Measurement of the Hand Transmitted Vibration of the Human Hand Arm System During Operation of a Hand Tractor

Summary

Here, we present a standardized method for measurement of the hand transmitted vibration from handles of a single-axle tractor with special reference to changes in grip force and vibration frequency.

Abstract

Operators of hand tractors are exposed to high levels of hand transmitted vibration (HTV). This vibration, which can be both irksome and hazardous to human health, is imparted to the operator via his or her hands and arms. However, a standardized method for measuring HTV of hand tractors has yet to be defined. The aim of the study was to present an experimental method for the investigation of the biodynamic response and vibration transmissibility of the hand-arm system during the operation of a hand tractor in a stationary mode. Measurements were performed with ten subjects using three grip forces and three handle vibration levels to examine the influences of the hand pressure and frequency on hand transmitted vibration (HTV). The results indicate that the tightness of grip on the handle influences the vibration response of the hand-arm system, especially at frequencies between 20 and 100 Hz. The transmission of lower frequencies in the hand-arm system was relatively unattenuated. In comparison, attenuation was found to be quite marked for higher frequencies during the operation of the hand tractor. The vibration transmissibility to different parts of the hand-arm system decreased with the increase of the distance from the vibration source. The proposed methodology contributes to the collection of consistent data for the evaluation of operator vibration exposure and the ergonomics development of hand tractors.

Introduction

Hand tractors, also known as power tillers, are widely used in developing countries for the land preparation of small fields. The field operation of a hand tractor involves walking behind the machine and holding its handles to control its movement. The operators of hand tractors are exposed to high levels of vibration, which could be attributed to the small single cylinder engine and lack of suspension system of hand tractors1. The hand-arm vibration syndrome (HAVS)2 can be caused by long-period endurance from the vibration, named hand transmitted vibration (HTV), which generated by the hand tractor and received by the operator's hands. To assess the health risks derived by operators' exposure to the HTV of hand tractors, it is necessary to establish a method for the measurement of the vibration response of the hand-arm system.

The hand-arm system is composed of bones, muscles, tissues, veins and arteries, tendons and skin3, and the direct measurement of HTV poses many problems. The relevant international standards4,5 provide guidelines pertaining to the measurement of the severity of vibration generated in the immediate vicinity of the hand, including the coordinate system for the hand, the location and mounting of accelerometers, the measurement duration, cable connector problems, etc. However, the standards do not take into consideration intrinsic variables, such as the grip force, the posture of the hand and arm, individual factors, etc. These factors have been examined extensively under a wide range of vibration excitations and test conditions6,7,8,9,10,11,12,13, but the results of different investigators are not in good agreement. Many of these factors have not been sufficiently understood to be incorporated into standard methods. This restriction is partially attributable to the complexities of the human hand-arm system, the test conditions, and the differences in the experimental and measurement techniques employed.

Moreover, most of the earlier measurements of HTV were performed under carefully controlled conditions with idealized vibration excitations, grip force, and postural conditions. The findings and experimental procedures of these measurements, therefore, may not truly replicate real-world conditions, such as the operating conditions of hand tractors. Moreover, only limited efforts have been undertaken to study the HTV of hand tractors with field measurements. These measurements were performed using accelerometers attached to the operator's wrist, arm, chest, and head to measure the whole body vibration under the tractor's transportation conditions1, or under the conditions of tilling in an untilled field and puddling in a submerged field with different levels of engine speeds14. The effect of the grip force, which could be a crucial factor of HTV7,8, was not isolated. These methods are therefore unsuitable as standardized measurement procedures due to the operator's various forced postures during farming ascribed to the harsh environmental conditions.

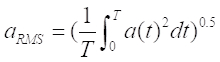

The present research was undertaken to contribute to the establishment of reliable and repeatable procedures for the HTV measurement of hand tractors in a stationary mode. Figure 1 presents the schematic diagram of the experimental design. A hand tractor manufactured in China and commonly used by Chinese farmers was employed, and ten research workers were chosen as subjects for the study. Seven lightweight piezoelectric accelerometers attached to the tractor-hand-arm system were used to measure the vibration. One tachometer and two thin-film pressure sensors monitored the engine speed and grip force during testing. The subjects were required to sequentially operate the hand tractor at specified engine speeds and with specified grip forces to obtain the vibration characteristics in various operational modes. This manuscript provides a detailed protocol for the HTV measurement of the tractor-hand-arm system with unique consideration of changes in the grip force and vibration frequency.

Protocol

All procedures were approved by the Ethics Committee of Chongqing University of Technology and each subject provided written informed consent prior to participation in this study.

1. Hand tractor preparation

- Ensure the hand tractor is subjected to proper test conditions with a full fuel tank, without looseness of bolts, and without other mechanical defects that would result in abnormal vibration.

NOTE: The specifications of the hand tractor used in this experiment are given in Table 1. - Place the hand tractor in a test site with a dry, firm, and level ground surface.

