In Situ Soil Moisture Sensors in Undisturbed Soils

Summary

The determination of soil water content is a critical mission requirement for many state and federal agencies. This protocol synthesizes multi-agency efforts to measure soil water content using buried in situ sensors.

Abstract

Soil moisture directly affects operational hydrology, food security, ecosystem services, and the climate system. However, the adoption of soil moisture data has been slow due to inconsistent data collection, poor standardization, and typically short record duration. Soil moisture, or quantitatively volumetric soil water content (SWC), is measured using buried, in situ sensors that infer SWC from an electromagnetic response. This signal can vary considerably with local site conditions such as clay content and mineralogy, soil salinity or bulk electrical conductivity, and soil temperature; each of these can have varying impacts depending on the sensor technology.

Furthermore, poor soil contact and sensor degradation can affect the quality of these readings over time. Unlike more traditional environmental sensors, there are no accepted standards, maintenance practices, or quality controls for SWC data. As such, SWC is a challenging measurement for many environmental monitoring networks to implement. Here, we attempt to establish a community-based standard of practice for in situ SWC sensors so that future research and applications have consistent guidance on site selection, sensor installation, data interpretation, and long-term maintenance of monitoring stations.

The videography focuses on a multi-agency consensus of best-practices and recommendations for the installation of in situ SWC sensors. This paper presents an overview of this protocol along with the various steps essential for high-quality and long-term SWC data collection. This protocol will be of use to scientists and engineers hoping to deploy a single station or an entire network.

Introduction

Soil moisture was recently recognized as an Essential Climate Variable in the Global Observing Climate System1. Soil moisture, or quantitatively volumetric soil water content (SWC), plays a major role in partitioning the flux of incoming radiation into latent and sensible heat between the earth's surface and the atmosphere, and partitioning precipitation between runoff and infiltration2. However, the spatiotemporal variability of soil moisture at the point, field, and watershed scales complicates our ability to measure SWC at the appropriate scale needed to meet research or management goals3. New methods to quantify SWC, including ground-based networks of in situ sensors, proximal detectors, and remote sensing, provide unique opportunities to map the variation of SWC at an unprecedented resolution4. In situ SWC sensors provide the most temporally continuous and depth-specific data records, but are also subject to small sensing volumes and local-scale variability inherent in soil properties, topography, and vegetation cover5.

Furthermore, there is a lack of standards or widely accepted methods for the installation, calibration, validation, maintenance, and quality control of in situ SWC sensors. Soil moisture is inherently a challenging parameter to measure and may be the most difficult variable to quality-assure6. While general protocols for SWC data collection have been produced by the International Atomic Energy Agency7, the Committee on Earth Observation Satellites8, federal agency reports9, and the American Association of State Climatologists10, there is limited specific guidance on the installation, maintenance, quality control, and verification of SWC data from buried in situ probes. This has made the adoption of such technologies challenging for operational monitoring networks, such as state Mesonets, to add SWC measurements. Similarly, it is also challenging for operational hydrologists, for example, at river forecast centers, to incorporate these data into their workflow. The objective of this videography and accompanying paper is to provide such guidance and document a cohesive installation protocol for buried in situ SWC probes.

Selecting a location for in situ soil moisture monitoring

The soils within any area of interest (AOI) form through a unique and coupled feedback over time between the topography, ecology, geology, and climate11,12. The variability of SWC across landscapes makes site selection a critical aspect to any soil moisture study. For some research goals, a site may be chosen to represent a particular feature or microsite on the landscape or ecosystem. For the purposes of monitoring networks, the site should be spatially representative of a larger landscape component. The goal is to find a location that provides the best spatial representation of the AOI. In the field, more pragmatic considerations must be reached, such as the requirements of other meteorological instrumentation, accessibility, or permittance. However, the dominant soil map unit within the AOI is usually a good spatial representation of the environmental conditions of a larger area13. The dominant soil map unit can be determined using the Web Soil Survey (https://websoilsurvey.sc.egov.usda.gov/); this soil map unit should also be verified with a shallow pit or test hole.

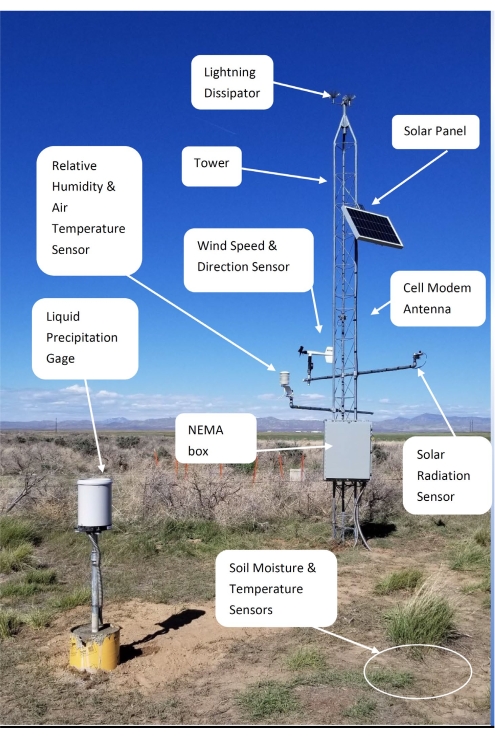

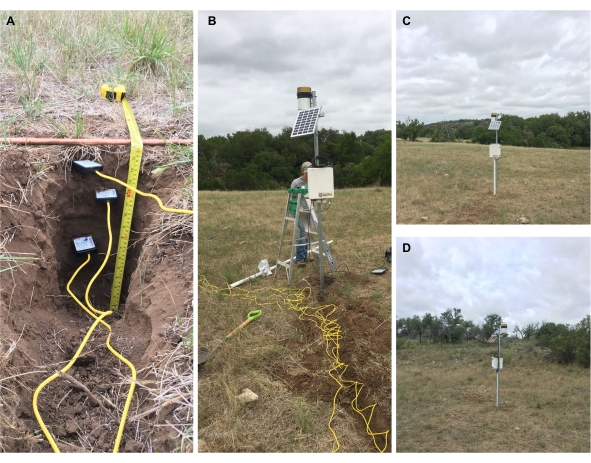

A typical monitoring station can occupy 5-50 m2, depending on the sensor needs and number of ancillary measurements. Figure 1 depicts a typical monitoring station with a 3 m tower that holds an anemometer for wind speed and direction, an air temperature and relative humidity sensor, a pyranometer for solar radiation, and a National Electrical Manufacturers Association (NEMA) weather-resistant and watertight enclosure (NEMA rating 4). The NEMA enclosure houses the data control platform (DCP), cellular modem, solar panel charge regulator, battery, and other related hardware (see Table of Materials; System components). The tower also provides a platform for the communication antenna, solar panel, and lightning rod. A liquid precipitation (PPT) gage is also typically included, which should be placed away from the tower and at the lowest elevation possible to reduce wind effects on PPT capture. The SWC sensors should be installed a sufficient distance away (3-4 m) and upslope so that there is no potential interference from the tower on either rainfall or overland flow. Any related cables should be buried in conduit at least 5 cm below the surface.

Figure 1: A typical monitoring station. The USDA SCAN collects hourly information on soil water content and temperature at standard depths (5, 10, 20, 50, and 100 cm), air temperature, relative humidity, solar radiation, wind speed and direction, precipitation, and barometric pressure. There are over 200 SCAN sites across the USA. Abbreviations: SCAN = Soil Climate Analysis Network; NEMA = National Electrical Manufacturers' Association. Please click here to view a larger version of this figure.

Measurement depth, orientation, and number of sensors

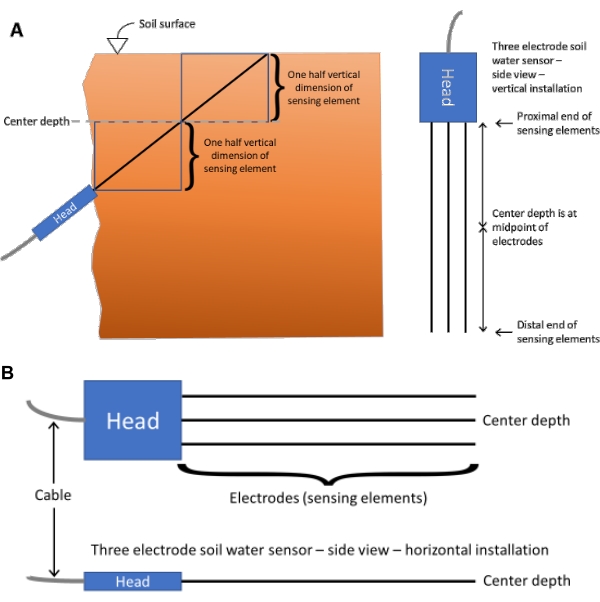

In situ SWC sensors are typically installed horizontally to represent specific depths in the soil (Figure 2). Federally funded, national networks such as the Soil Climate Network (SCAN)14, Snow Telemetry Network (SNOTEL)15, and U.S. Climate Reference Network (USCRN)16 measure SWC at 5, 10, 20, 50, and 100 cm. These depths were reached by consensus during SCAN development for a variety of reasons. The 5 cm depth corresponds to remote sensing capabilities17; 10 and 20 cm depths are historical measurements for soil temperature18; 50 and 100 cm depths complete root zone soil water storage.

Probes can be oriented vertically, horizontally, or inclined/angled (Figure 3). Horizontal installation is most common to achieve a uniform soil temperature measurement at a discrete depth. While the sensor may be centered at a discrete depth, SWC measurement is a volume around the tines (i.e., electrodes), which can vary with moisture levels, measurement frequency, and the geometry of the installation (horizontal, vertical, or angled). For horizontal installation, the sensing volume integrates moisture above and below the depth, and 95% of the sensing volume is typically within 3 cm of the tines19. Vertical or angled installations integrate SWC along the tines, so vertical installation can represent the storage along the entire length of the sensor depths20. Some sensors do not evenly measure along their tines. For example, transmission line oscillators are more sensitive to moisture near the probe head where the electromagnetic pulses are generated21. Vertical installations are more suitable for deeper probes where temperature and moisture gradients tend to be reduced.

