How to Build a Vacuum Spring-transport Package for Spinning Rotor Gauges

Summary

Here we describe how to build a robust spring-transport mechanism for a spinning rotor gauge. This device securely immobilizes the rotor and keeps it under vacuum during transportation. We also describe packaging that minimizes the risk of damage during transport. Tests show our design works for typical shocks during transport.

Abstract

The spinning rotor gauge (SRG) is a high-vacuum gauge often used as a secondary or transfer standard for vacuum pressures in the range of 1.0 x 10-4 Pa to 1.0 Pa. In this application, the SRGs are frequently transported to laboratories for calibration. Events can occur during transportation that change the rotor surface conditions, thus changing the calibration factor. To assure calibration stability, a spring-transport mechanism is often used to immobilize the rotor and keep it under vacuum during transport. It is also important to transport the spring-transport mechanism using packaging designed to minimize the risk of damage during shipping. In this manuscript, a detailed description is given on how to build a robust spring-transport mechanism and shipping container. Together these form a spring-transport package. The spring-transport package design was tested using drop-tests and the performance was found to be excellent. The present spring-transport mechanism design keeps the rotor immobilized when experiencing shocks of several hundred g (g = 9.8 m/sec2 and is the acceleration due to gravity), while the shipping container assures that the mechanism will not experience shocks greater than about 100 g during common shipping mishaps (as defined by industry standards).

Introduction

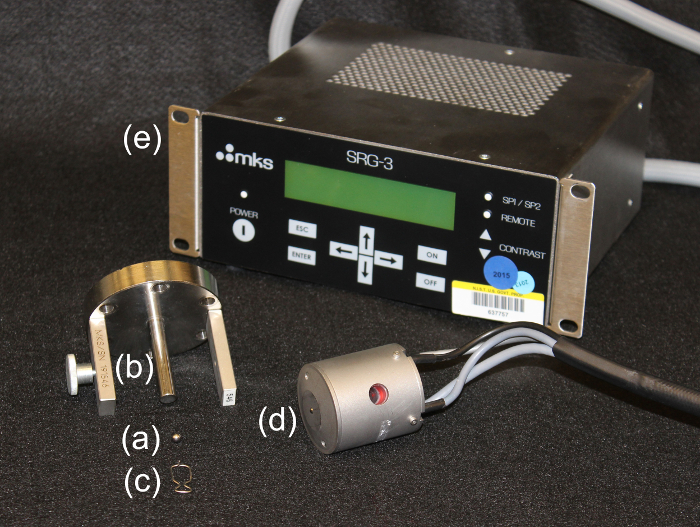

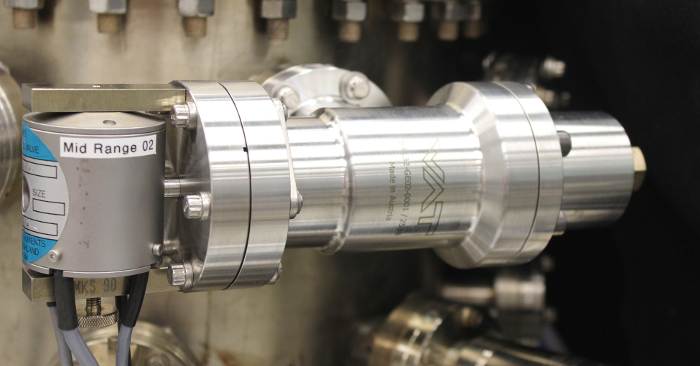

The spinning rotor gauge (SRG) is a high-vacuum gauge used to determine vacuum pressures in the range of 1.0 x 10-4 Pa to 1.0 Pa. It is fundamentally a rotating steel ball that is suspended between two permanent magnets. Electro-magnets are used to rotate, or "spin-up", the ball to some frequency (typically 410 Hz); the ball is then allowed to freely rotate, but the rotation rate will decrease over time because of collisions of gas molecules in the vacuum system with the ball surface. Vacuum pressure is thus related to the deceleration rate of the steel ball or rotor. Figure 1 shows the essential elements of the SRG: the rotor, thimble, head with connecting cable, and electronic controller. The rotor, or ball, is contained within the thimble during operation and is normally not handled by nor is visible to the SRG user. The thimble is connected to the vacuum system. To operate the SRG, the head is slipped over the thimble. The head contains two permanent magnets and several sets of wire coils used for vertical and horizontal stabilization, driving the rotor, and sensing the rotation. The electronic controller interprets the signal from the sensing coil so that a pressure measurement can be made. For a rotor with ideal surface conditions, the deceleration rate is related to the vacuum pressure by fundamental physics. To make absolute pressure measurements using an SRG, a calibration factor, known as the effective accommodation coefficient, must be determined. The effective accommodation coefficient depends on the real surface conditions of the rotor, such as the roughness, adsorbed gases, and scratches. These factors tends to be stable over the course of its use. Additional details of SRGs can be found in other references.1–3

The SRG is used in applications where absolute vacuum measurements are required. For example, calibration laboratories often use SRGs as an absolute vacuum standard. In this case, high-vacuum gauges are calibrated by comparing their reading to that of the SRG. In turn, the SRG standard must be periodically calibrated by shipping the SRG to a primary calibration laboratory to have its accommodation coefficient re-determined. Primary calibration labs are usually National Metrology Institutes such as the National Institute of Standards and Technology (NIST). The primary lab determines the SRG accommodation coefficient by comparing its reading to a primary vacuum standard, and then returns the SRG to the "secondary" calibration lab. The SRG is also used as a transfer standard for the comparison of standards between calibration laboratories or National Metrology Institutes. In this application, the SRG is transported domestically or internationally between the various laboratories.4–8 During shipment, events can occur that change the accommodation coefficient. Prior to shipment, the rotor must be de-suspended and the head is removed; the rotor then rests on the interior wall of the thimble. During transport, the rotor surface is subject to change from the mechanical action between the rotor and thimble due to vibrations and shocks, or the surface may change due to the exposure of the rotor to atmospheric gas and humidity. These changes affect the long-term stability of the accommodation coefficient. Ideally, the rotor should remain in vacuum and immobilized during transport.