NOTE: If this experiment was conducted in an indoor laboratory, the laboratory must be well-ventilated to prevent any injurious effects of the exhaust gas from the hand tractor. - Remove the dust cover of the engine pulley to conveniently calibrate the engine speed with a speedometer during the experiment.

- Remove the elastomeric materials of the handles according to ISO 5349-2 standard5.

2. Subject preparation

- Ensure that all subjects are healthy with no physical ailment and are above the age of 18 years3. Inform each subject about the study objectives and test procedures. Obtain written informed consent from all subjects.

- Exclude subjects with the following diseases: primary Raynaud's disease or secondary Raynaud's phenomenon, impairment of blood circulation to the hands, deformity of bones and joints, disorders of the peripheral nervous system or musculoskeletal system3.

- Ask subjects to wear sleeveless or short-sleeved clothing, and to remove watches, bracelets, rings, etc.

- Warn each subject not to touch the gear shift lever of the hand tractor during operation. Warn each subject to stay away from the engine pulley when the hand tractor is running.

- Provide subjects with speed regulation training on the hand tractor. Inform each subject to shut down the engine at the end of the experiment by pressing down on the engine switch button.

NOTE: Generally, the engine speed regulation is controlled by the throttle switch located on the right handle, and subjects are trained to regulate the engine speed by turning the throttle switch to the left (speed decrease) or to the right (speed increase) with their right hands. - Instruct each subject how to operate the hand tractor and how to regulate the engine speed from 1500 rpm to 3500 rpm.

- Measure each subject's body dimensions (standing height, mass, forearm length, upper arm length, hand length).

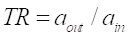

NOTE: Table 2 summarizes the physical characteristics of ten healthy subjects in this experiment. - Wrap the accelerometer adapters tightly on the hand and arm of each subject at the locations indicated in Figure 2.

NOTE: Each adapter was fabricated using a nylon strap and a piece of the galvanized iron sheet (0.3 mm) to provide a rigid and light attachment.

3. Measurement system setup

- Acceleration measurement system setup

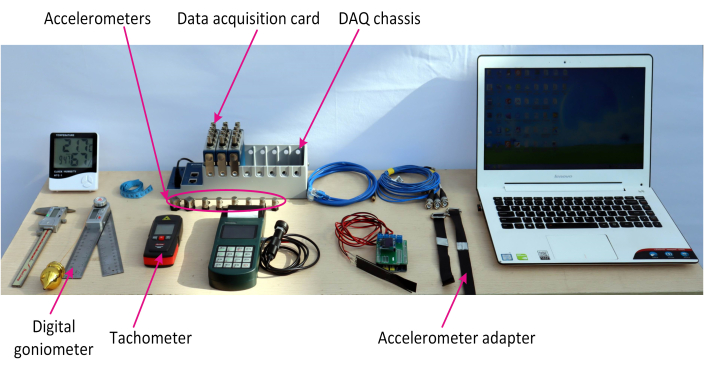

NOTE: The present steps aim to collect the vibration acceleration signals from the handle of the hand tractor and six locations of operator's hand-arm system. The proposed approach employs a compact Data Acquisition (DAQ) system composed of seven accelerometers, three data acquisition cards, a DAQ chassis, a laptop computer, and some associated cables (Figure 3). Other types of DAQ systems with proper characteristics for the involved application can be similarly applied.- Before initiating a measurement, gather all the components of the measurement system (accelerometers, data acquisition system, thin-film pressure sensing system, tachometer, digital goniometer, and other relevant components).

- To set up the acceleration measurement system, connect the accelerometer with the data acquisition cards using the accelerometer cables. Using an Ethernet cable, connect the chassis with the computer.

NOTE: Two tri-axial accelerometers and five single-axis accelerometers fixed with magnetic mounting base were used in this experiment. - Attach one tri-axial accelerometer on the left handle of the hand tractor and attach the other one on the accelerometer adapter of the subject's hand. Attach single-axis accelerometers, one by one, on the accelerometer adapters of the subject's arm and shoulder.

NOTE: The locations of the accelerometers are as shown in Figure 1. The location selection of the tri-axial accelerometer on the left handle of the hand tractor should be as close to the operator's left hand as possible. - Adjust the orientation of the tri-axial accelerometers on the hand to be consistent with the basicentric coordinate system (Figure 4) for measurement of hand-arm vibration refer to ISO 5349-1 standard4. Using adhesive tape, secure the accelerometer cables on the skin surface of the subject's arm and the tractor's handlebar.

