A Fabrication Method for Highly Stretchable Conductors with Silver Nanowires

Summary

A simple synthesis method is used to chemically solder silver nanowire thin film to fabricate highly stretchable and conductive metal conductors.

Abstract

Stretchable electronics are identified as a key technology for electronic applications in the next generation. One of the challenges in fabrication of stretchable electronic devices is the preparation of stretchable conductors with great mechanical stability. In this study, we developed a simple fabrication method to chemically solder the contact points between silver nanowire (AgNW) networks. AgNW nanomesh was first deposited on a glass slide via spray coating method. A reactive ink composed of silver nanoparticle (AgNPs) precursors was applied over the spray coated AgNW thin films. After heating for 40 min, AgNPs were preferentially generated over the nanowire junctions to solder the AgNW nanomesh, and reinforced the conducting network. The chemically modified AgNW thin film was then transferred to polyurethane (PU) substrates by casting method. The soldered AgNW thin films on PU exhibited no obvious change in electrical conductivity under stretching or rolling process with elongation strains up to 120%.

Introduction

Deformable electronic devices with large stretchability have been identified as critical parts to the realization of wearable and portable electronics in the next generation.1 Those stretchable electronic devices not only show great flexibility as those electronic devices on plastic sheets,2, 3 but also exhibit excellent performance under severe stretching or twisting conditions.4 To realize the stretchable electronics, materials with great electric performance under large deformation is needed. Recent advancements in material sciences have shown the possibility to synthesize such functional materials and have used them to design stretchable optoelectronic devices 5-9 with great tolerance to complex shape deformations. Among all the electronic functional materials, stretchable conductors are necessary to supply electrical power to those optoelectronic devices and thus are of critical importance for device performance. Because regular conducting materials, like metal or indium tin oxide, lack of mechanical robustness under large deformation, interconnects made of these materials are unable to exhibit good electrical conductivity under stretching process. Thus, elastic substrates covered with a thin layer of flexible conductive materials, such as carbon nanotube,1 graphene,10 or AgNWs,11-14 are designed for conductors with excellent stretchability. Because of the high bulk conductivity, AgNW thin films have been shown to be the most promising material for composite stretchable conductors.13 The percolating networks of AgNW thin films can effectively accommodate large elastic deformations in stretching process with great electrical conductance, and are considered as a promising stretchable electrode candidate. To implement AgNW thin films as stretchable conductors, it is necessary to have effective electrical contacts between AgNWs. After liquid deposition and drying on substrate surfaces, AgNWs regularly stack together to form a percolating mesh with loose contact points, which yield in large electrical resistances. Thus, one needs to anneal the contacts between nanowires by high-temperature or high-pressure annealing methods15-20 to reduce the contact resistances.

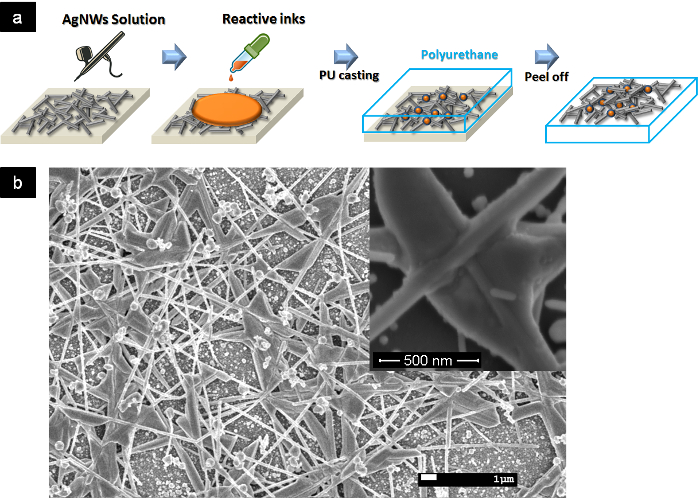

In contrast to these annealing processes in the literature, here, we will demonstrate a simple chemical method to anneal AgNW network connections under regular laboratory conditions.21 The fabrication process is shown in Figure 4A. A reactive ink is used to sinter the spray coated AgNW thin films on a glass plate. After reaction, the contacts between nanowires are covered with silver and hence the AgNW network is soldered chemically together. A cast-and-peel method is then used to transfer the soldered AgNW network to a stretchable PU substrate to form a composite conductor, which can exhibit no obvious change in electrical conductivity even at large tensile strain of 120%.

Protocol

1. Preparation of Silver Precursor Ink

- Add 1.85 g of diethanolamine (DEA) in 3.15 ml deionized water.

