One-pot Microwave-assisted Conversion of Anomeric Nitrate-esters to Trichloroacetimidates

Summary

A 2-azido-1-nitrate-ester can be converted to the corresponding 2-azido-1-trichloroacetimidate in a one-pot procedure. The goal of the manuscript is to demonstrate utility of the microwave reactor in carbohydrate synthesis.

Abstract

The goal of the following procedure is to provide a demonstration of the one-pot conversion of a 2-azido-1-nitrate-ester to a trichloroacetimidate glycosyl donor. Following azido-nitration of a glycal, the product 2-azido-1-nitrate ester can be hydrolyzed under microwave-assisted irradiation. This transformation is usually achieved using strongly nucleophilic reagents and extended reaction times. Microwave irradiation induces hydrolysis, in the absence of reagents, with short reaction times. Following denitration, the intermediate anomeric alcohol is converted, in the same pot, to the corresponding 2-azido-1-trichloroacetimidate.

Introduction

Due to their ubiquity in molecular biology, carbohydrates have been longstanding targets for chemical synthesis.1,2,3 At the core of any successful synthetic campaign is the correct deployment of glycosylation reactions to build the oligosaccharide chain.4,5,6,7,8,9,10,11,12 Not surprisingly, there are a large number of methods to install glycosidic bonds.13,14 The Koenigs-Knorr method is one of the earliest known procedures and involves coupling a glycosyl chloride or bromide with an alcoholic component, usually under heavy metal (mercury or silver) activation.15 Related glycosyl fluorides were first introduced as donors in 1981 by the Mukaiyama group and have found widespread application due to their increased thermal and chemical stability.16 On the opposite end of the reactivity spectrum are glycosyl iodides, which are far more reactive than the other halides. Increased reactivity is accompanied by increased stereocontrol, particularly when forming α-linked oligosaccharides.17 In addition to "haloglycosides", thioglycosides have found wide utility, in part, due to their ease of formation, stability to a multitude of reaction conditions, and activation with electrophilic reagents.18

The methods described above focus on converting an anomeric alcohol to a "non-oxygen" containing, latent leaving group that is activated and ultimately displaced by an alcohol from an acceptor molecule. Anomeric oxygen activation as described by the Schmidt school, focuses on converting the C1 oxygen itself, to a leaving group.19 This method is the most powerful and widely used in chemical glycosylation reactions. Trichloroacetimidate donors are readily prepared from a reducing sugar and trichloroacetonitrile in the presence of a base such as potassium carbonate (K2CO3) or 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU). These species are then activated using Lewis acids.20

Recently, we have reported that 2-azido-1-trichloroacetimidate donors can be directly prepared from glycals. The process involves a two reaction, one-pot procedure from 2-azido-1-nitrate esters.21 This detailed protocol is intended to assist practitioners in successfully completing the transformation in high yield. Of particular interest is the first step of the sequence, which focuses on thermal denitration under microwave- assisted heating. We also hope to provide a visual tutorial on employing microwave reactors in organic synthesis.

Protocol

1. Representative Microwave-Assisted Denitration

- Place the azido nitrate ester (1.0 equiv., 0.2 mmol) in an 8 mL microwave reaction vial. The scale of the reaction can be increased to several mmol without any adverse effect on reaction progress.

- Dissolve the azido-nitrate ester in 20% aq. acetone (0.1 M, 2.0 mL). Add pyridine (5.0 equiv., 0.08 mL, 1.0 mmol) to the reaction vessel. Cap the microwave irradiation vial and place the reaction vessel in a microwave reactor cavity.

- Irradiate the solution at 120 °C for 15 min with stirring and with a fixed hold time. The hold time represents how long the irradiation will occur at the designated temperature and resultant pressure. Heat all reactions to the reported temperature over a 2-minute ramping period. Monitor the temperature by a builtin IR sensor.

- After 15 min, analyze the reaction mixture using thin layer chromatography (TLC) to confirm consumption of the starting material. Use 1:1 ethyl acetate/hexanes as the eluent.

- Visualize the TLC plate using ceric ammonium molybate stain. The Rf of the reactant and product will vary, but the reducing alcohol is generally 0.05 to 0.1 lower Rf than the reactant.

