Design and Application of a Fault Detection Method Based on Adaptive Filters and Rotational Speed Estimation for an Electro-Hydrostatic Actuator

Summary

In this paper, an adaptive filter based on a normalized least mean square (NLMS) algorithm and a rotational speed estimation method are introduced to detect the electrical and hydraulic faults of the electro-hydrostatic actuator (EHA). The efficacy and feasibility of the aforementioned methods are verified through simulations and experiments.

Abstract

The electro-hydrostatic actuator (EHA) is a promising actuating apparatus used in flight control systems for more electric aircraft (MEA) due to its high power density and low maintenance. Since the reliability of the system decreases with increasing complexity, fault detection is becoming increasingly important. In this paper, an adaptive filter was designed based on a normalized least mean square (NLMS) algorithm, which could identify the resistance of the motor windings online to detect electrical faults in the EHA. Additionally, based on the analytical relationship between rotational speed and displacement, a rotational speed estimation method was designed. By comparing the actual rotational speed with the estimated one, hydraulic faults could be detected. To verify the efficacy of the aforementioned method, software was applied for the modeling and simulations, which included fault injection and detection. On this basis, an experimental platform was built and then subjected to a series of validation experiments. The results indicate that the fault detection method has the potential to detect electrical and hydraulic faults in an EHA.

Introduction

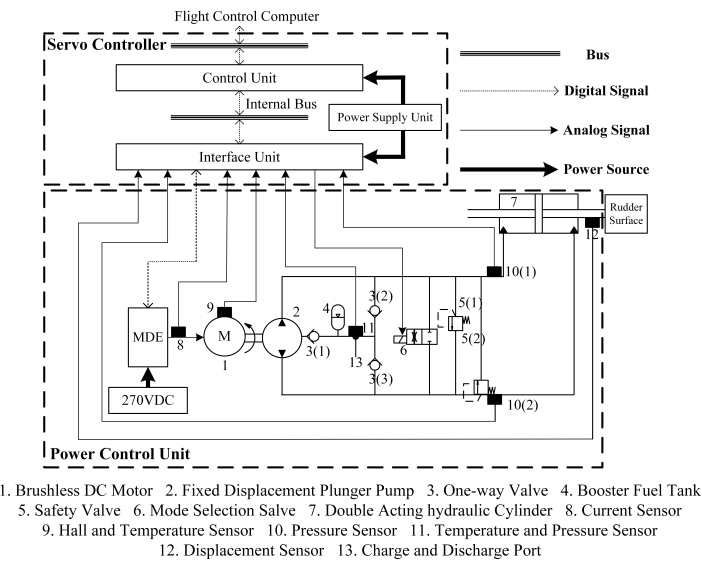

The electro-hydrostatic actuator (EHA) is a key component for flight control in more electric aircraft (MEA). The typical structure of an EHA is shown in Figure 1. Its compact structure guarantees high power density, low maintenance, and higher fault tolerance and safety compared with the traditional hydraulic servo actuator (HSA)1. However, the current reliability of the EHA cannot meet the practical requirements of more electric aircraft2. As a result, redundancy technology has been introduced into the design of the EHA. To maximize the effectiveness of the redundancy technology, the operating status of the system should be monitored by a fault detection method3. According to the location where the fault occurs, the fault modes of the EHA can be divided into servo controller faults and power control unit (PCU) faults. PCU faults can be further divided into sensor faults, electromechanical unit faults, and hydraulic unit faults. The fault mechanism of the servo controller has little relationship with the EHA body, and the fault probability of the sensor is much lower than that of the equipment component4. Therefore, we focus on the faults of the electromechanical unit and hydraulic unit in this paper.

Electromechanical unit faults include motor drive module faults and brushless DC motor (BLDCM) faults. Generally, the probability of a power drive electronics (PDE) fault (e.g., a short-circuit fault, an open-circuit fault) is relatively high. When a short-circuit fault occurs, the PDE current rises sharply in a short amount of time, causing severe consequences such as a motor shutdown or damage to the electrical components. Although the motor can maintain its working status after an open-circuit fault occurs, overcurrent and overvoltage for the other electrical components are still inevitable, and secondary faults may consequently happen5. As for the BLDCMs, the motor windings are most prone to faults from a short circuit or an open circuit6. The PDE in the electromechanical unit is connected in series with the corresponding motor windings. The fault detection method designed for the motor windings is also effective when dealing with faults in the PDE. Therefore, electromechanical unit faults, including both in the motor and the PDE, should be detected online.

Hydraulic unit faults include fault occurrences in the fixed-displacement piston pump, integrated valve block, and actuating cylinder7. The EHA's piston pump is composed of pistons, swash plates, and valve plates; damage to the seal and wear of the valve plate are the main forms of fault8. These two fault modes increase the leakage of the pump. Abnormal changes in the output flow and pressure follow and, eventually, lead to a decrease in the speed of the actuating cylinder and a reduction in the servo performance of the system. The fault modes of the integrated valve block include a pressurized reservoir fault, a check valve fault, a relief valve fault, and a mode selection valve fault. The pressurized reservoir usually adopts a self-boosting design with high reliability. When a fault occurs, however, insufficient charge pressure causes cavitation of the pump, resulting in abnormal output flow. Spring fatigue, component wear, and deformation are common fault modes in the check valves and relief valves. A check valve fault presents as a reverse leakage, which directly leads to abnormal flow. A relief valve fault leads to an invalid protection function, resulting in abnormal pressure. The common faults of the mode selection valve are failure of the return spring and broken wire coils. The former causes in-current switching of the working status, leading to abnormal movement of the actuating cylinder. An actuating cylinder fault results in a decrease in position control precision and dynamic performance. In summary, faults of the hydraulic units cause abnormal flow and pressure9. Since the flow and motor rotational speed are approximately proportional in an EHA system, the rotational speed can be monitored online to detect abnormal flow and pressure due to sudden faults.

