Experimental Implementation of a New Composite Fabrication Method: Exposing Bare Fibers on the Composite Surface by the Soft Layer Method

Summary

A protocol to expose bare fibers on the composite surface by eliminating resin rich area is presented. The fibers are exposed during fabrication of the composites, not by the post surface treatment. The exposed carbon composites exhibit high electrical conductivity in the through-thickness direction and high mechanical property.

Abstract

The bipolar plate is a key component in proton exchange membrane fuel cells (PEMFCs) and vanadium redox flow batteries (VRFBs). It is a multi-functional component that should have high electrical conductivity, high mechanical properties, and high productivity.

In this regard, a carbon fiber/epoxy resin composite can be an ideal material to replace the conventional graphite bipolar plate, which often leads to the catastrophic failure of the entire system because of its inherent brittleness. Though the carbon/epoxy composite has high mechanical properties and is easy to manufacture, the electrical conductivity in the through-thickness direction is poor because of the resin-rich layer that forms on its surface. Therefore, an expanded graphite coating was adopted to solve the electrical conductivity issue. However, the expanded graphite coating not only increases the manufacturing costs but also has poor mechanical properties.

In this study, a method to expose fibers on the composite surface is demonstrated. There are currently many methods that can expose fibers by surface treatment after the fabrication of the composite. This new method, however, does not require surface treatment because the fibers are exposed during the manufacture of the composite. By exposing bare carbon fibers on the surface, the electrical conductivity and mechanical strength of the composite are increased drastically.

Introduction

The bipolar plate is a multi-functional key component of energy conversion systems and energy storage systems such as fuel cells and batteries. The key functional requirements of the bipolar plate are as follows: high electrical conductivity in the through-thickness direction to reduce ohmic-loss, high mechanical properties to withstand high compaction pressure and external impacts, and high productivity for mass production.

Compared with the graphite and metals that were conventionally adopted as materials for the bipolar plate, carbon fiber/epoxy composites have a higher specific strength and stiffness, which indicates that the weight of the system can be greatly reduced by replacing the conventional bipolar plate materials with composites1. However, conventional carbon/epoxy composites have poor electrical conductivity in the through-thickness direction, which results in a large areal specific resistance (ASR), due to the resin-rich layer that is formed on the composite surface. The insulating resin-rich layer prevents direct contact between the conductive carbon fibers and adjacent components, such as another bipolar plate, gas diffusion layer (GDL), and carbon felt electrode (CFE).

Many studies were conducted to resolve the high ASR due to the resin-rich layer. The first approach was surface treatment methods to selectively remove the resin-rich layer. For example, mechanical abrasion was attempted to remove the resin on the surface2. However, the carbon fibers were also damaged, which resulted in a poor ASR. Plasma treatment3,4 and microwave treatment methods5,6 were also developed to avoid fiber damage, but they resulted in low productivity and uniformity. The second approach, conductive layer coating methods, includes expanded graphite coating7,8. This method successfully reduced the ASR and has been regarded as a standard method to manufacture a composite bipolar plate. However, it is costly and has durability and delamination issues due to the low mechanical strength.

In this study, the “soft layer method”, a novel manufacturing method that can expose carbon fibers on the composite bipolar plate surface, is demonstrated. The main purpose of this method is to obtain a low ASR with a low manufacturing cost. The soft layer method adopts a thin soft layer such as a polymer release film between the compression mold and bipolar plate. After curing in the compression mold and the detaching of the soft layer, the fabricated bipolar plate displays carbon fibers exposed on the surface without any post-surface treatment. This method not only decreased the ASR but also significantly increased the mechanical properties and solved the gas permeability issue. This method can be applied for many other purposes: the development of an electrically conductive plate, the manufacture of a thin composite, and the fabrication of an adhesive joint without surface treatment.

Protocol

1. Material Preparation

- Preparation of the composite material

NOTE: CAUTION, Please consult all relevant material safety data sheets (MSDS) before use. Several of the chemicals used in these methods may be toxic and carcinogenic. Nanomaterials may have additional hazards compared to their bulk counterparts. Please use all appropriate safety practices when performing an experiment, including the use of engineering controls (fume hood, glove box) and personal protective equipment (safety glasses, gloves, lab coat, full-length pants, closed-toe shoes).