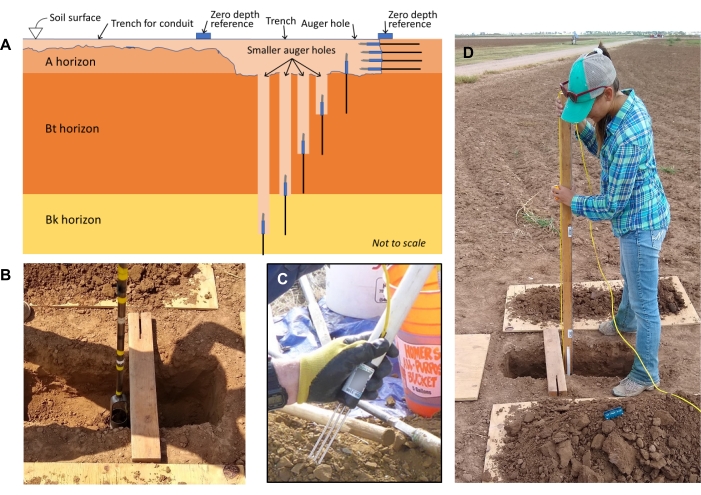

Figure 2: Installation of in situ SWC sensors. Horizontal sensor placement at chosen depths using (A,B) a zero-depth reference jig and (C) a zero-depth board or (D) a zero-depth shovel handle for reference. Please click here to view a larger version of this figure.

Figure 3: Orientation of probes vertically, horizontally, or at an inclination. (A) Slanted and vertical insertion and (B) horizontal-vertical insertion and horizontal-horizontal insertion center depth of a three-tined SWC sensor. Abbreviation: SWC = soil water content. Please click here to view a larger version of this figure.

Installation to depths less than 50 cm is relatively intuitive, while deeper sensors take slightly more effort. Root zone SWC or profile soil water storage typically requires measurements to 1 or 2 m. As illustrated in this protocol, 0-50 cm installations are completed in an excavated pit or auger-hole with probes installed horizontally into the undisturbed soil, minimizing the surface disturbance. For deeper sensors (e.g., 100 cm), both SCAN and USCRN install the sensor vertically in separate, hand-augered holes using an extension pole (Figure 4).

Given the heterogeneity of SWC, particularly near the surface, and the small measurement volumes of sensors, triplicate measurements allow for a better statistical representation of SWC. However, one profile of in situ sensors is typical for most networks (e.g., SCAN and SNOTEL). The USCRN uses three profiles spaced 3-4 m apart to make triplicate measurements at each depth16. Furthermore, redundancy in measurement adds resiliency and continuity to the station record if financial resources are available.

Figure 4: Installation of sensors. (A) Shallow sensors are typically installed horizontally into the side wall of an excavated soil pit. For deeper sensors, (B) a hand auger is used to dig a hole to depth using a zero-depth reference (e.g., wood spanning the trench) and the sensors are pushed vertically into the bottom of holes using (C) a section of PVC pipe modified to secure the sensor and cable during installation or (D) an installation tool. Soil layers are noted as topsoil (A horizon) and subsoil horizons with translocated clays (Bt) and carbonate accumulation (Bk). Please click here to view a larger version of this figure.

In situ SWC sensor type

Commercially available sensors infer SWC from the measured response to an electromagnetic signal propagated along tines in direct contact with the soil22. Buried sensors fall into five classes depending on the type of electromagnetic signal propagated and the method of measuring the response: capacitance, impedance, time-domain reflectometry, time-domain transmissometry, and transmission line oscillation (Supplemental Table S1, with links to each manufacturer's information). These technologies tend to group by operating frequency and manufacturer. Longer tines integrate a larger volume of soil; however, they can be more difficult to insert and are more subject to signal loss in soils with clay and higher bulk electrical conductivity (BEC). Manufacturers report SWC measurement errors of 0.02-0.03 m3m−3, while users typically find these to be significantly larger23. Proper calibration and standardization of electromagnetic sensors improves performance22; however, these soil-specific calibrations are beyond the scope of this protocol, which focuses on installation.

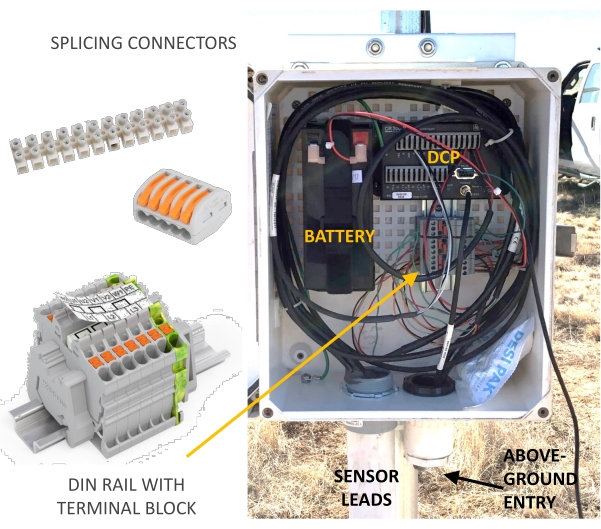

Sensor selection should consider the desired output, measurement method, operating frequency, and compatibility with other measurements. Prior to 2010, most SWC sensors were analog and required the DCP to make measurements of differential voltages, resistances or pulse counts, which required more expensive components and individual channels (or multiplexers) for each sensor. Now, serial data interface at 1,200 baud (SDI-12) communication protocols (http://www.sdi-12.org/) allow smart sensors to implement internal measurement algorithms and then transmit digital data along a single communication cable. Each sensor can be wired together in sequence (i.e., a daisy chain) using a common wire connected by lever nut or terminal block connectors (Figure 5) with each sensor having a unique SDI-12 address (0-9, a-z, and A-Z). The common communication wire of SDI-12 sensors forms a single circuit along with a power and ground wire. Multiplexers or any measurements at the DCP are not required; instead, the DCP simply sends and receives digital commands and lines of text. Many SDI-12 SWC sensors also include soil temperature, relative permittivity (ε), and BEC measurements. Such measurements are useful for sensor diagnostics and soil-specific calibration. At this point, the user has selected a site, determined the sensor type, number, and depths, and obtained all the necessary hardware and field tools (Table of Materials). Thus, they can proceed to the installation protocol.

Figure 5: Wire splice connectors and terminal blocks used to join common power, ground, and communication wires to a single input on the data collection platform. Please click here to view a larger version of this figure.

Protocol

1. Preinstallation preparation of sensors

- Check the SDI-12 address. Sensors are set to a default address by the manufacturer. Separately wire each sensor to a data control platform (DCP) using the ?! command to query the sensor's address.

NOTE: Each sensor on a common data line must have a unique address (e.g., 0-9). Refer to the sensor manual for SDI-12 addressing and changing a sensor's value, if needed. - Take a measurement (e.g., "aM!", where a is the address) in air, dry sand, and submerged in water.

NOTE: Air measurements should read 0.00 m3m-3 (relative permittivity [ε] ~1), play sand < 0.02 m3m3 (ε < 4), and water ~1.00 m3m-3 (ε ~80). - Record these values along with the serial number and SDI-12 address of each sensor in a lab book. Using a marker, label the sensor head and the cable end with the address number.

- Check the DCP program. Some DCPs are plug-and-play, but most require a program to make measurements and record data. Set up the SWC sensors and any ancillary sensors in the lab, connecting all of them to the DCP and battery. Leave the SWC sensors suspended in the air, inserted in dry play sand, or submerged in water, ensuring the tines are not touching.

NOTE: Air measurements should read 0.00 m3m-3 (relative permittivity [ε] ~1), play sand < 0.02 m3m3 (ε < 4), and water ~1.00 m3m-3 (ε ~80). - Let the system run overnight or longer. Verify that the data are recording at the appropriate rates and the values (e.g., right number of columns, significant digits) are appropriate.

- Check any ancillary SWC sensor outputs (e.g., temperature and BEC) as well. Allow the system to run for at least 1 day. Verify that the data tables are correct.

NOTE: Some DCPs are plug-and-play but most require a program to make measurements and record data.

2. Determine the field layout

- Before beginning any digging, call 811 (US and Canada) at least 2 days before excavation to verify the presence of any underground infrastructure (e.g., electrical wires, water supply, gas pipes). Failure to assure such clearances can lead to substantial penalties and liability.

- Verify the soil map unit at the pit location. Use the USDA SoilWeb app, available for iOS and Android smartphones, to query the location. Dig a test hole using a 5-10 cm diameter hand auger to check that the field texture is consistent with the map unit description. Check for any issues such as hard layers (e.g., plow pans, caliche, or argillic horizons) or layers with high rock fragments; either case can make probe insertion difficult, or even impossible.

- Determine the best location for the sensors. Each sensor will be installed into the vertical face of an undisturbed soil.

NOTE: If any slope exists, the face should be upslope to minimize preferential flow occurring through disturbed soil and along cable trenches. - Use a small (1 m2) sheet of plywood or a tarp to protect the soil surface and keep field workers from milling around on the undisturbed soil.

- Determine the location of the instrument mast. Ensure that the sensors are suitably far away from the mast to minimize foot traffic and any effects from the tower.

NOTE: Stock 5 m cables are generally sufficient for most installations.- Use the shortest possible cable length to minimize surface disturbance and the potential for breakage.