Corresponding fault detection methods aimed at the previously mentioned electromechanical unit faults and hydraulic unit faults need to be designed. The methods for fault detection in an electromechanical system mainly include state estimation and parameter identification10. A state observer is built on the basis of a mathematical model of the system that makes a state estimation and determines faults by analyzing the residual sequence generated by the observer. Alcorta et al. proposed a simple and novel nonlinear observer with two correction terms for vibration fault detection in commercial aircraft, which is highly effective11. However, this type of method must solve the robustness problem of the observer. In other words, it must suppress the changes in the residual sequence caused by non-fault information such as model error or external disturbances. Moreover, this method often requires very accurate model information, which is usually difficult to collect in practical engineering applications.

The parameter identification method employs certain algorithms for identifying the important parameters in the system. When a fault occurs, the corresponding parameter value also changes. Therefore, faults can be detected by detecting a change in the parameters. The parameter identification method does not require the calculation of the residual sequence, so it can avoid the effect of disturbances on the detection accuracy. The adaptive filter has been widely used in parameter identification due to its easy implementation and stable performance, meaning it is a favorable and feasible method for electromechanical fault detection12. Zhu et al. proposed a new multi-model adaptive estimation fault detection method based on kernel adaptive filters, which realizes the estimation of the real flight state value and the actuator fault detection online with good performance13.

Referring to the previous research, corresponding fault detection methods have been designed. The resistance of the windings abruptly changes when electrical faults occur, such as open-circuit faults or short-circuit faults. Therefore, an adaptive filter was designed based on an NLMS algorithm to identify the resistance of the windings, which can determine whether an electrical fault has occurred. Combining an adaptive filter with an NLMS algorithm to minimize the change of the parameter vector leads to a better and faster convergence effect14. For hydraulic unit faults, a rotational speed estimation algorithm was proposed based on the clear analytical relationship between the rotational speed of the pump and the position of the actuating cylinder. EHA hydraulic faults were detected online by comparing the estimated rotational speed with the actual speed in real time.

In this paper, a test method combining simulations and experiments was adopted. First, a mathematical model of the EHA was built, and a simulation for the proposed fault detection method was performed. The simulation included the verification of the detection methods in non-fault and fault injection conditions. Then, the fault detection method was realized in the real servo controller. Finally, the results of the simulations and experiments were analyzed and compared to evaluate the efficacy of the fault detection method.

Protocol

1. Establishment of the EHA simulation model

- Open the simulation software on a PC.

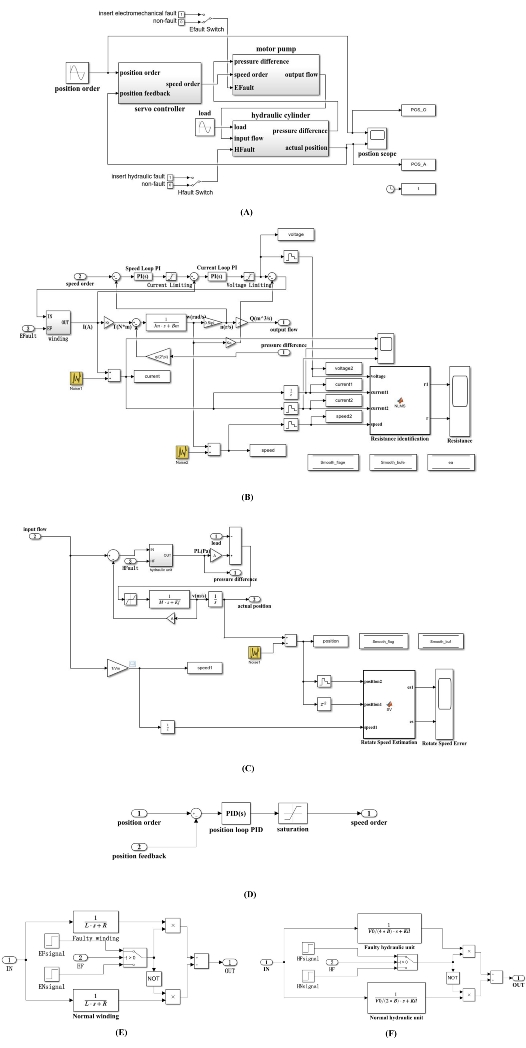

- Build the simulation model for the EHA (Figure 2), according to the mathematical equations of the EHA model15, and conduct a three-loop PI as the controller. Encapsulate the hydraulic module (Figure 2C), electrical module (Figure 2B), and controller (Figure 2B, D) in three submodels.