- Dissolve 0.15 g of silver nitrate in 5 ml deionized water.

- Mix the aqueous silver nitrate solution with DEA at a 1:1 volume ratio to have 10 ml silver precursor ink right before use.

2. Fabrication of Stretchable Conductive Thin Films

- Preparation of AgNW ink

- Dilute 2 ml of 0.5 wt% AgNWs in isopropanol with 18 ml deionized water.

- Place it in ultrasonic bath for 30 sec at 25 °C.

- Fabrication of AgNW thin films by auto-spray coating

- Cut standard microscope slides into pieces of size equal to 1×2.5 cm2. Prepare 16 glass pieces of this size and clean them with ethanol-wetted lens cleaning tissue.

- Transfer 16 ml AgNW ink (from section 1) into the paint cup of the airbrush with a pipette. Mount the airbrush on a computer-controlled robot for spray coating.

- Place 8 of glass pieces in a 4×2 arrangement on the stage and fix them with heat-resistant tapes. The total area of all glass substrates on the stage is 4×5 cm2.

- Set working pressure and heating stage temperature at 3 bar and 100 °C, separately.

- Open the robot control software. Click to select brush motion command sequence under the "Command" column. Type in necessary input parameters to complete the auto-spraying program as shown in Figure 1. Run the program.

Note: The "Line Speed" command makes the airbrush travel at 200 mm/sec. By the "Brush Area" command, the airbrush moves back and forth in the direction of the short side of the glass substrate array while the stage moves along the direction of the long side and the space between two strokes is 5 mm. The "Line Start" and "Line End" commands determine the positions of starting and end points of the auto-spraying operation. The positions of them depend on the position of the glass substrate array on the stage. The "Wait Point" command sets a waiting time of 20 sec in the end of each auto-spraying cycle. "Loop Address" command enables multiple spray cycles and the number of auto-spraying cycles is 15 times. More detailed instruction of the commands can be found in the manufacturer's protocol. - Change the number of auto-spraying cycles into 30 times. Repeat steps 2.2.3 – 2.2.5 to fabricate AgNW thin films of 30 spraying cycles.

- After spray coating, bake silver nanowire thin films on a hot plate at 120 °C for 10 min.

- Chemical soldering process

- Cast 400 μl of silver precursor ink over each spray-coated silver nanowire thin film on the glass substrate.

- Bake the films on a hot plate at 100 °C for 40 min.

- Rinse the reactive coatings carefully with deionized water to remove unreactive chemical residues and air-dry the coated films.

- Cast-peeling process

- Cast 200 μl commercially available water-based PU emulsion over each silver nano-composite thin film on the glass substrate.

- Air-dry the films for 10 hr to ensure full solidification.

- Peel off the samples from the glass substrates as free standing composite films.

3. Characterization

- Stretching test

- Turn on the linear motorized stage and wait 10 min for the machine to warm up.

- Open the stage control software. Set the number of the moving steps of the motor as 8,000. Click "X+" in the stage control software to move the mobile stage until it touches the fixed stage and click "SET 0" to set the position of the mobile stage as zero in the stage control software.

Note: The mobile stage moves 0.00125 mm in one step of the motor. For example, the mobile stage moves 1 cm if the motor moves 8,000 steps. The plus sign of "X+" means that the mobile stage moves in the direction of approaching fixed stage while the negative sign of "X-" means moving away from the fixed stage. - Click "X-" to move the mobile stage to leave 1 cm space between the mobile and fixed stage. Secure both ends of the sample with wired holders onto the stages. Thereby, the stretching area of the sample is 1×1 cm2. The setup of stretching machine is shown in Figure 2.

- Use the alligator clips, which are the other ends of the wiring cables to the stage holders (Figure 2), to connect to the digital multimeter for resistance measurements.

- Set the number of the moving steps of the motor as 800. Click "X-" to move the mobile stage 1 mm (10% strain) away from the fixed stage to stretch the sample and record the resistance. Repeat this step until the resistance increases significantly (~150% strain).

- Stability test

- Prepare the test as in steps 3.1.2 – 3.1.4.

- Open the digital multimeter software. Connect the digital multimeter to the computer. Long press the "REL Δ" button on the digital multimeter until a computer icon appears in the upper left corner of the digital multimeter monitor. Click "USB connection" in the digital multimeter software and the software starts to record measured resistances.