NOTE: If the instrument mast is already in place at an existing site, a longer lead may be required to reach a representative soil; alternatively, wireless technologies could be considered (see "Additional thoughts on site selection"). - Ensure that the total distance to the instrument stand is 80%-90% of the cable length to account for extra cable needed to route from the installation depth, through conduit, and up into the enclosure.

NOTE: Wire management can be awkward when many SWC sensors come to a central point. - Thinner cables require burial in PVC conduits, while more rigid, thick cables can be buried directly. For both, dig a trench that is >10 cm deep and 10-15 cm wide.

- Ensure that the enclosure has an entry point for any aboveground sensors and a conduit port for below-ground sensors (Figure 5). Mount the enclosure at a comfortable height (1 m) for wiring.

- Recommendation: Uncoil a sensor. Lay the sensor head at the pit face and position to the cable end at the instrument stand. Verify that the cable length is correct and adjust as needed.

- Use the shortest possible cable length to minimize surface disturbance and the potential for breakage.

3. Excavation of the soil pit

NOTE: The soil pit can be excavated manually or mechanically. The goal is to minimize overall site disturbance.

- For the hand-dug pit, lay another larger tarp (2 m2) adjacent to the excavation area. Use a narrow spade (e.g., sharpshooter) to excavate a rectangular hole to a depth of ~55 cm. Ensure that the pit face, currently protected by plywood or tarp (step 2.4), is vertical (or slightly cut back) so that each sensor will have undisturbed soil above it. Also ensure that the pit is 20-40 cm wide and ~25% longer than the total sensor length. Begin removing soil in 10 cm increments and placing each lift on the far end of the tarp, moving closer with each increment; break up any clods and remove large rocks.

NOTE: Ensure that the excavation area is as small as possible and allows enough room to insert the deepest horizontal probe. - For the hydraulic post hole auger, use a wide diameter (>30 cm) and a 1 m long, trailer-mounted auger.

NOTE: Two- or one-person fence-post augers can be dangerous.- Set up the auger ~5 cm back from the intended pit face.

- Drill down until >50 cm, raising the auger occasionally to expel soil.

- Use a narrow spade to create a flat and vertical pit face.

- Use a spade or a hand trowel to move soil from the pit to the tarp.

NOTE: The excavated soil will be well-mixed; there is no way to avoid this.

- Make a mechanically dug trench using heavy equipment.

NOTE: Unless horizontal installation below 100 cm is necessary, large digging equipment is not encouraged. Dealing with the spoil pile (i.e., excavated soil) can be challenging, and the tracks and stabilizers of the backhoe cause significant disturbance.- Use a lightweight backhoe with a narrow bucket, ideally less than 50 cm, to dig a similar narrow trench to a 100 or 200 cm depth.

NOTE: Avoid moving the backhoe to minimize surface impact. - Begin removing the soil in 10 cm increments and placing each lift on the far end of the tarp, moving closer with each increment. Ensure that the excavation area is as small as possible and at a depth of ~55 cm, allowing enough room to insert the deepest horizontal probe.

- Use a lightweight backhoe with a narrow bucket, ideally less than 50 cm, to dig a similar narrow trench to a 100 or 200 cm depth.

- For the sensor cable trench, dig a trench from the back of the soil pit to the instrument tower. Use a trenching shovel assisted by a pick mattock or Pulaski in hard sections. Excavate a straight, narrow (~10 cm), >10 cm deep trench, laying the soil on one side of the trench.

4. Assembling/erecting the instrument stand and enclosure

NOTE: The instrument stand has three options: a simple pole, a tripod, or a tower. For a basic soil moisture station with a PPT gage, a galvanized steel pole or stainless-steel instrument stand (120 cm tall) with legs is sufficient. For basic meteorological measurements, a taller mast is needed to install sensors at 2 m. Most mesonets prefer 10 m tall towers; however, such towers are beyond the scope of this protocol.

- Use a galvanized steel pole.

NOTE: A 4 cm diameter, galvanized steel water pipe, ~3 m long is the most economical method.- Hand auger a small hole to a minimum of 60 cm depth. Position the pole in the hole. Ensure that the pole height is sufficiently aboveground to hold the enclosure, solar panel, and any antennas needed.

NOTE: A height of <2 m is recommended. - Mix quick-set concrete or fence-post foam, according to instructions.

NOTE: Concrete is not allowed on some federal lands, and some private landowners may object. Foam alternatives for fence-post installations are a good alternative and require no water. - Pour either material around the pole and ensure it is level using a torpedo level. Let the concrete cure for several hours (ideally overnight) and secure the pole with braces to ensure it remains level. Although foam cures in 30 minutes, be sure to hold the pipe in place for at least 2 minutes, ensuring it remains vertical.

- Hand auger a small hole to a minimum of 60 cm depth. Position the pole in the hole. Ensure that the pole height is sufficiently aboveground to hold the enclosure, solar panel, and any antennas needed.

- Instrument stand or tripod (see manufacturer's instructions)

- Loosen or unbolt each of the three stand legs.

- Rotate or extend each leg and position over the end of the excavated trench.

- Insert the instrument mast into the legs and tighten.

- Adjust the length of each leg to assure the mast is vertical.

- Stake each leg into the soil and check the mast again with a torpedo level.

- Using U-bolts, mount the enclosure on the instrument stand at 1-1.5 m. Hand-tighten the bolts to secure it; its final height and tightening will occur later.

NOTE: It is recommended to mount on the northern side of the pole to avoid hitting one's head on the solar panel later.

5. Soil characterization and sample collection

NOTE: Visually characterizing the soil is critical for interpreting soil moisture dynamics after installation. Sample collection can aid the interpretation with quantitative data. Collect samples even if funding is unavailable or in-house facilities are unable to process them. Air-dry and archive them, in case soil characterization is needed in the future.

- For basic soil description, note the depth of any obvious changes in soil color or texture (horizons).

NOTE: The National Soil Survey Center provides an excellent overview of soil profile descriptions and interpretations24. If the location is not ideal, now is the time to move. - For basic soil characterization, collect representative soil samples in a 1 quart (1 L) freezer bag at each sensor depth, following the procedure of Lawrence et al.25.

- On return to the office or lab, lay all the 1 quart bags on the counter, open, and allow them to air-dry for at least 48 hours.

NOTE: Air-drying removes most of the soil moisture while preserving the organic and chemical properties for future analyses. - Submit the samples either to a university extension laboratory (e.g., https://agsci.colostate.edu/soiltestinglab/) or a commercial laboratory (e.g., http://www.al-labs-west.com/) for further analyses. Alternatively, run the sample in-house by trained technicians, using accepted methods noted below.

- Perform basic laboratory analysis, including physical soil parameters such as particle size distribution26, rock fraction (RF; weight percentage greater than 2 mm), soil fraction (SF; percentage less than 2 mm), and texture (sand, silt, and clay percentages). Check the basic chemical parameters, including saturated paste electrical conductivity (dS m-1)27 and organic matter28.

- Recommended: Perform volumetric soil core sampling at 5, 10, 20, and 50 cm depths using a coring device to collect an undisturbed, volumetric sample. Determine the soil bulk density (BD; g cm-3) from the total dry soil weight and the core volume29. Soil porosity (φ; [-]) is the physical upper boundary of SWC. For mineral soils, estimate φ as 1 – BD/PD, where the particle density (PD) for predominantly quartz mineral soils is 2.65 g cm-3.

NOTE: Samples for BD are either collected in a core of known volume or using soil peds29.

- On return to the office or lab, lay all the 1 quart bags on the counter, open, and allow them to air-dry for at least 48 hours.

6. Horizontal insertion of the 5, 10, 20, and 50 cm probes

NOTE: The goal is to ensure complete soil contact around the sensor tines, avoiding any air gaps.

- Carefully snip any zip ties and unroll each sensor, removing any coil in the cables. Position the sensor head near the soil pit and the cable in the trench.

- Installation depth is defined as the center of the sensor when installed horizontally, regardless of whether the face of the sensor is round or rectangular. Install the sensor at the precise depth below the land surface and as horizontally into the soil as possible. Use a zero-depth reference and a measuring device (tape measure or ruler) for accurate sensor depth (Figure 2) and a spacer to maintain tine spacing during insertion (Figure 2C).

- First, insert the 50 cm sensor. Push the sensor horizontally into the soil, trying not to wiggle the sensor as this can create gaps. As the 50 cm probe is often the most difficult, use a grounding rod to provide more leverage to push that sensor in, being careful not to break the epoxy head or separate the tines. Repeat the insertion process, working upward to the 20, 10, and 5 cm sensor depths. Stagger (Figure 2D) or stack (Figure 2B) the sensors.

NOTE: The measurement timing in SDI-12 protocols generally prevents sensors from reading simultaneously and generating interference between adjacent sensors (e.g., the 5 and 10 cm depths). - Orient each sensor cable to the same side of the pit face, allowing them to hang to the bottom of the excavation pit. Take a photo of the excavated hole and sensors with a tape measure for scale (Figure 6A). Use a GPS to determine the latitude and longitude within a few meters of the pit. If excavating multiple sites in a day, use a placard with a unique identifier to differentiate between the pits.

Figure 6: Example photographs for metadata. (A) The instrumented soil pit with tape measure for scale, (B) the cable trench excavated back to the instrument mast, and final site photos facing (C) north and (D) south. Please click here to view a larger version of this figure.

7. Vertical insertion for the 100 cm probe

- For sensor installations at depths greater than 50 cm, auger a separate hole for each sensor in or near the cable trench (Figure 4A).

- Using a hand auger (5-10 cm diameter), dig to the appropriate installation depth(s). The depth is defined as the center of measurement (e.g., 50 cm) minus half of the tine length relative to the zero-depth reference (Figure 4B).

- Arrange the excavated soil onto a tarp in the order in which it was removed.

