Determination of the Mechanical Properties of Flexible Connectors for Use in Insulated Concrete Wall Panels

Summary

We propose a testing protocol that can be combined with widely available analytical methods to assess the mechanical properties of shear connectors for use in the design of insulated concrete wall panels to predict full-scale insulated panel behavior.

Abstract

This document contains recommendations for performing a non-standard, double-shear test suitable for both continuous and discrete insulated concrete sandwich wall panels (ICSWPs). Such a standardized test does not exist, but several iterations of this and similar tests have been performed in the literature to varying degrees of success. Further, the tests in the literature are rarely-if ever-described in detail or discussed at length with respect to the testing, data analysis, or safety procedures. A test specimen configuration is recommended herein, and variations are discussed. Important mechanical properties are identified from the load versus displacement data, and their extraction is detailed. The use of test data for design, such as for determining the stiffness of the connectors, is briefly demonstrated to show how ICSWP deflection and cracking behavior may be calculated. The strength behavior of panels may be determined using the full load versus displacement curve or only the maximum connector strength. Shortcomings and unknowns are acknowledged, and significant future work is delineated.

Introduction

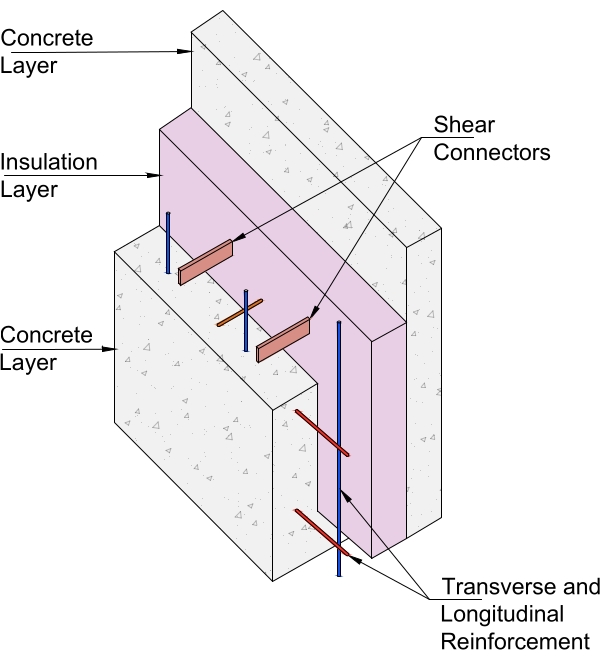

Insulated concrete sandwich wall panels (ICSWPs) comprise a layer of insulation placed in between two concrete layers, often called wythes, which synergically provide a thermally and structurally efficient component for building envelopes or load-bearing panels1 (Figure 1). To adapt to the rapidly changing construction industry and new building code regulations on thermal efficiency, precasters are fabricating ICSWPs with thinner concrete layers and thicker insulation layers with higher thermal resistance; additionally, designers are using more refined methods to account for the partially composite interaction of the concrete wythes to reduce the overall building costs while increasing the thermal and structural performance2. While it is known that structural efficiency largely depends on the structural connection between the concrete layers and that multiple proprietary shear connectors are available on the market, no standardized testing protocol exists in the literature to examine the mechanical properties of those connectors. The available connectors vary widely in their geometry, materials, and manufacturing, so it is difficult to obtain a unified analytical approach to determine their mechanical properties. For this reason, many researchers have used their own customized setups in the lab that try to mimic the fundamental behavior of the connectors at the service and strength limit states3,4,5,6,7,8,9,10. However, only two of them are part of a testing evaluation scheme5,8, despite them not being useful for all ranges of connectors due to their wide variation in shape, stiffness, and material composition.

Figure 1: Typical composition of a sandwich wall panel specimen. Please click here to view a larger version of this figure.

A common method for testing these connectors is what is often termed single shear with either one row or two rows of connectors, as described previously3,11,12, which is often based on ASTM E488, a concrete anchor testing standard13. ASTM E488 does not require, but strongly implies through drawings of the suggested test setups, that a single anchor protruding from a fixed base of concrete will be tested. Once the specimens are tested, a set of load versus displacement curves is plotted, and the average values of the ultimate elastic load (Fu) and the elastic stiffness (K0.5Fu) are obtained from such curves. One of the main advantages of using this approach is that it produces low-variability results and does not necessitate large lab spaces or many sensors14. A different approach consists of loading a wythe connector in double shear to determine the mechanical properties for use in the design of those panels6,7,14,15,16. The resulting data are processed in the same fashion, and the average values of the ultimate elastic load (Fu) and the elastic stiffness (K0.5Fu) are obtained from testing. Although this testing approach involves using more material and needs more sensors, it is anecdotally easier to apply the loading and boundary conditions in a laboratory.

