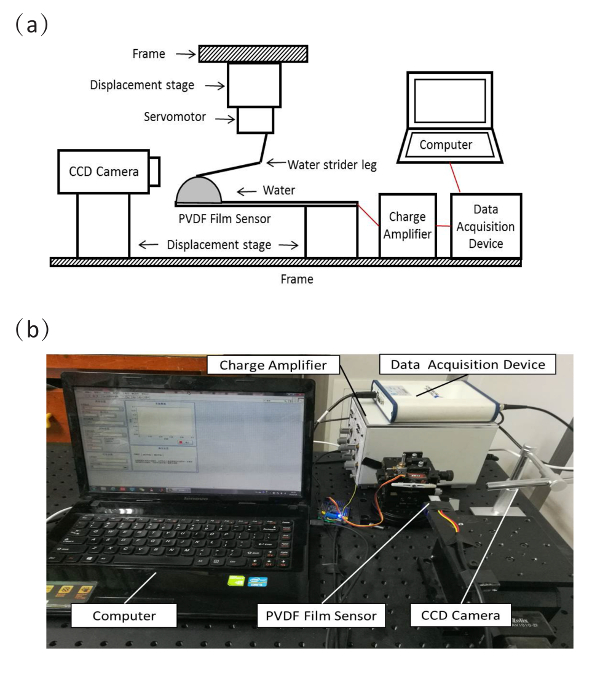

- Read the voltage-time signal of step 4.2 in the computer using the software LabVIEW, which helps read the output voltage signals of the PVDF film sensor.

- Download the software LabVIEW and the hardware driver NI-DAQmx in the official website of National Instruments.

- Open the demo of the continuous analog voltage measurement using the LabVIEW, as shown Figure 3.

- Select the physical channel of the data acquisition device connected with the charge amplifier in the module of Channel Settings.

- Set the sample rate to 100000 and the number of samples to 100000 in the module of Timing Settings.

- Select the Log and read as the logging mode and write the file path in to store the voltage data in the module of Logging Settings.

- Select No trigger in the module of Trigger Settings.

- Click the arrow-shape button in the toolbar to sample the voltage signal.

- Analyze the voltage curve, in which the peak voltage is corresponding to force acted on the sensor.

- Repeat the steps 4.1-4.4 at different force input, in which a series of voltage-force points are gained.

- Determine the relationship about the peak output voltage and standard force in the calibration result.

5. Measurement of Adhesion Force at A Certain Speed

- Place a water drop (5 µL) on the free end of the PVDF film sensor using a mechanical micropipette.

NOTE: The location of the droplet should be close to the tip of the PVDF film sensor. - Stick a single leg to the servomotor below the high-precise displacement stage.

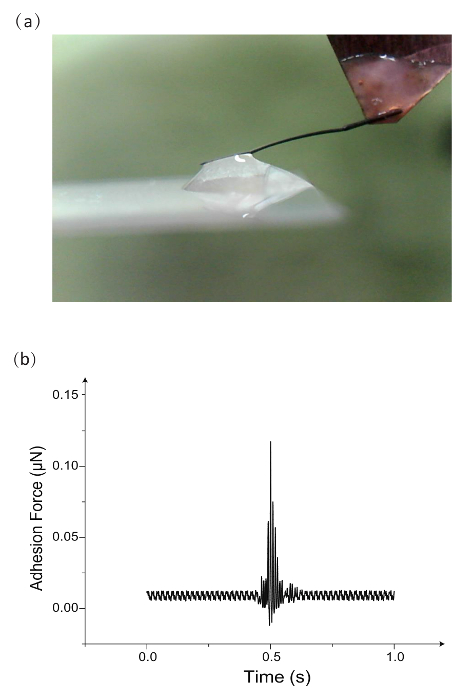

- Move the high-precise displacement stage downward until the leg contacts with the water surface, as shown in Figure 4a. Monitor the distance between the leg and water surface by the camera system mounted on the left side of the sensor.

- Lift the leg away from the water surface at a constant speed through the servomotor.

- Calculate the force corresponding to each point of voltage curve of the departing process using the model established in step 4.6, and then draw the force-time curve of departing process, as shown in Figure 4b.

- Record the peak adhesion of the departing process at a certain speed.

6. Measurement of Adhesion Force at Different Speeds.

- Alter the lifting speed of the legs by the servomotor and measure the adhesion force according to step 5.

- Plot the adhesion force versus lifting speed curve using the data gained in step 6.1.