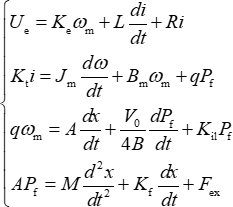

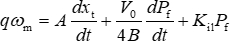

NOTE: The mathematical equations of the EHA model are as follows in Eq (1):

(1)

(1)

In this equation, Ue is the voltage of the armature, Ke is the back electromotive force coefficient of the motor, ωm is the rotational speed of the motor, L is the equivalent inductance of the armature, i is the current of the winding, R is the resistance of the winding, Kt is the torque coefficient of the motor, Jm is the rotor moment of inertia, Bm is the friction coefficient of the motor, q is the displacement of the pump, Pf is the pressure difference between the two chambers in the hydraulic cylinder, A is the effective area of the piston, x is the position of the piston rod, V0 is the effective cavity volume of the hydraulic cylinder, B is the bulk modulus of the hydraulic oil, Kil is the total internal leakage coefficient of the system, M is the mass of the piston and the load, Kf is the viscous damping coefficient of the hydraulic cylinder, and Fex is the external load force. - Program the adaptive filter based on an NLMS algorithm in an M file, which can be called at runtime.

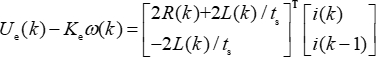

NOTE: The derivation of the adaptive filter based on the NLMS algorithm is shown here. The electromechanical faults can be judged by identifying the winding resistance, and the discretized motor equation is as follows:

(2)

(2)

In this formula, ts is the sampling time, and R(k) and L(k) are the parameters that need to be identified. Eq (2) can be written as follows:

(3)

(3)

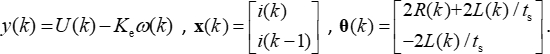

In this formula,

By adding two items for the parameter vector θ(k), the sampling time, ts, can be eliminated to obtain the resistance, R(k). When any one of the three-phase windings fails, R(k) deviates from the normal value.

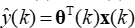

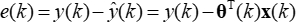

An adaptive filter can be constructed from Eq (3), and the estimation error of the filter is as follows:

(4)

(4)

In this formula, e(k) is a fluctuating random signal. When e(k) is small enough, the estimated value of the filter is ŷ(k). Finally, if it can converge to the real output, y(k), of the system, then the parameter vector θ(k) converges to the real system parameters.

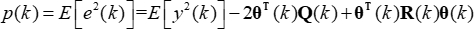

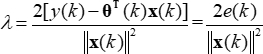

The least mean square (LMS) algorithm takes the minimum mean square error as the criterion to realize the optimal prediction and filtering. Perform an automatic iterative adjustment to make θ(k) converge to the true value of the system. The expression of the cost function is as follows:

(5)

(5)

In this formula,

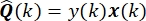

Q(k) is the cross-correlation vector of y(k) and x(k). R(k) is the auto-correlation matrix of the input vector.

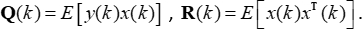

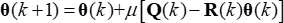

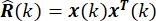

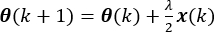

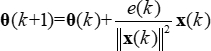

According to the steepest descent method, the recurrence formula for θ(k) approaching the optimal solution is as follows:

(6)

(6)

In this formula, µ is the adaptive variable step size. In the actual iterative process, the values of the current sampling point are used to estimate Q(k) and R(k), which can be expressed as and

and  .

.

Then, the LMS algorithm can be simplified as follows:

(7)

(7)

The LMS algorithm can make θ(k) gradually converge to the real system parameters.

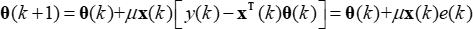

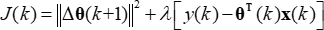

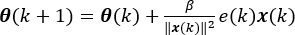

In practical applications, the NLMS algorithm is usually used to overcome the slow convergence speed of the LMS algorithm. The constraint of the NLMS algorithm is as follows:

(8)

(8)

With the use of the Lagrange multiplier method to solve the constrained optimization problem, the cost function is as follows:

(9)

(9)

In this formula, λ is the Lagrange coefficient. In order to find the minimum value of J(k), find the partial derivative of J(k) to θ(k) and set it equal to 0. Calculate the solution as follows:

(10)

(10)

Put Eq (10) into Eq (8), and then get the solution of λ as follows:

(11)

(11)

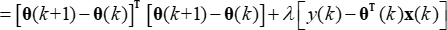

(12)

(12)

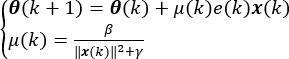

In order to control the incremental change in the parameter vector, a step factor, β, is introduced into this formula, and the expression is as follows:

(13)

(13)

At the same time, in order to avoid the difficulty of numerical calculation due to the small input vector, a relatively small positive constant, γ, is introduced. Li et al. proved that when 0 < β < 2 and 0 < γ < 1, the NLMS algorithm can achieve better convergence effects16. The final expression is as follows:

(14)

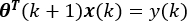

(14) - Program the rotational speed estimation algorithm in an M file, which can be called at runtime.

NOTE: The derivation of the rotational speed estimation algorithm is shown here. The flow equation of the actuator can be written as follows:

(15)

(15)

When the hydraulic unit is working in a normal condition, the total flow loss, Qf, caused by oil compression and leakage can be approximately expressed as follows:

(16)

(16)

In this formula, η is the volumetric efficiency of the EHA.

Thus, the approximate analytical relationship between the speed, ωm, and the displacement, x, can be obtained as follows:

(17)

(17)

The discretized rotational speed estimation error equation is as follows:

In this formula, eωm(k) is the estimated rotational speed error and is the estimated rotational speed. Changes in eωm(k) reflect the working condition of the hydraulic unit. When eωm(k) suddenly deviates from the normal value, it means that the condition of the hydraulic unit is abnormal, which can be used to detect hydraulic faults online.

is the estimated rotational speed. Changes in eωm(k) reflect the working condition of the hydraulic unit. When eωm(k) suddenly deviates from the normal value, it means that the condition of the hydraulic unit is abnormal, which can be used to detect hydraulic faults online. - Build the fault injection module and provide fault injection switches (Figure 2E, F), which can decide whether to inject a fault.