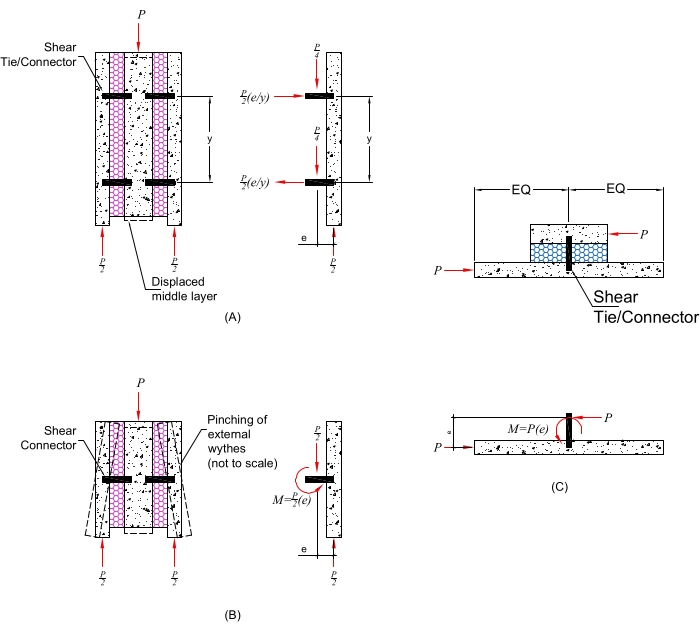

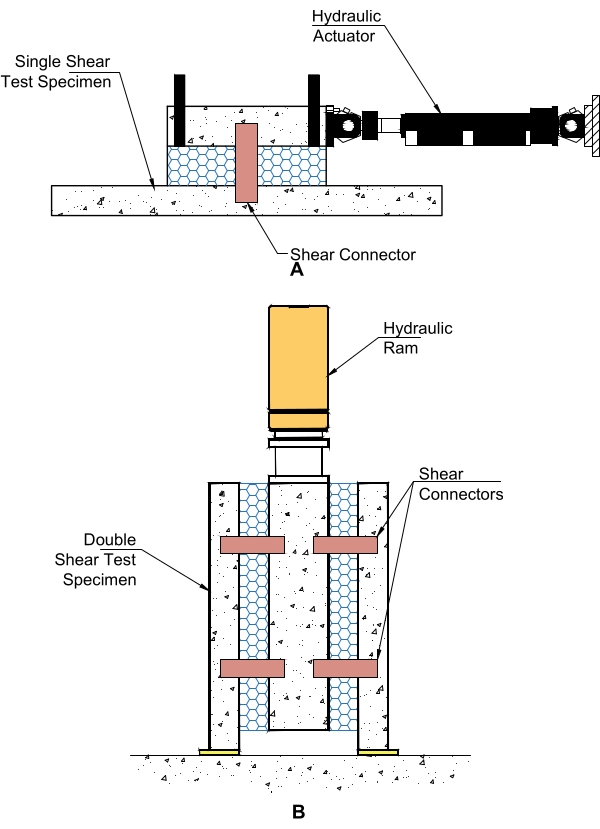

The two styles of testing do not seem dramatically different but produce different results largely based on their ability to mimic the connector behavior in a full-scale panel. The single-shear, single-row test setup produces a pinching action, as displayed in Figure 2B,C, and an additional overturning moment, as described previously14,17, which would not be present in a full-scale panel. The double shear does a better job of mimicking this full-scale behavior-it models the pure shear translation of the outer wythes relative to the central wythe. As a result, the double-shear values employed in analytical methods have been shown to produce results that are closer to those obtained in large-scale testing of representative insulated wall panels14. Figure 3 shows the schematic test setup for the single- and double-shear testing of a connector.

Figure 2: Examples of different connector testing configurations employed in the literature. Single connector specimens have been shown to cause loading that does not represent the parallel translation of wythes seen in full-scale panels. (A) Double shear with two connectors; (B) Double shear with one connector; (C) Single shear with one connector. Please click here to view a larger version of this figure.

A common denominator of all these studies' conclusions is that both the testing methodologies are appropriate for determining the mechanical properties of flexible connectors, but the double-shear testing scheme results resemble more closely the behavior of the connector in a real panel under flexure. In other words, when the user employs such testing results in an analytical model, they closely match the results of large-scale tests where the connectors are used. It is important to mention that the results of such testing are appropriate for models that rely on the mechanical properties as input design parameters directly, such as empirically derived methods, closed-form solutions of the sandwich beam theory, and finite element models with 2-D and 3-D springs7,18,19,20.

Figure 3: Schematic view of the testing protocols in the literature. A ram is used to translate the wythes of the specimens relative to each other. (A) Single-shear and (B) double-shear testing protocols. Please click here to view a larger version of this figure.

In this work, an experimental protocol for obtaining the values of the backbone curve and the mechanical properties of insulated wall panel wythe connectors, namely Fu and K0.5Fu, is presented. The method is based on testing connectors using a double-shear test approach with some modifications to eliminate sources of variability and produce more reliable results. All the samples are constructed in a temperature-controlled environment, where they are tested when the concrete reaches the target compressive strength. The main advantage of this testing protocol is that it can be easily followed, can be replicated by different technicians, and closely describes the real behavior of the wythe connector in a real, insulated concrete wall panel under flexure or flexure and axial force combined, as has been shown in the literature.

The application of the suggested wythe connector testing protocol for determining the mechanical properties and material behavior will enhance the accuracy of testing results for the insulated concrete wall panel industry and decrease the barriers for entrepreneurs interested in creating innovative new connectors. The future large increase in insulated panel construction in both the tilt-up and precast concrete industries will require better use of materials and more unified methods to obtain engineering properties of the panels.