- Enter commands into the input fields in the program panel of the stage control software as shown in Figure 3. The command ":U-4000" means to move the mobile stage 4,000 steps away from the fixed stage while the command ":U4000" means to move the mobile stage 4,000 steps back to the fixed stage (4,000 for 50% strain, 8,000 for 100% strain). The number of stretching cycles is 15 times. The default speed of the mobile stage is 1 mm/sec.

- Click "Run 123" in the program panel of the stage control software to execute the automatic program. The mobile stage moves in a reciprocating motion to stretch the sample with elongation cycles of triangular waveform.

- Click the save icon in the multimeter software and export the data of the resistance response profiles as an .xls file.

- LED lighting test

- Prepare the test as in steps 3.1.2 – 3.1.3. Connect the wired holders in series with a LED and a power supply.

- Turn on the power supply. Increase the voltage to 9 V to light the LED.

- Click "X-" to move the mobile stage 1 mm (10% strain) away from the fixed stage to stretch the sample and take a picture to record the brightness of the LED. Repeat this step until the light of LED becomes dim. Be careful that the auto-exposure of the camera should be turned off while taking pictures.

Representative Results

The morphology of the AgNW thin film after chemical soldering process is shown in Figure 4B. Recovered AgNPs preferentially grow on the surface of AgNWs and wrap over the wire/wire junctions. Figure 5 shows the variation in sheet resistance with applied elongation strains for the unsoldered and the soldered thin films containing different amount of AgNWs. After the chemical soldering process, AgNW thin film conductors can maintain high conductivity under high strain conditions, regardless of the sprayed amount of AgNWs. Both soldered AgNW thin films show sheet resistance below 100 Ω/sq when strains below 120% are applied. The composite stretchable conducting thin films show great mechanical stability in dynamic deformation process. Figure 6 shows the resistance variations of the stretchable conductor under elongation cycles of a triangular waveform at a fast strain rate of 0.05 sec-1. No obvious resistance change is observed with a strain amplitude of 50%. When the strain amplitude increases to 100% strain, the peak resistance increases with the number of the pulsation cycles, and the resistance of the film returns to the original value after the pulsation stops. Figure 7 demonstrates an electronic application of the chemically soldered thin films.

Figure 1. Screenshot of the robot control software. Please click here to view a larger version of this figure.

Figure 2. Stretching machine configuration. Please click here to view a larger version of this figure.

Figure 3. Screenshot of the stage control software. Please click here to view a larger version of this figure.

Figure 4. Schematic diagram of fabrication process for the highly stretchable and conductive metal conductors. (A) The samples are prepared as indicated in the figure. (B) SEM images of chemical-soldered AgNW thin film before being transferred to PU substrate. Please click here to view a larger version of this figure.

Figure 5. Stretching test. Comparison of electric resistances of unsoldered and soldered AgNW thin films with various sprayed AgNW amounts under stretching conditions. Please click here to view a larger version of this figure.

Figure 6. Stability test. Resistance response profiles of stretching films under elongation cycles of triangular waveform. The pulsating strain rate is 10 sec-1. The tested sample is made from AgNW thin films with 15 spraying cycles. Please click here to view a larger version of this figure.

Figure 7. Video of LED light connected with a stretchable conductor under various strain conditions. The brightness change of LED caused by the stretched conductor is shown in the figure. The testing sample is made from AgNW thin films with 15 spraying cycles. (Right click to download)

Discussion

The chemical soldering process can help reinforce the contact between silver nanowires. As shown in Figure 4b, the wire/wire junctions are covered with silver after applying the reactive silver ink over the spray coated AgNW thin film. The silver recovery relies strongly on the formaldehyde generated from DEA degradation, and thus the soldering process or silver reduction can be accelerated with increasing temperature.22 Because the metal surfaces of AgNWs provide effective electron exchange sites, silver nanoparticles are preferentially reduced along the AgNW surfaces, and wrap over the wire-wire junctions to form amalgamated contacts. This chemical soldering process, however, needs a rinsing process to remove the excessive reactive solutions afterwards. One needs to rinse the solder AgNW thin films slowly and carefully due to the low adhesion between AgNWs and glass before drying. After rinsing and drying, the AgNW thin films can be easily transferred to PU by the cast-and-peel method. With a mold or spacer on top of the glass, one can also easily adjust the thickness of the PU layers in the composite stretchable conductors.

