Predicting Catalyst Extrudate Breakage Based on the Modulus of Rupture

Summary

Here we present a protocol to measure the modulus of rupture of an extruded catalyst and the breakage of said catalyst extrudates by collision against a surface or by compression in a fixed bed.

Abstract

The mechanical strength of extruded catalysts and their natural or forced breakage by either collision against a surface or by a compressive load in a fixed bed are important phenomena in catalyst technology. The mechanical strength of the catalyst is measured here by its bending strength or flexural strength. This technique is relatively new from the perspective of applying it to commercial catalysts of typical sizes used in the industry. Catalyst breakage by collision against a surface is measured after a fall of the extrudates through the ambient air in a vertical pipe. Quantifying the impact force is done theoretically by applying Newton’s second law. Measurement of catalyst breakage due to stress in a fixed bed is done following the standard procedure of the bulk crush strength test. Novel here is the focus on measuring the reduction in the length to diameter ratio of the extrudates as a function of the stress.

Introduction

Catalyst manufacturing is the backbone that supports the petrochemical industry and related industries. Commercial catalysts, see Le Page1, are typically extruded according to recipes that are well guarded trade secrets or have patented methods of manufacture. Typical catalyst sizes range from 1 mm to about 5 mm in diameter and come in a variety of shapes like a cylinder, a trilobe or a quadrulobe together also with a variety of their hollow counterparts. While the diameter and the cross section of extruded catalysts are often very well controlled, the length of individual extrudates have a more Gaussian like distribution and the individual lengths typically range from about equal to one diameter to several diameters. An exception is extruded catalysts of sufficiently large diameter, that allows them to be cut as they exit the die face, and these have a much tighter length distribution. The length distribution of the smaller 1 mm to 3 mm diameter extruded catalysts that are typical for the petrochemical industry are normally obtained by natural breakage or forced breakage depending on their intrinsic strength.

Le Page1, Woodcock2, Bertolacini3, Wu4 and Li5 show typical catalyst properties and the intricacies of the strength measurements. Typical strength measurements in the literature and in commercial settings comprise of the average crush strength of single extrudates and of the bulk crush strength. Both strength properties are in use to judge whether a catalyst has adequate strength to survive the loading and use in processes. Often also an attrition test is added to judge the catalyst attrition resistance in the process. Though a very large database exists in commercial plants on catalyst strength and use, that information is rarely accessible in the open literature. Also, many of the catalyst recipes are ad hoc and have been established after much trial and error. The modeling of this aspect of catalyst manufacturing is still challenging to say the least.

Applied here is the flexural strength of the catalyst obtained from a measurement of the Euler-Bernoulli modulus of rupture which is typically obtained in a three-point bending test. Li6 and Staub7 comment on the flexural strength of catalysts but their work is done on fairly large diameter extrudates and no direct application is given to model catalyst breakage. The flexural strength is rarely measured and reported in the literature for typical commercial catalyst sizes. Further, the flexural strength is often not applied for guidance in catalyst manufacturing