Protocol

1. Fabricating the testing specimen

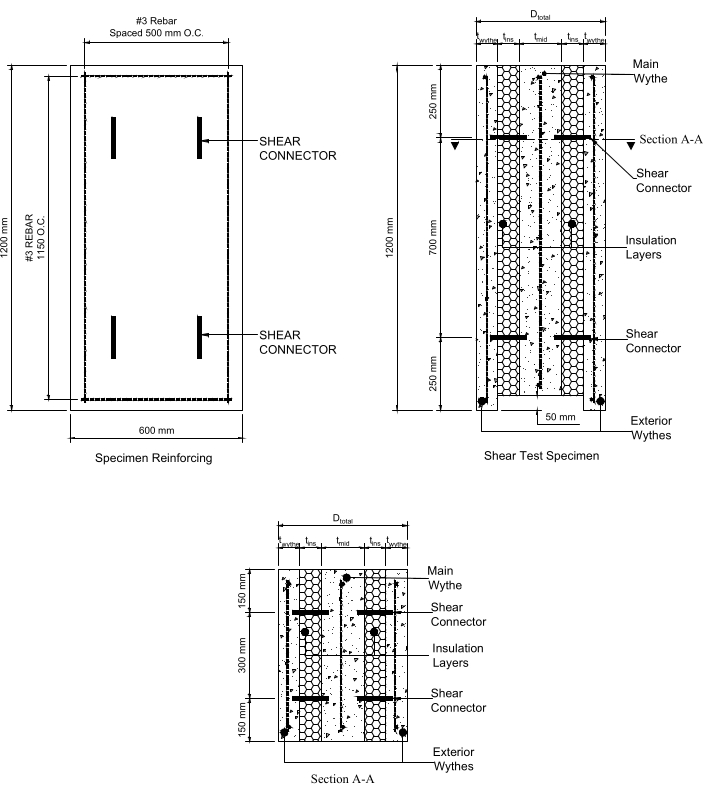

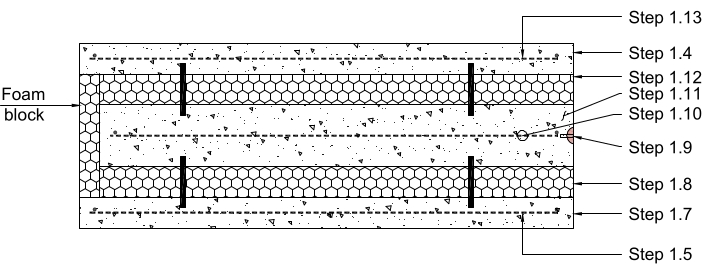

- Select the discrete or continuous shear connector to test and adhere to the dimensions of the specimen indicated in Figure 4. Modify the dimensions to the test edge distance clearances if needed by changing the edge distance for the connector.

NOTE: Generally, adhering to the manufacturer's guidelines is important, though this test may be used to develop these guidelines. The concrete and insulation wythe dimensions will be dictated by the connector of interest. The mechanical properties from the test are only valid for this specific combination of wythe dimensions, concrete strength, insulation density and type, and connector. - Indicate the target compressive strength of the concrete representative of the design situation of interest. If trying to model full-scale testing results, ensure that the concrete strength is the same as that of the full-scale specimen or the intended design at the time of testing. If targeting a certain scenario, like the minimum strength for the lifting of the panel, perform the test at that strength.

- Fabricate the concrete formwork using either a vertical or horizontal layout of the concrete layers. Ensure that the testing matches the construction style so that the installation of the connectors matches the in-field situation.

NOTE: Most in-service ICSWPs are fabricated with a horizontal layout of each layer. - Perforate the foam insulation (for pin-style ties) or orient the insulation pieces (for seam-installed ties) and place the connectors at the locations indicated in the standard drawings provided by the manufacturer. Place the connectors using the orientation that the testing facility desires to gather the properties (e.g., a 0° or 90°-or other-angle to the strong axis and the applied load).

NOTE: The installation of the connectors should be as indicated by the manufacturer/supplier unless installation is a testing variable of interest. - Place the first steel reinforcement layer in the forms to prevent the specimen from brittle failure if the concrete pieces crack during handling or testing.

NOTE: As the specimens rarely crack due to applied loads, mild reinforcement is not thought to be necessary unless it is expected to participate in the bond of the connector to the concrete. Figure 5 shows the organization of steps 1.5-1.14 through the process. - If all the layers of concrete cannot be placed in a timely manner prior to the initial set of the concrete, cast the layers a minimum of 3 h apart or according to the connector manufacturer's recommendations.

NOTE: Steps 1.7-1.14 indicate consecutive concrete placement. - Pour the fresh concrete into the forms and vibrate adequately to prevent the formation of large air voids in the concrete or the poor compaction of particles.

- Place the first insulation layer containing the connectors or push them into the foam, as appropriate. Place the insulation layer so that it makes contact with the fresh concrete. To ensure the concrete is consolidated around the connectors, vibrate the connector with an internal concrete vibrator at 12,000 vibrations/min, unless otherwise recommended by the connector's manufacturer.

NOTE: Vibrating for 2-5 s is enough to ensure consolidation around the connectors. - Place a 1 ton capacity (or stronger depending on the specimen's final weight) lifting anchor in the middle layer of the concrete for ease of handling.

- Place the second steel reinforcement layer in the forms in the center of the center wythe.

- Pour the second layer of fresh concrete into the forms and adequately consolidate the concrete as described above.

- Place the second insulation layer containing the connectors or install them into the foam, as described in step 1.4. Carefully ensure that the concrete is consolidated around the connectors.

- Place the third steel reinforcement layer in the forms at the center of the third concrete layer.

- Pour the third and final layer of fresh concrete into the forms and vibrate adequately.

- Make concrete cylinders for each concrete used in the construction of the specimens for the purpose of compression strength documentation.

NOTE: This step may be completed at any time during the construction of the specimens but is recommended when halfway through the placement of a given batch. The cylinder preparation and field curing should follow ASTM C3121. - Cure the specimens in a temperature-controlled environment until the concrete has reached the desired strength. Take the specimens out of the forms once the concrete has hardened adequately for the lifting hardware.