- Grip force measurement setup

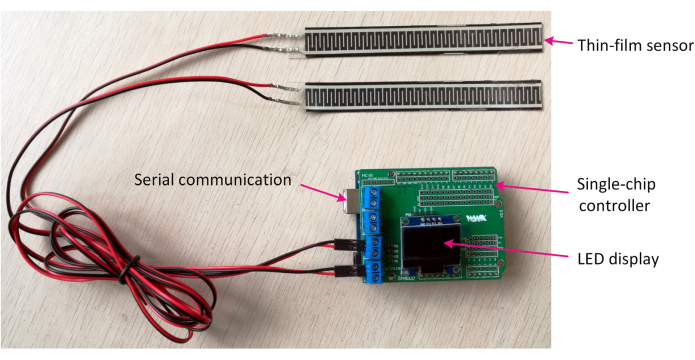

NOTE: A thin-film pressure sensing system15,16 was designed with two resistive pressure sensitive sensors, a single-chip controller, and an LED display, and was calibrated before measurement, as shown in Figure 5.- Attach two thin-film sensors symmetrically on opposite sides around the central axis of the handle using double-sided adhesive tape.

- Place the screen of the sensing system at a convenient height so that the subject could monitor and adjust the grip force to the specified level during the operation of the hand tractor.

- Engine speed measurement setup

NOTE: Engine speed refers to the revolutions per minute (RPM) of the propeller of the employed hand tractor engine, which equals to the RPM of the engine pulley. A laser tachometer was used to calibrate and monitor the engine speed during operation.- Attach a piece of retroreflective tape (approximately 10 × 10 mm) to the engine pulley surface for laser tachometer measurement.

- Place the tachometer at a proper height and perpendicular to the retroreflective tape.

- Posture measurement

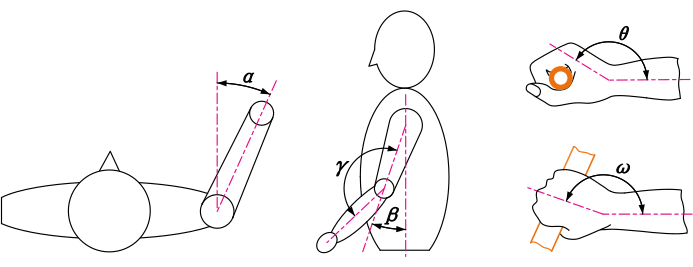

- Instruct the subject to hold and raise the handle to a horizontal position. Measure the subject's hand and arm posture using a digital goniometer.

NOTE: The five angles17 used to describe the hand and arm posture during the operation of the hand tractor are shown in Figure 6. The subjects' posture angles measured in this experiment are presented in Table 2. - Ask the subject to maintain the posture until the end of the trial.

- Instruct the subject to hold and raise the handle to a horizontal position. Measure the subject's hand and arm posture using a digital goniometer.

4. Experiment and data acquisition

- Start the hand tractor in neutral and keep it running at a low engine speed (around 1500 rpm) for about 30 s until it stabilized.

- Turn on the tachometer, the thin-film pressure sensing device, the laptop computer and the acceleration data acquisition system, respectively.

- Open the DAQ software and create a new file for each subject. Set the parameters of acceleration, acquisition mode, and sampling rate for data collection.

NOTE: To obtain the accurate characterization of the HTV, the sampling rate should be no less than 1500 Hz. In this study, the sampling rate was set at 1650 Hz. If a more higher sampling rate was used for data collection, a low-pass filter with a cut-off frequency at 1500 Hz was advised to remove the noise influences such as the irrelevant high-frequency contributions. - Click the Run and wait about 10 s until the system is stabilized. Then click Record to start recording the acceleration data.

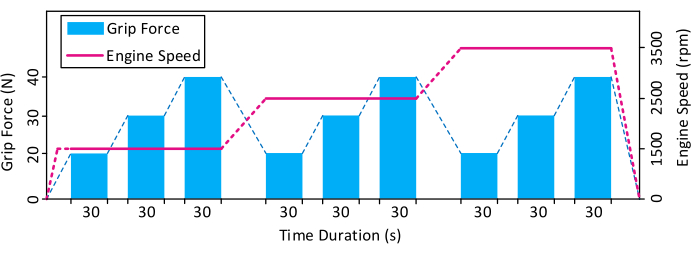

- Adjustment of the engine speed and grip force

NOTE: As shown in Figure 7, this experiment was conducted at three levels of engine speed (1500, 2500 and 3500 rpm) and three levels of grip force (20, 30, and 40 N) during each trial. The approximate duration of each subject's HTV testing is 6 min.- Ask the subject to monitor the tachometer and adjust the engine speed to 1500 rpm until it stabilized.

- Instruct the subject adjust the grip force carefully to 20 N by looking at the displayed force signals from the thin-film pressure sensing system, and keep this grip force level for about 30 s.

NOTE: The adjustment of the grip force denotes the increase or decrease of pressure between the hand and the handlebar of the hand tractor. Subjects should perform the adjustment of the grip force through holding the handlebar more tightly or lightly. - Adjust the grip force to 30 N and keep about 30 s. Then, adjust the grip force to 40 N and keep about 30 s.