Historically, SRGs have been used as transfer standards in key comparisons of vacuum standards among national metrology institutes, where SRGs are internationally transported many times among the various institutes.9 During an early key comparison, it was found that the long-term stability of the SRG accommodation coefficient could be improved by utilizing a spring-transport mechanism which both immobilized the rotor and kept it under vacuum during transportation.1,10 Since then, the spring-transport mechanism has been used many times in international key comparisons. A recent study of the historical data showed that 90% of these comparisons had stabilities better than 0.75%, and 70% had stabilities of 0.5%.9 Therefore, using a spring-transport mechanism will, in most cases, yield a stability that is more than sufficient for most applications.

Until now, there has been little guidance in the literature on how to build a spring-transport mechanism. Early versions of these devices have been known to fail to fully immobilize the rotor, due to a combination of being insufficiently designed for robustness, and being mishandled during shipment. These early lessons show that it is important both to build a robust spring-transport mechanism, and to properly package it in a way that minimizes shock during transport. This later point is critical but often ignored. Here we will describe the construction of a robust spring-transport mechanism in addition to a properly constructed transport package. Our design is based on a few simple, tested, engineering principles that enable the construction of a durable spring-transport package that minimizes the possibility of failure during transport. We also describe our tests of the robustness of our design. Additional details of the test methods can be found in Fedchak et al. (2015).11

Protocol

1. Procure Non-custom Parts for the Spring Transport Mechanism

- Procure the springs, threaded rod, standoffs, nuts, and washers. These items are listed in the List of Specific Materials/Equipment. Purchase the springs and standoffs before manufacturing the ball holder. Use 18-8 stainless steel (except 303), or preferably 316 stainless steel, for all materials.

- Procure rotor. The rotor is a ball-bearing 4.5 mm in diameter made of 440C stainless steel or E52100 alloy steel.

- Procure the right-angle valve listed in the List of Specific Materials/Equipment.

2. Procure Materials for the Shipping Container

- Procure the shipping container. Use rotationally-molded, polyethylene hard-shell cases with protected recesses since these were the type of cases that were successfully tested. The case in the List of Specific Materials/Equipment meets the minimum interior space requirements.

- Procure the foam packing.

- Procure 2# (32 kg/m3) polyurethane (ester) foam. Purchase enough ester foam to fill the top and bottom of the shipping container. Purchase a piece of 5 cm egg-carton ester foam.

- Procure 2# (PE) polyethylene foam that is 7.6 cm thick and has a large enough area to cover the width and depth of the shipping container.

3. Procurement and Fabrication of Custom Parts for the Spring-transport Mechanism

Note: Example drawings of the custom parts described in this section are given in Figures 2-4.

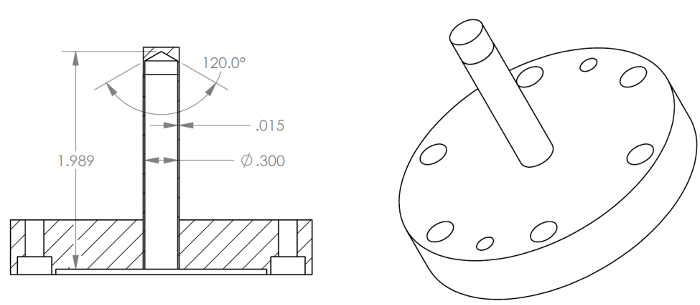

- Produce and submit drawings to custom vendor or in-house shop for manufacturing the spinning rotor gauge (SRG) thimble/flange. Critical dimensions are given in Figure 2. The custom manufacturer must be familiar with ultra-high vacuum (UHV) manufacturing techniques. The thimble is relatively simple to manufacture and is well within the ability of many vacuum component companies.

- Acquire the tines that hold the SRG head to the flange (see Figure 1). These may be removed from the commercial SRG thimble/flange assembly that comes with the SRG electronic control unit. Each tine is held in place by a single bolt (typically a metric hex socket head) with a lock washer, and may be removed by unbolting using the appropriate wrench (such as a metric hex key).

- Alternatively, fabricate these by the same vendor providing the thimble/flange as in the previous step, but ultra-high vacuum manufacturing techniques need not be followed. Make exact copies of the commercial SRG tines.

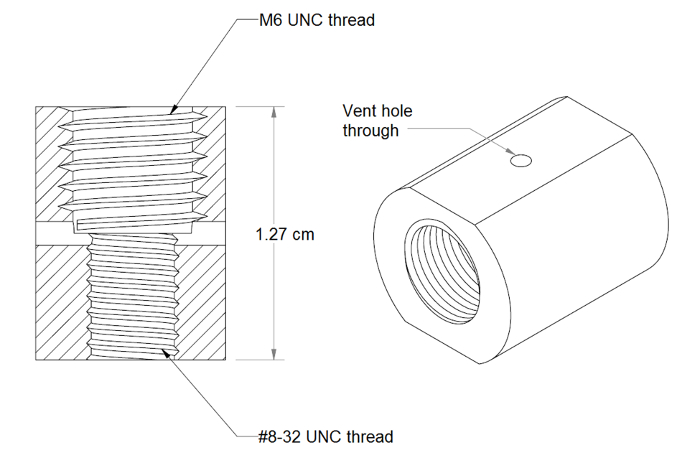

- Produce and submit drawings for the simple adapter to connect the M6 stud on the right-angle valve to an 8-32 all-thread stud (American standard hardware). See Figure 3.

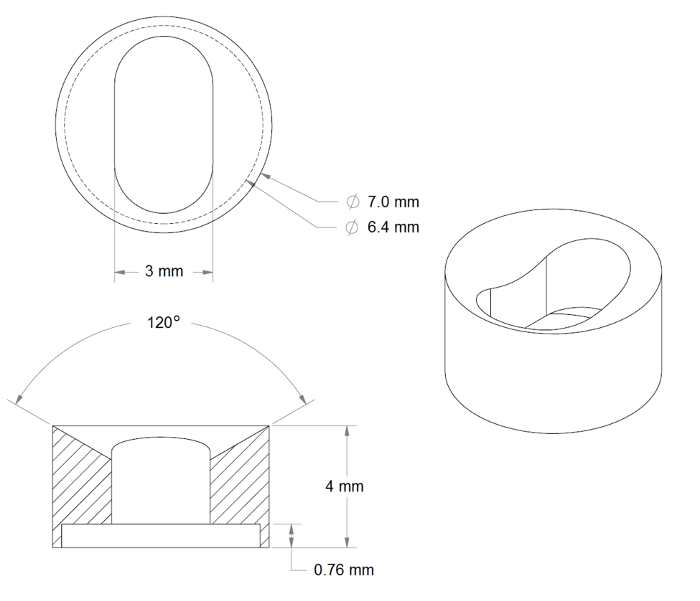

- Produce and submit drawings for the fabrication of the ball holder. Critical dimensions are given in Figure 4. Fabricate the ball holder of 316L stainless steel in accordance with UHV manufacturing techniques. Tack weld the ball holder to one end of a spring. Tack weld the other end of the spring to the standoff. Clean all parts in accordance to the cleaning procedure given in section 5.