2. Formation of the trichloroacetimidate

- Following complete consumption of the starting material, evaporate the solvent to a reduced volume using an airline. Then, dilute with (dichloromethane) CH2Cl2 (1.0 mL) and use a syringe to remove the water layer. Once the water layer is removed, cool the reaction mixture to 0 °C using an ice-water bath.

- Next, add DBU (10 eq, 0.3 mL, 1.9 mmol) and 2,2,2-trichloroacetonitrile (50 eq, 1.0 mL, 10 mmol) to the reaction vessel. Both reagents are added in excess and a minimum of 1 equivalent of base and 1 equivalent of 2,2,2-trichloroacetonitrile are needed.

- Allow the reaction mixture to stir while warming to ambient temperature. Monitor the reaction by TLC to confirm consumption of the starting material.

- Use 1:1 ethyl acetate/hexanes as the eluent. Visualize the TLC plate using ceric ammonium molybate stain. The Rf of the reactant and product will vary.

- After complete consumption of starting material, transfer the reaction mixture to a recovery flask and concentrate the mixture in vacuo at 30 °C. Evaporation of solvent will provide a crude pale yellow to brown oil.

- Purify the crude product by silica gel column chromatography with a 1.5 cm chromatography column and 1:4 ethyl acetate/hexanes as eluent. The physical form of the imidate will vary from molecule to molecule.

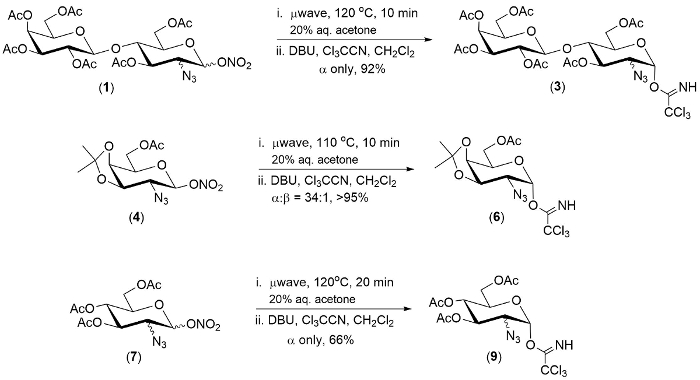

Figure 1. Representative examples of the one-pot conversion of 2-azido-1-nitrate esters to 2-azido-1-trichloroimidates. Please click here to view a larger version of this figure.

Representative Results

The technology described herein was demonstrated on a pool of three 2-azido-1-nitrate esters. In each case the first step of the reaction was complete within 20 minutes.

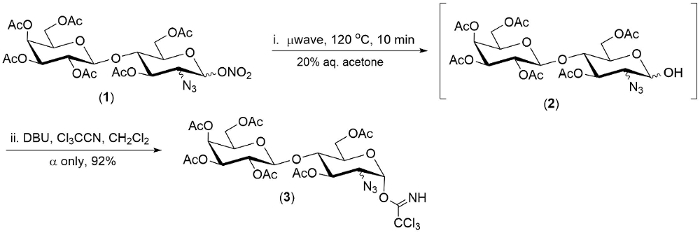

Figure 2. Representative example of hydrolysis (1 ->2), and one-pot conversion of 2-azido-1-nitrate ester of 1 (1->3). Please click here to view a larger version of this figure.