- Analyze the relationship between the adhesion force and the lifting speed through the curve.

Representative Results

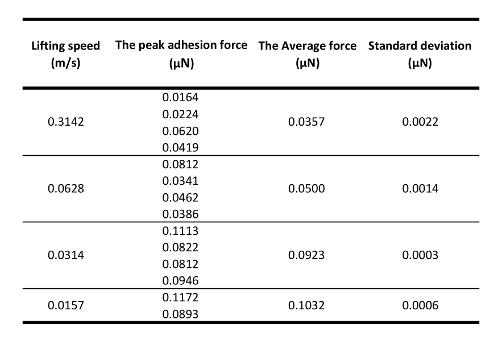

The relation between lifting speed and adhesion force is shown in Table 1. When the lifting speed increases from 0.01 m/s to 0.3 m/s, the adhesion force between the water surface and leg decreases dramatically from 0.10 to 0.03 . The results of the departing experiment showed that the peak adhesion force would decrease dramatically as the lifting speed increase, which indicated that the water striders may feel comfortable if they move quickly on water surface.

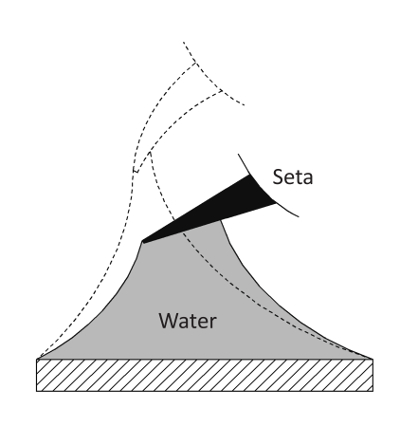

In this paper, a model of the legs departing from water surface based on the microstructure of the legs and the shape of setae is established, which could elucidate the mechanism of easy jumping from the water surface with low energy reduction. The seta of legs was a tapered post with the front part thin and the rear extremely thick, as shown in Figure 1, which resulted in the stiffness of the front part much lower than the rear. Thus, the front part of the seta tended to bend easily, while the rear did not due to the excellent rigidity. When the leg was pulled away from water, the setae on the leg would be bent as a result of the adhesion force and finally be vertical to the water surface as shown in Figure 5. Water would fall along the setae naturally with low energy dissipation, which could be neglected. The bending of the seta would reduce the contact line significantly to a circle with diameter of 0.2 m and the energy reduction could be expressed as:

where, y was surface tension coefficient, 72 mJ/m2 and D was the diameter of the seta's tip, respectively. Hence, the water striders can jump in the water easily.

The relation between the adhesion force and lifting speed was interpreted thoroughly through previous departing model. According to the conservation of energy, the total energy of lifted water due to the adhesion force was approximately equal to the energy reduction of the leg Ediss. In this model, Ediss was constant at different lifting speed. Thus, the energy of the water pulled up, including the potential energy Ep and the kinetic energy Ek, was changeless. The high lifting speed will lead to the small potential energy Ep and large kinetic energy Ek. Therefore, as the lifting speed increased, the adhesion force, proportional to potential energy Ep, would decrease drastically.

Figure 1: The nonwetting water striderlegs. (a) The setae on the superhydrophobic leg. (b) The nanoscale grooves on the setae. Please click here to view a larger version of this figure.

Figure 2: The dynamic force measurement system. (a) The Schematic illustration of the dynamic force measurement system is composed of a PVDF film sensor, a CCD camera, a charge amplifier, a data acquisition device and a computer. (b) The real experiment instrument of the dynamic force measurement system. Please click here to view a larger version of this figure.

Figure 3: The front panel of the demo of the continuous analog voltage measurement. The demo of the LabVIEW is used to sample voltage signals of the PVDF film sensor. Please click here to view a larger version of this figure.

Figure 4: The departing experiment of the legs at a certain speed. (a) The detachment of the legs away from water surface. (b) The real-time adhesion force measured by the PVDF film sensor. Please click here to view a larger version of this figure.

Figure 5: Theoretical model of the water strider's leg departing from the water surface. This model demonstrates that the seta is bending peeling away from the water surface. Please click here to view a larger version of this figure.

Table 1: The peak adhesion force measured at different lifting speeds. The adhesion force decreases dramatically from 0.10 μN to 0.03 μN with an increase of lifting speed from 0.01 m/s to 0.3 m/s.