- Adjust the engine speed to 2500 rpm and repeat steps 4.5.2 and 4.5.3.

- Adjust the engine speed to 3500 rpm and repeat steps 4.5.2 and 4.5.3.

- Ask the subject to turn the throttle switch to the lowest engine speed. Put down the handle and shut down the engine of the hand tractor.

- Save the data and shut down the DAQ system. Remove and place the accelerometers on the next subject.

- Repeat steps 4.3 to 4.7 until the end of the data collections of all subjects.

- Export the acceleration time-series data for further analysis.

5. Data processing and analysis

- Import the recorded vibration time domain signals to MATLAB software. Calculate the root-mean-square (RMS) values of the vibration acceleration of hand tractor's handle, which represent the vibration exposure during the operation of the hand tractor, with the Equation (1):

(1)

(1)

where, aRMS is the RMS of vibration acceleration (m/s2) calculated for each 1/3rd octave band, a(t) is the measured vibration acceleration amplitude (m/s2), and T is the duration of the measured vibration acceleration (s).

NOTE: In ISO 5349-1 standard, it is important to use RMS acceleration to represent the magnitude of vibrations transmitted to the operator's hands. - Calculate the RMS values of vibration acceleration on hand, wrist, arm and shoulder of each subject using Equation (1). Calculate the vibration transmissibility (TR) using Equation (2)1,14:

(2)

(2)

where, ade is the handle vibration for HTV, and aout is the respective vibration in the six locations of the subject's hand-arm system (see Figure 2).

NOTE: According to ISO 5349-1, the factors (except for grip force and vibration frequency) may influence the results of hand transmitted vibration measurement include: the operator's skill, body posture, climatic conditions, noise, etc. To decrease these random factors, the TR values of all the measurement locations of the ten subjects in this study were averaged. - Convert the time domain signals of the handle to frequency domain signals by fast Fourier transform (FFT) algorithm using MATLAB program to examine the input vibration.

Representative Results

The experiment was carried out in the laboratory (air temperature 22.0 °C ± 1.5 °C) on ten healthy subjects (Table 2) during the operation of a hand tractor in a stationary condition.

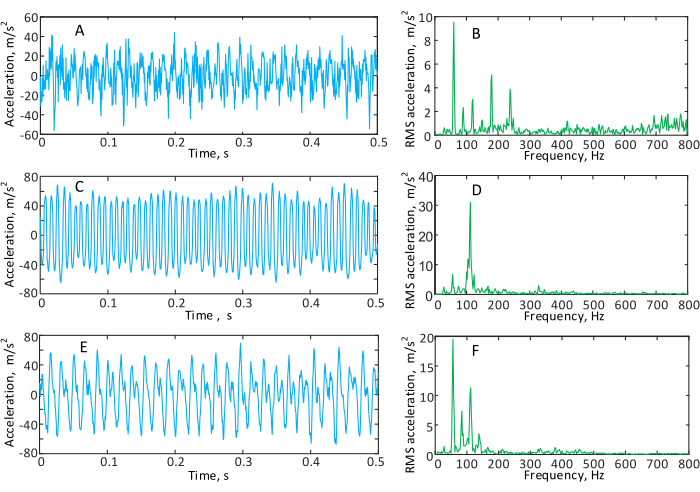

Following the protocol, vibration acceleration data were collected from the handle of the hand tractor, as well as the back of the hand, the wrist, the arm, and the shoulder of each subject. The spectrum of the vibration acceleration occurring at the handle (input to the hand) was obtained. Figure 8 displays samples of the time domain and RMS frequency domain accelerations on the handle at the engine speed level of 3500 rpm for a given time duration. It is evident that the vibration acceleration was the highest along the Y-axis and the lowest along the X-axis. The maximum accelerations of the X and Z directions occurred at the frequency of 58 Hz (which is the working frequency of the engine corresponding to the rotational speed of 3500 rpm). Most of the vibration energy was found to be centralized in the frequency range from 50 to 200 Hz. With the same analytical process, the characteristics of both the time domain and frequency domain signals could be obtained, such as the vibration amplitude, peak, dominant frequency, etc.