- Install the sensor vertically by pushing it into the bottom of the hole using an installation tool (Figure 4C,4D). Repack the auger hole with the excavated soil from the deepest to shallowest. Replace the soil in small lifts, packing it sufficiently to prevent soil bridging in the hole and the creation of voids.

NOTE: Packing tools may be a capped piece of PVC or wooden dowels. Avoid damage to the sensor head or cable.

8. Completing the sensor installation and wiring to DCP

- If the sensor cables are directly buried, ensure that the aboveground ends running into the enclosure are in PVC conduit using a bulkhead connector to enter the enclosure (Figure 5).

NOTE: If using a separated rain gage (step 9.1), be sure to include this cable when routing into the enclosure. - If using conduit, lay it out in the cable trench and cut to the desired length. Feed the cable through the conduit-this may require a pull string or fish tape to pull the cables through. Use flexible conduit or a 90° sweep elbow plus a length of vertical conduit to route the cables from into a conduit port onto the bottom of the enclosure.

- Lay the cable or cable/conduit in the bottom of the cable trench. Pull the cable ends through the bottom enclosure port and secure with zip ties. If there is excess cable in the enclosure, pull it back through the conduit and coil in the bottom of the excavation trench.

- Take a photo of the installation pit and trench with cables leading back to the enclosure (Figure 6B).

- For soil moisture sensor wiring, use a common power (5-12 volt) and ground wire for each SDI-12 sensor. Use lever connectors, splice connectors, or terminal blocks (Figure 5) to make these connections easier and more secure. If using more than one type of sensor, use a different communications port on the DCP, if available.

NOTE: One faulty SDI-12 sensor can interrupt other sensors in a series.

9. Ancillary sensors and hardware setup

- Precipitation (PPT) gage

NOTE: To improve catch, rain gages should be installed on a separate vertical mast as close to ground level as possible. Installing the gage higher on the cross-arm mount can reduce catch due to greater wind speeds.- Determine the location. Install the rain gage as low as possible above groundcover (~1 m) and at a distance twice the height of any nearby obstruction30. The ideal location is close to the cable trench.

NOTE: The rain gage cable will be buried alongside the sensor cables before entering the bottom of the enclosure. - Install a vertical mast. Using a hand auger, excavate a hole to ~50 cm depth. Set a section of galvanized steel pipe of sufficient length in cement or foam (see step 4.1).

- After curing, install the gage using hose clamps or a flat mount base, as per the sensor instructions. Ensure that the gage is perfectly level.

NOTE: Most gages have a built-in bubble level. - Run cables between the rain gage and enclosure in the underground conduit with the soil moisture cables.

- For a tipping gage, wire the two leads into a pulse count channel on the DCP.

NOTE: The wires can go in either side. - Be sure to remove the top and check that the tipping mechanism is free moving. The buckets are often secured during shipment with rubber bands.

NOTE: Rain gages require routine cleaning and calibration. If mounting the rain gage directly on the instrument stand or cross-arm, follow step 9.2.

- Determine the location. Install the rain gage as low as possible above groundcover (~1 m) and at a distance twice the height of any nearby obstruction30. The ideal location is close to the cable trench.

- Other sensors

- Install ancillary measurements and any antenna to the vertical mast or cross-arm mounts at the appropriate height above ground10,30.

- Route leads into the aboveground enclosure entry, and secure where needed with cable ties. Wire into the appropriate measurement channels on the DCP.

- Grounding rod

- Install a >1 m long copper grounding rod 0.5 m from the instrument mast. Use a fence-post driver to insert the rod into ground, leaving ~20 cm exposed.

- Secure heavy (8-10) gage copper wire to the rod using a ground clamp. Secure the other end to the enclosure or tripod.

NOTE: Grounding may not be advisable in all situations.

- Connect the battery.

NOTE: Most DCPs need 5-24 volts (V), although 12 V is most common and 7 or 12 Ampere hours (AH) is sufficient to power most soil moisture stations. A 12V 12AH battery pack and voltage regulator are used here.- Ensure the charge regulator is in the off position. Using a multi-meter set to DC for direct current voltage, verify the voltage on the battery is sufficient (>10V for a 12V battery) and identify the + and – terminals, if not marked.

- Slide the terminal connector of the black (–) wire over the spade terminal on the ground (–) post of the battery, and the red wire over the + battery post. Plug the other end of the red/black wires into the BAT port on the voltage regulator.

- Solar panel

NOTE: A 10 or 20 watt panel is typically sufficient. Increased wattage is needed at higher latitudes, more shaded areas, or on systems with a high power draw (e.g., cellular modems, cameras). The panel should be oriented to receive maximum incident solar radiation over the course of 1 year.- Wrap electrical tape separately around each lead on the solar panel.

NOTE: These wires will carry current if the panel is exposed to sunlight. - Using U-bolts, mount the solar panel above the enclosure and on the side of the instrument stand facing the equator (e.g., south in the USA). Use the appropriate angle for the site latitude, typically 25° to 35° in the conterminous USA.

- Route the cable into the aboveground enclosure entry point. Remove the tape from the panel leads. Using a multi-meter set to A for amperage, verify the output of the solar panel is >0.1 A.

- Using a multi-meter set to DC for direct current voltage, verify the output of the solar panel is >10V and identify the + (usually red) and – (usually black) leads, if not marked. Connect the – lead from the solar panel to the G (ground) port, then the + lead from the SOLAR port on the charge regulator.

NOTE: Cover the solar panel with a tarp or something opaque to minimize sparking. - Check that the CHG or charging light is now illuminated.

- Wrap electrical tape separately around each lead on the solar panel.

- Remote data communications

NOTE: Cellular data telemetry provides the ability to transmit and send data from the DCP. Smartphone apps, such as OpenSignal, can measure signal strength and the heading to the nearest cell tower. Omni-directional, multi-band antennas are preferred; however, a directional (Yagi) type antenna can improve signal in more remote areas.- Attach the antenna to the top of the instrument mast using supplied U-bolts.

- Connect the coaxial cable to the antenna and route other end into the enclosure through the aboveground sensor conduit. Secure the cable with zip ties.

- Connect the other end to the cellular modem in the enclosure.

- Powering up the system

NOTE: At this point, the assumption is that the DCP program is written, and all sensors are wired in an appropriate manner. The solar panel and rechargeable battery are wired to a voltage regulator with a red/black power wire connected to the DCP power ports.- Switch the toggle on the voltage regulator to on. Launch the DCP software and connect a laptop to the DCP. Confirm that all sensors are reporting values and not not-a-number (NaN) or an error value.

- Check each soil sensor for SWC, BEC, and T values. Ensure that the SWC values are >0.05 m3/m3 and <0.60 m3/m3. Check any out-of-range sensor; reinsert or replace any sensor that is questionable. Pour some water through the rain gage and verify that the DCP is recording counts.

NOTE: Low BEC values (<0.001) can indicate poor sensor contact (or very dry soils). When installing in warmer seasons, T is generally warmest at the top and coolest at the bottom. - Check cellular communication strength. Follow the manufacturer's documentation to determine signal strength.

NOTE: Signal strength should be > -100 dBm to ensure decent signal quality. Direction antennas can be rotated to possibly improve signal. Many other communication options exist beyond cellular (e.g., satellite).

10.Site completion

- Once certain everything below ground is functioning, and the cables or cables in conduit are all in the trench and routed into the enclosure, fill and seal the openings of the above- and belowground enclosure entries with electrical putty to protect from moisture and keep insects out of the enclosure.

- Delineate the outside perimeter of sensor locations on the surface with permanent stakes with bright flagging.

- Backfill the excavated area using the soil on the tarp and in the reverse order of removal (Step 3.1) (deepest to shallowest). Start by hand-packing the soil against the trench face and around the sensor head at 50 cm, taking care to avoid disturbing the sensor. Support the sensor head while packing soil around it so that the sensor tines do not move.

- Ensure that all the remaining sensor cables are still positioned near the bottom of the trench; then, carefully cover them with deeper soil from the tarp. Compact the soil into the bottom of the pit to secure the cables, being careful not to pull them downward with any force. Use sufficient force during compaction to assure similar bulk density of the removed material.

NOTE: Wetter soils during installation can easily be over-compacted, while drier soils may stay loose regardless of force. - Backfill the pit in 10 cm lifts, smoothing and compacting the surface until the 20 cm sensor is reached. Again, carefully hand-pack the soil under and around the sensor, before returning to backfilling another 10 cm lift of soil.

- Lastly, hand-pack the soil around the 10 cm sensor, then the 5 cm sensor, assuring both remain horizontal and in place. Fill the remainder of the soil pit with upper soils from the tarp.

NOTE: All the soil removed should go back into the pit. Leftover soil indicates that the soil was not packed to the original bulk density. - Using the trenching shovel, push the excavated soil beside the trench over the conduit. Ensure everything is buried completely and below 5 cm.

- Use a steel rake to level the repacked soil in the pit and trench flush with the original surface. Compact soil in the conduit trench sufficiently to minimize any preferential flow into the installation site.

- Optional: Sprinkle some diatomaceous earth around any subsurface opening and on the surface to discourage ants, slugs, and other insects.

- Recommended: use a portable SWC sensor to take readings of the surface soil around the in situ sensors to aid data verification over time and any scaling needs. Take readings in cardinal directions (north, south, east, and west) at consistent distances away (e.g., 5, 10, 25, and 50 m).

11. Record station metadata, the data behind the data23

NOTE: Document metadata at installation and each site visit (see Table 1). Consistent metadata reporting supports the growing community of practice and is critical to ensure data and network integrity.

- Document the installation details, including a unique site identifier, installation date, sensor serial numbers, corresponding SDI-12 addresses, insertion orientations (horizonal or vertical), and depths.

- Describe the soil profile and take associated photos. Record sample identifiers for any soil samples collected.