2. Testing the double-shear specimen

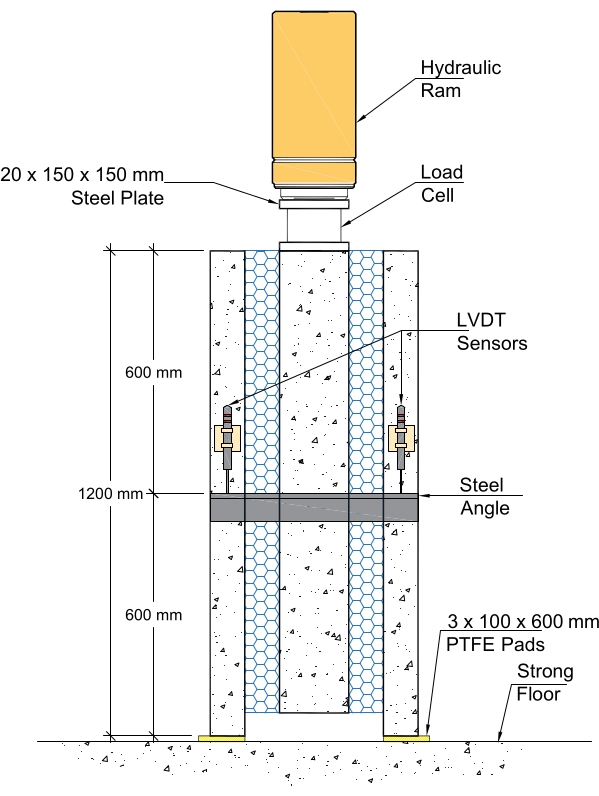

NOTE: Figure 6 shows a representative layout of the test specimen ready to be tested (ratchet strap not pictured).

- Take the specimen to the laboratory for sampling when the concrete used to fabricate the specimens has reached the desired strength.

NOTE: Compressive strength testing should follow ASTM C3922. The room temperature should remain relatively constant during the physical act of testing, with the temperature suggested to be 25 °C ± 5 °C, and during the testing and storing of the specimens. The testing temperature range is not intended to be rigorously controlled as the properties of the materials involved should not vary significantly with typical room temperatures. - Place two 3 mm x 100 mm x 600 mm polytetrafluoroethylene (PTFE) pad strips at the bottom of the outer concrete wythes to minimize friction during testing.

- Set the specimen under the loading frame with the middle concrete layer centered under the loading apparatus. Use a hydraulic ram or a large universal testing machine to apply loading at the top of the middle wythe, taking care to spread the load out with a bearing plate that is sufficiently large to prevent a bearing failure for the expected loads.

- Attach the steel angle to the middle wythe with a concrete or masonry screw. Create a separation of at least 5 mm between the steel angle and the concrete surface using steel or plastic washers to prevent the angle from otherwise interacting with the specimen (Figure 6).

- Attach the displacement sensors to the two exterior wythes, on opposite sides of the specimen (four in total), to measure the movement of the steel angle relative to their fixed position on the exterior wythe.

NOTE: The recommended displacement sensors are linear variable differential transducers or potentiometers. Sensors should always be stored in a dry case that is free of dust, moisture, and magnetic effects to prevent the loss of calibration. Analog dial gauges are not recommended. - Place a 50 mm wide nylon strap loosely around the upper part of the specimen to ensure that an unexpected brittle connector break will not cause any damage to the surroundings, including harming the technician and the sensors. Ensure that the strap is loose enough to not interfere with the specimen displacement, as shown in Figure 7.

NOTE: The strap will prevent the wythes from complete separation and facilitate the removal of the specimen after failure even if the wythes are no longer separated. However, this step (step 2.6) is optional. - Place the load cell centered on top of the middle wythe, sandwiched in between two 20 mm x 150 mm x 150 mm steel plates. Ensure that the steel plates do not overhang the center wythe so as not to interfere with the insulation during the deformation of the specimen.

- Plug the load and displacement sensors into the data acquisition system (DAQ).

- Start the data collection using a sampling rate of at least 10 Hz to ensure the load and displacement are recorded properly.

- Load the specimen in the center wythe until the maximum realistic displacement has been reached and the strength has dropped substantially; after 50% of the load has been lost, stopping the test is recommended, although this is arbitrary. If additional information along the descending branch is desired, use any desired deformation. Apply loading in a monotonic, quasi-static fashion that is fast enough that the connector and concrete creep does not interfere with the test results but not so fast that it can no longer be considered static, unless a high load rate is the testing variable of interest.

NOTE: This would indicate that the test should take in the order of 5 min to perhaps several hours. Adequate results have been found using a hydraulic hand pump with a test duration in the order of 5-10 min. - Stop the data acquisition and retract the load application apparatus to the original position.

- Remove all the sensors and store them in a safe place, as indicated above.

- Move the tested specimen to a clean area and separate the three concrete layers to identify the type of failure: concrete breakout, connector shear failure, or other. Record the failure mode, the quality of the insulation bond, and any other pertinent visual information. Remember to take photographs.

3. Analyzing the data and reporting the results

NOTE: This section describes the data analysis to assess several engineering properties that have been used in the literature. Other engineering properties may be of interest, and the data's usefulness is not limited to the properties below.

- Transfer the data files resulting from testing from the DAQ to the computer/folder where the data analysis is performed.

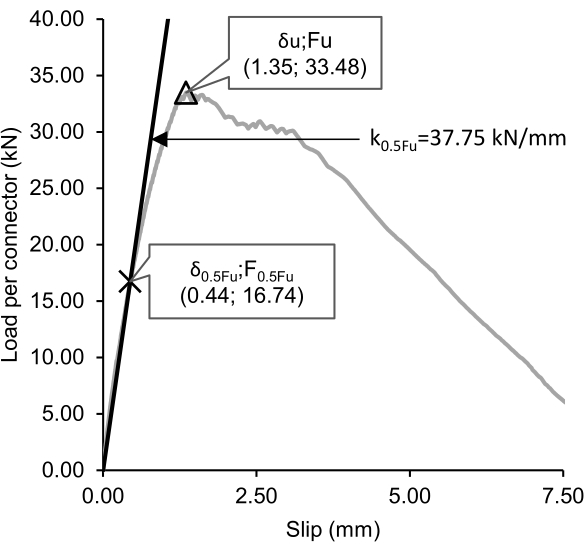

- Plot the average of the four displacement sensors on the abscissa with the connector load on the ordinate (defined as the measured load divided by the number of connectors).