Measuring and modeling the breakage of catalysts either during its manufacture or during its use in the process is difficult. Often the catalyst extrudate length to diameter ratio is modeled based on empirical methods that relate it to strength via power laws, however, this in many instances still has a strong ad hoc component. Bridgwater8 provides a comprehensive overview of particle breakage due to shear but the length to diameter ratio of the extrudates are outside of the commercial range of extrudates discussed in this paper. Discrete element methods (DEM) and finite element methods (FEM) are now also used to investigate breakage of granules and these methods approach the problem at a fundamental level. Reference is given to Heinrich9, Wassgren10, Potyondy11, Potapov12, Carson13, and Farsi14 for details on this approach. The methods and techniques employed herein attempt to help improve modeling catalyst breakage due to collision via Newton's second law to determine the impact force and balancing this with the strength expressed by the Euler-Bernoulli modulus of rupture. For breakage by load stress in a fixed bed, a balance of load force and bed flexural strength is applied, and this allows to predict the aspect ratio of the bed as a function of the load. Very important are the measurement methods themselves that must be applied under well controlled conditions and this aspect is here in this paper detailed comprehensively. For instance, it is well known that the catalyst strength is strongly influenced by the heat treatment that is applied and also by the conditions of use when the catalyst can pick up moisture. Higher heat treatment temperatures typically strengthen the catalyst while high moisture pick-up typically weakens it. It is, therefore, important that the strength is measured on a catalyst that has seen the appropriate heat treatment and that moisture is controlled where it is necessary in order to make it representative for the use of the catalyst either during its manufacture or during its use in the process. Little is found in the literature that specifically measures and models the length to diameter ratio of catalyst extrudates that are typical for the petrochemical industry. Recently, Beeckman15,16 has used the bending strength of the catalyst to predict natural breakage and forced breakage of catalysts due to the collision. Here specific attention is given to the catalyst aspect ratio (L/D) which is defined as the arithmetic mean of the length to diameter ratios of the individual catalyst extrudates in a representative sample. The experimental methods described herein are relatively simple and allow to fundamentally study and compare experimental measurements with theoretical treatments.

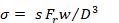

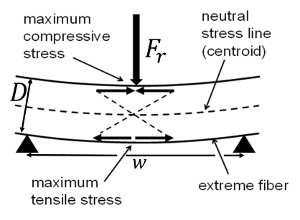

The modulus of rupture (MOR) of the catalyst is a measure of its bending strength. Leonhard Euler and Daniel Bernoulli developed the first theoretically sound approach to elastic behavior and strength at rupture back in the 1750's. Figure 1 shows a schematic of the bending test and the rupture force Fr. For the specific case of a cylindrical extrudate, the modulus of rupture can be calculated from:

(1)

(1)

Where σ is called the modulus of rupture and has dimensions of stress (Pa). D stands for the diameter of the extrudate while w is the distance between the two support points. The variable s is the shape factor and equals 8/π for a cylinder. For a comprehensive explanation of the forces and stresses at hand during the experiment as well as how to deal with different cross-sectional shapes reference is given to Beeckman16. Specifically, σ is the tensile stress at rupture directed perpendicularly to the cross section of the extrudate and located at the extreme fiber in the middle between the two support points.

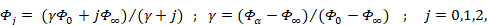

For collision of an extrudate with a surface, Beeckman15 shows that two asymptotes exist with respect to the extrudate aspect ratio. The first asymptote called Φ∞ is reached upon many repeated impacts. This asymptotic behavior is easily understood since, after breakage upon collision, shorter catalysts have less momentum and therefore experience less force upon impact. At the same time, shorter catalysts also require more force to break from a perspective of torque and hence the catalyst is expected to reach an asymptotic aspect ratio Φ∞ upon many impacts. The second asymptote called Φα is reached after a single impact when extrudates are dropped that are sufficiently long. Long extrudates have proportionally more momentum and break upon the first impact in several places along their length and the aspect ratio post collision reaches the second asymptote designated Φα. Both asymptotes can be found by regression of collision data that measure the aspect ratio as a function of the number of repeated impacts from:

(2)

(2)

Where Φ0 is the initial aspect ratio and Φj is the aspect ratio after j drops. Both the parameters Φ∞ and Φα have a physical-mechanical meaning that is related to the severity of the impact and the strength of the catalyst. The severity of the impact can be varied by varying the drop height though for large drop heights the catalyst approaches terminal velocity and hence the severity will level out.