- Cut the 8-32 all-thread stud to a length of 18 mm and clean as described in section 5.

4. Fabrication of Custom Foam Cut-out

- Make a cut-out for the spring-transport mechanism in the PE foam. Follow the contours of the valve assembly as closely as possible. Do this by hand using a sharp utility knife; alternatively, the contour may be professionally cut by a packaging supplier.

- Use the dimensions of the valve given by the valve manufacturer and the thimble/flange dimensions given in Figure 2. Cut the space for the thimble large enough to accommodate the tines (1.5 cm x 3.8 cm).

5. Cleaning of the Vacuum Components

- Clean all vacuum components for ultra-high vacuum (UHV) before assembly. Our recommended cleaning procedure is as follows.

- Handle vacuum parts using Nitrile, Latex, or vinyl gloves. Do not touch with bare hands.

- Clean parts using a mild detergent (such as listed in the materials/equipment list) dissolved in distilled or de-ionized water and a lint-free cloth.

- Place parts in a bath of mild detergent dissolved in distilled or de-ionized water and place in an ultra-sonic cleaner for 20 min.

- Rinse parts thoroughly with distilled or de-ionized water.

- Cover parts with acetone and place in an ultra-sonic cleaner for 20 min.

- Remove parts from acetone. Cover parts with ethanol and place in an ultra-sonic cleaner for 20 min.

- Remove parts from ethanol. Rinse thoroughly with distilled or de-ionized water.

- Blow the parts dry with dry nitrogen or clean dry air.

- Let parts air dry on a clean-room quality lint-free cloth for 24 hr.

6. Assemble the Spring-transport Mechanism

- During assembly, wear nitrile, vinyl, or latex gloves. Do not touch vacuum parts with bare hands.

- Gather the necessary tools: needle nose pliers, socket head driver for 8-32 nut, wrench for adapter, ruler or caliper. Wipe clean the ruler/micrometer with ethanol; clean all other tools using the procedure in step 5.

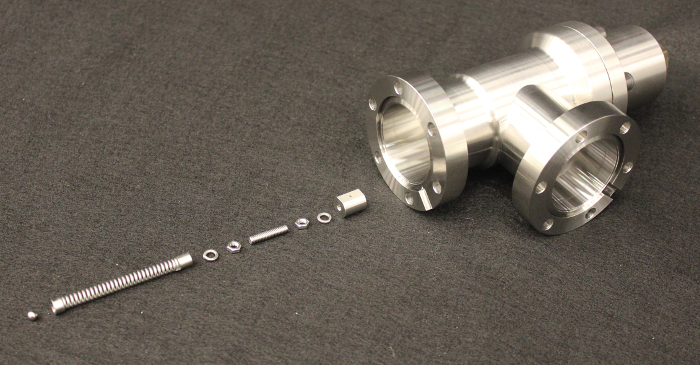

- Gather the necessary parts: the valve, thimble, ball-bearing, ball-holder/spring assembly (see step 3.5), 18 mm long 8-32 stud, thread adapter, nuts, and lock-washers, 3 mm Allen wrench and masking tape. See Figure 5.

- Spring-Transport Mechanism Assembly:

- Fully close the right-angle valve by turning it clockwise until it stops.

- Looking through the valve ports, identify the M6 stud centered on the valve seat.

- Screw the adapter snugly onto the M6 stud. Insert an UHV clean wrench or pliers through the port to get the adapter as snug as possible.

- Insert 8-32 stud into the other end of the adapter. Tighten as snugly as possible. The 8-32 stud will extend through the adapter and push against the M6 stud.

- Place lock-washer on 8-32 stud and then a nut. Tighten the nut using a clean socket driver or pliers. The valve may be closed during this step to make tightening easier.

- Place a nut on the 8-32 stud. Turn it until nearly touching the nut on the other end. Place lock washer on 8-32 stud.

- Attach spring/ball-holder to the 8-32 stud by the standoff. Turn the standoff until it is touching the lock-washer.

Note: The following procedure describes how to check the length adjustment of the spring assembly, see Figure 6. - Place the rotor in the custom thimble and secure it with a magnet (from a commercial SRG) by placing it on the thimble end and fixing it with masking tape. The rotor is now at the end of the thimble.

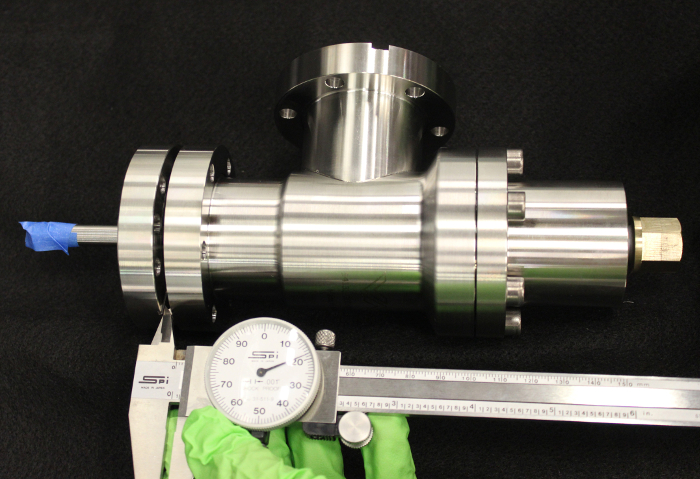

- Slide thimble over spring/ball-holder, stop when the ball-holder touches the ball. Measure the gap between the valve flange and thimble flange, as in Figure 6.

- If the gap is in the range of 2 mm to 6 mm, skip to step 6.4.10.2). A nominal gap of 3 mm is ideal, but a gap in the range is of 2 to 6 mm sufficient. A gap smaller than 2 mm is not acceptable.