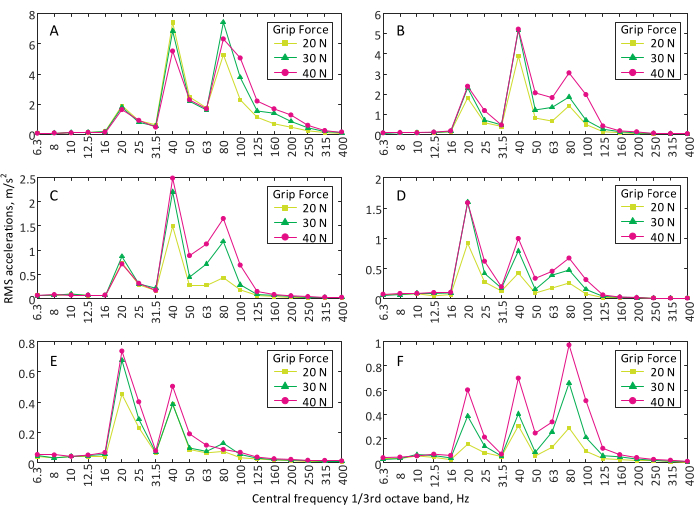

The influences of the grip force and engine speed on the vibration response of the hand-arm system were also examined. As shown in Figure 9, it was observed that the increase in the grip force increased the vibration acceleration notably at frequencies between 20 and 100 Hz, and three resonance frequencies (20, 40, and 80 Hz) were found to increase almost linearly with the increase of the grip force. This is attributed to the increase of the contact stiffness and joint stiffness18,19. These findings indicate that the presented measurement and adjustment methods of the grip force could be effectively applied to HTV measurement.

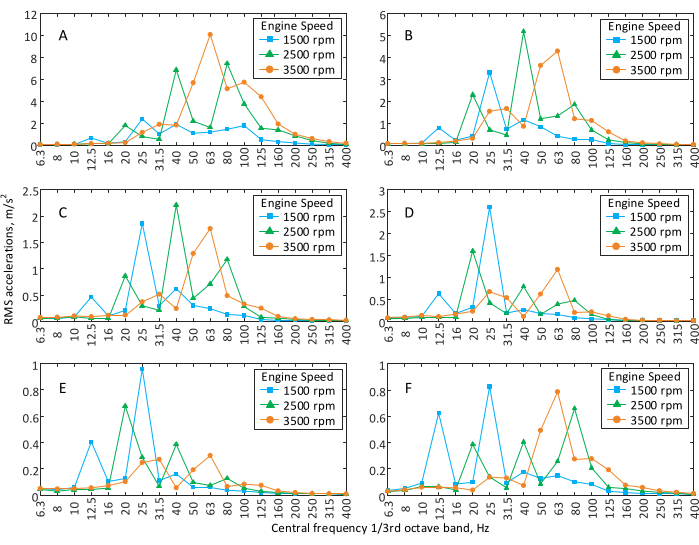

As shown in Figure 10, this experiment examined the effect of the input frequency on HTV via engine speed adjustment at three levels (1500, 2500, and 3500 rpm). At the location of the back of the hand (Figure 10A), a higher value of acceleration was obtained at 3500 rpm compared to lower engine speeds. In contrast, at the upper arm and shoulder (Figure 10D, E, and F), the peak acceleration occurred at 1500 rpm. Through the comprehensive comparison of both the locations and exciting frequencies, it is reasonable to conclude that lower frequencies were transmitted relatively unattenuated in the hand-arm system, while attenuation was quite marked for higher frequencies. Thus, most of the vibration energy was dissipated in the hand and forearm.

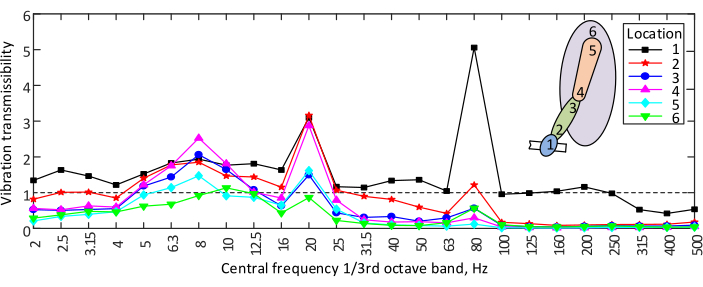

Figure 11 presents the averaged transmissibility to the back of the hand, forearm, upper arm and shoulder from the ten subjects that are with engine speed of 2500 rpm and grip force of 30 N. It was found that the transmissibility to the different parts of the hand-arm system decreased with the increase of the distance from the vibration source. The highest transmissibility was observed at the back of the hand (location 1), with a peak value of 5.1 at around 80 Hz. The amplification of vibration may be due to the resonance of the skin at the metacarpal20,21. Consistent with the findings of previous studies22,23, the resonant frequency of the wrist (location 2) and elbow (location 4) transmissibility was around 20 Hz, with a magnitude of approximately 3.0. Additionally, the shoulder (location 6) transmissibility peak was 1.1 at around 10 Hz. It was also found that only vibrations of less than 25 Hz were effectively transmitted to the forearm, upper arm, and shoulder. With Equation (2) in section 5.2 and following the analytical process of the transmissibility, it is feasible to examine the influences on transmissibility with different exciting frequencies and changing grip force, and a reasonable suggestion of operating hand tractor for farmers could be made.