The composite stretchable conductors show great electrical conductivity at high strain conditions regardless of the amounts of spray coated AgNWs. As a result of the firmly joined nanowire contacts, the AgNW network remains intact under stretching conditions and provide great electron transfer paths. As shown in Figure 5, the sheet resistances of unsoldered stretchable conductors increase rapidly as the applied strains increase because the elongation of the conductors leads to the dislocation of the unsoldered wire-wire junctions and reduce the conductive paths of AgNW network. On the other hand, the sheet resistances of soldered stretchable conductors remain as low as ~100 Ω/sq at a large strain of 120%, indicating that reduced silver nanoparticles do anneal the contacts between AgNWs and enhance the connectivity of AgNWs to prevent the dislocation of the AgNW mesh. Once an effective percolating AgNW network is formed, the composite stretchable conductors can exhibit high conductivity regardless of deposited AgNW amounts. As evidenced in the resistance-strain curves in Figure 5, the stretchable conductor with half AgNW amount (15 vs. 30 spraying cycles) shows virtually the same electrical conductivity under stretching process, indicating that the amount of AgNWs has negligible effects on conductivity after chemical soldering. As a result, an even lower AgNW amount can be used as long as the initial spray coated AgNW thin films are conductive before the chemical soldering process.

The stretchable conductors show fairly good mechanical stability even under large dynamic strains with fast stretching rates. As shown in Figure 6, the soldered AgNW mesh network remain intact when one applies a triangular elongation cycles with a large strain of 50% deformation. Thus, the electrical resistance of the stretchable conductor remains nearly unchanged with a very small variation of ~5 Ω/sq, which is consistent with the resistance change (~4 Ω/sq) under a static strain of 50%. However, when an even large strain amplitude (100%) is applied, large resistance variation is observed, indicating structural changes in the AgNW network integrity in the pulsating process. The dynamic resistance variation is much larger than that in static stretching. Compared with the data in Figure 5, the static resistance is about 25 Ω/sq at 100% strain while the dynamic resistance is 90 Ω/sq at first peak and increases up to 400 Ω/sq in the dynamic pulsation. At the large strain of 100%, the sample cannot sustain the dynamic stress and some structure of the soldered Ag nanowire network may be damaged, leading to the inconsistency between the sheet resistance under static and dynamic strains. Moreover, while stretching direction reverses, where peak resistance occurs, an instantaneous large velocity acceleration is applied by the mobile stage and can lead to further structural damages, which reflect in the increases in the dynamic peak resistances. Besides, parts of the difference in the static and dynamic resistances may come from possible temporary dislocations between AgNWs and the PU substrates under dynamic strains. Those dislocation can be restored, as evidenced by the fact that the resistance returns to the original value after the pulsation stops. Thus, to avoid resistance variation, one needs to be carefully evaluate the adhesion and mechanical compatibility between AgNW mesh and the elastic substrates.

The stretchable conductors can serve directly as an ideal elastic interconnects in many electronic applications. Figure 7 shows the dynamic observation when a stretchable conductor is connected with a LED in series. When supplied with a constant voltage, the brightness of the LED light remains almost unchanged even with a strain up to 110%. This synthesized composite stretchable conductor can be easily applied in any electrical devices as elastic conductive tracks. However, to further implementation in real electrical devices, one needs miniaturized electrode patterns for complete circuitry. Thus, more research on creating stretchable circuits with printing techniques is still underway.

In summary, this work presents a simple method to fabricate highly stretchable conductors at low temperatures. The chemically soldered AgNW networks on PU can accommodate substantial elastic strains and exhibit excellent electrical conductivity as well as mechanical stability in stretching process. Moreover, the chemically soldered conductors show nearly identical electric and mechanical performances regardless of the amount of AgNWs, indicating a possible reduction in material waste. We believe that this stretchable conductor material can directly serve as effective interconnects in wearable and stretchable optoelectronic devices, such as LED and solar cells, for the next generation electronics.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors are grateful for the financial support from Ministry of Science and Technology.

Materials

| Silver nanowire | Sigma-Aldrich | 778095-25ML | AgNW, 120 nm in diameter and 20-50 mm in length, 0.5 wt% in IPA |

| Silver nitrate crystal | Macron Fine Chemicals | MK216903 | |

| Diethanolamine | Sigma-Aldrich | D8885-500G | |

| Polyurethane emulsion | First Chemical | 20130326036 | 35 wt% water-based anionic polyester-polyurethane emulsion |

| Airbrush | Taiwan Airbrush & Equipment | AFC-sensor | |

| Desktop robot | Dispenser Tech | DT-200 | |

| Digital dispenser controller | Dispenser Tech | 9000E | |

| Auto-spraying program | Dispenser Tech | Smart robot edit version 3.0.0.5 | |

| Air compressor | PUMA Industrial | NCS-10 | |

| Linear motorized stage | TANLIAN E-O | Customized | |

| Stage control software | TANLIAN E-O | Customized | |

| Digital multimeter | HILA INTERNATIONAL | DM-2690TU | |

| Digital multimeter software | HILA INTERNATIONAL | NA | |

| Power supply | CHERN TAIH | CT-605 | |

| LED | PChome | M08330766 | http://www.pcstore.com.tw/sun-flower/M08330766.htm |

References

- Rogers, J. A., Someya, T., Huang, Y. Materials and mechanics for stretchable electronics. Science. 327 (5973), 1603-1607 (2010).