- Remove thimble/flange assembly and set aside. If the gap was smaller than 2 mm, rotate the standoff counterclockwise to make the gap larger. If the gap was larger than 6 mm, rotate the standoff clockwise to make the gap smaller. Go back to step 6.4.10.

- Remove thimble/flange assembly and set aside. If the gap was smaller than 2 mm, rotate the standoff counterclockwise to make the gap larger. If the gap was larger than 6 mm, rotate the standoff clockwise to make the gap smaller. Go back to step 6.4.10.

- Tighten the nut against the standoff.

- Open the valve by turning counter-clockwise.

- Assemble the Flange:

- Remove rotor by removing masking tape and magnet and carefully allowing the rotor to roll out of the thimble.

- Attach the two tines to the flange using a lock-washer and bolt inserted through the back-side of the custom flange/thimble. The lock-washer and bolt are provided by the commercial SRG. The lock-washer and bolt do not need to be cleaned for ultra-high vacuum.

- Rotate the tines so that they are square with one another, as in Figure 1 and Figure 9.

- Check tines for straightness by slipping the SRG head over the thimble. The head should slide on freely.

- Give the two bolts a final tightening and re-check for alignment as in step 6.5.3.

- Place rotor back into the thimble, and secure with the magnet and masking tape.

- Complete Spring Transport Assembly:

- Place copper or silver-plated copper gasket on the valve port.

- Place the rotor into the thimble (if not already in thimble from step 6.5.6).

- Slide the flange/thimble assembly over the spring/ball-holder. Orient the flange such that the set-screw in the tines will be pointing downward when the valve is attached to the chamber.

- Using ¼-28 bolts and nuts, secure the flange to the valve.

- Close the valve.

- Remove magnet and tape holding the ball.

7. Assemble the Shipping Container

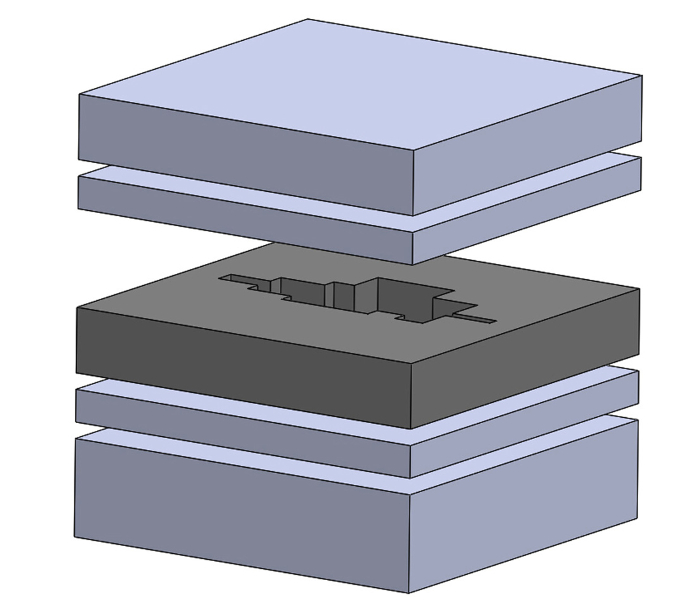

- Cut the ester foam to the size of the shipping container. The thickness of the foam will depend on the height of the container. Place a minimum thickness of 7.6 cm of foam in the bottom. Figure 7 shows the foam assembly.

- Place the PE foam cutout on top of the ester foam.

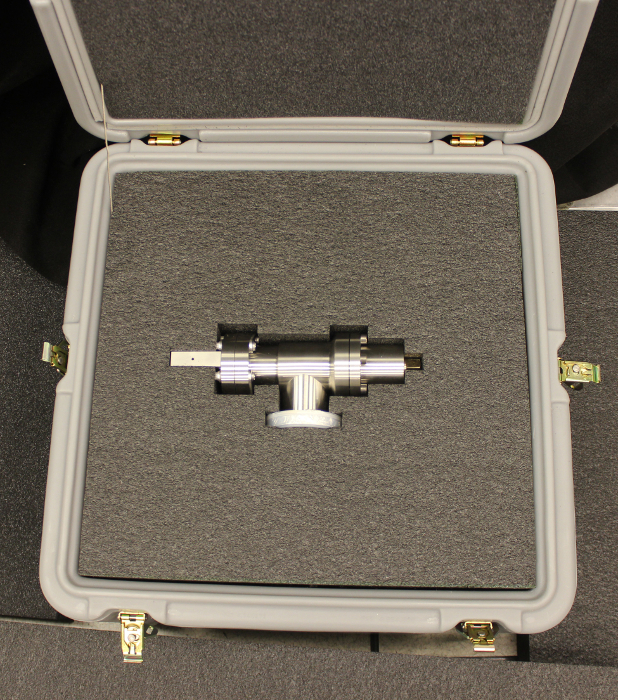

- Place a layer of ester foam in the lid. The minimum thickness should be 7.6 cm. Figure 8 shows the final placement of the spring-transport mechanism. Use clean aluminum foil and a plastic endcap (that came with the valve) to protect the open end of the valve port during shipment.

8. Using the Spring-transport Mechanism

- Mounting and suspending the rotor:

Note: Figure 9 shows the mounted spring-transport mechanism with the head attached. The first step is remove the spring-transport mechanism from the shipping container. In the following, it is assumed that the reader is familiar with the operation of the spinning-rotor gauge. Details of operating the controller can be found in the controller user manual. It is also assumed the reader is familiar with high-vacuum technology.- Remove the endcap and foil from the open port of the spring transport mechanism. Attach the open port to a DN 40 (CF 2.75") port on a vacuum chamber using a new copper or silver-plated copper gasket and a ¼-28 bolt set. The orientation of the valve will depend on the orientation of the tines. The proper orientation is shown in Figure 9. The tine with the set screw points downward. Slip the head over the thimble, the orientation of the thimble should be vertical to within 2°. Check orientation with a level.

- Evacuate the vacuum chamber to less than 10-3 Pa. Slowly open the spring-transport mechanism valve.

- Attach head to the controller. Turn on controller and suspend the ball.

- De-mounting the Spring-Transport Mechanism

- De-suspend the rotor using the electronic controller. Turn off controller.