| Engine model and type | JUWEI FC 170, gasoline, single cylinder, four-stroke, OHV, forced-air cooled |

| Swept volume, cc | 208 |

| Rated power, kW | 4.0 kW at 3600 rpm |

| Maximum Torque, Nm/rpm | 12/2500 |

| Number of speeds | 2 forward, 1 reverse |

| Start mode | Recoil start (pull start) |

| Dry weight of engine, kg | 19 |

| Weight of hand tractor with full fuel tank, radiator and lubricating oils, kg | 72 |

| Tyre type | Rubber wheel |

| Tyre size(pneumatic), mm | 155×330 (350-6) |

Table 1. Specifications of the hand tractor.

| Dimensions and Postures | Minimum | Maximum | Mean | SD |

| Age, years | 18 | 37 | 22.6 | 5.6 |

| Weight, kg | 50 | 72 | 62.6 | 7.3 |

| Stature, cm | 164 | 179 | 172.1 | 4.7 |

| Forearm hand length, cm | 22.1 | 26.8 | 25.2 | 1.3 |

| Upper arm length, cm | 26.8 | 34 | 31.1 | 2.1 |

| Hand length, cm | 15.2 | 21 | 17.1 | 1.6 |

| Shoulder horizontal abduction (α), degrees | 22.6 | 31.5 | 27.1 | 3.2 |

| Shoulder vertical abduction (β) , degrees | 16.5 | 24.2 | 20.7 | 2.6 |

| Elbow extension (γ) , degrees | 134.1 | 169.3 | 150.1 | 10.9 |

| Wrist extension (θ) , degrees | 160.5 | 174.8 | 169 | 5.5 |

| Wrist deviation (ω) , degrees | 139.2 | 159.5 | 148.1 | 5.6 |

Table 2. Subject physical characteristics.

Figure 1. The experimental protocol and data acquisition set up. This example depicts a single trial (from right to left) for the measurement of a subject's body dimensions, the wearing of 6 accelerometer adapters, the operating posture of the hand tractor, and the data acquisition set up for the acceleration, grip force, and engine speed. Please click here to view a larger version of this figure.

Figure 2. The locations of the accelerometer adapters. 6 accelerometer adapters were wrapped in the locations of back of the hand, distal end of the forearm, proximal end of the forearm, distal end of the upper arm, proximal end of the upper arm and the acromion along the hand-arm system. Please click here to view a larger version of this figure.

Figure 3. Vibration measurement instrumentation. The components of the measurement system including accelerometers, data acquisition system, thin-film pressure sensing system, a tachometer, a digital goniometer and other relevant components (computer, accelerometer adapters, cables, tape measure, thermometer). Please click here to view a larger version of this figure.

Figure 4. The basicentric coordinate system for hand-arm vibration measurement. The X-axis is defined parallel to the longitudinal axis of the grip. The Y-axis is directed along the third metacarpus bone of the hand. The Z-axis is perpendicular to the palm surface area. Please click here to view a larger version of this figure.

Figure 5. The thin-film pressure sensing system. This system consists of two thin-film sensors, a single-chip controller, and an LED display to show the real time grip force. The test data can also be exported to a computer by the serial communication. Please click here to view a larger version of this figure.

Figure 6. The five angles used to describe the hand and arm posture. α describes the shoulder horizontal abduction, β describes the shoulder vertical abduction, γ identifies the elbow extension, θ characterizes the wrist extension, and ω identifies the wrist deviation. Please click here to view a larger version of this figure.

Figure 7. Adjustment of the engine speed and grip force during the experiment. The blue bars represent different grip forces of 20, 30, and 40 N. The red lines indicate adjustment of engine speed from 1500, 2500 to 3500 rpm. Therefore, there are 9 test cases from 1500 rpm, 20 N to 3500 rpm, 40 N. The duration of each test case is about 30 s. Please click here to view a larger version of this figure.

Figure 8. Samples of the time domain wave and amplitude spectra of the accelerations on handle at the engine speed of 3500 rpm. (A) The time domain wave and (B) amplitude spectra in the X direction; (C) the time domain wave and (D) amplitude spectra in the Y direction; (E) the time domain wave and (F) amplitude spectra in the Z direction. Please click here to view a larger version of this figure.

Figure 9. The mean relationship between the grip force and RMS vibration acceleration measured at six locations of the hand-arm system of ten subjects: (A) back of the hand; (B) distal end of the forearm; (C) proximal end of the forearm; (D) distal end of the upper arm; (E) proximal end of the upper arm; (F) acromion. Please click here to view a larger version of this figure.

Figure 10. The mean relationship between the engine speed (frequency) and RMS vibration acceleration measured at six locations of the hand-arm system of ten subjects: (A) back of the hand; (B) distal end of the forearm; (C) proximal end of the forearm; (D) distal end of the upper arm; (E) proximal end of the upper arm; (F) acromion. Please click here to view a larger version of this figure.

