A Simple Method for the Size Controlled Synthesis of Stable Oligomeric Clusters of Gold Nanoparticles under Ambient Conditions

Summary

We describe a simple method for producing highly stable oligomeric clusters of gold nanoparticles via the reduction of chloroauric acid (HAuCl4) with sodium thiocyanate (NaSCN). The oligoclusters have a narrow size distribution and can be produced with a wide range of sizes and surface coats.

Abstract

Reducing dilute aqueous HAuCl4 with sodium thiocyanate (NaSCN) under alkaline conditions produces 2 to 3 nm diameter nanoparticles. Stable grape-like oligomeric clusters of these yellow nanoparticles of narrow size distribution are synthesized under ambient conditions via two methods. The delay-time method controls the number of subunits in the oligoclusters by varying the time between the addition of HAuCl4 to alkaline solution and the subsequent addition of reducing agent, NaSCN. The yellow oligoclusters produced range in size from ~3 to ~25 nm. This size range can be further extended by an add-on method utilizing hydroxylated gold chloride (Na+[Au(OH4-x)Clx]–) to auto-catalytically increase the number of subunits in the as-synthesized oligocluster nanoparticles, providing a total range of 3 nm to 70 nm. The crude oligocluster preparations display narrow size distributions and do not require further fractionation for most purposes. The oligoclusters formed can be concentrated >300 fold without aggregation and the crude reaction mixtures remain stable for weeks without further processing. Because these oligomeric clusters can be concentrated before derivatization they allow expensive derivatizing agents to be used economically. In addition, we present two models by which predictions of particle size can be made with great accuracy.

Introduction

The use of gold nanoparticles as tools in both biomedical applications and basic research has grown tremendously over the past few decades. Few modern nanomaterials have been applied to so many diverse fields, finding their use in everything from solar panels to photothermal cancer treatment; from electrical to biological sensors; from chemical catalysis to drug delivery systems 1-7. The interests in gold nanoparticles as tools in these areas are driven by the unique properties gold nanoparticles possess which include special structural, optical and electronic properties 8.

There is an increasing use of gold nanoparticles 9,10 in biological and chemical assays. Despite the availability of many sources for the purchase of gold nanoparticles, they come at a considerable price when compared to the cost of in house synthesis. The high cost of commercially available nanoparticles makes in house synthesis desirable. Our procedure involves synthesis of oligomeric nanoclusters made by small 2-3 nm spherical gold subunits. Having all of the advantages of classical gold nanoparticles, oligomeric nanoclusters are preferred choice when it comes to permeability or filtration rates measurements because their modular structure mimics the structure of proteins.

Currently, the most common approaches to the in house synthesis of gold nanoparticles involve the reduction of gold chloride (HAuCl4) under aqueous conditions 11,12. Reduction of HAuCl4 with common reducing reagents, such as sodium borohydride (NaBH4) or sodium citrate, allows for the production of spherical nanoparticles 13. Gold nanoparticles synthesized by these methods are limited in their useful size range, because they become sensitive to the presence of salts in biological buffers as their core diameters increase. A method has previously been described for the synthesis of yellow nanoparticles of 2-3 nm diameter from the reduction of HAuCl4 with sodium thiocyanate under alkaline conditions 14,15.

Here, we describe a modification of that method which produces a grape-like oligocluster of the yellow nanoparticles without the need for additional capping agents. By simply varying the time between the addition of HAuCl4 to alkaline solution and the subsequent addition of reducing agent, sodium thiocyanate, we are able to vary the resulting size of the gold particles from ~3 nm to ~25 nm. To produce larger particles, a simple add-on procedure can be used to grow these oligoclusters by the addition of hydroxylated gold (HG) to the as-synthesized oligoclusters in the presence of sodium thiocyanate. Using these two methods, we are able to reliably produce oligoclusters covering a range from ~3 nm to ~70 nm. The fact that this method allows well controlled synthesis of high quality gold oligoclusters under bench-top conditions with standard equipment and a limited number of reagents potentially extends the benefits of gold nanoparticles as a research tool to researchers with little or no expertise in chemical synthesis.

Protocol

1. Preparation of Reagents

Caution: Always use caution when working with chemicals and solutions. Follow appropriate safety practices and wear gloves, glasses and a lab coat at all times. Be aware that nanomaterials may have additional hazards as compared to their bulk counterpart.