NOTE: Depending on the application, the type of reinforcing fiber can be one or a combination of the following: unidirectional fiber, woven fabric, non-woven felt, chopped fiber.- Unidirectional fiber type

- Use pre-impregnated composite material (prepreg), as it is the most convenient to use.

- Stack the prepreg in a stacking sequence containing both 0 ° and 90 ° to avoid splitting. For example, stack into [03/903]s.

- Woven fabric type

- Prepare the woven carbon fabric and film-type epoxy resin. If using a prepreg, skip steps 1.1.2.1 to 1.1.2.6.

- Cleanse the fabric with 99.5% acetone or another solvent for degreasing. Take caution when handling the fabric after cleaning to avoid contamination. Place the fabric on a clean surface or lint-free wipe.

- Remove the solvent by drying under ambient conditions for 10 min.

- Peel off the backup film of the epoxy resin and attach 1 ply of film-type epoxy to 1 ply of carbon fabric.

- Place the epoxy-attached carbon fabric on a hot plate that is pre-heated to 70 °C for 10 s for pre-impregnation.

- Cool the prepared prepreg in ambient conditions for 10 min and peel off the other backup film.

- Stack the fabric with the desired stacking sequence; for example, stack into [0]3.

- Non-woven felt

- Prepare the non-woven felt.

- Cleanse the felt with 99.5% acetone or another solvent for degreasing. Take caution when handling the felt after cleansing to avoid contamination. Place the felt on a clean surface or lint-free wipe.

- Peel off the backup film of the epoxy resin and attach 3 plies of film-type epoxy to 1 ply of carbon felt on each side.

- Place the epoxy-attached carbon felt on a hot plate that is pre-heated to 70 °C for 10 s for pre-impregnation.

- Cool the prepared prepreg in the ambient condition for 10 min and peel off the other backup film.

- Unidirectional fiber type

- Preparation of the soft layer

NOTE: For the soft layer, a fluoropolymer such as polytetrafluoroethylene (PTFE) or fluorinated ethylene propylene (FEP), a polyolefin such as polyethylene or polypropylene, or a synthetic rubber such as silicone rubber or a fluoroelastomer can be used. In this protocol, FEP film is adopted, and its yield strength drops drastically over 120 °C. 25-µm-thick FEP is suitable for unidirectional fiber and non-woven felt composites, whereas a thicker 100-µm-thick FEP is appropriate for woven fabric type composites10.- Cleanse the soft layer with 99.5% acetone. Handle with care to avoid wrinkles and pinholes.

- Wipe off the acetone on the soft layer with lint-free wipes. Ensure that there is no contaminant on the soft layer because it will be transferred to the composite during the curing process. Always keep the soft layer away from dust and small particles because these may damage not only the composite but also the compression mold.

2. Composite Fabrication

- Installation of the compression mold

- Prepare a compression mold with a cavity of size 120 mm × 120 mm.

- Apply the mold release to the compression mold. Simply paste or spray the mold release to the mold, and wipe with lint-free wipes until only a thin layer of mold release remains.

- Cut the prepared composite laminate to a size of 118 mm × 118 mm.

- Place 1 ply of 25 µm-thick FEP film on the lower mold.

- Place the composite laminate on the FEP film and place another FEP film on the laminate.

- Flatten the soft layer and remove the air bubbles that are entrapped between the soft layer and composite laminate.

- Close the mold for the compression molding.

- Compression molding

- Heat the hot press to 150 °C.

NOTE: The temperature of the specimen inside the mold is 140 °C in this condition. The use of a lower temperature is also possible if an elastomer or polyolefin is adopted for the soft layer. Consider both the curing temperature of the composite and the softening temperature of the soft layer to determine the curing temperature. - Place the mold in the hot press.

- Apply pressure using the hot press; the curing schedule and pressure depend on the composite type.

- For a unidirectional fiber composite, apply a constant pressure of 20 MPa for 30 min; no additional process is required.

- For a woven fabric type composite, apply 20 MPa. After 4 min and 8 min, release the applied pressure to zero and immediately apply 20 MPa again.

NOTE: This process is called purging, and its purpose is to remove excessive resin and entrapped air bubbles. The number of purging steps may be increased depending on the size of the composite; larger-size composites require more purging.- However, after the viscosity of the resin starts to increase, do not purge. Cure for 30 min in total.