Discussion

In this protocol, a dynamic force measurement system based on the PVDF film sensor was successfully devised, assembled, calibrated to measure the adhesion force away from the water surface. Among the whole steps, it was crucial that the adhesion force was measured at different speeds by lifting the leg from the water surface as this study focused on the remarkable characteristic of the quick maneuvering on the water. The results of departing experiment showed that the adhesion force decreased when the lifting speed increased. These clarified that the water striders would feel relaxed if they moved at a high speed on the water.

The PVDF-based dynamic force measurement method is an important complement to the traditional method. In past studies, the adhesion force of the water striders in the detachment process was usually measured by the atomic force microscope (AFM) in a quasi-static mode. Compared to the AFM method, despite that the measurement accuracy is slightly inferior, the PVDF film sensor is able to measure the force of bigger macroscopic objects. In addition, due to its large frequency response characteristics, the PVDF film sensor can measure the dynamic interaction between the legs and water surface while the AFM could be only used in the quasi-static condition conversely.

The proposed method for measuring dynamic force was confined that only micro-force could be gauged. If we applied a large force to the dangling sensor, it would cause a considerable deformation of the PVDF film sensor, which would lead to imprecise result. Moreover, the sensitive area of the PVDF film sensor was small, which limited the size of measured object. However, in contrast to the conventional method, the proposed method was able to measure the dynamic force rather than merely measure the static force, which could exhibit the whole interaction process.

This method based on PVDF film sensor has broad applications in many fields due to its high sensitivity in dynamic force sensing and remarkable flexibility. For example, it has been drawn much attention to the application in structural health monitoring by monitoring the response of buildings under the vibration or big motions27,28. In addition, the PVDF film sensors are used to directly measure the interaction between two inviscid droplets in coalescence process, in which the fluid mechanics have not been fully understood. Moreover, the PVDF film sensor also plays an important role in tactile sensing in the robots29. The sensor is embedded in the robot's fingertips to measure the contact force as well as the contact temperature of an object. In the field of biological research, PVDF-based force sensors help improve the success rate of the single cell manipulation, such as DNA injection and gene therapy, through the precise mechanical feedback control with high sensitivity.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors thank the National Key Technology Research and Development Program of the Ministry of Science and Technology of China (No. 2011BAK15B06) for their support. Thank Shuya Zhuang who is a master student from our laboratory for helping us complete the video shoot.

Materials

| PVDF film sensor | TE Connectivity | DT1-028K/L | The PVDF film sensor is used to sense the dynamic contact force . |

| Charge amplifier | Wuxi Shiao Technology co.,Ltd | YE5852B | The charge amplifier is an electronic current integrator that produces a voltage output proportional to the integrated value of the input |

| Data acquisition device | National Instruments | USB-4431 | The data acquisition device is used to read the voltage data. |

| Displacement stage | ZOLIXINSTRUMENTS CO.LTD | KSAV1010-ZF | KSAV1010/2030-ZF is a wedge vertical stage with high-resolution, high-stability and high-load. |

| CCD camera | Shenzhen Andonstar Tech Co., Ltd | digital microscope A1 | Frame rate: 30 frames/sec;Focal distance: 5mm – 30mm |

| Computer | Lenovo | G480 | |

| Servomotor | EMAX US Inc. | ES08MD | It's not bad this servo with speed varying from 0.10 sec/60° / 4.8v to 0.08 sec/60°/6.0v. |

| Mechanical Pipettes | Dragon Laboratory Instruments Limited | YE5K693181 | The pipettes cover volume range of 0.1 μl to 2.5 μl |

References

- Gao, X., Jiang, L. Biophysics: Water-repellent legs of water striders. Nature. 432 (7013), 36 (2004).

- Hu, D. L., Chan, B., Bush, J. W. M. The hydrodynamics of water strider locomotion. Nature. 424 (6949), 663-666 (2003).

- Jiang, C. G., Xin, S. C., Wu, C. W. Drag reduction of a miniature boat with superhydrophobic grille bottom. AIP Advances. 1 (3), 032148 (2011).

- Su, Y., et al. Nano to micro structural hierarchy is crucial for stable superhydrophobic and water-repellent surfaces. Langmuir. 26 (7), 4984-4989 (2010).

- Feng, X. Q., Gao, X., Wu, Z., Jiang, L., Zheng, Q. S. Superior water repellency of water strider legs with hierarchical structures: experiments and analysis. Langmuir. 23 (9), 4892-4896 (2007).

- Suter, R. B., Stratton, G., Miller, P. R. Water surface locomotion by spiders: distinct gaits in diverse families. Journal of Arachnology. 31 (3), 428-432 (2003).