- Mazzeo, A. D., et al. Paper-based, capacitive touch pads. Adv. Mater. 24 (21), 2850-2856 (2012).

- Yang, C., et al. Silver nanowires: from scalable synthesis to recyclable foldable electronics. Adv. Mater. 23 (27), 3052-3056 (2011).

- Sekitani, T., Someya, T. Stretchable, Large-area Organic Electronics. Adv. Mater. 22 (20), 2228-2246 (2010).

- Lipomi, D. J., Tee, B. C., Vosgueritchian, M., Bao, Z. Stretchable organic solar cells. Adv. Mater. 23 (15), 1771-1775 (2011).

- Liang, J., Li, L., Niu, X., Yu, Z., Pei, Q. Elastomeric polymer light-emitting devices and displays. Nat. Photonics. 7 (10), 817-824 (2013).

- White, M. S., et al. Ultrathin, highly flexible and stretchable PLEDs. Nat. Photonics. 7 (10), 811-816 (2013).

- Chang, I., et al. Performance enhancement in bendable fuel cell using highly conductive Ag nanowires. Int. J. Hydrogen Energ. 39 (14), 7422-7427 (2014).

- Yan, C. Y., et al. An Intrinsically Stretchable Nanowire Photodetector with a Fully Embedded Structure. Adv. Mater. 26 (6), 943-950 (2014).

- Lee, M. S., et al. High-performance, transparent, and stretchable electrodes using graphene-metal nanowire hybrid structures. Nano Lett. 13 (6), 2814-2821 (2013).

- Xu, F., Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 24 (37), 5117-5122 (2012).

- Yun, S., Niu, X., Yu, Z., Hu, W., Brochu, P., Pei, Q. Compliant silver nanowire-polymer composite electrodes for bistable large strain actuation. Adv. Mater. 24 (10), 1321-1327 (2012).

- Lee, P., et al. Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv. Mater. 24 (25), 3326-3332 (2012).

- Akter, T., Kim, W. S. Reversibly Stretchable Transparent Conductive Coatings of Spray-Deposited Silver Nanowires. ACS Appl. Mater. Interfaces. 4 (4), 1855-1859 (2012).

- Madaria, A., Kumar, A., Ishikawa, F., Zhou, C. Uniform, highly conductive, and patterned transparent films of a percolating silver nanowire network on rigid and flexible substrates using a dry transfer technique. Nano Res. 3 (8), 564-573 (2010).

- Lee, J., et al. Room-Temperature Nanosoldering of a Very Long Metal Nanowire Network by Conducting-Polymer-Assisted Joining for a Flexible Touch-Panel Application. Adv. Funct. Mater. 23 (34), 4171-4176 (2013).

- Tokuno, T., et al. Fabrication of silver nanowire transparent electrodes at room temperature. Nano Res. 4 (12), 1215-1222 (2011).

- Garnett, E. C., et al. Self-limited plasmonic welding of silver nanowire junctions. Nat. Mater. 11 (3), 241-249 (2012).

- Zhu, S., et al. Transferable self-welding silver nanowire network as high performance transparent flexible electrode. Nanotechnology. 24 (10), 1321-1327 (2013).

- Han, S., et al. Fast Plasmonic Laser Nanowelding for a Cu-Nanowire Percolation Network for Flexible Transparent Conductors and Stretchable Electronics. Adv. Mater. 26 (33), 5808-5814 (2014).

- Chen, S. P., Liao, Y. C. Highly stretchable and conductive silver nanowire thin films formed by soldering nanomesh junctions. Phys. Chem. Chem. Phys. 16 (37), 19856-19860 (2014).

- Chen, S. P., Kao, Z. K., Lin, J. L., Liao, Y. C. Silver conductive features on flexible substrates from a thermally accelerated chain reaction at low sintering temperatures. ACS Appl. Mater. Interfaces. 4 (12), 7064-7068 (2012).