Particle length and particle diameter are important properties of the catalyst during its manufacture and use. The size and the shape of catalyst particles are also determining factors in their packing characteristics and influence the pressure drop across the catalyst bed. In earlier days, these properties were often measured by hand and this is a very tedious procedure. Now, these properties can be readily obtained by first optically scanning a large sample of catalyst extrudates. Then, imaging software is used to determine individual particle sizes. This allows a large number of particles to be analyzed quickly and accurately, see Beeckman15. These systems are tuned to effectively recognize and measure particles with a diameter in the range of 0.8 to 4.0 mm and with lengths that can be several diameters long. This method uses a "top down" view of the catalyst and hence yields an "optical" diameter. For certain shapes, care must be exerted when comparing the optical diameter with diameter values determined manually with calipers.

The bulk crush strength test for catalysts and catalyst carriers, ASTM D7084-0417 used herein is an accepted standard test method.The catalyst is loaded in a cylindrical cell and pressure (stress) is applied typically in the 5-1,000 kPa range and is allowed to equilibrate. After each pressure point, the catalyst is unloaded. The catalyst fines are screened out from the catalyst sample and weighed while the bulk of the catalyst sample is riffled to obtain a representative sample to accurately measure the aspect ratio. While the standard bulk crush strength test procedure focusses on the amount of fines that is created in order to gauge catalyst strength, this manuscript focusses on the reduction of the aspect ratio after breakage as a function of the load, see also Beeckman18.

Protocol

Use adequate personal protective equipment e.g. safety glasses, gloves etc. for performing any tasks referred to in this manuscript. The starting material used here whether, for the measurement of bending strength, collision, aspect ratio or bulk crushing is always extrudates obtained from laboratory studies or pilot equipment studies or are commercial materials. Catalyst extrudate strength depends on pretreatment conditions hence it is important for the user to select the appropriate treatments. The outcome of the measurements allows to decide which materials to use in further studies at least from a strength perspective.

1. Bending Strength

- Bending Strength Sample Preparation

- Riffle the extrudate sample of interest to a representative size of 25 particles minimum. Use a spinning riffler or riffle-type sample divider.

Note: Catalyst strength is dependent on the thermal pretreatment, hence the sample requires certain choices to be made by the user concerning pretreatments. - Perform one of the following two typical pretreatments but their conditions may be changed depending on the need of the user.

- Calcine the sample at 538 °C for 1 h.

- Place a minimum of 25 riffled catalyst extrudates in a porcelain dish or heat resistant beaker.

- Place the dish with the catalyst into a refractory-type muffle oven at 538 °C for 1 h.

- After calcination, place the hot sample into a desiccator and allow it to cool to ambient conditions.

- Dry the sample at 121 °C for 2 h minimum.

- Place a minimum of 25 riffled catalyst extrudates in a porcelain dish or heat resistant beaker.

- Place the dish with catalyst in a drying oven, set for 121 °C for a minimum of 2 h.

- Remove the hot sample from the drying oven and place it into a desiccator and allow it to cool to ambient conditions

- Calcine the sample at 538 °C for 1 h.

- Riffle the extrudate sample of interest to a representative size of 25 particles minimum. Use a spinning riffler or riffle-type sample divider.

- Bending Strength Instrumentation Set-up

Note: The error bar for the modulus of rupture is +/- 10%. Calibrate the equipment daily according to the procedure set forth by the manufacturer. Choose the method that correctly matches the shape of the sample, as the calculation of MOR depends on the shape factor.- Start the bending test frame and allow the system to warm up for at least 20 min before using. Then open the required software.

- Attach the 10 N (10 Newton force) load cell per manufacturer instructions.

- Select an anvil speed of 0.2 mm/sec with a 5-mm support span.

Note: It was observed that for this rate of speed, the catalyst is not in a strain rate sensitive region and the rupture force is reproducible. - Select 'Modulus of Rupture (MOR)' and 'Maximum Force' in the Results tab.

- Ensure the crosshead on the MOR frame is in the "Zero" position by firmly pressing the "Return" button on the frame console. The position of the crosshead and anvil may be changed if necessary to accommodate extrudates of different diameter.

- Bending Strength Measurement

- Take the catalyst extrudate sample from the desiccator and place it in an inverted 5-6 cm diameter filter with N2 blowing upwards through it to create a blanket of dry gas.