Note: All chemical solutions are made as molal (gram moles per kg of solvent) rather than molar (gram moles per liter of solution).

- Preparation of gold chloride

- Dissolve 1 g of gold(III) chloride trihydrate in 100 g of H2O to give 25 mM HAuCl4.

- Preparation of borax (Na2B4O7·10H2O)

- Dissolve 3.81 g of borax into 100 g of H2O to give 0.1 molal borax (warm if necessary to ensure complete solution).

- Preparation of sodium thiocyanate

- Dissolve 8.1 g of sodium thiocyanate in 100 g of H2O to give 1 molal NaSCN.

- Preparation of sodium carbonate

- Dissolve 5.3 g of anhydrous sodium carbonate in 100 g of H2O to give 0.5 molal Na2CO3.

- Preparation of glutathione

- Dissolve 154 mg of reduced glutathione (GSH) per 1 ml of 0.5 molal Na2CO3 to give 0.5 molal GSH.

2. Synthesis of Gold Oligoclusters

- Delay-time Synthesis of Gold Oligoclusters

- Add 59.5 ml of H2O to a clean 125 ml Wheaton glass bottle containing a stir bar. Use any flat bottom clean glass container, but ensure that it is very clean.

- Add 7 ml of 0.1 molal borax and bring solution to a vigorous stir.

- Add 2.8 ml of ~25 mM HAuCl4 under vigorous mixing and wait desired delay time (addition of HAuCl4 begins the delay-time). Delay times will determine the size of the as synthesized oligoclusters as shown in Table 1.

- After desired delay time, add 700 µl of 1 molal NaSCN under brief vigorous stirring (1,200 rpm for 30 sec).

- Remove stir bar and allow the reaction to go to completion O/N (size distribution of the oligoclusters can be further improved by allowing mixture to stir continuously O/N while the reaction goes to completion). Once reaction has come to completion the as-synthesized crude oligoclusters are stable for weeks.

- Add-on Growth of Oligoclusters

- Combine 10 ml of as-synthesized oligoclusters to 60 ml of HG. The ratio of as-synthesized oligoclusters to HG determines the size of resulting oligoclusters, increasing the relative amount of HG produces larger oligoclusters.

- Add 900 µl of 1 molal NaSCN under brief vigorous stirring (1,200 rpm for 30 sec).

- Allow the reaction to go to completion O/N (size distribution of the oligoclusters can be further improved by allowing mixture to stir continuously O/N while the reaction goes to completion).

3. GSH Derivatization and Concentration of Oligoclusters

- Add 70 ml of as-synthesized crude oligoclusters (or oligoclusters from the add-on method) to a 70 ml 30 kDa cutoff centrifugal filter.

- Spin for 15 min at 3,000 x g. This concentrates the particles down to a volume of ~250 µl.

- Flip device over and recover retentate by spinning device for 3 min at 500 x g. Recovered volume should be ~250 µl.

- Measure recovered volume using a micropipette.

- Add a volume of 0.5 molal glutathione (or other thiol) equal to 1/9th the recovered volume of concentrated oligoclusters (final concentration 50 mmolal GSH).

- Allow derivatization reaction to sit at RT for 5-10 min. Derivatization occurs quickly. Overly long times may dissolve particles.

- Dilute derivatized oligoclusters into 50 ml of Dulbecco’s phosphate buffered saline. (Other buffers or H2O can be chosen as the diluent/wash buffer at this step. The choice is usually determined by intended downstream application.)

- Add all of the diluted derivatized oligoclusters to 30 kDa cutoff centrifugal filter.

- Spin the centrifugal filter for 15 min at 3,000 x g.

- Flip device over and recover retentate by spinning device for 3 min at 500 x g. Recovered volume should be ~250 µl. The recovered concentrated particles are ready for use and are stable for months at 4 °C.

4. Analysis and Verification of Oligocluster Synthesis

- Gel electrophoresis of Oligoclusters

- Electrophoresis of crude oligocluster preparation

- Mix the as-synthesized oligocluster preparations 2:1 with load buffer containing 60% glycerol, ~0.15% bromophenol blue, and 150 mmolal GSH (from stock of 0.5 molal GSH dissolved in 0.5 molal Na2CO3).