- Close the spring-transport mechanism valve.

- Remove head.

- Vent vacuum chamber.

- Remove the spring-transport mechanism by un-bolting the valve port from the vacuum chamber.

- Place clean foil and a plastic endcap over the open port of the spring-transport mechanism. Place spring-transport mechanism in cut-out in shipping container.

Representative Results

All of the components of commercial SRG are shown in Figure 1. This includes the rotor, thimble, head containing the permanent magnets and wire coils used for suspension and pickup, and the electronic controller. The small spring shown (Figure 1c) is used to retain the ball in the thimble; this retainer spring is not used in the spring-transport mechanism. The commercial controller and head are used in the spring-transport mechanism. The tines from the commercial thimble may be removed and used in the spring-transport mechanism, or a copy of these simple parts may be fabricated. The rotor may also be used, or a different ball-bearing may be used, as specified in the materials list. The mechanical drawings in Figures 2-4 give the critical dimensions of the custom parts that must be fabricated to build the spring-transport mechanism. The ball-holder in Figure 4 is tack welded onto one end of a spring and the other end of the spring is tack-welded to a standoff. With the exception of the thimble, all of the parts necessary to assemble the spring-transport mechanism are shown in Figure 5. The spring must be compressed a minimum of 2 mm and nominal compression of 3 mm is suggested by the authors. Figure 6 shows the measuring technique to determine if the spring will be properly compressed, as discussed in the procedure.

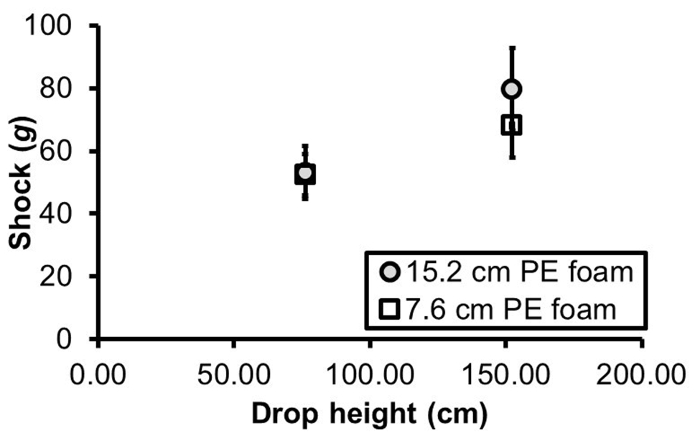

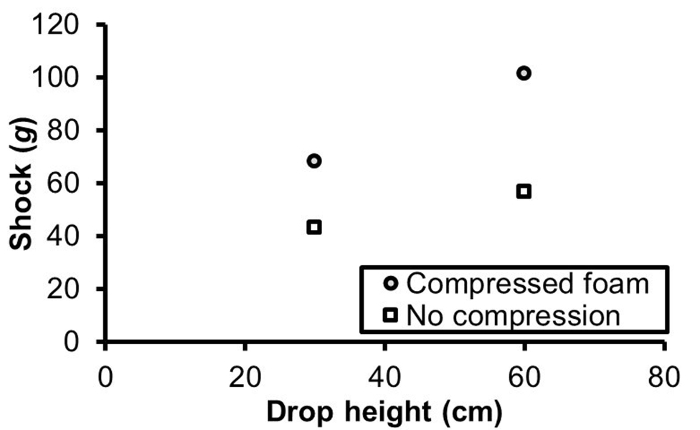

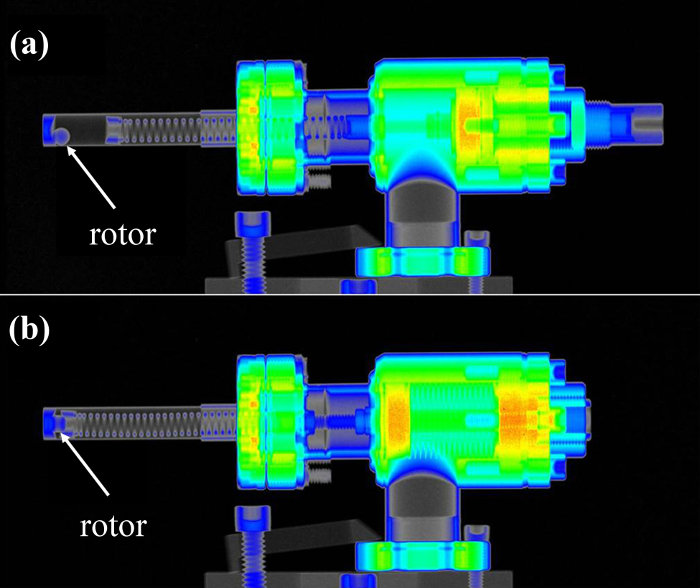

Figure 7 shows a typical assembly of the foam inserts, Figure 8 shows the spring transport mechanism in the transport package. A shipping container should be selected that is sufficiently large to allow room for 7.6 cm of foam surrounding the spring-transport mechanism on all sides and ends. By using a minimum of 7.6 cm of ester foam on the top and bottom and a minimum of 7.6 cm of PE foam on the sides, the shock experienced by the spring-transport mechanism will be held to less than 100 g even when dropped from 152 cm, as shown in Figure 10. It is very important to make certain the foam is not compressed when packing the spring-transport mechanism. This can be caused by using foam that is too thick. Figure 11 shows the effect of compressing the foam even by a small amount: the shock is increased by about 40%. In this case, the foam compressed roughly 1 ¼ cm over 22 ¾ cm. After performing over 180 drop tests of one of our prototypes, we took a neutron radiograph image, Figure 12, which clearly demonstrates the spring-transport mechanism working as designed. Note that the valve in Figure 12 is from a different manufacturer than the valve specified in the present procedure. The former is no longer commercially available. Finally, Figure 9 shows the spring-transport mechanism mounted for use.