Figure 11. Vibration transmissibility at the 1/3rd octave band at different locations in the hand-arm system at the engine speed of 2500 rpm and grip force of 30 N. The 6 curves represent the TR values from back of the hand (location 1) to the acromion (location 6) as shown in the legend. The dashed line is a dividing line of vibration amplification (above this line) and vibration attenuation (below this line). Please click here to view a larger version of this figure.

Discussion

The protocol presented in this study was established based on HTV standards4,5,24, and was developed as the standard steps for the measurement of the HTV of the human hand-arm system during the operation of a hand tractor in a stationary condition. This condition is the most stable state of the hand tractor to help ensure the reliable measurement of the vibration actually transmitted to the hand and arm. The range of variables considered to perform the test, via the adjustment of the engine speed and grip force, covers the normal and safe operating range of the hand tractor. Considering the complexity of the hand-arm system, the experimental results yielded from this protocol were found to agree well with data reported in articles on the characteristics of vibration sources25, vibration transmissibility1,26, and the essential factors8,27 that affect the response of the hand-arm system during the operation of hand tractors.

The results are dependent on some critical components of this setup within the protocol. First, because the weight of the accelerometer affects the magnitude of the vibration of the hand-arm system20, the total weight of the accelerometer and adapter should be as light as possible to reduce measurement errors. Second, each accelerometer adapter should be tightly secured on the hand-arm system to prevent any relative motion between the measurement point and the accelerometer.Third, the test trial of each subject should be completed without interruption to reduce the effect of the operating posture.

The main limitation of this study is that the vibration transmissibility to the hand-arm system was only measured and analyzed in the Z-axis direction (Figure 4) due to the use of single-axis accelerometers at the locations of arm and shoulder. Although flexible and thin-film sensors were used to measure grip force during the test, further measurement efforts along the shear direction are expected to provide considerable insights into the characterization and assessment of HTV, which represents another limitation of the present study. Additionally, the intrinsic factors of operators, such as their body size, body posture, and hand and arm size, influence HTV. As a subsequent step, more data will be collected to examine these factors using the presented protocol.

This protocol will be helpful for the understanding of the vibration transmission characteristics of the hand tractor-hand-arm system. The main potential applications of the proposed methodology are the estimation of human-tractor interaction phenomena, the ergonomics development of hand tractors, and the development of protective devices such as isolators and gloves.

Declarações

The authors have nothing to disclose.

Acknowledgements

This work was supported by the Natural Science Foundation of Chongqing, China (cstc2019jcyj-msxmX0046), the project of Chongqing Education Commission of China (KJQN202001127), and the project of Banan District Science and Technology Commission, Chongqing, China (2020TJZ010). The authors would like to thank Prof. Yan Yang for providing the test site. We are also grateful to Dr. Jingshu Wang and Dr. Jinghua Ma for their guidance of using the vibration measurement instrumentation. Thanks are also due to the subjects for their wholehearted cooperation during the experiments.

Materials

| Accelerometers | PCB Piezotronics Inc. | 352C33, 356A04 | Used to measure vibration signals. Including 2 tri-axial accelerometers and 5 single-axis accelerometers. |

| CompactDAQ System | National Instruments | cRIO-9045,NI-9234 C | Used for acceleration acquisition. The system consists of a chassis and 3 data acquisition cards. |

| Digital caliper | Sanliang | 160800635 | Used to measure dimensions of the hand. |

| Digital goniometer | Sanliang | 802973 | Used to measure hand and arm posture. |

| Laptop computer | Lenovo | Ideapad 500s | To run the softwares. |

| Matlab | MathWorks Inc. | Version 2020a | Used for data processing. |

| NI SignalExpress | National Instruments | Trial version 2015 | Use to acquire, analyze and present acceleration data. |

| Tachometer | Sanliang | TM 680 | Used to measure engine speed. |

| Thin-film pressure sensing system | YourCee | n/a | Used to measure grip force. The system consists of 2 thin-film sensors, a STM32 singlechip and a LED display. |

Referências

- Ahmadian, H., Hassan-Beygi, S. R., Ghobadian, B., Najafi, G. ANFIS modeling of vibration transmissibility of a power tiller to operator. Applied Acoustics. 138, 39-51 (2018).

- Heaver, C., Goonetilleke, K. S., Ferguson, H., Shiralkar, S. Hand-arm vibration syndrome: a common occupational hazard in industrialized countries. Journal of Hand Surgery. 36 (5), 354-363 (2011).

- Geethanjali, G., Sujatha, C. Study of Biomechanical Response of Human Hand-Arm to Random Vibrations of Steering Wheel of Tractor. Molecular & Cellular Biomechanics. 10 (4), 303-317 (2013).

- International Organization for Standardization. ISO 5349-1: Mechanical Vibration: Measurement and Evaluation of Human Exposure to Hand Transmitted Vibration Part 1: General requirements. International Organization for Standardization. , (2001).