- Load 30 µl onto precast polyacrylamide gradient gel (any kDa) and run with Tris-Glycine Running buffer (25 mM Tris, 192 mM glycine; no SDS is used) for 26 min at constant voltage (200 V).

- Electrophoresis of GSH Derivatized Oligoclusters

- Dilute GSH-derivatized oligocluster preparation 1:3 with H2O (Typically 2 µl of GSH-oligoclusters with 6 µl H2O).

- Mix diluted GSH-derivatized oligoclusters 2:1 with load buffer containing 60% glycerol, ~0.15% bromophenol blue, and 150 mmolal sodium bicarbonate.

- Load 10 µl onto precast polyacrylamide gradient gel (any kDa) and run with Tris-Glycine Running buffer (25 mM Tris, 192 mM glycine; no SDS is used) for 26 min at constant voltage (200 V).

- Electrophoresis of crude oligocluster preparation

- Transmission Electron Microscopy (TEM)

- Preparing Oligoclusters for TEM

- To wash oligoclusters dilute 20 µl of concentrated oligoclusters with 0.5 ml of H2O and load into to a 0.5 ml 30 kDa cutoff centrifugal filter.

- Spin at 14,000 x g for 10 min.

- Remove filtrate and resuspend retentate with a fresh 0.5 ml of H2O.

- Repeat washing twice for a total of 3 washes.

- Dilute final retentate 500 fold in H2O (oligoclusters are ready for gridding at this point).

- Gridding Oligoclusters

- Glow discharge carbon-coated grid.

- Deposit 0.6 µl of washed and diluted oligoclusters onto a carbon-coated glow discharged grid.

- Allow grid to air-dry for 10 min.

- Visualize oligoclusters by TEM at 100,000X magnification. Operate at 80 kV for images shown here.