- Set the parameters of the simulation model according to Table 1 by double-clicking the specific component in each submodel.

- Program the drawing software, which can draw simulation curves after completing a group of experiments.

2. Simulation of the fault detection methods

- Give a position command, which is a sinusoid with an amplitude of 0.01 m and a frequency of 1 Hz.

- Enter the MODELING menu and click the Model Settings button. Set the simulation operation parameters: a Start time of 0 s, a Stop time of 6 s, the Type as Variable-step, and the solver as auto.

- Double-click the fault injection switches to set the model to work in a non-fault condition.

- Click the Run button to run the simulation and receive the non-fault condition results.

- Run the drawing software to draw the curve of the piston rod displacement.

- Double-click the insert electromechanical fault switch to inject an electromechanical fault at 3 s, which sets the resistance to 1,000 Ω to simulate an open-circuit fault of the motor windings.

- Repeat step 2.4 and step 2.5 to attain the results for the electromechanical fault condition. Run the drawing software to draw the curves of the piston rod displacement and identified resistance.

- Turn the insert hydraulic fault switch to inject a hydraulic fault at 3 s, which increases the leakage value to 2.5 × 10−9 (m3/s)/Pa to simulate a hydraulic unit fault.

- Repeat step 2.3 and step 2.4 to attain the results for the hydraulic fault condition. Run the drawing software to draw the curves of the piston rod displacement and rotational speed estimation results.

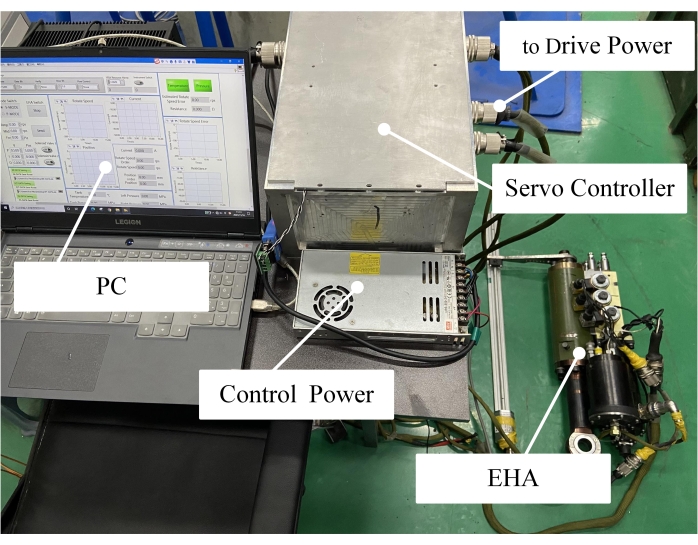

3. Establishment of the experimental platform (Figure 3)

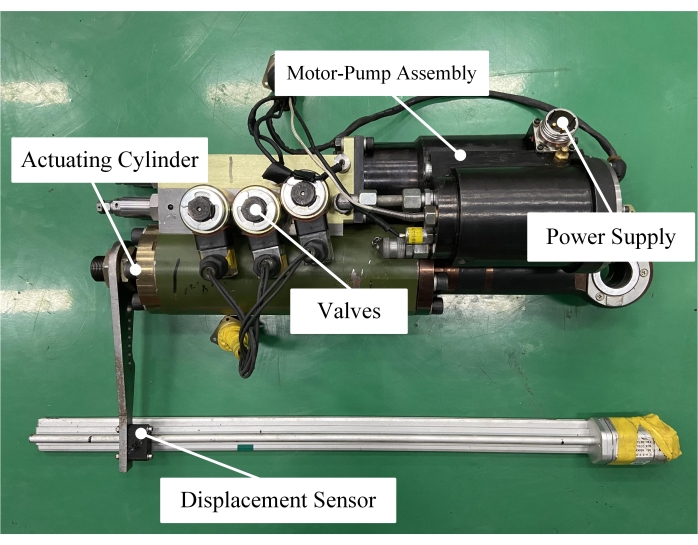

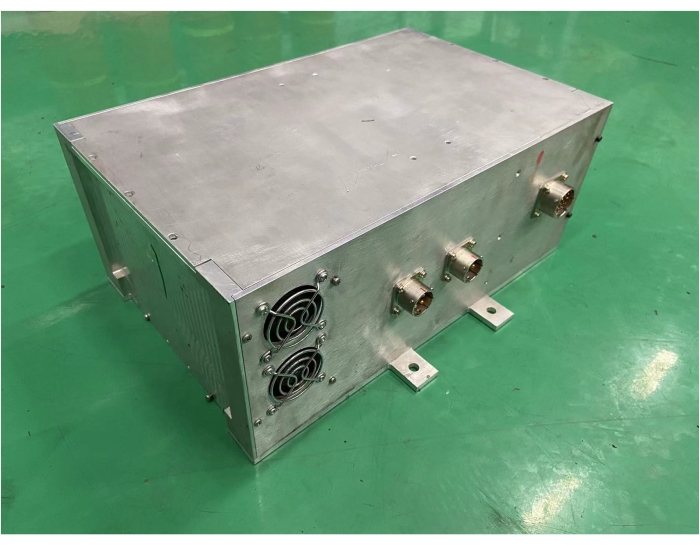

- Set the PC, EHA, and servo controller in position. The EHA is shown in Figure 4, and the servo controller is shown in Figure 5.