Drop-tests are a common practice in the packaging industry and, according to typical industry guidelines, for packages less than 34 kg (75 lbs) the standard drop height for testing is 76 cm (30 inches). A reasonable design goal was that the spring-transport mechanism experience a shock of less than 50 g when dropped from 76 cm, and less than 100 g when dropped from 152 cm, which is twice the recommended height for a drop test. Hard rotationally molded cases and two types of standard foam were chosen to package the spring transport mechanism. Polyurethane (ester) foam and polyethylene (PE) foam are common foams available for packaging. They come in different densities and are usually specified by their nominal densities such as 2# foam (32 kg/m3). Commercial packaging guides give curves showing the desired fragility level (in g, representing the maximum shock that can be withstood by the artifact) versus foam thickness, with different curves representing dropping the box from different heights. For example, if an object with a static load of 0.77 N/cm2 is dropped from 76 cm, 7.6 cm thick 2# ester foam and 12.7 cm thick 2# PE foam both give a shock of about 30 g. The foam must be elastic enough to gently decelerate the object over a reasonable distance, but stiff enough so that there is little or no compression of the foam when under static load. Compression will compromise the foam's ability to absorb the shock. 2# ester foam was used on the top and bottom of the spring-transport mechanism, and 2# PE foam was used for the cutout, as shown in Figure 7. The reason that PE foam was used for the cutout because the static load is greater on the ends of the valve because of the smaller area.

Drop tests were performed on the spring-transport package by attaching an accelerometer to the spring-transport mechanism and dropping the package from different heights and orientations. Figure 10 shows the performance of 7.6 cm and 15.2 cm black 2# PE foam. As can be seen, the thicker foam did not perform any better than the 7.6 cm foam. This is because once the foam is thick enough to fully decelerate the object over its thickness, adding more foam does not help. Therefore it was concluded that 7.6 cm PE foam was sufficient for the sides. On the top and bottom, it was found that a 7.6 cm thickness of 2# ester foam was necessary and sufficient. This is consistent with the lighter static load (larger area) of the valve sides. A small piece of 5 cm thick egg-carton style ester foam was also used to pad the bottom of the cutout so that the spring-transport mechanism would not move within the cutout. Figure 11 illustrates the importance of not compressing the foam. In drop tests where the foam was slightly compressed, the shock was much larger. Different sizes of cases were also tested. It was found that a small case with less padding produced a smaller shock than a larger case. At first this result seemed surprising, but it must be remembered that once the foam thickness is sufficient, adding more foam does not yield better shock results. One hypothesis is that smaller cases produce less shock when dropped since these weigh less than larger cases and bounce more when dropped, thereby dissipating some of the energy. The minimum interior dimensions should be large enough to surround the spring transport mechanism by 7.6 cm of foam on each side, specifically 39.5 cm x 25.4 cm x 23 cm.

Many drop tests with the spring-transport mechanism were performed. Contact between rotor and conical end of thimble was monitored during the drop tests by logging the electrical continuity between the ball and two wires passing through a specially made test thimble, as described in Reference 11. We did not observe a failure of the spring mechanism to hold the rotor during any of the drop tests. Figure 12 shows a neutron radiograph12 of a spring-transport mechanism built by NIST and subjected to over 180 drop tests. As can be seen in the radiograph image, the spring-transport mechanism functions as designed even after being dropped so many times. By following the procedures outlined here, a robust spring-transport package can be created that is capable of minimizing the effects of transport on the long-term stability of spinning rotor gauges.

Figure 1: Elements of a Typical Spinning Rotor Gauge. This picture shows all of the elements of a spinning rotor gauge: (a) the steel ball or rotor; (b) thimble that contains the rotor (commercial version), the two rectangular parts near the edge of the flange are the "tines" that hold the head assembly; (c) retaining spring for the rotor (not used in a spring-transport mechanism); (d) the head and cable assembly; (e) the electronic controller.

Figure 2: Mechanical Drawing of the Custom Thimble. Critical dimensions are shown and are given in United States customary units (1 inch = 25.4 mm). All tolerances are 0.005 inches (0.1 mm). A *.step file is included as a supplemental file. The part should be made of 316L stainless steel, RA16 finish (micro-inches; RA 0.4 µm). Please click here to view a larger version of this figure.

Figure 3: Mechanical Drawing of the Thread Adapter. Critical dimensions are shown and are given in United States customary units (1 inch = 25.4 mm). All tolerances are 0.005 inches (0.1mm). A *.step file is included as a supplemental file. The part should be made of 316L stainless steel; the threads are of type 2A. The M6 Thread has a 1 mm pitch. Please click here to view a larger version of this figure.

Figure 4: Mechanical Drawing of the Ball Holder. Critical dimensions are shown and are given in United States customary units (1 inch = 25.4 mm). All tolerances are 0.005 inches (0.1mm). A *.step file is included as a supplemental file. The part should be made of 316L stainless steel, RA16 finish (micro-inches; RA 0.4 µm), with no sharp edges. Please click here to view a larger version of this figure.

Figure 5: Elements of the Spring Transport Mechanism. In order of assembly (from right to left), the parts shown are: valve, thread adapter, lock-washer, nut, cut 8-32 stud, nut, lock-washer, ball-holder/spring assembly, and 4.5 mm rotor.

Figure 6: Setting the Distance of the Ball-Holder. After assembling the spring-transport mechanism, close the valve, place the rotor in the custom thimble, secure the rotor with a magnet tapped to the end of the thimble and then place thimble over the ball-holder/spring. The gap should measure a minimum of 2 mm, but no more than 6 mm.

Figure 7: Assembly of the Foam. The dark grey represents the PE foam cutout, the light grey rectangles are the ester foam.

Figure 8: The spring-transport mechanism in the transport package. The spring-transport mechanism is fit into a cut-out in PE foam. Ester foam is used under the PE foam and in the case lid. The ester foam is greater than 7.6 cm thick. The case is a rotationally molded hard-shell case.

Figure 9: The spring-transport mechanism mounted to a vacuum chamber. The spring transport mechanism must be mounted on the vacuum chamber such that the head is vertical to within 2°, as shown.

Figure 10: Shock versus Height for PE Foam. The shock for two different thicknesses of PE foam are shown as a function of drop height. The average shock at 76 cm drop height is near 50 g, but the scatter in the data as measured by the standard deviation is nearly 10% (shown as the uncertainty bars). Even at a drop height of 152 cm, the shock is less than 100 g and well within the holding force of the spring.

Figure 11: The Effect of Compressed Foam. A small amount of foam compression degrades the ability of foam to reduce shock, as seen by the larger shock values of the compressed foam.