NOTE: The user of the experimental method must review the data for any faulty sensors or unreliable measurements prior to averaging and reporting them. - Find the maximum load and its corresponding displacement using the appropriate function of the data analysis software and store these values as Fu and δu, respectively.

- Divide the maximum load by 2 to obtain the half-maximum force, F0.5Fu, and find its corresponding displacement δ0.5.

- Find the elastic stiffness (K0.5Fu) of the connector by dividing the half-maximum force, F0.5Fu, by the displacement at the half-maximum force, δ0.5. If the F0.5Fu is not in the generally elastic portion of the test, select a lower load that is obviously in the region and report the number. If a lower value is used, be sure to document the fraction of Fu and the corresponding magnitude of force.

NOTE: Currently, the end of the K0.5Fu line is used by some designers as an upper limit for service forces in the connector. - Report the average results of five samples for each connector brand, type, or concrete strength sampled.

NOTE: The reported results are valid only for the specific combination of concrete wythe, insulation wythe, concrete strength, and connector selected.

Representative Results

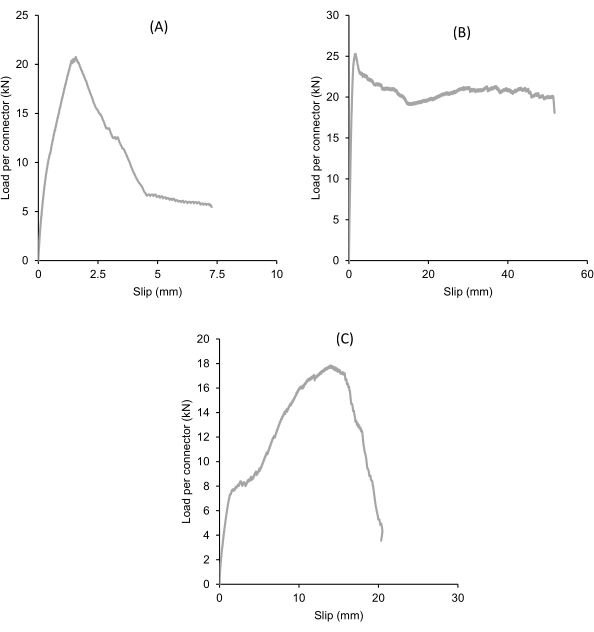

Figure 8 and Figure 9A show a typical load per connector versus the average displacement curve resulting from a double-shear test of a fiber-reinforced polymer (FRP) connector in the laboratory. As the figures depict, the load increases steadily up to the maximum point and then drops dramatically, which is typically observed in most testing involving polymers. However, as Figure 9B suggests, the curve flattens after the maximum load is reached if a ductile metallic connector is sampled, thus giving two possible outcomes for the load versus displacement plot: a ductile or a brittle failure (Figure 9A,B). Although some FRP connectors in the literature have exhibited certain ductility (Figure 9C), this is very small when compared to the connectors made of ductile metals. Data for Figure 8 are presented in Supplementary File 1. Data for each sub-figure in Figure 9 are presented in Supplementary File 2, Supplementary File 3, and Supplementary File 4.

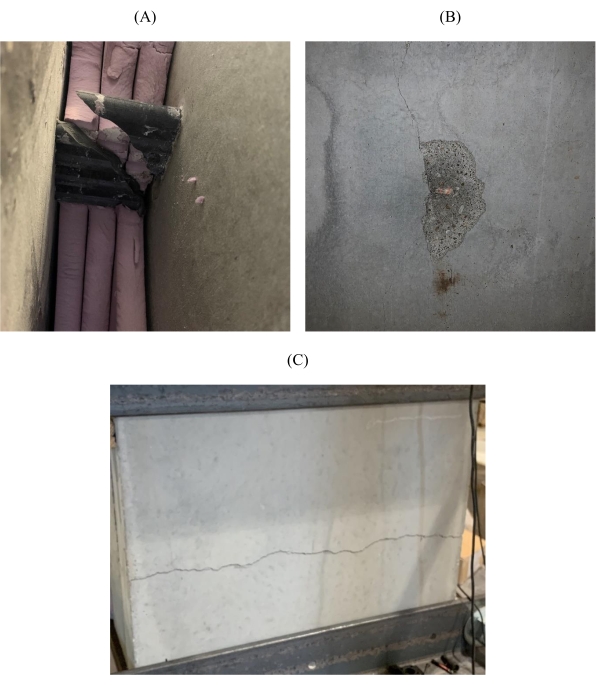

Figure 10 displays two possible failure modes that can occur in double-shear testing. The first and the most desirable is the failure of the connector, which solely involves a shear fracture without concrete spall. The second failure mode is a concrete breakout combined with a fracture of the connector, which could be indicative that the connector is too strong for the concrete thickness or that the concrete is not strong enough for the connector to reach the maximum strength. The final failure mode is a concrete tensile rupture on the outer wythe surfaces. This failure mode usually occurs when the connector is far from breaking but the tensile stress on the outer wythe exceeds that of the concrete.