- For a non-woven felt type composite, apply 3 MPa for 30 min. Beware of pressure overshoot, which will result in voids and defects in the final product. Increase the pressure slowly to avoid pressure overshoot.

- Cool the compression mold in the hot press without releasing the pressure to below 120 °C, which is the glass transition temperature of the fabricated composite.

- Release the pressure and remove the compression mold from the hot press.

- Demold the final product from the compression mold.

- Heat the hot press to 150 °C.

Representative Results

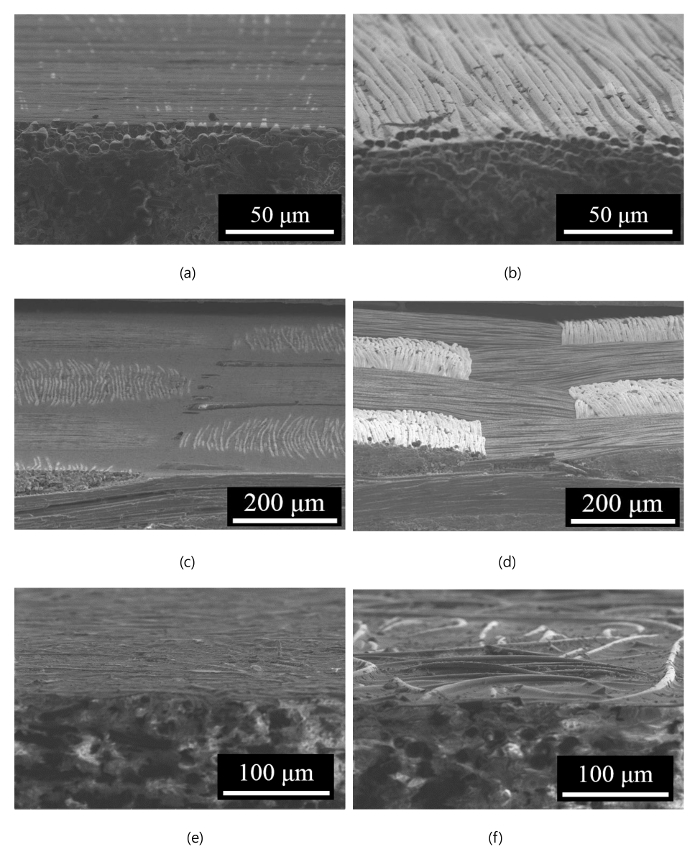

The fabricated specimens are observed using scanning electron microscopy (SEM) (Figure 1). Because the resin-rich layer that covers the top of the fibers is only a few micrometers thick, an optical microscopic image observed at the top of the specimen is not appropriate. A SEM image observed by tilting the specimen by 5° provides a more representative image. Compared to the composites fabricated by conventional compression molding, which has its surface covered with resin, bare fibers are exposed without defects when the composites are fabricated by the soft layer method. The soft layer method was applicable to the unidirectional carbon composite, carbon fabric composite, and carbon felt composite.

Figure 1: SEM images of the fabricated specimen. (a) Unidirectional fiber composite with conventional method11; (b) Unidirectional fiber composite with soft layer method11; (c) Woven fabric composite with conventional method12; (d) Woven fabric composite with soft layer method12; (e) Non-woven felt composite with conventional method13; (f) Non-woven felt composite with soft layer method13. All referenced images have been reprinted with permission from original publishers. Please click here to view a larger version of this figure.