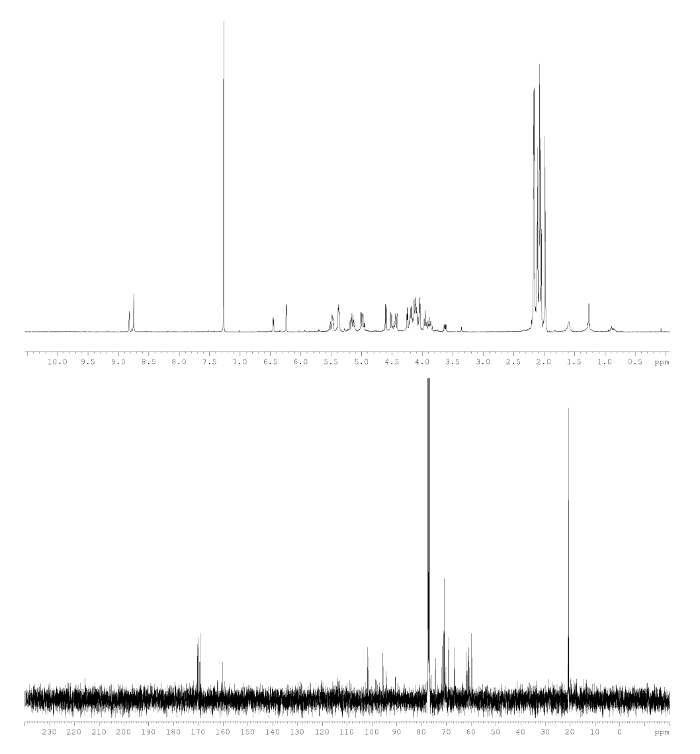

(2S,3R,4S,5S,6R)-2-(((2R,3S,4R,5R,6R)-4-acetoxy-2-(acetoxymethyl)-5-azido-6-(imino(2l3-trichloran-2-yl)methoxy)tetrahydro-2H-pyran-3- yl)oxy)-6-(acetoxymethyl)tetrahydro-2H-pyran-3,4,5-triyl triacetate (3) A mixture of 11:1:6 (alpha manno-/alpha gluco-/beta gluco-) configured azidonitrate esters 1 (1.0 equiv., 0.133 g, 0.20 mmol) was dissolved in 20% aq. acetone (2.0 mL) and treated with pyridine (5.0 equiv., 1.0 mmol, 0.8 mL). The reaction was heated by microwave irradiation to 120 °C for 10 min. Next, the reaction mixture was cooled to 0 °C and treated with CH2Cl2 (1.0 mL). The aqueous layer of the reaction was removed. Then the reaction was added DBU (10 equiv., 0.3 mL, 1.9 mmol), and 2,2,2- trichloroacetonitrile (50 equiv., 1.0 mL, 10 mmol).15 The reaction was allowed to warm to rt. After complete consumption of the starting material, the mixture was concentrated in vacuo. The crude oil was purified by flash chromatography (10:3 – 1:1 hexanes/ EtOAc) to give a 5:1 (gluco-/ manno-) mixture of alpha imidate products 3 (0.133 g, 0.174 mmol, 87% overall). Under these reaction conditions the manno- configured starting material is more resistant to hydrolysis as previously mentioned. In this reaction, >95% of the gluco- configured starting material was successfully converted to alpha imidate 3 while 62% of the manno- configured starting material was converted to imidate product. Spectroscopic data agreed with previously reported data21. As a mixture of complex C-2 isomers: 1H NMR (400 MHz, CDCl3) δ 8.64 (s, 1H), 6.46 (d, J = 3.6 Hz, 1H), 5.54 (m, J = 9.6 Hz), 5.33 (d, J = 3.6 Hz), 5.11 (dd, J = 10.6 Hz, J = 7.9 Hz), 5.04 (dd, J = 9.6, 3.6 Hz), 4.93 (dd, J = 10.6, 3.6 Hz, 1H ), 4.49 (d, J = 7.9 Hz, 1H), 4.48 (m, 1H ), 4.10 (m, 4H), 3.85 (m, 2H), 2.14 (s, 3H), 2.09 (s, 3H,), 2.06 (s, 3H), 2.02 (s, 6H), 1.99 (s, 3H), 1.95 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 171.2, 170.4, 170.2, 170.1, 169.4, 169.2, 169.0, 162.1, 101.3, 92.9, 76.6, 71.2, 70.9, 70.8, 69.8, 69.5, 69.2, 66.7, 61.5, 60.8, 21.1, 21.0, 20.7, 20.6.

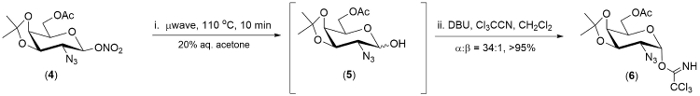

Figure 3. Representative example of hydrolysis (4 ->5), and one-pot conversion of 2-azido-1-nitrate ester of 4 (4->6). Please click here to view a larger version of this figure.