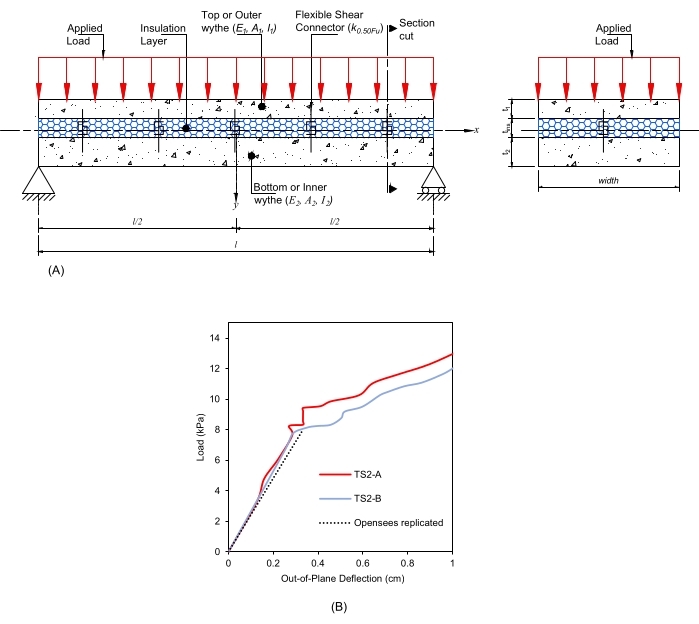

The testing data can be used in a finite element model that uses springs as the numerical connector analog23,24, or they can be used with other mechanics-based methods such as shear-flow calculations25,26,27. Such results have been copiously demonstrated in other papers cited above, but an example is reproduced in Figure 11 for the completeness of this work. It is important to mention that these results depend on other properties, such as the insulation type and thickness, the compressive strength of the concrete, and the depth of embedment of the connectors9. Therefore, the testing facility must conduct a test that closely matches the situation in which the connector will be employed, including all the variables mentioned above.

Figure 4: A typical specimen configuration as described herein. The specimen consists of three concrete layers and two insulation layers. Connectors penetrate the insulation layers. Nominal reinforcement is included in the concrete layers to prevent brittle failure in the case of cracking. A block-out is provided at the bottom to facilitate the wythe translation; however, this is optional. Please click here to view a larger version of this figure.

Figure 5: Specimen fabrication steps in the recommended position. These steps intentionally mimic the process of installing connectors in a production environment. The specimen is cast flat, with each layer installed in a successive manner. If this cannot be accomplished before the first set, it is permissible to wait at least 3 h before casting the next layer. See protocol section 1 on fabricating the testing specimen. Please click here to view a larger version of this figure.

Figure 6: Double-shear testing scheme. Instruments are placed on the non-visible face identically to those here. Abbreviations: LVDT = linear variable differential transformer; PTFE = polytetrafluoroethylene. Please click here to view a larger version of this figure.

Figure 7: Nylon strap placed around the specimen. Note that the straps are loose and only intended to prevent the specimen from falling after failure. The exaggerated pinching action is also exhibited in this photo. Please click here to view a larger version of this figure.

Figure 8: Plot of an FRP shear connector and the corresponding features. The calculation of the secant stiffness and the ultimate strength of the connector are identified. Abbreviation: FRP = fiber-reinforced polymer. Please click here to view a larger version of this figure.

Figure 9: Representative load per connector versus the slip response of three possible outcomes from the testing. (A) Brittle behavior, (B) ductile behavior, and (C) semi-ductile behavior. Please click here to view a larger version of this figure.

Figure 10: Documentation of the concrete or connector failure; sample photos of possible outcomes when testing connectors. (A) Connector failure shear rupture, (B) concrete punch-through, and (C) concrete flexural failure with or without connector rupture. Please click here to view a larger version of this figure.

Figure 11: A finite element model using beam and spring elastic elements, including the results from the double shear tests. (A) Model composition, and (B) comparison of the elastic model results with a large-scale test from Naito et al.28. Please click here to view a larger version of this figure.

Supplementary File 1: "Fig 8 Data.xlsx" presents the data shown in Figure 8 as collected. Column A contains the time stamp. Columns B, C, D, and E are each of the four LVDT readings. Column F is the load cell reading. Columns G, H, I, and J are the zeroed LVDT readings. Column K is the zeroed load cell reading. Column L is the average LVDT reading of each of the G, H, I, and J columns. The plot is reproduced in this file as well. Please click here to download this File.

Supplementary File 2: "Fig 9A Data.xlsx" presents the data shown in Figure 9A as collected. Column A contains the time stamp. Columns B, C, D, and E are each of the four LVDT readings. Column F is the load cell reading. Columns G, H, I, and J are the zeroed LVDT readings. Column K is the zeroed load cell reading. Column L is the average LVDT reading of each of the G, H, I, and J columns. The plot is reproduced in this file as well. Please click here to download this File.

Supplementary File 3: "Fig 9B Data.xlsx" presents the data shown in Figure 9B as collected. Column A contains the time stamp. Columns B, C, D, and E are each of the four LVDT readings. Column F is the load cell reading. Columns G, H, I, and J are the zeroed LVDT readings. Column K is the zeroed load cell reading. Column L is the average LVDT reading of each of the G, H, I, and J columns. The plot is reproduced in this file as well. Please click here to download this File.

Supplementary File 4: "Fig 9C Data.xlsx" presents the data shown in Figure 9C as collected. Column A contains the time stamp. Columns B, C, D, and E are each of the four LVDT readings. Column F is the load cell reading. Columns G, H, I, and J are the zeroed LVDT readings. Column K is the zeroed load cell reading. Column L is the average LVDT reading of each of the G, H, I, and J columns. The plot is reproduced in this file as well. Please click here to download this File.