- Preparing Oligoclusters for TEM

Representative Results

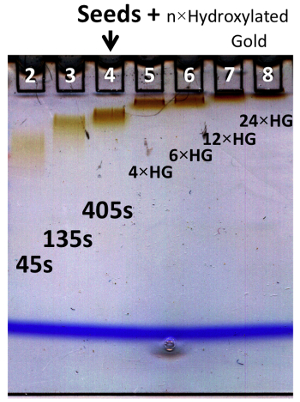

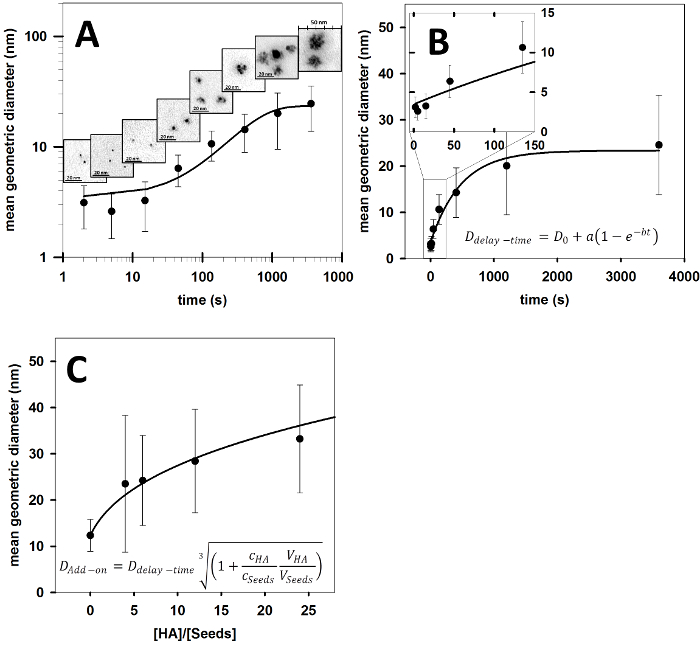

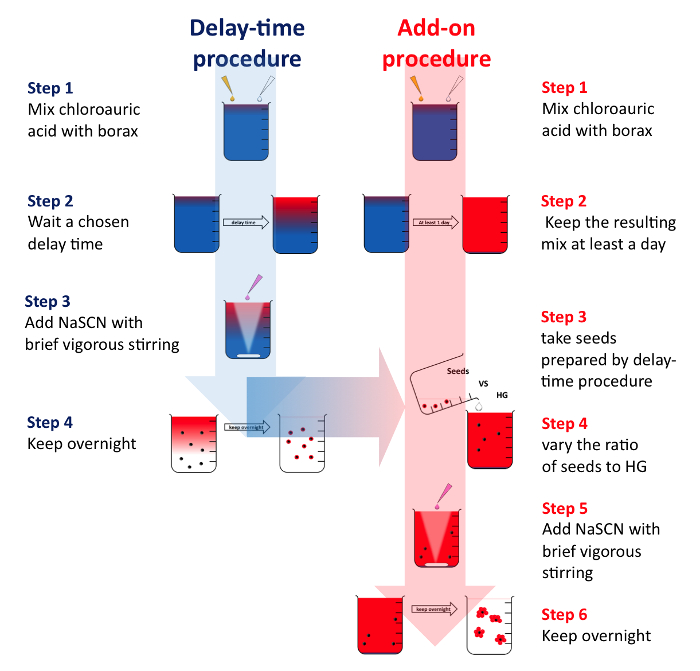

The syntheses of gold oligoclusters were analyzed by gel electrophoresis (Figure 1) and transmission electron microscopy (TEM) (Figure 2). The size of GSH-coated oligoclusters can be monitored by electrophoresis as larger particles migrate less and appear darker. In addition, the quality of any given size preparation can be inferred by the broadness of the band seen after electrophoresis (i.e., for a given size, preparations with narrower size distributions will produce tighter bands than preparations of the same size with broader size distributions). Figure 2 describes the relationship of time delay (delay-time method) or HG:seed (add-on method) to oligocluster size. Mean diameters calculated by TEM are used to determine delay-time and HG:seed dependence growth of oligoclusters for delay-time and add-on methods, respectively. A flow chart (Figure 3) outlining the procedure for both methods and a table (Table 1) providing predicted parameters to produce oligoclusters of the desired size are presented.

Figure 1. Polyacrylamide gradient gel electrophoresis of oligoclusters formed by the Delay-time and Add-on methods. Oligoclusters produced by delay-time and add-on methods were analyzed on gradient gel electrophoresis. Lanes 2-4: oligoclusters formed after different delay times (45, 135, and 405 sec) between making the HAuCl4 alkaline and the addition of NaSCN. Lanes 5-8: oligoclusters formed by the add-on method. Seed was formed by the delay-time method with 405 sec delay, indicated by ↓. Varying amounts of HG were used for add-on. The ratios of HG solution (1 mM in gold) to seed solution (1 mM in gold) used for preparing each sample are indicated, as 4xHG, 6xHG, 12xHG, and 24xHG. Please click here to download this file.

Figure 2. Diameters of gold oligoclusters formed by the delay-time and add-on methods. Oligoclusters prepared by delay-time and add-on methods were analyzed by TEM. A) and B) are adapted with permission from ref.16, Copyright 2014 American Chemical Society. (A) Representative TEM images of 50 nm x 50 nm areas of grids prepared from samples made using the delay-time method. Diameter of the particles (Y axis) and the delay times used in their preparation (X axis) are indicated, both axis are logarithmic. The heavy black line (R2 = 0.973) is a best fit with empirical 3-parameter equation Ddelay-time = D0 + a(1 – e-bt), where Ddelay-time is the mean diameter of clusters in nm, D0 is minimum diameter of clusters (~3.5 nm); a is the maximum increase in core size caused by extending the delay time (~20 nm), and b = 0.0021 sec-1. (B) Diameters of the oligoclusters formed after different delay times before adding NaSCN (delay-time method) presented on a linear scale. (C) Diameters of the oligoclusters formed after addition (add-on method) of different amounts of HG onto preformed gold seeds formed by the delay-time method with 405 sec delay time. As shown by the heavy black line, it can be easily seen that the diameter of oligoclusters formed by the add-on method is  , where cHG and cSeeds are the concentrations of chloroauric acid used in making the solution of HG in add-on method and in making oligoclusters by the delay-time method, respectively. Similarly VHG and VSeeds are the corresponding volumes. Please click here to download this file.