- For the site location, record the latitude and longitude, elevation, slope, aspect, land use, and land cover.

- Make a note of landowner and contact information, as well as site accessibility, including gate or lock codes.

- Using the Compass App on a smartphone (or an actual compass) and a measuring tape, measure the angle and distance to the sensor pit (and any sensor auger holes) from two reference points (e.g., grounding rod or a tripod leg).

NOTE: This will help triangulate their positions later. - Take photos of the completed station and orientations north (Figure 6C), south (Figure 6D), east, and west from the instrument mast. Delineate sensor installation location with flagging or other distinct items.

Table 1: Station metadata for soil moisture data collection. Abbreviations: Dec. = decreasing; GPS = Global Positioning System; 3DEP = 3D Elevation Program; O&M = operation and maintenance; SSURGO = Soil Survey Geographic Database; Mukey = map unit key. Please click here to download this Table.

12. Operations and maintenance

NOTE: A detailed maintenance log should be added to the metadata record, including sensor replacement, vegetation health or changes, or any site disturbance.

- Perform routine site inspections annually at a minimum (Table 2). Record any sensor calibrations or replacements.

- Ensure regular vegetation management, especially for permanent stations so that the site does not become overgrown or anomalous to the surrounding area.

- Adapt animal management to local wildlife, possibly including fencing.

- In case of sensor failure, do an emergency site visit and install a replacement (Table 2).

Table 2: Example maintenance schedule. Abbreviation: DCP = data control platform. Please click here to download this Table.

Representative Results

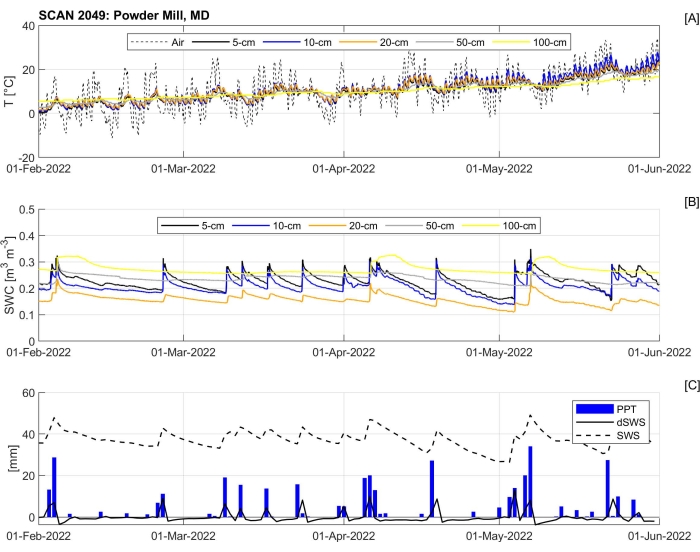

The SCAN network began as a pilot project of the NRCS in 1991. It is the longest operating SWC data collection network15 and the basis for the representative results in this protocol. All SCAN sites originally began with an analog capacitance sensor. The field installation site (SCAN 2049) in Beltsville, Maryland, used in the video component of this protocol, monitors (Figure 7A) hourly air and soil temperature and (Figure 7B) hourly SWC at 5, 10, 20, 50, and 100 cm depths. Daily PPT, soil water storage (SWS) to 20 cm, and its change over time (dSWS) are shown in Figure 7C. For each PPT event, there was a sharp increase in SWC near the surface (5 and 10 cm) and a more attenuated and delayed increase at greater depths as the wetting front propagated downward under gravity. During events in early February and April of 2022, the deepest sensor at 100 cm reached a plateau of 0.33 m3/m3, which was sustained for several days. Such conditions indicate short saturation duration. The soil horizon dry bulk density from characterization data (Table 3) was 1.73 g/cm3, with an estimated porosity (φ) of 0.35 [-], providing additional evidence that the pore-space was entirely filled with water. Given the sandy loam/loamy sand of the soil profile, saturated conditions were most likely produced by poor drainage or a shallow water table that inhibited drainage. Note, the air temperature at this site drops below freezing most evenings until April; however, soil temperatures remained above 2 °C and there was no indication of frozen water in the SWC data at any depth.

Figure 7: Example results from the field station (SCAN 2049) located in Beltsville, Maryland. (A) Hourly air and soil temperature, (B) hourly SWC, and (C) daily precipitation, soil water storage to 20 cm, and its difference over time. Abbreviations: SWC = soil water content; PPT = precipitation; SWS = soil water storage; dSWS = differences in SWS over time. Please click here to view a larger version of this figure.

Table 3: Site data and soil characterization for data examples presented in the representative results. All data presented in figures and tables were retrieved from the NRCS on-line database at the URL noted for each site. Soil characterization data were not available for Table Mountain (#808). Abbreviations: NRCS = Natural Resources Conservation Service; URL = uniform resource locator; c = clay; fsl = fine sandy loam; ls = loamy sand; s = sand; sc = sandy clay; scl = sandy clay loam; si = silt; sil = silty loam; sl = sandy loam; nd = no data; BD = bulk density 33 kPa. Please click here to download this Table.

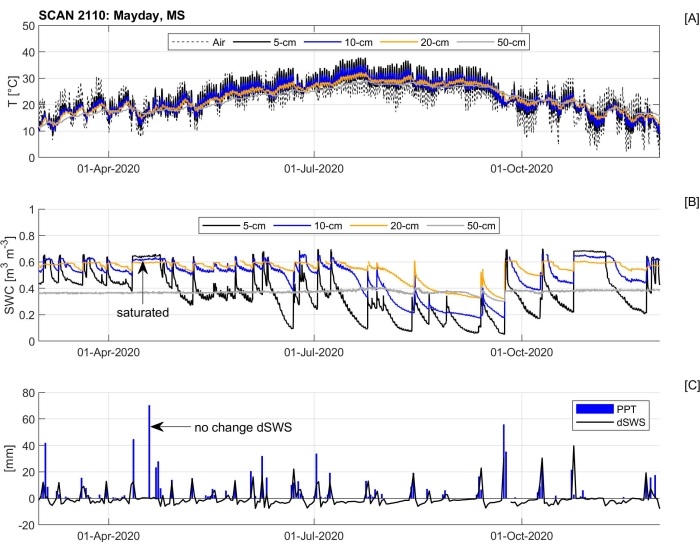

A more extreme example of saturation is shown in Figure 8 for a SCAN location (2110) near Yazoo, Mississippi. The soils have very high clay contents (above 60%), low bulk densities ranging from 1.06 to 1.23 g/cm3, and a φ ranging from 0.54 to 0.60 [-] (Table 3). The first PPT event of ~40 mm on 13 April 2020 saturated the soil to an SWC of >0.60 m3/m3 at all depths for 12 consecutive days-values very close to the measured φ. A second event of 70 mm/day on 20 April 2020 had no effect on dSWS, suggesting saturation-excess runoff. A similar period of saturation was notable in November 2020. While there was no measurement at 100 cm, the SWC at 50 cm remained steady at 0.39 m3/m3, except in late summer where it modestly dropped to 0.36 m3/m3. Site notes (Supplemental Table S2) indicate that the 'loam' sensor-specific calibration31 was used, as is the case for capacitance sensors used in most SCAN and USCRN sites. Both examples illustrate the importance of soil characterization and BD data, collected during site characterization (step 5), on the interpretation of SWC data.

Figure 8: Example results from a humid, temperate site (SCAN 2110) located near Yazoo, Mississippi. (A) Hourly air and soil temperature, (B) hourly SWC, and (C) daily precipitation and change in soil water storage. Abbreviations: SWC = soil water content; PPT = precipitation; SWS = soil water storage; dSWS = differences in SWS over time. Please click here to view a larger version of this figure.

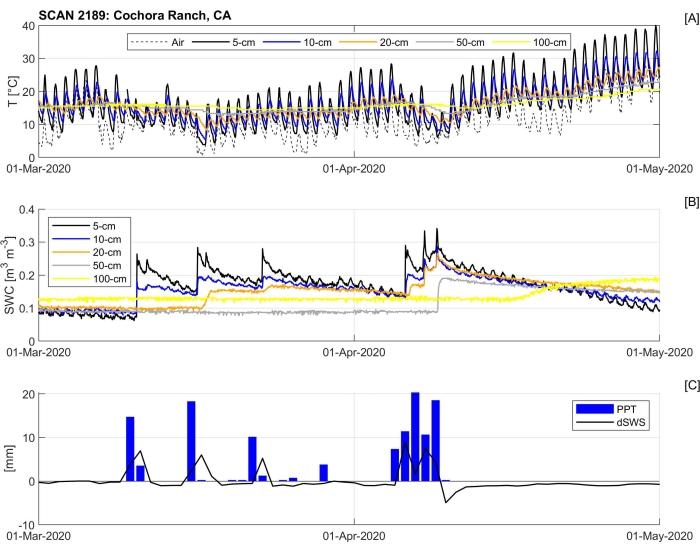

Figure 9 presents a more straightforward time series of in situ SWC at five depths with five wetting events that result in the sequential propagation of the wetting front downward in the soil profile. This SCAN site (2189) was located near San Luis Obispo, CA, in a Mediterranean climate with a wet spring and a long, dry summer on a sandy loam soil with a φ ranging from 0.37 to 0.51 [-] (Table 3). The response to soil surface wetting was rapid and decreased in magnitude with depth. The final large PPT event over 5 days was enough to show response at the 50 and 100 cm depths. As the depth increased, the diurnal cycle of the soil temperature amplitude decreased, and the time of maxima and minima temperatures lagged further behind air temperature and shallower depths (Figure 9A). While these characteristics can be useful to discriminate between sensor depths, as discussed in the next section, there was also a notable effect on the fluctuation of SWC at 5 and 10 cm depths. The SWC amplitude was ~0.02 m3/m3 at 5 cm, ~0.01 m3/m3 at 10 cm, and more negligible in the deeper sensors. It was also in phase with soil temperatures, and noise was more likely induced in the sensor by temperature fluctuations and unlikely to be the result of any physical movement of soil moisture or actual precipitation. This drier site (2189) has much larger diurnal changes in soil temperature than the more mesic field installation site (2049), which shows no temperature noise in the SWC data (Figure 7B).