Discussion

Many researchers have used some variation of this type of test for ICSWP, but this is the first instance of outlining all the individual steps. The literature does not address the critical steps in testing, including sensor types and specimen handling. This method describes a manner of testing that mimics more closely the behavior of the connectors when a panel is loaded in flexure as opposed to the single-shear test. There are several variables for this work that are yet to be studied. Specifically, information related to the boundary conditions is not well known but could affect the test. Similarly, the tolerance on load placement could be important, as could the load application rate. Based on the mechanics for the double-shear specimen outlined elsewhere10,14, the critical variable is the length of the specimen.

While seemingly adequate results have been shown for specimens that are 1,200 mm tall, and although several researchers have tried many different lengths, the optimum length is not known. Anecdotally, the authors have found pinching behavior at lengths lower than this 1,200 mm specimen, which was demonstrated previously14. It is not known whether choosing greater lengths will make any significant difference. Transverse dimensions are not thought to affect the testing, unless edge effects or interaction between the connectors are noted. The recommendations presented here should not create edge effects or interaction between the connectors based on the embedment dimensions for commercial connectors. Care should be taken to eliminate this effect if individual connector behavior is the goal or if understanding these effects through the closer spacing of connectors is the goal.

Additionally, the effect of cracking of the specimen (near to the connectors or otherwise) is not known. The authors have tested several specimens that have arrived cracked. In some cases, the cracks seemed to affect the test, while in others, they did not. Future work should strive to better understand this. The International Code Council (ICC) testing protocols stipulate uncracked specimens5. Clearly, in-service ICSWPs crack for various reasons. It is important to understand if this affects connector behavior at the double-shear level and at the in-service level. Future testing programs could perform such testing.

Different failure modes have been observed in the literature, but either the concrete or the connector will fail. Some connectors rely on the bond of the concrete to the insulation. In these instances, it is imperative that a good bond with fresh concrete be achieved, though there is usually little guidance for this. The concrete failures observed in the literature include concrete breakout29, where the connectors pull out of the concrete, and concrete punch-through19, where the connector pushes through the concrete face. Connector failures can be highly variable and generally consist of brittle shear rupture, tensile rupture, tensile laminar tearing, and plastic flexural hinging10,29. Connector failure should be documented, particularly if the failures are inconsistent between specimens of the same type. The insulation bond condition should be noted with photographs and written descriptions in cases where the insulation is intentionally bonded to the concrete.

Though it was mentioned above, it deserves additional discussion that the wythe thickness, concrete strength, insulation type, and connector geometry tested in any given test are only applicable to that specific combination. If thinner concrete wythes are used, there could be a punch-through failure19 of the wythes that may not be represented in the double-shear test. If a different insulation density or type is used for connector systems that rely on the insulation for some load transfer, the apparent mechanical behavior of the double-shear specimen would be different. The insulation layer thickness and connector geometry likely play the largest roles, but the intention of this test is to identify the system behavior (concrete, insulation, and wythe connector acting together) and, ultimately, extend that to full-scale behavior, design, or analysis.

The precision and bias of this test are not known, nor has there been any interlaboratory round-robin study to address this. The authors believe this should be done as this test is strongly needed within the industry for quality-control purposes and the development of an ICSWP testing standard. A rigorous ruggedness study30 considering the factors mentioned above or others factors should also be undertaken.

The authors make several recommendations for a successful test. Once a test has begun, the test should not be stopped, as this could result in an unknown amount of permanent damage to the connector, resulting in a restart providing incorrect data. All specimen defects should be properly noted prior to and following the test. A thorough sensor check should be performed prior to testing. A malfunctioning (i.e., not reading) displacement sensor may create artifacts in the average sensor reading used for the backbone curve.

Proper personal protective equipment is paramount because this test can involve significant load and brittle failure. The recommended safety equipment includes steel-toed boots and, possibly, metatarsal protectors, a hard hat, eye protection, gloves, long durable pants, and ear protection. Care should be taken not to stand too close to the specimen as a brittle failure can cause the load cell and plate assembly to fall at an angle from the specimen. Unexpected failure can occur for several reasons, including brittle connectors, improperly installed connectors, or improper load placement, resulting in a bearing failure.

There are no known limitations to the technique, but shorter specimens are likely to produce conservative estimates of strength and stiffness for the reasons outlined in the introduction. However, with more widespread use, the limitations may become apparent. The future applications for this method include studying additional parameters such as the load rate dependence, cyclic behavior, and creep behavior of flexible wythe connectors.

DATA AVAILABILITY:

All data underlying the results of this study are available in their original file format as part of this manuscript. Supplementary files are uploaded for the data contained in Figure 8 and Figure 9A–C. These files are labeled with the corresponding figure number in .xlsx format.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The work described above was not directly financed by a single organization or over the course of a single grant, but the information was gathered over years of industry-sponsored research. To that end, the authors thank their sponsors from over the last decade and are grateful to work in a rapidly evolving industry.

Materials

| Battery-powered Drill | |||

| Concrete Screws | 50 mm long commercial concrete scews. | ||

| Data Logger | Capable of sampling at a frequency of at least 10 Hz. | ||

| Double Shear Test Specimen | Fabricated according to the dimmensions in the testing protocol. | ||

| Four Linear Variable Displacement Transformer | With at least 25 mm range for Fiber-reinforced Polymer (FRP) connectors and 50 mm for ductile steel connectors. | ||

| Hydraulic Actuator | With at least 50-Ton capacity. | ||

| Lifting anchors rated at 1 Ton | |||

| Load Cell | With at least 50-Ton capacity. | ||

| Load Frame | Capable of resisting the forces generated by the testing specimen. | ||

| Polytetrafluoroethylene (PTFE) Pads | 3 mm x 100 mm x 600 mm | ||

| Ratchet Strap | At least 50 mm wide. | ||

| Steel angle | |||

| Steel Plate | Two 20 mm x 150 mm x 150 mm steel plates. | ||

| Steel Washers | Capable of producing a separation of at least 5 mm between the steel angle and the specimen. |

References

- Collins, T. F. Precast concrete sandwich panels for tilt-up construction. Journal of the American Concrete Institute. 50 (2), 149-164 (1954).