, where cHG and cSeeds are the concentrations of chloroauric acid used in making the solution of HG in add-on method and in making oligoclusters by the delay-time method, respectively. Similarly VHG and VSeeds are the corresponding volumes. Please click here to download this file.

Figure 3. Wall chart diagram of Delay-time and Add-on methods for making gold oligoclusters of different sizes. Flow chart outlining the procedures for synthesizing gold oligoclusters of different sizes using either the delay-time or add-on methods. The alkaline solution of chloroauric acid is blue. The HG is red. The gold nanoparticle seeds and oligoclusters are black. Please click here to download this file.

| Delay-time procedure | Add-on procedure | ||||||||

| predicted diameter (nm) | |||||||||

| delay time (sec) | delay time (min) | predicted diameter (nm) | measured diameter ± s.d. (nm) | 4×HG | 6×HG | 12×HG | 24×HG | 100×HG | 1000×HG |

| 1 | 0.02 | 3.5 | |||||||

| 2 | 0.03 | 3.6 | 3.1±1.3 | 6.1 | 6.9 | 8.4 | 10.5 | 16.7 | 36 |

| 3 | 0.05 | 3.6 | |||||||

| 4 | 0.07 | 3.7 | |||||||

| 5 | 0.08 | 3.7 | 2.6±1.1 | 6.3 | 7.1 | 8.7 | 10.8 | 17.3 | 37 |

| 6 | 0.10 | 3.8 | |||||||

| 7 | 0.12 | 3.8 | |||||||

| 8 | 0.13 | 3.8 | |||||||

| 9 | 0.15 | 3.9 | |||||||

| 10 | 0.17 | 3.9 | 6.7 | 7.5 | 9.2 | 11.4 | 18 | 39 | |

| 11 | 0.18 | 4.0 | |||||||

| 12 | 0.20 | 4.0 | |||||||

| 13 | 0.22 | 4.0 | |||||||

| 14 | 0.23 | 4.1 | |||||||

| 15 | 0.25 | 4.1 | 3.3±1.5 | 7.0 | 7.9 | 9.7 | 12.0 | 19 | 41 |

| 20 | 0.33 | 4.3 | |||||||

| 25 | 0.42 | 4.5 | |||||||

| 30 | 0.50 | 4.7 | |||||||

| 35 | 0.58 | 4.9 | |||||||

| 40 | 0.67 | 5.1 | |||||||

| 45 | 0.75 | 5.3 | 6.4±2 | 9.1 | 10.1 | 12.5 | 15.5 | 25 | 53 |

| 60 | 1.0 | 5.9 | |||||||

| 75 | 1.3 | 6.4 | |||||||

| 90 | 1.5 | 6.9 | |||||||

| 105 | 1.8 | 7.5 | |||||||

| 120 | 2.0 | 8.0 | |||||||

| 135 | 2.3 | 8.4 | 11±3 | 14.4 | 16.1 | 20 | 25 | 39 | 84 |

| 165 | 2.8 | 9.4 | |||||||

| 195 | 3.3 | 10 | |||||||

| 225 | 3.8 | 11 | |||||||

| 255 | 4.3 | 12 | |||||||

| 285 | 4.8 | 13 | |||||||

| 315 | 5.3 | 13 | |||||||

| 345 | 5.8 | 14 | |||||||

| 375 | 6.3 | 14 | |||||||

| 405 | 6.8 | 15 | 14±5 | 26 | 29 | 35 | 44 | 70 | 150 |

| 435 | 7.3 | 15 | |||||||

| 465 | 7.8 | 16 | |||||||

| 495 | 8.3 | 16 | |||||||

| 525 | 8.8 | 17 | |||||||

| 555 | 9.3 | 17 | |||||||

| 585 | 9.8 | 18 | |||||||

| 615 | 10 | 18 | |||||||

| 900 | 15 | 20 | |||||||

| 1200 | 20 | 22 | 20±11 | 37 | 42 | 51 | 64 | 102 | 219 |

| 1500 | 25 | 23 | |||||||

| 1800 | 30 | 23 | |||||||

| 2100 | 35 | 23 | |||||||

| 2400 | 40 | 23 | |||||||

| 2700 | 45 | 23 | |||||||

| 3000 | 50 | 23 | |||||||

| 3300 | 55 | 23 | |||||||

| 3600 | 60 | 23 | 25±11 | 40 | 45 | 55 | 69 | 109 | 235 |

Table 1. Oligocluster size prediction table. Predicted diameters of gold oligoclusters formed using either the delay-time or add-on methods. Predicted diameter for the delay-time method is calculated using an empirical formula for average oligocluster diameter Ddelay-time = D0 + a(1 – e-bt), where D is the mean diameter of gold oligoclusters in nm, D0 is the minimum diameter (3.5 nm), a is the maximum increase in core size (20 nm), and b is 0.0021 sec-1, as shown previously 16. Predicted diameter for the add-on method is calculated taking into account that new nanoparticles cannot form from HG, rather it is deposited uniformly around preformed spherical seeds, thus making them larger. No other assumption is necessary. It can be easily seen that the diameter of oligoclusters formed by the add-on method is  , where cHG and cSeeds are the concentrations of chloroauric acid used in making the solution of HG in add-on method and in making oligoclusters by the delay-time method, respectively. Similarly VHG and VSeeds are the corresponding volumes.