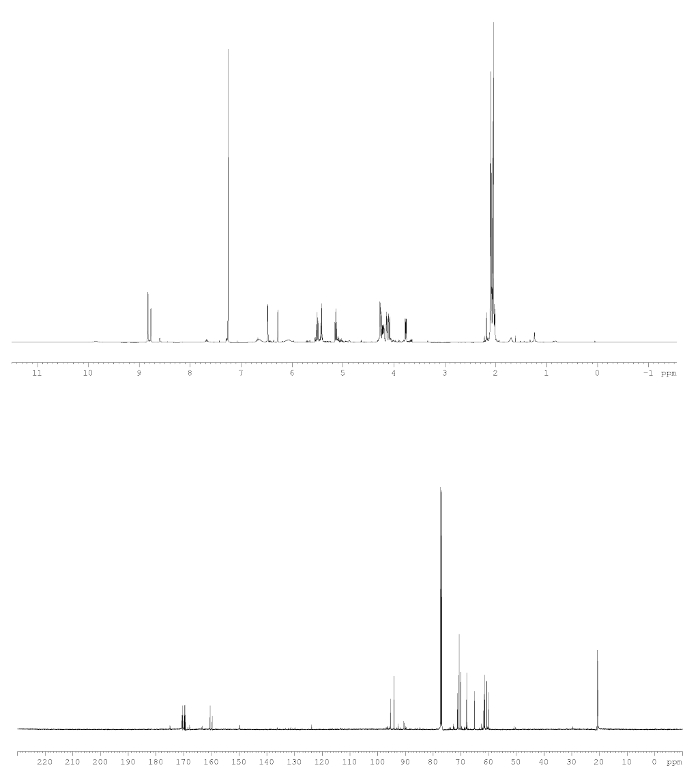

((3aR,4R,7R,7aR)-7-azido-6-hydroxy-2,2-dimethyltetrahydro-4H-[1,3]dioxolo[4,5-c]pyran-4-yl)methyl acetate (6). Azidonitrate ester 4 (1.0 equiv., 0.150 g, 0.451 mmol) in a solution of 1:4 water/acetone (4.0 mL) and pyridine (5.0 equiv., 0.18 mL, 2.26 mmol) was heated by microwave irradiation to 110 °C for 10 min. Then, the reaction was vial was concentrated under a stream of air to reduce the solvent mixture to ~1/2 its initial volume. The crude reaction mixture was added CH2Cl2 (4.0 mL). The aqueous layer of the reaction was removed. Then the reaction was added DBU (2.0 equiv., 0.14 mL, 0.90 mmol), and 2,2,2-trichloroacetonitrile (10 equiv., 0.45 mL, 4.51 mmol) at 0 °C. At 30 min., the reaction was concentrated to a crude dark brown oil. The crude oil was passed through a plug of silica gel in a filter funnel and concentrated then purified by flash chromatography (2:5 EtOAc/hexanes) to give a 34:1 mixture (alpha/beta) imidate 6 (0.189 g, 0.438 mmol, >95%) as a yellow oil. Spectroscopic data agreed with previously reported data21. Rƒ 0.26 (1:3 EtOAc/hexanes); [α]D20 +6.63° (c 0.3, CHCl3); IR (thin film, cm-1) 3943.02, 3689.98, 3053.89, 2986.53, 2684.50, 2409.92, 2304.81, 2115.20, 1735.63, 1674.77, 1616.82, 1421.56, 1265.14, 741.47, 705.37; 1H NMR (400 MHz, CDCl3): alpha anomer δ8.75 (s, 1H), 6.34 (d, J = 3.4 Hz, 1H), 4.48 (dd, 1H, J = 5.5, 7.9 Hz, 1H), 4.44-4.24 (m, 4H), 3.76 (dd, J = 3.4, 7.7 Hz, 1H), 2.04 (s, 3H), 1.54 (s, 3H), 1.36 (s, 3H); 13C (100 MHz, CDCl3): δ170.69, 160.47, 110.54, 94.34, 90.67, 73.35, 72.32, 68.13, 63.13, 60.11, 27.92, 26.00, 20.75; HRQ-TOF/MS (m/z): calcd for [M+Na]+, C13H17Cl3N4O6, 453.0111, found 453.1277.