- Wire the electrical parts.

- Connect the EHA sensors to the sensor ports for the servo controller via several aviation plugs.

- Connect the EHA motor drive port to the inverter port for the servo controller via the aviation plug.

- Connect the servo controller to the control power and the drive power via the aviation plug.

CAUTION: Turn off the voltage temporarily for safety.

- Establish communication between the servo controller and the PC.

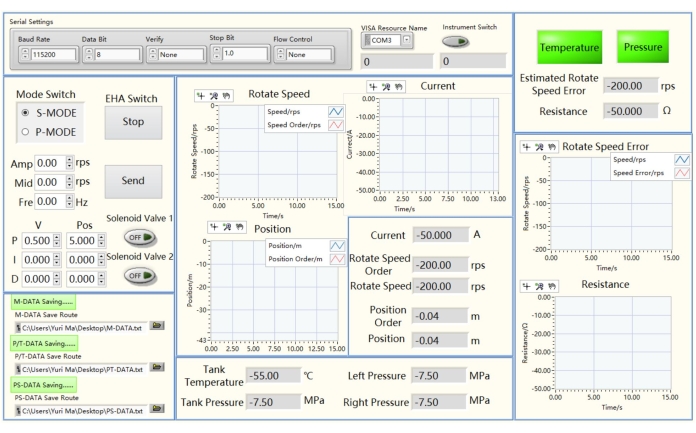

- Open the Host Software Interface (Figure 6) on the PC.

- Connect the PC and the servo controller through a 422-to-USB serial cable to set up the communication.

- Provide control power to the servo controller. The control power voltage is 24 V DC.

- Select the appropriate serial port from the VISA Resource Name drop-down window in the software.

NOTE: If communication is not successfully established, check the cable or restart the software until RS422 communication is established. - Click the Run button to start the software.

- Observe the receiving area and the corresponding curves of the software to determine whether the data receiving function is normal. Click the Solenoid Valve 1 button to observe whether the solenoid valve has a pull-in sound, and determine whether the data transmission function is normal.

4. Experiment for the fault detection method

- Provide drive power to the servo controller and set the voltage to 50 V DC.

NOTE: A 50 V DC undervoltage operation ensures safe work since the system is load-free. - Click the EHA Switch button on the software to set the EHA at a running state. Click the Data Log button to start data logging. The recorded data include the actual position, the target position, the actual speed, the target speed, the bus current, the voltage, etc.

- Conduct a pre-run for the EHA. Give position commands on the software, which include a step of +0.005 m and -0.005 m. Observe whether the EHA is actuating normally.

CAUTION: If the EHA does not work normally, check the error immediately before continuing this experiment. - Give a position command on the software, which is a sinusoid with an amplitude of 0.01 m and a frequency of 1 Hz.

- Observe whether the identified resistance and the estimated rotational speed are consistent with the values under non-fault operating conditions.

- Put the position command back to the original state if the result is correct. Click the EHA Switch button to stop the EHA and cut off the drive power, stop the host computer software, and interrupt the communication between the servo controller and the PC.

- Export the experimental data, analyze the data, and draw curves of the experimental results using drawing software.

- Analyze the experimental results, and compare them with the simulation results to derive conclusions.