Figure 9: Example results from a semi-arid, Mediterranean site (SCAN 2189) located near San Luis Obispo, California. (A) Hourly air and soil temperature, (B) hourly SWC, and (C) daily precipitation and change in soil water storage. Abbreviations: SWC = soil water content; PPT = precipitation; SWS = soil water storage; dSWS = differences in SWS over time. Please click here to view a larger version of this figure.

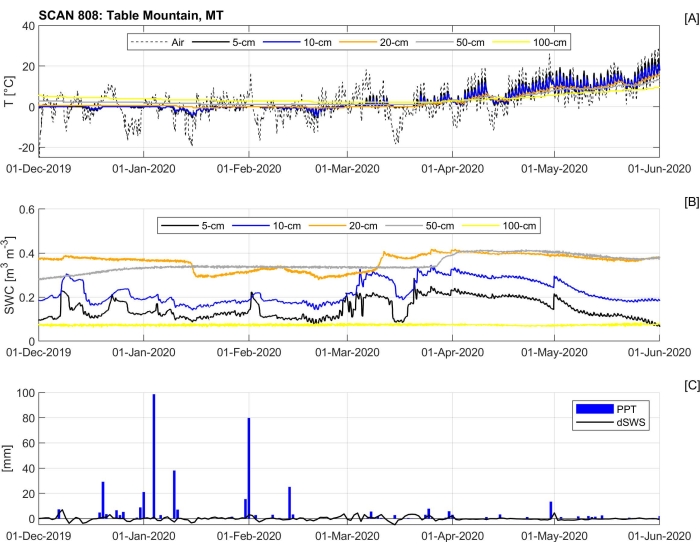

Figure 10 presents one of the more challenging SWC data interpretations that exist with frozen soil and snow cover. This site (808) was located near Boseman, MT, at 4,474 feet above sea level. Daily air temperatures occasionally exceeded freezing temperatures during the winter (December, January, and February) of 2020. Soil temperatures remained just above 0 °C until March. The presence of snow on the surface would insulate the soil from air temperature variations. Furthermore, in moist soils, the release of latent heat and consumption of energy, accompanied by phase transition processes related to freeze-thaw cycles, buffered soil temperatures, keeping them very close to 0 °C until these phase changes were complete. The small ε of ice in freezing soils appears as dramatic decreases in SWC followed by increases during thawing without any indication of PPT. This was most apparent in mid-December and mid-March, when air temperatures rapidly dropped and SWC at 5 and 10 cm decreased for 3 days and then rebounded. The soil temperature at 100 cm reached freezing point in mid-November and was at a low SWC the prior fall, all winter, and did not change during the spring thaw, suggesting it might have been malfunctioning. However, the rapid drops and recovery in the other sensors may or may not be real changes in liquid soil water; interpreting such data can be extremely challenging without ancillary measurements of snow presence or depth. Often, SWC data at or below freezing are censored in quality control. More discussion on soil temperatures near freezing is presented in the data record quality control section.

Figure 10: Example results from a semi-arid, alpine site (SCAN 808) located near Three Forks, Montana. (A) Hourly air and soil temperature, (B) hourly SWC, and (C) daily precipitation and change in soil water storage. Abbreviations: SWC = soil water content; PPT = precipitation; SWS = soil water storage; dSWS = differences in SWS over time. Please click here to view a larger version of this figure.

Other examples and characterization data were pulled from the SCAN database (see Table 3 for Uniform Resource Locator, [URL]). The reporting and quality control of these data need some interpretation to determine if there is a physical mechanism to explain any erratic behavior. Our interpretation lacks any local site knowledge, and despite years of evaluating SWC time series, it can still be challenging to assess a good sensor or installation from a failing or bad one.

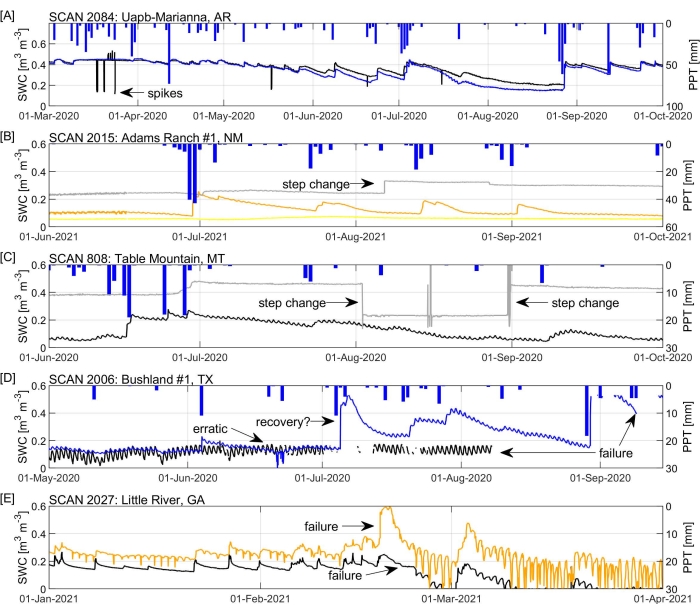

Figure 11 presents common examples of problem data records, randomly picked from 40 SCAN stations between 2020 and 2021. The most common errors include spikes (Figure 11A) and step changes either upward (Figure 11B) or downward (Figure 11C), as flagged by the International Soil Moisture Network32. For each of these, there is no concurrent PPT event to explain such changes, and they can be considered erroneous. The issue with instantaneous spikes or dips is compounded when only looking at daily means, which can hide such events. It is best to remove them before making any mean calculation. The start and end of a step change may be obvious, but it is difficult to fill any data in between. We do not approach data filling in this protocol, but rather only flag erroneous data. Erratic behavior (Figure 11D) presents itself as wild fluctuation without any response to PPT events. In some cases, spikes may go away after wiring checks and multiplexor replacement, as shown in Figure 11A after August 2020. More often, erratic behavior is a prelude to a failing sensor, as shown in Figure 11E. The sensor at 10 cm depth gave a reasonable warning of erratic behavior in January and failing in late March. The sensor at 5 cm depth, however, failed without warning on 1 March 2021.

Figure 11: Examples of problem records. (A) SCAN 2084, Uapb-Marianna, Arkansas, showing periodic dips at 5 cm, (B) SCAN 2015, Adams Ranch #1, New Mexico, with a positive step change at 50 cm depth, (C) SCAN 808, Table Mountain, Montana, with a downward step change, spikes, and even recovery at 50 cm depth, (D) SCAN 2006, Bushland #1, Texas, showing no response to precipitation events at the 5 or 10 cm sensor, with some recovery of the 10 cm sensor followed by the eminent failure of both, and (E) SCAN 2027, Little River, Georgia, with a glitching sensor at 20 cm and catastrophic failure at both the 5 and 20 cm depths. Sensor depths are denoted as 5 cm (black), 10 cm (blue), 20 cm (orange), 50 cm (dark gray), and 100 cm (yellow). Abbreviations: SWC = soil water content; PPT = precipitation. Please click here to view a larger version of this figure.

At SCAN 2084, the site began recording data on 2/6/2004 and had several notes of erratic behavior related to SDI-12 multiplexers, which were replaced several times (Supplemental Table S2). However, the sensors are original and, after 18 years, remain functional. At SCAN 2015, data collection began on 10/25/1993 and the 50 cm sensor in Figure 11B was considered suspect in 2017 (Supplemental Table S2). The oldest site, SCAN 808, began reporting on 9/30/1986 and was converted to a SCAN station on 10/25/2006; it has not had any sensors replaced to date. Anomalies, as shown in Figure 11E, do not always result in failure, since Figure 10 has reasonable data. SCAN 2006 began reporting on 10/1/1993; the original 5 and 10 cm sensors in Figure 11D were replaced on 1/24/2022. SCAN 2027 began reporting on 5/19/1999; the original 5 and 10 cm sensors in Figure 11E were replaced on 8/13/2021. As noted, SCAN sites began with an analog capacitance sensor. Many of these sensors have lasted over 20 years and, while not necessarily producing the highest quality data throughout, have remained functional. Determining the point at which to replace a sensor remains an open question for practitioners. Site metadata and soil properties for sites in Figure 11 can be found in Supplemental Table S3.

Data reporting

Continuous in situ SWC sensors report three to six values per time-recording interval. Along with any ancillary measurements, the long-term deployment of SWC sensors generates large amounts of unit-value data that need to be stored and delivered. Environmental measurements are made at discrete sampling intervals that are aggregated over time and reported as the data record. Atmospheric measurement sampling frequency varies by measurement; it is larger for wind and solar radiation measurements (<10 s) and larger for air temperature and humidity (60 s)30. These sample values are averaged or accumulated over a reporting interval that can range from 5 min to 1 h. Similarly, SWC can be instantaneously sampled at the reporting interval or sampled (e.g., every 5 min) and averaged into 30 min or 60 min averages, since the dynamics of SWC are relatively slower in comparison. Although averaging from more frequent sampling can reduce noise from temperature fluctuations, electrical interference, and inherent sensor variability, it is not advisable, because data spikes can bias the mean value as discussed previously. Most SWC data records can be satisfied with sensing at every hour, but for regions with higher velocity drainage conditions (sandy soil) and intensive PPT (monsoonal conditions), some networks record on a 20 min time interval to fully capture rainfall events. Lastly, data transmission or telemetry can be limited by the technology (e.g., satellite systems) or have cost tiers based on data size and frequency. Optimizing reporting intervals and telemetered variables can help control costs. For example, transmitting raw values (e.g., ε or counts) is preferred to derived values (e.g., SWC) that can be calculated in postprocessing. Data resolution can also affect telemetry package size; however, it is important to represent SWC as either a percentage (0.0-100.0%) at a resolution of 0.1% or as a decimal (0.00-1.00) at a resolution of 0.001 m3m-3. The decimal version in m3m-3 is greatly preferred to avoid confusion with percentage changes of water content in later analyses and reporting, and to avoid confusion with mass basis water contents (g/g) that may also be reported as percent water content. Soil temperature, ε, and BEC are commonly reported at 0.1 °C, 0.1 [-], and 0.1 dS m-1 resolutions, respectively.