Figure 12: Neutron Radiograph of the Spring-Transport Mechanism. (a) is the valve in the open position and (b) is the valve in the closed position, showing the rotor nicely captured in the apex of the conically shaped ball-holder and thimble. The spring-transport mechanism shown was dropped more than 180 times before the radiograph image was taken. This figure was previously published in Fedchak, J.A., Scherschligt, J., Sefa, M., Phandinh, N. Building a spring-transport package for spinning rotor gauges. J. Vac. Sci. Technol. A. 33 (3), 033201 (2015); used in accordance with the Creative Commons Attribution 3.0 Unported License.

Discussion

The objective was to design a spring-transport mechanism with a sufficient holding force such that the rotor would remain immobilized during transport. Designing a robust spring-transport mechanism is not enough to insure the rotor will remain immobilized because, for example, dropping the mechanism from tall height onto a hard surface can produce an enormous shock. The force on the rotor can be greatly reduced by packaging the spring-transport mechanism such that it gently decelerates over a distance within the package, thereby reducing the shock. The impulse force experienced by an object when in is dropped is called the shock and is typically measured in terms of the acceleration due to gravity, g. If an object is dropped from a height h and decelerates over a distance d, the shock is just (h/d) x g. For example, if an object is dropped from a height of 1 m and is decelerates over a distance of 1 cm, the shock experienced by the object is 100 g. This example represents a reasonable estimate of the shock we can expect when a well-packed object is dropped during handling. Therefore the spring-transport mechanism was designed to keep the rotor immobilized during shock of at least 100 g. This was not difficult to achieve. A spring with a spring constant of 3 N/mm, which was compressed by 3 mm with the valve fully closed. The mass of the rotor was 0.37 g and the mass of the ball-holder was 0.55 g, thus the compressed spring produced a holding force of several hundred g. From the length of the spring, it would seem that a compression of at least 2 mm is easily achieved; however, we noticed that the heat generated by the tack-welding tended to shorten the spring slightly by reducing the spring spacing near the ends. The conical shaped thimble and ball-holder insure that the ball will not move laterally with respect to the thimble axis. The thimble had to be custom made for two reasons: the interior end was designed to be conically shaped to constrain the ball, and the length had to be such that the spring would obtain the proper compression when the valve is closed. The valve stroke is the total linear displacement of the valve seat and critical in determining the thimble length. If a brand or model of valve is chosen that has a different stroke than the valve in the materials list, a different thimble length may be necessary. The valve we chose in this application is specified at more than 1,000 closings, does not require a torque wrench to close, and has a conveniently placed stud for mounting the spring, making it ideal for this application. Finally, the use of lock washers and tight assembly assures robustness of the devices, as our tests presented below indicate.

As discussed previously, other institutions have made and used spring-transport mechanisms. There is little information in the literature on how these other versions were designed or tested. The historical evidence of the long-term stability of spinning-rotor gauges transported using these other versions of the spring-transport mechanism demonstrates that it is effective in preserving the accommodation coefficient of the SRG, provided that the spring transport mechanism operates as designed and does not fail to immobilize the rotor during transport. The NIST version presented here has been rigorously tested for robustness and is expected to preserve the SRG accommodation coefficient at least as well as the previous versions. Moreover, the importance of packaging the spring-transport mechanism in such a way to minimize shock has not been discussed in the literature. Here detailed specifications and instructions are given on how to package the spring-transport mechanism. The drop tests discussed in the preceding section indicate that the packaging will reduce the shock as designed.

Other methods are often used to transport spinning rotor gauges. The most common method used for the customers of NIST's calibration service is to secure the rotor to the thimble by using an external magnet. Another method is to remove the rotor from the thimble and place it in a glass vial or wrap the rotor in aluminum foil or lint-free cloth. A study of 70 customer rotors with repeat calibrations at NIST indicated that the mean repeatability was 0.94%.13 As previously pointed out, historical data for the spring-transport mechanics indicated that, 90% of the time, rotors had repeatability's better than 0.75% in intercomprisons where the rotors are shipped multiple times internationally. One other shipping method used to ship rotors that has yielded excellent stability results is to hand-carry the rotor. Unfortunately this method is not practical in most cases.

The design present in the protocol is specific to the valve model and type specified. Other valves may be used, but it would be necessary to alter the design. Specifically, the length of the thimble needs to be adjusted to accommodate the valve stroke such that the spring compresses by at least 2 mm when the valve is fully closed. In addition, it is necessary to pick a valve that has a convenient mount for the spring assembly; not all valves have such features.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors are thankful for the help of the NIST neutron imaging facility instrument scientist Dr. Daniel Hussey for assisting us with neutron radiographs.

Materials

| Spring, 3 N/m | Lee Spring (www.leespring.com) | LC 042C 18 S316 | Outside diameter 0.240 in, Wire Diameter 0.042 in, Rate 17.1 lb/in, Free Length 2.25 in, Number of Coils 29.3 |

| 8-32 threaded rod, 316 stainless steel | McMaster-Carr (www.mcmaster.com) | 90575A260 | Type 316 Stainless Steel Fully Threaded Stud 8-32 Thread, 3" Length. Cut to length specified in protocol |

| standoffs, 8-32 Screw Size | McMaster-Carr (www.mcmaster.com) | 91125A140 | 18-8 Stainless Steel Female Threaded Round Standoff, 1/4" OD, 1/4" Length, 8-32 Screw Size |

| nuts, 8-32 | McMaster-Carr (www.mcmaster.com) | 90205A309 | 316 SS Undersized Machine Screw Hex Nut 8-32 Thread Size, 1/4" Width, 3/32" Height |

| Split Lock-Washers, 316 Stainless Steel | McMaster-Carr (www.mcmaster.com) | 92147A425 | Type 316 Stainless Steel Split Lock Washer NO. 8 Screw Size, .3" OD, .04" min Thick |

| Steel Rotor | McMaster-Carr (www.mcmaster.com) | 9292K38 | Bearing-Quality E52100 Alloy Steel, Hardened Ball, 4.5 mm Diameter |

| Right-Angle Valve | VAT Valve (www.vatvalve.com) | 54132-GE02-0001 | Easy-close all-metal angle valve, DN 40 (1.5") |

| Shipping Container | Allcases, Reekstin & Associates (www.allcases.com) | REAL1616-1205 | Zinc Hardware w/Zinc Handles, Rotationally Molded, light-weight, high-impact, Polyethylene Case with protected recessed hardware. 15.75" X 15.88" X 16.45" |