, where cHG and cSeeds are the concentrations of chloroauric acid used in making the solution of HG in add-on method and in making oligoclusters by the delay-time method, respectively. Similarly VHG and VSeeds are the corresponding volumes.

Discussion

This manuscript provides a detailed protocol for bench top synthesis of monodisperse gold oligoclusters (Figure 3). The method is capable of producing a wide range of sizes by simply varying the time between the addition of HAuCl4 to alkaline solution and the subsequent addition of the reducing agent, sodium thiocyanate. The addition of HAuCl4 to alkaline buffered aqueous solution results in the time dependent hydroxylation of HAuCl4 to hydroxylated gold (Na+[Au(OH4-x)Clx]–). This hydroxylation results in less HAuCl4 being available, though the hydroxylation does not go to completion as it is an equilibrium reaction. The nucleation and formation of de novo gold monomers can only be initiated by HAuCl4. Hydroxylated gold is only capable of adding on to existing gold nanoparticles, resulting in the formation of gold oligoclusters; our add-on method takes advantage of this 16. Oligoclusters formed with the delay-time method can be used as seeds upon which hydroxylated gold is deposited, thereby increasing the size of seeded oligoclusters. Seeded growth can be controlled by varying the ratio of hydroxylated gold (HG) vs. as-synthesized oligocluster (Figure 1). In both methods the size of particles can easily be predicted by choosing the right time delay (Figure 2A, B) or by choosing the right starting seeds and the right ratio of added hydroxylated gold (HG) (Figure 2C). Predictions for most useful particle sizes are presented (Table 1). The increasing size of GSH derivatized oligoclusters can be monitored by electrophoresis as larger particles migrate less and appear notably darker, the later resulting from the fact that the extinction coefficient of gold nanoparticles increase in proportion to particle size.

The add-on method has two limitations, the first of which is the large reaction volumes required at high HG:seed ratios. A second limitation to the add-on method originates from the aforementioned fact that the hydroxylation of HAuCl4 is an equilibrium reaction and does not go to completion. The incomplete hydroxylation of HAuCl4 has minimal influence on the add-on reaction when the concentration of oligocluster seeds remains high. When the concentration of oligocluster seeds are low, as is the case when using long delay-time seed and high HG:seed ratios, the influence of unhydroxylated HAuCl4 can become significant. Under these conditions HAuCl4 is able to nucleate the synthesis of new oligoclusters, resulting in heterogeneous populations of oligoclusters.

The as-synthesized oligoclusters produced by delay-time or add-on method are stable for weeks, only developing trace amounts of gold precipitate. Even after being concentrated 300 fold the oligoclusters remain stable and resist aggregation. The gold oligoclusters described here also have the additional benefit of being able to be concentrated without prior derivatization, thus allowing expensive derivatizing agents to be used in smaller volumes. After being derivatized with glutathione (GSH), clusters remained stable up to one year. GSH-derivatization also provides strong negative charge 13 that makes them resist aggregation when exposed to physiological buffers or animal plasma, thus making them suitable for in vivo experiments. Derivatization can be achieved with a wide variety of thiol group containing reagents.