Representative Results

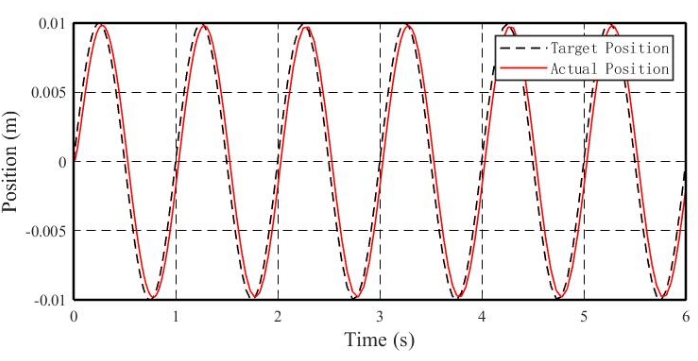

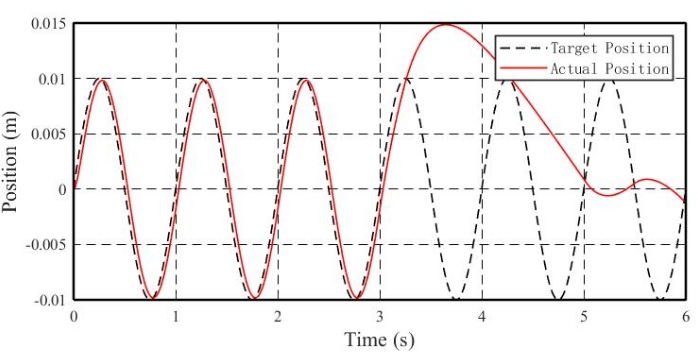

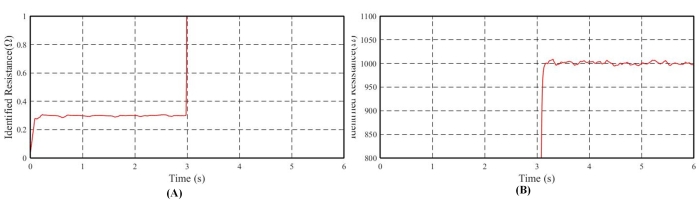

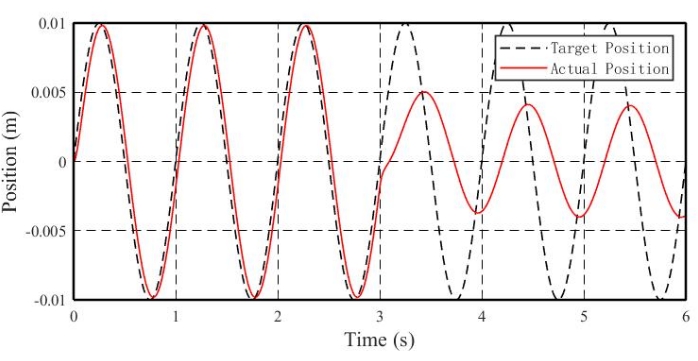

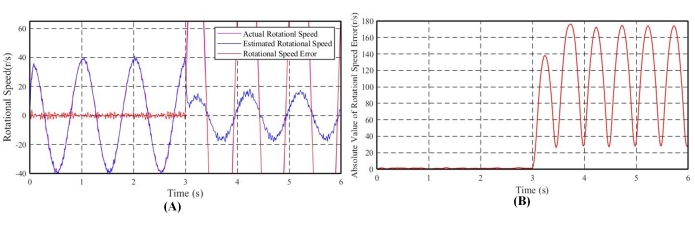

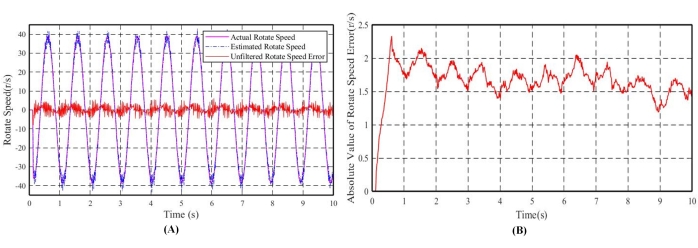

In the simulation, the actual position and target position curve of the EHA piston rod in the non-fault condition is shown in Figure 7. According to the curve, the system was operating normally, with good dynamic characteristics. The actual position and target position curve of the EHA piston rod in the electromechanical fault injection condition is shown in Figure 8. According to the curve, the system could not track the target accurately. The results of the resistance identification algorithm are shown in Figure 9, and these results demonstrated that before injection, the identified value converged to the true value of 0.3 Ω and fluctuated by ±0.02 Ω, while after injection, the identified value converged to the true value of 1,000 Ω and fluctuated by ±3 Ω, indicating that the method achieved the desired effect. The actual position and target position curve of the EHA piston rod in the hydraulic fault injection condition is shown in Figure 10. According to the curve, the system could not track the target accurately. The results of the rotational speed estimation algorithm are shown in Figure 11. The curves indicated the actual rotational speed, the estimated rotational speed, the rotational speed error, eωm, and its absolute value, |eωm|. Before injection, the estimated rotational speed was very close to the actual rotational speed, while after injection, a hydraulic fault could be determined according to the excessive error in the rotational speed.

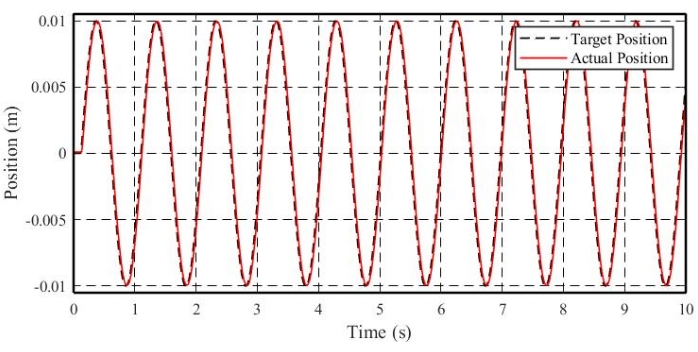

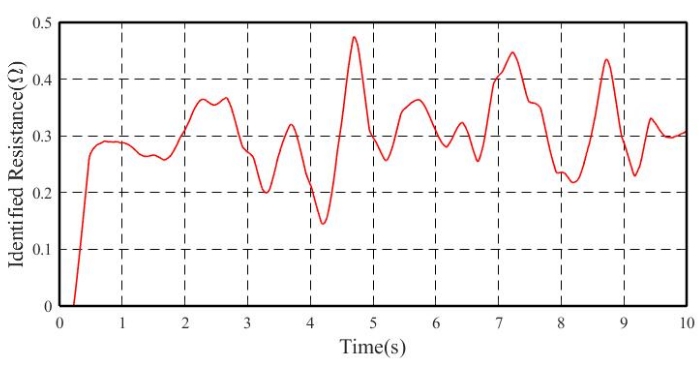

The actual position and target position curve of the EHA piston rod from the experiment is shown in Figure 12. The experimental results were in accordance with the simulation results. According to the curve, the system was operating normally, with good dynamic characteristics, thus meeting the operating condition requirements. The results of the resistance identification algorithm are shown in Figure 13, and these results showed that the identified value converged to the true value of 0.3 Ω, which was consistent with the simulation, indicating that the method achieved the desired effect. Compared with the simulation results, the identified resistance value of the experiment fluctuated more. As the identified resistance was very small, this difference was acceptable. The results of the rotational speed estimation algorithm are shown in Figure 14. The curves showed the actual rotational speed, the estimated rotational speed, the rotational speed error, eωm, and its absolute value, |eωm|. The estimated rotational speed was very close to the actual rotational speed, and |eωm| essentially fluctuated in the range of 0-2.5 rps, which is a reasonable range. This was consistent with the simulation result, which shows the efficacy of the proposed method.