- Luebke, J. . Out-of-plane behavior of concrete insulated wall panels with 2-inch, 8-inch, and 10-inch insulation. , (2021).

- Einea, A., Salmon, D. C., Tadros, M. K., Culp, T. A new structurally and thermally efficient precast sandwich panel system. PCI journal. 39 (4), 90-101 (1994).

- Frankl, B., Lucier, G., Rizkalla, S., Blaszak, G., Harmon, T. Structural behavior of insulated prestressed concrete sandwich panels reinforced with FRP grid. Proceedings of the Fourth International Conference on FRP Composites in Civil Engineering (CICE2008). 2224, (2008).

- Naito, C., Hoemann, J., Beacraft, M., Bewick, B. Performance and characterization of shear ties for use in insulated precast concrete sandwich wall panels. Journal of Structural Engineering. 138 (1), 52-61 (2012).

- Tomlinson, D. . Behaviour of partially composite precast concrete sandwich panels under flexural and axial loads. , (2015).

- . AC320 – Fiber-reinforced Polymer Composite or Unreinforced Polymer Connectors Anchored in Concrete Available from: https://shop.iccsafe.org/es-acceptance-criteria/ac320-fiber-reinforced-polymer-composite-or-unreinforced-polymer-connectors-anchored-in-concrete-approved-oct-2015-editorially-revised-sept-2017-pdf-download.html (2015)

- . Developing a General Methodology for Evaluating Composite Action in Insulated Wall Panels. Report to PCI. Precast/Prestressed Concrete Institute Available from: https://digitalcommons.usu.edu/cee_facpub/3531 (2017)

- Gombeda, M. J., Naito, C. J., Quiel, S. E. Development and performance of a ductile shear tie for precast concrete insulated wall panels. Journal of Building Engineering. 28, 101084 (2020).

- Kinnane, O., West, R., Grimes, M., Grimes, J. Shear capacity of insulated precast concrete façade panels. CERI 2014 – Civil Engineering Research in Ireland. , (2014).

- Jiang, H., Guo, Z., Liu, J., Liu, H. The shear behavior of precast concrete sandwich panels with W-shaped SGFRP shear connectors. KSCE Journal of Civil Engineering. 22 (10), 3961-3971 (2018).

- ASTM International. Standard test methods for strength of anchors in concrete elements. ASTM. , (2022).

- Syndergaard, P., Tawadrous, R., Al-Rubaye, S., Maguire, M. Comparing testing methods of partially composite sandwich wall panel glass fiber-reinforced polymer connectors. Journal of Composites for Construction. 26 (1), (2022).

- Woltman, G., Tomlinson, D., Fam, A. Investigation of various GFRP shear connectors for insulated precast concrete sandwich wall panels. Journal of Composites for Construction. 17 (5), 711-721 (2013).

- Olsen, J., Maguire, M. Pushoff shear testing of composite sandwich panel connectors. 2016 PCI Convention and National Bridge Conference. , (2016).

- Gombeda, M. J., Naito, C. J., Quiel, S. E. Flexural performance of precast concrete insulated wall panels with various configurations of ductile shear ties. Journal of Building Engineering. 33, 101574 (2021).

- Bai, F., Davidson, J. S. Composite beam theory for pretensioned concrete structures with solutions to transfer length and immediate prestress losses. Engineering Structures. 126, 739-758 (2016).

- Cox, B., et al. Lumped GFRP star connector system for partial composite action in insulated precast concrete sandwich panels. Composite Structures. 229, 111465 (2019).

- Pozo, F. . On thermal bowing of concrete sandwich wall panels with flexible shear connectors. , (2018).

- ASTM International. Standard practice for making and curing concrete test specimens in the field. ASTM International. , (2019).

- ASTM International. Standard test method for compressive strength of cylindrical concrete specimens. ASTM International. , (2018).

- Pozo-Lora, F., Maguire, M. Thermal bowing of concrete sandwich panels with flexible shear connectors. Journal of Building Engineering. 29, 101124 (2020).

- Al-Rubaye, S., Sorensen, T., Thomas, R. J., Maguire, M. Generalized beam-spring model for predicting elastic behavior of partially composite concrete sandwich wall panels. Engineering Structures. 198, 109533 (2019).

- Losch, E. D., et al. State of the art of precast/prestressed concrete sandwich wall panels. PCI Journal. 56 (2), 131-176 (2011).

- Al-Rubaye, S., Sorensen, T., Maguire, M. Iterative and simplified sandwich beam theory for partially composite concrete sandwich wall panels. Journal of Structural Engineering. 147 (10), 4021143 (2021).

- Holmberg, A., Plem, E. Behaviour of Load-bearing Sandwich-type Structures. The National Swedish Institute for Building Research. , (1965).

- Naito, C. J., et al. Precast/prestressed concrete experiments performance on non-load bearing sandwich wall panels. Air Force Research Laboratory. Materials and Manufacturing Directorate. , (2011).

- Al-Rubaye, S., Sorensen, T., Olsen, J., Maguire, M. Evaluating elastic behavior for partially composite precast concrete sandwich wall panels. PCI Journal. 63 (5), 71-88 (2018).

- ASTM International. Standard practice for conducting ruggedness tests. ASTM International. , 1169-1121 (2021).