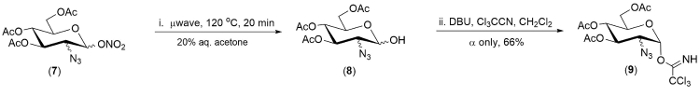

Figure 4. Representative example of hydrolysis (7 ->8), and one-pot conversion of 2-azido-1-nitrate ester of 7 (7->9). Please click here to view a larger version of this figure.

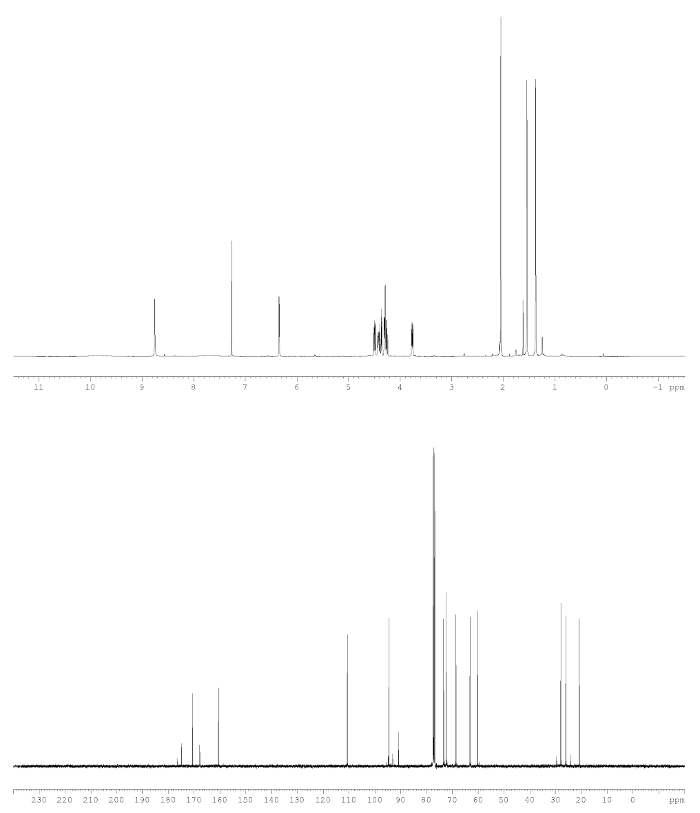

2R,3S,4R,5R,6R)-2-(acetoxymethyl)-5-azido-6-(2,2,2-trichloro-1-iminoethoxy)tetrahydro-2H-pyran-3,4-diyl diacetate and (2R,3S,4R,5S,6R)-2-(acetoxymethyl)-5-azido-6-(2,2,2-trichloro-1-iminoethoxy)tetrahydro-2H-pyran-3,4-diyl diacetate (9). A 1:14.4:27.4 (beta gluco-/ alpha manno-/ alpha gluco-) mixture of triacetate 7 (1.0 equiv., 0.438 g, 1.164 mmol) in a solution of 1:4 water/acetone (10.0 mL) and pyridine (5.0 equiv., 0.47 mL, 5.82 mmol) was heated by microwave irradiation at 120 °C for 20 min. Then, the reaction vial was concentrated under a stream of air to reduce the initial amount of solvent mixture to ~1/2 of its initial volume. The crude reaction mixture was added CH2Cl2 (10.0 mL). The aqueous layer of the reaction was removed. Then the reaction was added DBU (1.0 equiv., 0.18 mL, 1.164 mmol), and 2,2,2-trichloroacetonitrile (10 equiv., 1.2 mL, 11.64 mmol) at 0 °C. At 1 h, the reaction was a light orange and the pH of the reaction mixture was 7. Additional DBU (1.0 equiv., 0.18 mL, 1.164 mmol) was added and the reaction quickly turned its characteristic dark brown color. At 3 h, the reaction was concentrated to crude dark brown oil. The crude oil was purified by flash chromatography (2:5 EtOAc/hexanes) to give a 1:1.7 gluco-/manno- configured mixture of alpha imidate 9 (0.3758 g, 0.790 mmol, 68%) as a yellow oil. Spectroscopic data agreed with previously reported data21. 1H NMR (400 MHz, CDCl3): As a complex mixture of isomers: δ 8.68 (s), 6.51 (d, J = 3.7 Hz), 5.51 (m), 5.13 (m), 5.09 (dd, J = 10.3, 3.7 Hz), 4.24 (dd, J = 12.0, 3.8 Hz), 4.19-4.15 (m) 4.09 (dd, J = 12.0, 1.8 Hz), 2.02 (s), 2.00 (s), 1.98 (s), 1.97 (s); 13C NMR (100 MHz, CDCl3): δ 170.5, 170.0, 169.8, 169.5, 160.7, 92.9, 90.7, 70.0, 69.8, 69.7, 67.7, 61.4, 20.7, 20.6, 20.5.