The simulations and experiments verified that the fault detection method studied in this paper is effective and has practical value.

Figure 1: Principle structure diagram of the EHA. This figure shows the principal structure diagram of a typical EHA. Please click here to view a larger version of this figure.

Figure 2: Simulation model of the EHA. This figure shows the EHA model applied in the simulation, which is composed of (B,D) a servo controller, (B) a motor pump, (C) an actuating cylinder, and (E,F) two fault injection switches. Please click here to view a larger version of this figure.

Figure 3: Structure composition of the experimental platform. This photograph shows the composition of the experimental platform, including an EHA, a servo controller, a 24 V DC control power source, a high-voltage DC drive power source, a PC as the host computer, and bundles of connecting cables. Please click here to view a larger version of this figure.

Figure 4: Detailed photograph of the EHA. This photograph shows the details of the EHA composition. Please click here to view a larger version of this figure.

Figure 5: Detailed photograph of the servo controller. This photograph shows the details of the servo controller. Please click here to view a larger version of this figure.

Figure 6: Detailed figure of the host software interface. This figure shows the details of the software interface. Please click here to view a larger version of this figure.

Figure 7: Simulation results for the actual position and target position curve of the piston rod in the non-fault condition. The results indicate that the EHA was operating in a non-fault condition with good dynamic characteristics. Please click here to view a larger version of this figure.

Figure 8: Simulation results for the actual position and target position curve of the piston rod in the electromechanical fault injection condition. The results indicate that before injection, the EHA was operating with good dynamic characteristics, while after injection, the EHA could not track the target accurately due to a fault. Please click here to view a larger version of this figure.

Figure 9: Simulation results for the identified resistance in the electromechanical fault injection condition. The results indicate that before injection, the identified resistance converged to the true value of 0.3 Ω and fluctuated by ±0.02 Ω, while after injection, the identified resistance converged to the true value of 1,000 Ω and fluctuated by ±3 Ω, meaning the method achieved its desired effect. Please click here to view a larger version of this figure.

Figure 10: Simulation results for the actual position and target position curve of the piston rod in the hydraulic fault injection condition. The results indicate that before injection, the EHA was operating with good dynamic characteristics, while after injection, the EHA could not track the target accurately due to a fault. Please click here to view a larger version of this figure.

Figure 11: Simulation results for the rotational speed estimation in the hydraulic fault injection condition. (A) This panel shows the curves of the actual rotational speed, the estimated rotational speed, and the error of the rotational speed. The curves indicate that, before injection, the estimated rotational speed was very close to the actual one, while after injection, the hydraulic fault could be determined according to the excessive error in the rotational speed. (B) This panel shows the curve of the absolute rotational speed error. The curve indicates that, before injection, the absolute rotational speed error fluctuated in the range of 0-2 rps in the non-fault condition, while after injection, the hydraulic fault could be determined according to the excessive absolute rotational speed error, meaning the method achieved its desired effect. Please click here to view a larger version of this figure.

Figure 12: Experimental results for the actual position and the target position curve of the piston rod. The results indicate that the EHA was operating in a non-fault condition with good dynamic characteristics. Please click here to view a larger version of this figure.

Figure 13: Experimental results for the identified resistance. The results indicate that the identified resistance converged to the true value of 0.3 Ω, which was essentially consistent with the simulation, meaning the method achieved its desired effect. Please click here to view a larger version of this figure.

Figure 14: Experimental results for the rotational speed estimation. (A) This panel shows the curves of the actual rotational speed, the estimated rotational speed, and the error of the rotational speed, which indicate that the estimated rotational speed was very close to the actual one. (B) This panel shows the curve of the absolute rotational speed error. The results indicate that the absolute rotational speed error fluctuated in the range of 0-2.5 rps, which was consistent with the simulation and, thus, validates the efficacy of the method. Please click here to view a larger version of this figure.

| Parameter | Symbol | Unit | Value | |||

| Resistance of winding | R | Ω | 0.3 | |||

| Equivalent inductance of armature | L | H | 5.5×10-4 | |||

| torque coefficient of motor | Kt | N·m/A | 0.257 | |||

| back electromotive force coefficient of motor | Ke | V/(rad/s) | 0.215 | |||

| Rotor moment of inertia of motor and pump | Jm | Kg·m2 | 4×10-4 | |||

| friction coefficient of motor | Bm | N·m/(rad/s) | 6×10-4 | |||

| total internal leakage coefficient of system | Kil | (m3/s)/Pa | 2.5×10-12 | |||

| displacement of pump | q | m3/r | 2.4×10-6 | |||

| effective area of piston | A | m2 | 1.5×10-3 | |||

| bulk modulus of hydraulic oil | B | N/m2 | 6.86×108 | |||

| mass of piston and load | M | kg | 240 | |||

| viscous damping coefficient of hydraulic cylinder | Kf | N/(m/s) | 10000 | |||

| effective cavity volume of hydraulic cylinder | V0 | m3 | 5.12×10-4 | |||

Table 1: Simulation parameters. This table shows the main parameters of the simulation model.

Table 2: Table of materials. This table indicates the main components of the test platform.