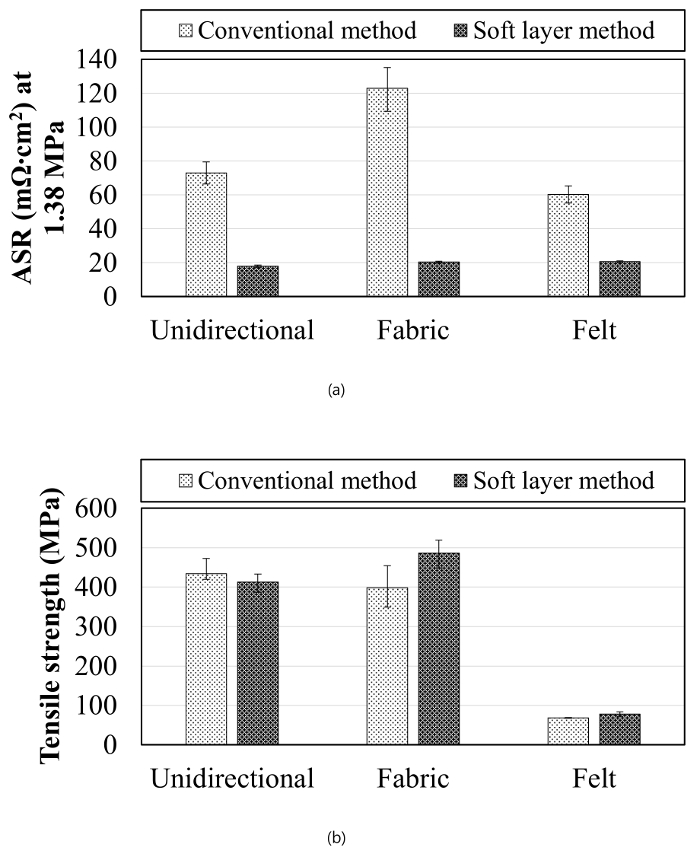

Figure 2: Performance of the composite bipolar plate. Here, the average value was taken as a representative value, while the maximum and minimum values were used for the error bars. (a) Electrical conductivity in the through-thickness direction, area of specific resistance (ASR) is shown; (b) Tensile strength. Please click here to view a larger version of this figure.

Discussion

The soft layer method provides significant advantages compared with the conventional methods, and with a lower manufacturing cost. All three types of composites manufactured by the soft layer method show unique characteristics in terms of the electrical properties, mechanical properties, gas permeability, and adhesion properties.

For the measurement of the electrical property, a four-point probe method was used. ASR was measured 5 times and the average value was taken as a representative value for that bipolar plate. A total of five bipolar plates were measured, and the maximum and minimum ASR values were used for the error bar.

The electrical conductivity in the through-thickness direction increases significantly due to the exposed carbon fiber (Figure 2a) and satisfies the DOE target (Department of Energy, United States) of ASR <20 mΩ∙cm2 under a compaction pressure of 1.38 MPa. For the measurement of the mechanical property, tensile tests were performed according to ASTM D3039. Nine specimens were tested and the average value was taken as a representative value while the maximum and minimum values were used for the error bar.

The tensile strength of the unidirectional carbon fiber composite does not change much, but the carbon fabric and carbon felt type composites show significant increases in the tensile strength of 22% and 15%, respectively, when the soft layer method is applied. The tensile strength increases because the soft layer can apply a uniform pressure on the entire surface. For this reason, the gas permeability of the composite is improved as well10,14. In addition, the adhesion characteristics are improved due to the rough surface generated by the fibers15.

Although the soft layer provides incomparable advantages, care should be taken in the implementation to achieve the best result. First, use a soft layer without pores or defects. Resin will bleed out through the hole, which will result in dents after curing as well as contamination to the mold and composite. Minor wrinkles will disappear under high temperature and pressure, but holes will not. Second, the thickness of the soft layer must be taken into account when designing a mold, such as in the design of a channel-shape mold for a fuel cell. Measure the thickness of the soft layer after applying an identical pressure and temperature to what will be used to cure the composite; this thickness shall be adopted for the mold design. Third, multiple plies of the soft layer are possible, but great care must be taken, as when the number of soft layers increases, the capability to remove resin increases. However, wrinkles may appear on the composite surface. This is especially noticeable for non-woven carbon felt composites.

If the fibers are not well exposed, there are four options to choose from: increase the curing pressure; increase the curing temperature; select another soft layer that has lower mechanical properties or thermal properties; or provide a cavity for the excess resin. Because the basic mechanism of the soft layer method lies in the deformation of the soft layer under the applied pressure, modifying the curing pressure or temperature may improve the results.

In conclusion, the soft layer method brings numerous benefits that were not possible with other methods when implemented with proper care. Compared to the conventional methods to expose fibers on the surface, the soft layer method does not require any post surface treatment, making it an ideal method for large-area industrial applications where productivity is a crucial factor. This method can be further expanded to a general composite fabrication method or a general composite surface treatment method.

Declarações

The authors have nothing to disclose.

Acknowledgements

This research was supported by the Climate Change Research Hub of KAIST (grant No. N11160012), the Leading Foreign Research Institute Recruitment Program through the National Research Foundation of Korea funded by the Ministry of Science, ICT and Future Planning (grant No. 2011-0030065), the Leading Human Resource Training Program of Regional Neo Industry through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (grant no. NRF-2016H1D5A1910603). Their support is greatly appreciated.