The amenability of the oligoclusters to derivatization with other thiol containing molecules 17,18 allows convenient and easy modification of the surface monolayer, thus controlling surface chemistry and reactivity of oligoclusters. Other chemicals used in this protocol can be readily substituted for similar chemicals without impairing synthesis. This includes the substitution of borax with other alkaline buffers (e.g., carbonate) and sodium thiocyanate for other thiocyanate salts (e.g., KSCN).

The main attribute of this protocol is its simplicity, which must be emphasized. Only a milligram weight scale and magnetic stirrer is required to produce commercial quality gold oligoclusters which can be used for advanced biological and material applications. Broad applicability is aided by the broad range of sizes than can be produced and by monodispersity. Additionally, in house production is low cost.

The oligoclusters are particularly valuable for studies of permeability of basal membranes and blood barriers. They can be easily administrated with saline through different routes and tracked in vivo 19-21. Obtained tissue samples can be subsequently examined under an electron microscope 16,22. Besides permeability, bio distribution provides valuable pharmacological information and the administration of mixture of oligoclusters of different sizes gives valuable information about size dependent distribution of particles inside the body 23-25. Lastly, because of their unique structure they fail to manifest localized surface plasmon resonance (LSPR) perhaps making them ideal candidates for fluorescent labeling, which is not readily achievable in gold nanoparticles because interference between the LSPR and fluorophore results in almost complete quenching of fluorescence 26.

Disclosures

The authors have nothing to disclose.

Acknowledgements

T.K. acknowledges support from the Slovenia Research Agency (ARRS, grants BI-US/13-14-040, and J3-6803). O.S. acknowledges support from National Institute of Health (NIH) grant RO1HL49277.

Materials

| 125 ml Wheaton glass bottles | Fisher Scientific | SC-06-404F |

| Borax (Na2B4O7·10H2O) | Fisher Scientific | S25537 |

| Gold(III) Chloride trihydrate | Sigma Aldrich | G4022 |

| Sodium thiocyanate | Sigma Aldrich | 251410 |

| Sodium carbonate | Sigma Aldrich | S7795 |

| Glutathione | Sigma Aldrich | G4251 |

| Dulbecco's phosphate buffered saline (DPBS) | Corning | 21-031-CV |

| Centricon Plus – 70 | Millipore | UCF703008 |

| Sodium bicarbonate | Sigma Aldrich | S6014 |

| CF200-Cu Carbon film on 200 mesh copper grids | Electron Microscopy Sciences | 71150 |

| 10X TRIS/GLYCINE buffer | Bio-Rad | 161-0734 |

| Any kD Mini-PROTEAN TGX Gel | Bio-Rad | 456-9033 |

References

- Dreaden, E. C., Austin, L. A., Mackey, M. A., El-Sayed, M. A. Size matters: gold nanoparticles in targeted cancer drug delivery. Ther. Deliv. 3 (4), 457-478 (2012).

- Huang, X., Jain, P., El-Sayed, I., El-Sayed, M. Plasmonic photothermal therapy (PPTT) using gold nanoparticles. Lasers Med. Sci. 23 (3), 217-228 (2008).

- Notarianni, M., et al. Plasmonic effect of gold nanoparticles in organic solar cells. Sol. Energy. 106, 23-37 (2013).

- Jain, P. K., Huang, X., El-Sayed, I. H., El-Sayed, M. A. Noble Metals on the Nanoscale: Optical and Photothermal Properties and Some Applications in Imaging, Sensing, Biology, and Medicine. Acc. Chem. Res. 41 (12), 1578-1586 (2008).

- Huang, X., El-Sayed, M. A. Gold nanoparticles: Optical properties and implementations in cancer diagnosis and photothermal therapy. J. Adv. Res. 1 (1), 13-28 (2010).

- Cioffi, N., et al. Electrosynthesis and characterization of gold nanoparticles for electronic capacitance sensing of pollutants. Electrochim. Acta. 56 (10), 3713-3720 (2011).

- Mikami, Y., Dhakshinamoorthy, A., Alvaro, M., Garcia, H. Catalytic activity of unsupported gold nanoparticles. Catal. Sci. Tech. 3 (1), 58-69 (2012).

- González, A. L., Noguez, C., Barnard, A. S. Map of the Structural and Optical Properties of Gold Nanoparticles at Thermal Equilibrium. J. Phys. Chem. C. 116 (26), 14170-14175 (2012).