Discussion

When conducting these experimental steps, it was important to ensure the real-time capability of the algorithm in order to obtain accurate calculation results. The white noise in the signal acquisition process was adopted to simulate the characteristics of the actual sensor in order to make the simulation closer to reality. In the simulations and experiments, moving average filters were applied to reduce the fluctuation in the identified resistance and estimated rotational speed, which made the fault characteristics more stable and easier to judge. During the experiment, it should be noted that, in the case of a sudden communication interruption, the drive power supply must be cut off immediately, and the experiment can only be carried out after communication has been re-established.

For the winding resistance identification algorithm, although the experiment results were nearly the same as the simulation results, which both fluctuated around 0.3 Ω, the identified resistance of the experiment fluctuated to a greater extent, and the effect was not ideal. The reason for this was that the current collection was subject to a lot of interference. For example, the switch status of the power device could not be changed instantaneously when the motor was under commutation, and a saw tooth would appear in the collected bus current. The current sensor was installed near the motor drive module and was affected by strong electromagnetic interference caused by the change of switch status of the power device. Therefore, the noise in the data collected by the current sensor was quite large. Although a filter was applied to smooth the data, the final results were still not as good as the simulation. Therefore, in future research, the electromagnetic compatibility design of the servo controller needs to be further optimized, and the filter needs to be improved for better practical effect.

The experiment was conducted under load-free conditions in which a sinusoidal position command with an amplitude of 0.01 m and a frequency of 1 Hz was applied. In reality, the threshold for judging faults varies according to the working conditions. In practice, experiments should be carried out under multiple working conditions to ensure that the thresholds of the identified resistance and the estimated rotational speed are reasonable.

Due to the difficulty and potential danger of injecting a fault in real objects, fault injections in the motor winding open circuit and increased leakage were only carried out under simulation rather than when using an experimental platform. Fault injection should be carried out after the operating conditions are met to further verify the feasibility of the method studied in this paper.

This study provides a demonstration and guidance for experimental research on EHA fault detection, and it is of great significance for the demonstration and application of the EHA and even for the research on EHA health management systems in the future.

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work was supported by the Chinese Civil Aircraft Project (No. MJ-2017-S49) and the China

Postdoctoral Science Foundation (No. 2021M700331).

Materials

| LabVIEW | NI | NI LabVIEW 2018 | |

| Matlab/SIMULINK | MathWorks.Inc | R2020a | |

| Personal Computer | Lenovo | Y7000 2020H | |

| 24V Switching Power Supply | ECNKO | S-250-24 | |

| Programmable Current Source | Greens Pai | GDP-50-30 |

References

- Fu, Y., et al. Review on design method of electro-hydrostatic actuator. Journal of Beijing University of Aeronautics and Astronautics. 43 (10), 1939-1952 (2017).

- Qi, H., et al. Modelling and simulation of a novel dual-redundancy electro-hydrostatic actuator. 2015 International Conference on Fluid Power and Mechatronics (FPM) IEEE. , 270-275 (2015).

- Chao, Q., et al. Integrated slipper retainer mechanism to eliminate slipper wear in high-speed axial piston pumps. Frontiers of Mechanical Engineering. 17, (2022).

- Yoo, M., et al. A resilience measure formulation that considers sensor faults. Reliability Engineering& System Safety. 199, 106393 (2019).

- Fang, J., et al. Online inverter fault diagnosis of buck-converter BLDC motor combinations. IEEE Transactions on Power Electronics. 30 (5), 2674-2688 (2015).

- Lisnianski, A., et al. Power system structure optimization subject to reliability constraints. Electric Power Systems Research. 39 (2), 145-152 (1996).

- Fu, T., Wang, L., Qi, H., Liu, H. Fault diagnosis and management of electric hydrostatic actuator. Machine Tool & Hydraulics. 38 (9), 120-124 (2010).

- Maddahi, A., Kinsner, W., Sepehri, N. Internal leakage detection in electrohydrostatic actuators using multiscale analysis of experimental data. IEEE Transactions on Instrumentation and Measurement. 65 (12), 2734-2747 (2016).

- Guo, S., et al. Hydraulic piston pump in civil aircraft: Current status, future directions and critical technologies. Chinese Journal of Aeronautics. 33 (01), 16-30 (2020).

- Jackson, E. Real-time model-based fault detection and diagnosis for automated systems. IEEE Industry Applications Society Dynamic Modeling Control Applications for Industry Workshop. , 26-28 (1997).

- Alcorta, G. E., Zolghadri, A., Goupil, P. A novel non-linear observer-based approach to oscillatory failure detection. 2009 European Control Conference (ECC). , 1901-1906 (2009).

- Castaldi, P., et al. Design of residual generators and adaptive filters for the FDI of aircraft model sensors. Control Engineering Practice. 18 (5), 449-459 (2010).

- Zhu, P., Dong, W., Mao, Y., Shi, H., Ma, X. Kernel adaptive filtering multiple-model actuator fault diagnostic for multi-effectors aircraft. 2019 12th Asian Control Conference (ASCC). , 1489-1494 (2019).

- Hidayat, R., Ramady, G. D., Lestari, N. S., Mahardika, A. G., Fadriani, H. Optimization of normalized least mean square algorithm of smart antenna beamforming for interference mitigation. Journal of Physics: Conference Series. 1783, 012085 (2021).

- Fu, J., et al. Modelling and simulation of flight control electromechanical actuators with special focus on model architecting, multidisciplinary effects and power flows. Chinese Journal of Aeronautics. 30 (1), 47-65 (2017).

- Li, Z., et al. New normalized LMS adaptive filter with a variable regularization factor. Journal of Systems Engineering and Electronics. 30 (2), 259-269 (2019).