- International Organization for Standardization. ISO5349-2: Mechanical vibration- Measurement and evaluation of human exposure to hand-transmitted vibration. Part 2: Practical guidance for measurement at the workplace. International Organization for Standardization. , (2001).

- Besa, A. J., Valero, F. J., Suñer, J. L., Carballeira, J. Characterisation of the mechanical impedance of the human hand-arm system: The influence of vibration direction, hand-arm posture and muscle tension. International Journal of Industrial Ergonomics. 37 (3), 225-231 (2007).

- Marcotte, P., Aldien, Y., Boileau, P. &. #. 2. 0. 1. ;., Rakheja, S., Boutin, J. Effect of handle size and hand-handle contact force on the biodynamic response of the hand-arm system under zh-axis vibration. Journal of Sound and Vibration. 283 (3-5), 1071-1091 (2005).

- Pan, D., et al. The relationships between hand coupling force and vibration biodynamic responses of the hand-arm system. Ergonomics. 61 (6), 818-830 (2018).

- Dong, R. G., Rakheja, S., Schopper, A. W., Han, B., Smutz, W. P. Hand-transmitted vibration and biodynamic response of the human hand-arm: a critical review. Critical Reviews In Biomedical Engineering. 29 (4), 393-439 (2001).

- Marchetti, E., et al. An investigation on the vibration transmissibility of the human elbow subjected to hand-transmitted vibration. International Journal of Industrial Ergonomics. 62, 82-89 (2017).

- McDowell, T. W., Welcome, D. E., Warren, C., Xu, X. S., Dong, R. G. Assessment of hand-transmitted vibration exposure from motorized forks used for beach-cleaning operations. Annals of Work Exposures and Health. 57 (1), 43-53 (2013).

- Tony, B. J. A. R., Alphin, M. S. Finite element analysis to assess the biomechanical behavior of a finger model gripping handles with different diameters. Biomedical Human Kinetics. 11 (1), 69-79 (2019).

- Tony, B. J. A. R., Alphin, M. S., Velmurugan, D. Influence of handle shape and size to reduce the hand-arm vibration discomfort. Work. 63 (3), 415-426 (2019).

- Dewangan, V. K. T. Characteristics of hand-transmitted vibration of a hand tractor used in three operational modes. International Journal of Industrial Ergonomics. 39 (1), 239-245 (2009).

- Kalra, M., Rakheja, S., Marcotte, P., Dewangan, K. N., Adewusi, S. Measurement of coupling forces at the power tool handle-hand interface. International Journal of Industrial Ergonomics. 50, 105-120 (2015).

- Gurram, R., Rakheja, S., Gouw, G. J. A study of hand grip pressure distribution and EMG of finger flexor muscles under dynamic loads. Ergonomics. 38 (4), 684-699 (1995).

- Tarabini, M., Saggin, B., Scaccabarozzi, D., Moschioni, G. Hand-arm mechanical impedance in presence of unknown vibration direction. International Journal of Industrial Ergonomics. 43 (1), 52-61 (2013).

- Aatola, S. Transmission of vibration to the wrist and comparison of frequency response function estimators. Journal of Sound and Vibration. 131 (3), 497-507 (1989).

- Kihlberg, S. Biodynamic response of the hand-arm system to vibration from an impact hammer and a grinder. International Journal of Industrial Ergonomics. 16 (1), 1-8 (1995).

- Gurram, R., Rakheja, S., Gouw, G. J. Vibration transmission characteristics of the human hand-arm and gloves. International Journal of Industrial Ergonomics. 13 (3), 217-234 (1994).

- Burström, A. S. L. Transmission of vibration energy to different parts of the human hand-arm system. Int Arch Occup Environ Health. 70 (3), 199-204 (1997).

- Hartung, E., Dupuis, H., Scheffer, M. Effects of grip and push forces on the acute response of the hand-arm system under vibrating conditions. International Archives of Occupational and Environmental Health. 64 (6), 463-467 (1993).

- Pope, M. H., Magnusson, M., Hansson, T. The upper extremity attenuates intermediate frequency vibrations. Journal of Biomechanics. 30 (2), 103-108 (1997).

- International Organization for Standardization. ISO 8041-1: Human response to vibration-Measuring instrumentation. International Organization for Standardization. , (2017).

- Ying, Y. B., Zhang, L. B., Xu, F., Dong, M. D. Vibratory characteristics and hand-transmitted vibration reduction of walking tractor. Transactions Of The ASAE. 41 (4), 917-922 (1998).

- Dewangan, K. N., Tewari, V. K. Characteristics of vibration transmission in the hand-arm system and subjective response during field operation of a hand tractor. Biosystems Engineering. 100 (4), 535-546 (2008).

- Xu, X. S., et al. Vibrations transmitted from human hands to upper arm, shoulder, back, neck, and head. International Journal of Industrial Ergonomics. 62, 1-12 (2017).