- Yin, W., Zheng, Y. L., Lu, H. Y. Three-dimensional topographies of water surface dimples formed by superhydrophobic water strider legs. Applied Physics Letters. 109 (16), 163701 (2016).

- Liu, J. L., Feng, X. Q., Wang, G. F. Buoyant force and sinking condition of a hydrophobic thin rod floating on water. Physical Review E. 76 (6), 066103 (2007).

- Ng, T. W., Panduputra, Y. Dynamical force and imaging characterization of superhydrophobic surfaces. Langmuir the Acs Journal of Surfaces & Colloids. 28 (1), 453-458 (2012).

- Zheng, Y., et al. Elegant Shadow Making Tiny Force Visible for Water-Walking Arthropods and Updated Archimedes’ Principle. Langmuir. 32 (41), 10522-10528 (2016).

- Zhao, J., Zhang, X., Chen, N., Pan, Q. Why superhydrophobicity is crucial for a water-jumping microrobot? Experimental and theoretical investigations. Acs Appl Mater Interfaces. 4 (7), 3706-3711 (2012).

- Shi, F., et al. Towards Understanding Why a Superhydrophobic Coating Is Needed by Water Striders. Advanced Materials. 19 (17), 2257-2261 (2010).

- Yang, E., et al. Water striders adjust leg movement speed to optimize takeoff velocity for their morphology. Nature communications. 7, 13698 (2016).

- Liu, J. L., Sun, J., Mei, Y. Biomimetic mechanics behaviors of the strider leg vertically pressing water. Applied Physics Letters. 104 (23), 231607 (2014).

- Kong, X. Q., Liu, J. L., Wu, C. W. Why a mosquito leg possesses superior load-bearing capacity on water: Experimentals. Acta Mechanica Sinica. 32 (2), 335-341 (2016).

- Liu, J. L., Mei, Y., Xia, R. A new wetting mechanism based upon triple contact line pinning. Langmuir. 27 (1), 196-200 (2011).

- Lee, D. G., Kim, H. Y. The role of superhydrophobicity in the adhesion of a floating cylinder. Journal of Fluid Mechanics. 624, 23-32 (2009).

- Wei, P. J., Chen, S. C., Lin, J. F. Adhesion forces and contact angles of water strider legs. Langmuir. 25 (3), 1526-1528 (2008).

- Su, Y., Ji, B., Huang, Y., Hwang, K. Nature’s design of hierarchical superhydrophobic surfaces of a water strider for low adhesion and low-energy dissipation. Langmuir. 26 (24), 18926-18937 (2010).

- Shen, Y., Xi, N., Lai, K. W. C., Li, W. F. A novel PVDF microforce/force rate sensor for practical applications in micromanipulation. Sensor Review. 24 (3), 274-283 (2004).

- Wang, Y. R., Zheng, J. M., Ren, G. Y., Xu, C. A flexible piezoelectric force sensor based on PVDF fabrics. Smart Materials and Structures. 20 (4), 045009 (2011).

- Liu, G., et al. Application of PVDF film to stress measurement of structural member. Journal of the Society of Naval Architects of Japan. 2002 (192), 591-599 (2002).

- Fujii, Y. Proposal for a step response evaluation method for force transducers. Measurement Science and Technology. 14 (10), 1741-1746 (2003).

- Zheng, Y., et al. Improving environmental noise suppression for micronewton force sensing based on electrostatic by injecting air damping. Review of Scientific Instruments. 85 (5), 055002 (2014).

- Zheng, Y., et al. The multi-position calibration of the stiffness for atomic-force microscope cantilevers based on vibration. Measurement Science and Technology. 26 (5), 055001 (2015).

- Sun, P., et al. The Differential Method for Force Measurement Based on Electrostatic Force. Journal of Sensors. 2017, 1857920 (2017).

- Song, L., et al. Highly Sensitive, Precise, and Traceable Measurement of Force. Instrumentation Science & Technology. 44 (4), 386-400 (2016).

- Kurata, M., Li, X., Fujita, K., Yamaguchi, M. Piezoelectric dynamic strain monitoring for detecting local seismic damage in steel buildings. Smart Materials and Structures. 22 (11), 115002 (2013).

- Qasaimeh, M. A., Sokhanvar, S., Dargahi, J., Kahrizi, M. PVDF-based microfabricated tactile sensor for minimally invasive surgery. Journal of Microelectromechanical Systems. 18 (1), 195-207 (2009).