- Neeley, A., et al. Selective Detection of Chemical and Biological Toxins Using Gold-Nanoparticle-Based Two-Photon Scattering Assay. IEEE Trans. Nanotechnol. 10 (1), 26-34 (2011).

- An, H., Jin, B. Prospects of nanoparticle-DNA binding and its implications in medical biotechnology. Biotechnol. Adv. 30 (6), 1721-1732 (2012).

- Wang, S., Qian, K., Bi, X., Huang, W. Influence of Speciation of Aqueous HAuCl4 on the Synthesis, Structure, and Property of Au Colloids. J. Phys. Chem. C. 113 (16), 6505-6510 (2009).

- Britton, H. T. S., Dodd, E. N. Electrometric studies of the precipitation of hydroxides. Part V. Tervalent gold chloride solutions. J. Chem. Soc. , 2464-2467 (1932).

- Schaaff, T. G., Knight, G., Shafigullin, M. N., Borkman, R. F., Whetten, R. L. Isolation and Selected Properties of a 10.4 kDa Gold:Glutathione Cluster Compound. J. Phys. Chem. B. 102 (52), 10643-10646 (1998).

- Baschong, W., Lucocq, J. M., Roth, J. Thiocyanate gold: Small (2-3 nm) Colloidal Gold for Affinity Cytochemical Labeling in Electron Microscopy. Histochemistry. 83 (5), 409-411 (1985).

- De Brouckère, L., Casimir, J. Préparation d’hydrosols d’or homéodisperses très stables. Bull. Soc. Chim. Belg. 57 (10-12), 517-524 (1948).

- Smithies, O., et al. Stable Oligomeric Clusters of Gold Nanoparticles: Preparation, Size Distribution, Derivatization, and Physical and Biological Properties. Langmuir. 30 (44), 13394-13404 (2014).

- Bartz, M., et al. Monothiols derived from glycols as agents for stabilizing gold colloids in water: synthesis, self-assembly and use as crystallization templates. J. Mater. Chem. 9 (5), 1121-1125 (1999).

- Hainfeld, J. F., Slatkin, D. N., Focella, T. M., Smilowitz, H. M. Gold nanoparticles: a new X-ray contrast agent. Br. J. Radiol. 79 (939), 248-253 (2006).

- Nam, S. Y., Ricles, L. M., Suggs, L. J., Emelianov, S. Y. Ultrasound and Photoacoustic Monitoring of Mesenchymal Stem Cells Labeled with Gold Nanotracers. PLoS One. 7 (5), (2013).

- Jokerst, J. V., Thangaraj, M., Kempen, P. J., Sinclair, R., Gambhir, S. S. Photoacoustic Imaging of Mesenchymal Stem Cells in Living Mice via Silica-Coated Gold Nanorods. ACS Nano. 6 (7), 5920-5930 (2013).

- Astolfo, A., et al. In vivo visualization of gold-loaded cells in mice using x-ray computed tomography. Nanomed. Nanotechnol. Biol. Med. 9 (2), 284-292 (2013).

- Menk, R. H., et al. Gold nanoparticle labeling of cells is a sensitive method to investigate cell distribution and migration in animal models of human disease. Nanomed. Nanotechnol. Biol. Med. 7 (5), 647-654 (2011).

- Kumar, A., Zhang, X., Liang, X. J. Gold nanoparticles: Emerging paradigm for targeted drug delivery system. Biotechnol. Adv. 31 (5), 593-606 (2013).

- Paciotti, G. F., et al. Colloidal Gold: A Novel Nanoparticle Vector for Tumor Directed Drug Delivery. Drug Deliv. 11 (3), 169-183 (2004).

- Khlebtsov, N., Dykman, L. Biodistribution and toxicity of engineered gold nanoparticles: a review of in vitro and in vivo studies. Chem. Soc. Rev. 40 (3), 1647-1671 (2011).

- Nerambourg, N., Werts, M. H., Charlot, M., Blanchard-Desce, M. Quenching of Molecular Fluorescence on the Surface of Monolayer-Protected Gold Nanoparticles Investigated Using Place Exchange Equilibria. Langmuir. 23 (10), 5563-5570 (2007).