Materials

| Unidirectional carbon/epoxy prepreg | SK Chemicals | USN020 | Used to fabricate unidirectional carbon composite |

| Plain weave carbon fabric/epoxy prepreg | SK Chemicals | WSN 1k | Used to fabricate fabric carbon composite |

| Plain weave carbon fabric | SK Chemicals | C-112 | Used to fabricate fabric carbon composite |

| Non-woven carbon felt | Newell | Graphite felt 3 mm | Used to fabricated felt carbon composite |

| Film type epoxy resin | SK Chemicals | K51 | Used as a matrix of the composite |

| Acetone 99.5% | Samchun | 67-64-1 | Used to cleanse the carbon fiber and the soft layers |

| Mold release | ShinEtsu | KF-96 | Used to coat the mold |

| Release film | Airtech | A4000V | Used as a soft layer |

| Compression mold | N/A | N/A | Machined in lab. Material: NAK80 |

| Hot press | Hydrotek 100 | N/A | Used to apply pressure and heat |

| Scanning electron microscope | FEI Compnay | Magellan 400 | Used to investigate the surface of the composite |

Referências

- Hwang, I. U., et al. Bipolar plate made of carbon fiber epoxy composite for polymer electrolyte membrane fuel cells. J Power Sources. 184 (1), 90-94 (2008).

- Avasarala, B., Haldar, P. Effect of surface roughness of composite bipolar plates on the contact resistance of a proton exchange membrane fuel cell. J Power Sources. 188 (1), 225-229 (2009).

- Yu, H. N., Lim, J. W., Kim, M. K., Lee, D. G. Plasma treatment of the carbon fiber bipolar plate for PEM fuel cell. Compos Struct. 94 (5), 1911-1918 (2012).

- Lim, J. W., Lee, D. G. Development of composite-metal hybrid bipolar plates for PEM fuel cells. Int J Hydrogen Energy. 37 (17), (2012).

- Kim, B. G., Lee, D. G. Electromagnetic-carbon surface treatment of composite bipolar plate for high-efficiency polymer electrolyte membrane fuel cells. J Power Sources. 195 (6), 1577-1582 (2010).

- Kim, B. G., Lim, J. W., Lee, D. G. A single-type aluminum/composite hybrid bipolar plate with surface modification for high efficiency PEMFC. Int J Hydrogen Energy. 36 (4), 3087-3095 (2011).

- Yu, H. N., Lim, J. W., Suh, J. D., Lee, D. G. A graphite-coated carbon fiber epoxy composite bipolar plate for polymer electrolyte membrane fuel cell. J Power Sources. 196 (23), 9868-9875 (2011).

- Kim, K. H., Kim, B. G., Lee, D. G. Development of carbon composite bipolar plate (BP) for vanadium redox flow battery (VRFB). Compos Struct. 109, 253-259 (2014).

- Lee, D., Lim, J. W., Nam, S., Choi, I., Lee, D. G. Gasket-integrated carbon/silicone elastomer composite bipolar plate for high-temperature PEMFC. Compos Struct. 128, 284-290 (2015).

- Lee, D., Lee, D. G. Electro-mechanical properties of the carbon fabric composites with fibers exposed on the surface. Compos Struct. 140, 77-83 (2016).

- Lee, D., Lim, J. W., Nam, S., Choi, I., Lee, D. G. Method for exposing carbon fibers on composite bipolar plates. Compos Struct. 134, 1-9 (2015).

- Lee, D., Lee, D. G. Carbon composite bipolar plate for high-temperature proton exchange membrane fuel cells (HT-PEMFCs). J Power Sources. 327, 119-126 (2016).

- Lee, D., Choe, J., Nam, S., Lim, J. W., Choi, I., Lee, D. G. Development of non-woven carbon felt composite bipolar plates using the soft layer method. Compos struct. 160, 976-982 (2016).

- Lee, D., Lim, J. W., Lee, D. G. Cathode/anode integrated composite bipolar plate for high-temperature PEMFC. Compos Struct. 167, 144-151 (2017).

- Lee, D., Oh, Y., Nam, S., Choe, J. Adhesion Characteristics of Fiber-exposed Glass Composites. Compos Struct. 165, 9-14 (2017).