Figure 5. 1H and 13C Spectra of 3. Please click here to view a larger version of this figure.

Figure 6. 1H and 13C Spectra of 6. Please click here to view a larger version of this figure.

Figure 7. 1H and 13C Spectra of 9. Please click here to view a larger version of this figure.

Discussion

The protocol described in this tutorial provides a method to convert nitrate esters to useful, reactive functionality. In a broader sense, employing a microwave reactor to complete specific maneuvers over the course of a carbohydrate synthesis has the potential to make difficult transformations facile and routine. Our goal in this tutorial is to demonstrate how to handle carbohydrates in the context of microwave irradiation.

In the case of the parent reaction, previous efforts to achieve denitration have typically relied on strongly nucleophilic reagents and extended reaction times. The strength of the technology described herein is that the microwave provides high-powered heating in a very short interval, allowing for quantitative manipulation of an anomeric nitrate ester. Thus far, the method works best with compounds that are glucose configured at C2 i.e. "equatorial" alcohol at this position. Compounds that feature "axial" mannose configuration at C2 must be subjected to prolonged irradiation, as they are resistant to hydrolysis. While the reaction is conducted in the presence of base to sequester the acid produced in the de- nitration, base can be excluded for molecules that are not acid labile. Moreover, reaction times can be increased to hydrolyze molecules that are resistant to the reaction (i.e. peracetylated sugars). In regards to purification, you can purify the alcohol produced after the microwave reaction.

Declarações

The authors have nothing to disclose.

Acknowledgements

The authors would like to acknowledge Vanderbilt University and the Institute of Chemical Biology for financial support. Mr. Berkley Ellis and Prof. John McLean are acknowledged for High-Resolution Mass Spectral Analysis.

Materials

| 230 400 mesh silica gel | SiliCycle Inc | R10030B | |

| TLC plates | SiliCycle Inc | TLG-R10014B-527 | |

| Ceric ammonium molybdate | Sigma-Aldrich | A1343 | |

| Solvent Still | Mbraun | MB-SPS-800 | |

| Infared spectrometer | Thermo | Thermo Electron IR100 | |

| Nuclear Magnetic Resonance | Bruker | 400, 600 MHz | |

| LC/MS | Thermo/Dionex | Single quad, ESI | |

| HRMS | Agilent | Synapt G2 S HDMS | |

| Microwave reactor | Anton Parr | Anton Parr G10 Monowave 200 | |

| DBU | Sigma-Aldrich | 139009 | |

| CCl3CN | Sigma-Aldrich | T53805 | |

| Pyridine | Sigma-Aldrich | 270970 | |

| Acetone | Fisher Scientific | A18-20 | Tech. grade |

| Phase separator | Biotage | 120-1901-A | |

| Rotary evaporator | Buchi | R-100 |

Referências

- Nicolaou, K. C., Mitchell, H. J. Adventures in Carbohydrate Chemistry: New Synthetic Technologies, Chemical Synthesis, Molecular Design, and Chemical Biology A list of abbreviations can be found at the end of this article. Telemachos Charalambous was an inspiring teacher at the Pancyprian Gymnasium, Nicosia, Cyprus. Angew. Chem. Int. Ed. Engl. 40 (9), 1576-1624 (2001).

- Danishefsky, S. J., Allen, J. R. From the laboratory to the clinic: A retrospective on fully synthetic carbohydrate-based anticancer vaccines. Angew. Chem. Int. Ed. Engl. 39 (5), 836-863 (2000).

- Nicolaou, K. C., Hale, C. R. H., Nilewski, C., Ioannidou, H. A. Constructing molecular complexity and diversity: total synthesis of natural products of biological and medicinal importance. Chemical Society Reviews. 41 (15), 5185-5238 (2012).