| Ester Foam | Carry Cases Plus (www.carrycasesplus.com) | ES-PAD 3" Thick | 3" Thick, 2lb Charcoal Ester Foam Pad, 24" x 27". |

| Ester Foam | Carry Cases Plus (www.carrycasesplus.com) | ES-PAD 1" Thick | 1" Thick, 2lb Charcoal Ester Foam Pad, 24" x 27". |

| Egg-carton ester foam | Carry Cases Plus (www.carrycasesplus.com) | ES-CONV | ES-CONV, 2lb, 24" x 27" x 1 1/2". "egg-crate" ester foam. |

| Foam Cutout, PE foam | Willard Packaging Co. (www.willardpackaging.com) | Custom Foam Cutout. | |

| Spinning Rotor Gauge | MKS Instruments (www.mks.com) | SRG-3 | Controller, head, and thimble. Custom thimble must be used for the spring-transport mechanism |

| Custom thimble | MDC vacuum Inc. (www.mdcvacuum.com) | drawing must be submitted for custom part | |

| Detergent | Fisher Scientific Co (www.fischersci.com) | 04-320-4 | Sparkleen 1 Detergent |

| Acetone | Fisher Scientific Co (www.fischersci.com) | A18-S4 | Acetone (Certified ACS) |

| Ethanol | Warner-Graham Company (www.warnergraham.com) | 190 proof USP | 190 Proof USP ethyl alcohol |

| Bolt set for valve | Kurt J. Lesker (www.lesker.com) | TBS25028125P | B,N&W SET,12 POINT,(25)1/4-28X 1.25"FOR 2.75"THRU,SILVER PLAT |

| Silver-plated copper gaskets | Kurt J. Lesker (www.lesker.com) | GA-0275LBNSP | |

| Spring Assembly (welding) | Omley Industries, Inc. (www.omley.com) | N/A | The machine work and welding were done in NIST's shop. However, Omley industries was used as an alternative for welding the spring assembly. |

References

- Fremerey, J. K. The spinning rotor gauge. J. Vac. Sci. Technol. A. 3 (3), 1715-1720 (1985).

- Jousten, K., Jousten, K. Chapter 13, Total Pressure Vacuum Gauges. Handbook of Vacuum Technology. , 573-583 (2008).

- Berg, R. F., Fedchak, J. A. NIST Calibration Services for Spinning Rotor Gauge Calibrations. NIST Special Publication. , 250-293 (2015).

- Messer, G., et al. Intercomparison of Nine National High-vacuum Standards under the Auspices of the Bureau International des Poids et Mesures. Metrologia. 26, 183-195 (1989).

- Jousten, K., et al. <a target="_blank" href="http://www.ncbi.nlm.nih.gov/entrez/query.fcgi?db=PubMed&cmd=Search&doptcmdl=Citation&defaultField=Title+Word&term=Results+of+the+regional+key+comparison+Euromet.M.P-K1.b+in+the+pressure+range+from+3+x+10-4+Pa+to+0.9+Pa.”>Results of the regional key comparison Euromet.M.P-K1.b in the pressure range from 3 x 10-4 Pa to 0.9 Pa. Metrologia. 42 (1A), 07001 (2005).

- Jousten, K., Santander Romero, L. A., Torres Guzman, J. C. <a target="_blank" href="http://www.ncbi.nlm.nih.gov/entrez/query.fcgi?db=PubMed&cmd=Search&doptcmdl=Citation&defaultField=Title+Word&term=Results+of+the+key+comparison+SIM-Euromet.M.P-BK3+(bilateral+comparison)+in+the+pressure+range+from+3+x+10-4+Pa+to+0.9+Pa.”>Results of the key comparison SIM-Euromet.M.P-BK3 (bilateral comparison) in the pressure range from 3 x 10-4 Pa to 0.9 Pa. Metrologia. 42 (1A), 07002 (2005).

- Yoshida, H., Arai, K., Akimichi, H., Hong, S. S., Song, H. W. <a target="_blank" href="http://www.ncbi.nlm.nih.gov/entrez/query.fcgi?db=PubMed&cmd=Search&doptcmdl=Citation&defaultField=Title+Word&term=Final+report+on+key+comparison+APMP.M.P-K3:+Absolute+pressure+measurements+in+gas+from+3+x+10-6+Pa+to+9+x+10-4+Pa.”>Final report on key comparison APMP.M.P-K3: Absolute pressure measurements in gas from 3 x 10-6 Pa to 9 x 10-4 Pa. Metrologia. 48 (1A), 07013 (2011).

- Fedchak, J. A., Bock, T. h., Jousten, K. <a target="_blank" href="http://www.ncbi.nlm.nih.gov/entrez/query.fcgi?db=PubMed&cmd=Search&doptcmdl=Citation&defaultField=Title+Word&term=Bilateral+key+comparison+CCM.P-K3.1+for+absolute+pressure+measurements+from+3+x+10-6+Pa+to+9+x+10-4+Pa.”>Bilateral key comparison CCM.P-K3.1 for absolute pressure measurements from 3 x 10-6 Pa to 9 x 10-4 Pa. Metrologia. 51 (1A), 07005 (2014).

- Fedchak, J. A., Arai, K., Jousten, K., Setina, J., Yoshida, H. Recommended practices for the use of spinning rotor gauges in inter-laboratory comparisons. Measurement. 66, 176-183 (2015).

- Rohl, P., Jitschin, W. Performance of the spinning rotor gauge with a novel transport device as a transfer standard for high vacuum. Vacuum. 38 (7), 507-509 (1988).

- Fedchak, J. A., Scherschligt, J., Sefa, M., Phandinh, N. Building a spring-transport package for spinning rotor gauges. J. Vac. Sci. Technol. A. 33 (3), (2015).

- Hussey, D. S., Jacobson, D. L., Arif, M., Coakley, K. J., Vecchia, D. F. In Situ Fuel Cell Water Metrology at the NIST Neutron Imaging Facility. J. Fuel Cell Sci. Technol. 7 (2), 021024 (2010).

- Chang, R. F., Abbott, P. J. Factors affecting the reproducibility of the accommodation coefficient of the spinning rotor gauge. J. Vac. Sci. Technol. A. 25 (6), 1567-1576 (2007).