Data record quality control

The data record quality control process verifies the data and documents its quality. Accurate field notes and calibration logs are essential in processing the data record. The typical steps in processing a record are an initial evaluation, removal of obvious erroneous data, application of any derived-value computations or corrections, and a final data evaluation. SWC records generally consist of a signal (e.g., ε, counts, or mV), soil temperature, and BEC that are used in varying degrees to derive the SWC. Sensors may also output a manufacturer-derived SWC. However, no sensor directly measures SWC; this calculation can be a part of the data computation step, assuming that an appropriate calibration equation is available and made part of the metadata record. A record may be an instantaneous measurement or an average over some period. It is desirable for raw data to be maintained so that the most appropriate formats can be calculated for quality control and improvements in calibration equations or sensor understanding can be applied to the raw data. Sensor characteristics should dictate whether instantaneous values or mean values of multiple readings are recorded, although instantaneous values are preferred for reasons given previously.

There are several ways to incorporate ancillary data (see data verification below) into a quality control workflow. Precipitation is the first check-"did SWC increase after a rain event?" There are situations where SWC can increase without PPT (e.g., snow melt, groundwater discharge, irrigation). The second check is to compare the change in soil water storage against the total amount of PPT for a specific event (Figure 7C). Ideally, this event should be an isolated, low-intensity rainfall event. Precipitation infiltrates the soil from the surface and percolates downward. The peak in SWC should follow a similar pattern downward (Figure 7B). However, preferential flow can cause infiltrating water to bypass a shallow sensor or cause a rapid response at deeper sensors. While these may be 'real' responses, poor compaction of the installation trench or around an individual sensor can preferentially funnel water toward a sensor. Bias in wetting front arrival should be used with caution and common sense when interpreting unusual responses to rainfall or snowmelt events. As illustrated in Table 3, BD dictates the upper limit of soil pore space, φ [-], in mineral soils. Water contents routinely larger than φ indicate either a malfunctioning sensor or inappropriate sensor calibration. In the former case, data may be expunged from the record. In the latter case, recalibration may allow the record to be retained, with values modified according to the recalibration.

Soil temperature is another variable that helps to quality control data. Soil temperature propagates downward in the soil column and attenuates with depth (Figure 7A). The temperature should peak earlier and higher nearer the surface with increasing lag time from the surface peak as sensor depth increases. Any out-of-order sensor lags may be an indication of a mis-identified depth or incorrect SDI-12 address. As shown in Figure 10 and discussed therein, electromagnetic sensors depend upon changes in ε, which range from ~3 for ice to ~80 for water. Changes between water and ice are recorded by SWC sensors. However, it may be necessary to raise the flagging threshold, as the sensing volume of the sensor is different from the sensing volume of the soil temperature thermistor, and the threshold could be as high as 4 °C. Because the degree of freezing and the relative amount of liquid water can be important for assessing soil hydrology, these data should be flagged as being influenced by freezing and not necessarily removed. At the most basic level, quality control should rationalize any erratic sensor response to some physical mechanism or else it is an error. Although automated quality control routines are a requirement for large networks and disparate data sources13,33,34,35, there is no substitute for eyes-on-data to maintain long-term data quality.

Data verification

One of the most challenging aspects of SWC data is verification-"is the sensor providing good and accurate data?" Most environmental sensors are accessible after deployment and can be replaced with a new sensor after some duration, returned to the manufacturer or laboratory to be recalibrated against standards, and/or have the data verified against a sample collected from the field. Meteorological organizations follow strict procedures for atmospheric sensors, including sensor rotations, sensor maintenance, and in-field calibrations that allow preventative maintenance to serve as the first pass of data verification10,30. SWC sensors are buried in situ and cannot be audited or recalibrated without significant site disturbance and potential damage to the sensor. Furthermore, there are no accepted standards for SWC sensors, and as such, data verification requires some knowledge of the anticipated sensor response and some confidence in the sensor itself. Both require practical experience and best practices that are followed in the field (i.e., site maintenance and inspections). If unusual performance issues, as presented in Figure 11, become chronic, there is a high likelihood of the sensor failing, and it should be replaced.

Electromagnetic sensors have no moving parts, and the wire and circuitry tend to be robust. After 3 years, the Texas Soil Observation Network reported a 2% failure rate for transmission line oscillator sensors21. After more than 10 years of service, the U.S. Climate Response Network reported a marked increase in the failure rate of impedance sensors at 15-18 probes per 100 from 2014 to 201736. As presented in Figure 11, most SCAN sensors were over 20 years old before failure. Replacing a sensor before failure is preferred so that the sensor can be re-evaluated in air, water, and sand to check for drift against predeployment values, if these were recorded (e.g., step 1), among other reasons. Routine replacement is somewhat impractical with SWC sensors and seldom done in large networks, and we are unaware of any long-term evaluations of electromagnetic SWC sensor change over time. The USCRN network is currently migrating to a new sensor technology after over 10 years using capacitance sensors. The plan is to have a minimum overlap of 2 years between old and new sensors to make any adjustments.

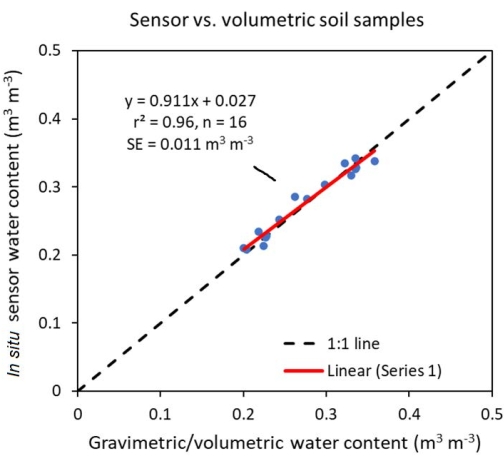

Regular maintenance visits should include verification of SWC data, ideally across a range of moisture conditions. This can be accomplished indirectly using a portable sensor, ideally calibrated to some soil samples or directly to volumetric soil cores collected onsite. The best approach is to compare in situ sensor readings with SWC from volumetric soil samples at equivalent depths37 (Figure 12). Scheduled maintenance should attempt to cover a range of soil moisture conditions so a simple regression between direct/indirect SWC measurements and coincident sensor readings can be compared. Deeper soil sampling can be made in auger holes or with mechanical coring devices. Verification of the surface sensors (e.g., 5 and 10 cm) may be sufficient since the deeper sensors should follow a similar characteristic response to PPT, as previously discussed. There are several limitations of this post hoc SWC assessment. The primary disadvantage is that the volumetric samples cannot (nor should they) be taken directly at the sensors and may not be truly representative of the SWC within the sensing volume around the tines (within 3 cm). This leads to the second disadvantage; many more sampling locations and depths may be needed to obtain a representative field SWC value. This can also result in a lot of holes and disturbance around the site. A third disadvantage is the difficulty of obtaining volumetric soil samples at depth without excavation that disrupts the soil profile.

Figure 12: Volumetric SWC data. SWC data from 60 cm3 soil cores taken as field calibration data compared with SWC from in situ sensors at depths of 15, 30, 45, and 60 cm, in textures ranging from loamy, fine sand to clay. This figure was adapted from Evett et al.37. Abbreviation: SWC = soil water content. Please click here to view a larger version of this figure.

The NRCS developed a soil sampling method in auger holes using a volumetric sampling tube (a Madera-style probe) on an extension rod for samples at the bottom of an auger hole38. These direct measurements can also be combined with indirect measurements from portable sensors37,39,40 to provide a calibrated assessment of the in situ sensors' spatial representativeness13,41. As described in protocol step 10.10, this process can be repeated to allow some metric (e.g., root mean square error, bias, correlation) to determine any recent deviation of the in situ sensors from the direct sampling or indirect estimates of SWC. More details are also presented by the International Atomic Energy Agency IAEA7. Soil excavation and characterization data presented in steps 3 and 5 also provide data on φ (SWC should not exceed this value). Soil texture and horizonation illustrate zones of high/low conductivity and soil water retention. These steps are very much in line with the forest soil sampling protocol25. The desired scale of representativeness can be used to collect the validation dataset, and thereafter, the station can be scaled to the validated footprint42. If a station sensor type is replaced, it would be reasonable to collect another set of validation data across a variety of soil water conditions to capture the installation bias again.

Ancillary data sets can assist in the verification and assessment of SWC data. It is obvious that a hydrologic time series is dramatically improved with an onsite PPT gage to verify the timing, duration, and magnitude of events. Soil matric potential sensors provide the energy status of the soil water, critical to quantifying plant available water. Meteorologic sensors, including air temperature, relative humidity, wind speed, and solar irradiance, allow the direct computation of reference evapotranspiration (ET), which is a useful guide to relative plant water uptake, and thus, soil drying rate43. Several economical, all-in-one weather sensors are available with SDI-12 output. Groundwater level information from a pressure transducer is another valuable measurement, if the water table is near the surface and a monitoring well can be installed. Finally, a field camera can provide both scientific value and site-security value. Digital images can record vegetation growth and greenness44, and the general condition of the station can be assessed without a field visit.