- Zhu, X., Schmidt, R. R. New principles for glycoside-bond formation. Angew. Chem. Int. Ed. Engl. 48 (11), 1900-1934 (2009).

- Danishefsky, S. J., Bilodeau, M. T. Glycals in organic synthesis: The evolution of comprehensive strategies for the assembly of oligosaccharides and glycoconjugates of biological consequence. Angew. Chem. Int. Ed. Engl. 35 (13-14), 1380-1419 (1996).

- Bongat, A. F., Demchenko, A. V. Recent trends in the synthesis of O-glycosides of 2-amino-2-deoxysugars. Carbohydr. Res. 342 (3-4), 374-406 (2007).

- Feizi, T., Fazio, F., Chai, W. C., Wong, C. H. Carbohydrate microarrays – a new set of technologies at the frontiers of glycomics. Curr. Opin. Struct. Biol. 13 (5), 637-645 (2003).

- Palmacci, E. R., Plante, O. J., Seeberger, P. H. Oligosaccharide synthesis in solution and on solid support with glycosyl phosphates. Eur. J. Org. Chem. (4), 595-606 (2002).

- Stallforth, P., Lepenies, B., Adibekian, A., Seeberger, P. H. 2009 Claude S. Hudson Award in Carbohydrate Chemistry. Carbohydrates: a frontier in medicinal chemistry. J. Med. Chem. 52 (18), 5561-5577 (2009).

- Danishefsky, S. J., Mcclure, K. F., Randolph, J. T., Ruggeri, R. B. A Strategy for the Solid-Phase Synthesis of Oligosaccharides. Science. 260 (5112), 1307-1309 (1993).

- Demchenko, A. V. Stereoselective chemical 1,2-cis O-glycosylation: From ‘sugar ray’ to modern techniques of the 21st century. Synlett. (9), 1225-1240 (2003).

- Fraserreid, B., Wu, Z. F., Udodong, U. E., Ottosson, H. Armed-Disarmed Effects in Glycosyl Donors – Rationalization and Sidetracking. J. Org. Chem. 55 (25), 6068-6070 (1990).

- Bohe, L., Crich, D. A propos of glycosyl cations and the mechanism of chemical glycosylation; the current state of the art. Carbohydr. Res. 403, 48-59 (2015).

- Toshima, K., Tatsuta, K. Recent Progress in O-Glycosylation Methods and Its Application to Natural-Products Synthesis. Chem. Rev. 93 (4), 1503-1531 (1993).

- Koenigs, W., Knorr, E. Ueber einige Derivate des Traubenzuckers und der Galactose. Chem. Ber. 34 (1), 957-981 (1901).

- Mukaiyama, T., Murai, Y., Shoda, S. An Efficient Method for Glucosylation of Hydroxy Compounds Using Glucopyranosyl Fluoride. Chem. Lett. (3), 431-432 (1981).

- Meloncelli, P. J., Martin, A. D., Lowary, T. L. Glycosyl iodides. History and recent advances. Carbohydrate Research. 344 (9), 1110-1122 (2009).

- Lian, G., Zhang, X., Yu, B. Thioglycosides in carbohydrate research. Carbohydr. Res. 403, 13-22 (2015).

- Schmidt, R. R., Kinzy, W. Anomeric-Oxygen Activation for Glycoside Synthesis – the Trichloroacetimidate Method. Advances in Carbohydrate Chemistry and Biochemistry. 50, 21-123 (1994).

- Schmidt, R. R., Toepfer, A. Glycosylation with highly reactive glycosyl donors: efficiency of the inverse procedure. Tetrahedron Lett. 32 (28), 3353-3356 (1991).

- Keith, D. J., Townsend, S. D. Direct, microwave-assisted substitution of anomeric nitrate-esters. Carbohydr. Res. 442, 20-24 (2017).

- Bukowski, R., et al. 3)-a-D-GalNAc-OMe).”>Synthesis and Conformational Analysis of the T-Antigen Disaccharide(B-D-Gal-(1->3)-a-D-GalNAc-OMe). Eur. J. Org. Chem. 14, 2697-2705 (2001).