Supplemental Table S1: Common (but not inclusive) in situ SWC sensor technologies. Please click here to download this File.

Supplemental Table S2: Sensor history logs extracted from the NRCS on-line database for all sites presented in this protocol. Data available through each URL. Please click here to download this File.

Supplemental Table S3: Site data and soil characterization for data examples presented in Figure 11. Please click here to download this File.

Discussion

Soil moisture state is a result of many different environmental factors, including precipitation, vegetation, solar irradiance, and relative humidity, along with soil hydraulic and physical properties. These interact over space and time at differing spatial and temporal scales. To model and forecast the water, energy, and carbon cycles, it is necessary to understand the SWC state. One of the most common types of automated measurement technologies is an electromagnetic SWC sensor with tines meant to be inserted in situ into undisturbed soil. This protocol is designed to provide guidance for the process of installing these common types of buriable sensors. Accuracy, performance, and cost are typically proportional to the operating frequency of the sensors; lower-frequency sensors cost less but are more confounded by soil and environmental factors45. Soil- or site-specific calibration can improve the accuracy of lower-frequency sensors. The measurement method also affects sensor performance due to the underlying physics of the electromagnetic field (EMF).

Two major electromagnetic physical laws govern electromagnetic sensing. One is Gauss' law, which describes how the sensor's propagated EMF is dependent on both the ε and BEC of the medium. Permittivity increases with SWC, however, so too does the BEC. Therefore, sensors dependent on Gauss' law are affected by SWC, BEC, and the temperature effect on BEC, as well as any interference from salinity. Capacitance sensing methods obey Gauss' law and thus are more prone to these effects46. Additionally, Gauss' law describes the dependence of the capacitance on a geometric factor, which changes with the shape of the EMF in the soil. Research has demonstrated that the EMF shape changes with soil structure and the small-scale spatial variability of water content around the sensor tines. Small-scale spatial variability of water content and soil structure is large in most soils, resulting in geometric factor changes and consequent capacitance changes that have little to do with bulk mean soil water content changes. These factors decrease capacitance sensor accuracy and increase data variability46,47,48. The impedance and transmission line oscillation methods also depend on Gauss' law, while time domain reflectometry and time domain transmissometry methods depend on Maxwell's equations, which do not include a geometric factor and are not dependent on BEC. While no sensor is problem-free, the time domain methods tend to be appreciably more accurate and less biased than either capacitance- or impedance-based methods.

There are several critical steps in the procedure. For a sparse network, proper site selection and sensor location are needed to have the most appropriate spatial representation of SWC. Site selection may be more influenced by external factors, such as land access, or other atmospheric monitoring requirements where soil moisture is the ancillary measurement. Meso-scale meteorological sites are located on broad and open, well-manicured grassy surfaces to minimize any microscale influences. Such locations may be less ideal for SWC monitoring. If applicable, wireless sensor technologies should be considered49,50,51,52,53 to allow SWC monitoring to occur away from the existing environmental monitoring station and in representative soil. Working around active farm operations and irrigation equipment is challenging. Most networks (e.g., SCAN and USDA-ARS) stay on the fringes of fields to avoid tillage activities such as plows or harvesters that can cut the cables and unearth sensors. Any in situ sensor and cable needs to be sufficiently buried and have a low-enough surface profile to avoid inferring with on-farm operations. Wireless systems53 and removable borehole sensors47 may be more appropriate. Groundwater conservation using large-scale, soil moisture-based irrigation54 is a growing field for SWC sensors; this protocol pertains to spatially representative long-term SWC data in undisturbed soils.

Some soils are more difficult to measure than others. In rocky, gravelly, or very dry soils, it may be impossible to insert the tines without any damage. One option is to excavate the soil pit and lay the sensors in place while backfilling, trying to compact to the original BD. Rocky soils tend to have little structure, which will likely heal after several wetting and drying cycles; however, such disturbance may never be truly representative of the soil hydrology of the site. Alternatively, if sensors are installed in the bottom of auger holes, the soil removed can be sieved to remove stones and repacked in the hole just deeply enough to accommodate the sensor tines. The sensor can then be installed vertically, and the auger hole refilled with the remaining non-sieved soil, with frequent compaction as soil is added.

Roots in forest soil pose similar challenges to probe insertion, however roots can be cut in some situations. Forest soils often have organic (O) horizons on top of the mineral soil, which can have very low BD and high specific surface area, with large amounts of bound water resulting in very nonlinear sensor responses at higher SWCs55. Furthermore, the practitioner sets the zero-datum as either the top of the O-horizon or the mineral soil-noting which in the metadata. Clay-rich soils and expansive clays with high shrink/swell potential can be extremely conductive to electromagnetic signals when wet and may crack when dry. Such soils may need additional corrections to get reasonable SWC from the raw measurements56,57. In shallow soils, bedrock or a restrictive soil horizon (e.g., caliche or hardpan) may be encountered before reaching the ideal maximum depth. It may be necessary to change location or simply not install the deeper sensor(s). Excessively dry or wet soils can be challenging, and it is also preferable to choose installation dates outside of seasonal extremes. Dry soil can be very strong, and it may prove impossible to insert a sensor without damage. If necessary, preaugered holes can be filled with water to soften the pit face, although it may take some time before the soils return to a natural state. Wet soils can be too weak to support pit faces or the trench can fill with water. It is also easier to over-compact a wet soil.

The sensor output should include permittivity, not just SWC, so that corrections or soil-specific calibrations can be made later. Higher-frequency sensors are more appropriate in high BEC soils, while shorter tines may be easier to install in more compact soils. Perhaps the most critical step, however, is soil contact; poor contact degrades the signal from any electromagnetic sensor. Finally, backfilling the excavation sounds trivial, but it is key to minimizing preferential flow into the area of the sensors, keeping cables protected, and discouraging animals from disturbing the area. A soil- or site-specific calibration can improve sensor accuracy but requires more detail than is possible in this protocol. Field soils adjusted or repacked to varying SWC levels are ideal to check the linearity of response and can serve as a site-specific calibration for some sensor types21. Dielectric liquids can also be effective media to check sensor response58. Temperature-controlled water baths can be used to improve soil temperature calibrations59. This protocol is the first step toward the establishment of a standard operating procedure for in situ SWC sensor installation, as there is no existing method, nor any accepted method of calibration for SWC sensors60,61.

While SWC monitoring has been the focus of this protocol, the method has limitations, and SWC alone cannot give a complete picture of soil water status. Many ecosystem processes are also regulated by soil water potential, which is less commonly measured in situ62. Soil water potential, recently reviewed by S. Luo, N. Lu, C. Zhang, and W. Likos 63, is the energy state of water; such sensors may be less affected by soil properties and provide quality control for SWC sensors64. Furthermore, the bulk field SWC includes gravels, rocks, roots, and void space (e.g., preferential flow paths). In situ SWC sensors are generally repositioned around rocks and roots, and the limited measurement volume, concentrated around the tines, may miss discrete yet important aspects of the bulk field SWC.

This protocol will hopefully lead to a more harmonized and uniform SWC data for a wide range of applications, including drought monitoring, water supply forecasting, watershed management, agricultural management, and crop planning. The advent of remote sensing platforms4 has greatly enhanced the ability to estimate SWC globally, but these products need ground validation, which is still only reasonably collected by in situ networks65. Computer advancements have allowed hyper-resolution SWC modeling66 to be developed, producing high-resolution and sub-daily SWC status, but these products also need in situ estimates of SWC to provide some basis for calculating uncertainty. Often, the first question asked when a new product is introduced is "what is the uncertainty?" For SWC products, the primary comparison for validation is in situ network data67.

There have been recent network expansions associated with the National Coordinated Soil Moisture Monitoring Network (NCSMMN), including the U.S. Army Corps of Engineers Upper Missouri River Basin soil moisture project and the NOAA-supported Southeast U.S. network buildup, all designed to improve water hazard prediction, monitoring, and provide resource management decision support. Certainty and accuracy of SWC estimates for such applications can only be accomplished with thorough protocols and procedures to provide confidence in data integrity. The NCSMMN is a federally led, multi-institution effort that aims to provide assistance, guidance, and support by building a community of practice around soil moisture measurement, interpretation, and application-a "network of people" that links data providers, researchers, and the public68. This protocol is a product of NCSMMN efforts. A data quality control workflow is forthcoming.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors acknowledge financial support from NOAA-NIDIS, the National Coordinated Soil Moisture Monitoring Network (NCSMMN), and the USGS Next Generation Water Observing Systems (NGWOS) program. We thank members of the NCSMMN Executive Committee, including B. Baker, J. Bolten, S. Connelly, P. Goble, T. Ochsner, S. Quiring, M. Svoboda, and M. Woloszyn for input on this protocol. We thank M. Weaver (USGS) for their initial review of the draft protocol.

Materials

| System components, essential | This system is the typcial micro-station used in the TxSON soil moisture network. The TxSON meteorlogical station is listed under optional components. https://acsess.onlinelibrary.wiley.com/doi/full/10.2136/vzj2019.04.0034 | ||

| Battery, sealed rechargable 12 V 12 AH | Campbell Scientific | BP12 | 7 amp-hour (AH) minimum |

| Charging regulator | Campbell Scientific | CH200 | Charge regulator, needed for any unregulated solar panel |

| Conduit, schedule 40 PVC, 1 to 2" diameter | Any home supply store | Diameter sized appropriate to number of sensors and cable thickness. Length dependent on height of enclosure | |

| Data aquistion software | Campbell Scientific | PC400 | Free versions with limited programability, for more basic applications, manual downloads and simple sensor configurations |

| Data control platform | Campbell Scientific | CR300 | Any SDI-12 compatible DCP is sufficint. Many also have integrated cellular modems available |