- Use tweezers to take an extrudate specimen from the filter tray and place it across the support beams. Minimize the time of extrudate specimen placement and measurement to minimize moisture pick-up.

- Center the catalyst extrudate specimen as best as possible left to right and front to back on the support beams

- Click the "Start" icon on the right toolbar.

Note: During this step, the extrudate is being bent beyond the breaking point and hence the test is destructive in that sense. - Ensure crosshead stops and returns to the starting position upon experiencing a 40% drop in load force.

Note: This usually occurs upon extrudate breakage. - Select the "Next" icon on the right toolbar to continue to the next extrudate.

- Hit "back" to view the data point on the graph and on the results table.

- Select 'Finish Sample' after measuring the 25th extrudate specimen.

Note: The software generates the report with the strength properties

2. Collision Test

Note: The feed rate with which catalyst is fed to the drop tube is kept low so that individual catalyst extrudates collide essentially with an empty surface at the bottom of the drop tube without hindering each other

- Collision Equipment Preparation

- Assemble the drop tube (0.15 m diameter and 1.83 m long plastic tube) with the recovery plate (316 SS) at the bottom. Set the feeder discharge at the correct height of choice (here 1.83m) centered over the drop tube. Alter the drop heights to vary the severity of the collision.

- Set resonate frequency of vibratory feeder to 250 Hz with power off.

- Position local ventilation over the feed hopper.

- Collision Sample Preparation

- Riffle the catalyst sample of interest to a representative size of 50 particles minimum. Use a spinning riffler or riffle-type sample divider.

- Gently sieve the prepared sample in order to avoid small particles with a length to diameter ratio less than or equal to 1.

- Measure the initial aspect ratio of the sample by using protocol section 3.

- Collision Catalyst Drop Procedure

- Manually transfer the entire sample into the feed hopper.

- Ensure the feeder chute outlet is centered over the drop tube.

- Turn on the toggle switch to power the feeder and set to 'Start.'

- Allow all particles to fall freely into the drop tube and impinge on the bottom plate.

- Turn off the power to the feeder once all particles have been fed and dropped.

- Transfer all the particles from the recovery plate and gently remove the fines from the sample by sieving to remove dust and chips.

- Measure the aspect ratio of the sample using protocol section 3 to complete the first drop measurement designated 1X.

- Using the sample of step 2.3.7, repeat steps 2.3.1 to 2.3.6 and measure the aspect ratio using protocol section 3 to complete the second drop measurement designated 2X.

- Repeat the above steps to complete up to 5X and 10X drop measurements.

Note: One can elect to skip the intermediate aspect ratio measurements since the aspect ratio only changes little after multiple drops.

3. Catalyst Aspect Ratio

- Aspect Ratio Sample Preparation

- Riffle the catalyst sample of interest to a representative size of 50 to 250 particles. Use a spinning riffler or riffle-type sample divider to obtain a representative sample.

- Sieve the prepared sample to avoid small particles with an L/D less than or equal to 1 where L stands for the length of an extrudate while D stands for the diameter of an extrudate.

- Aspect Ratio Software and Set-up

- Open the software and select the "SCAN" toolbar button at the top of the screen.

- Wipe the glass with a microfiber cloth to remove any dust. Place a clean transparency sheet on the scanner.

- Sprinkle the extrudates on top of the transparency and avoid particles from touching each other. Place the particles within a rectangular area measuring maximum 10 cm by 20 cm.

- Randomly distribute the extrudates across the area to be scanned. Use a pair of tweezers to slide particles away from each other or to place them in more open areas.

- Close the scanner lid.

- Select the shape of the particle

- Enable the message function in the software setting, for touching particles (highlighted in red on the screen), particles that are overlapping (or brushing) the edge of the scan area and these are automatically removed, any particles with excessive curvature, any particles that are too small (e.g. dust specks), and any particles that are touching each other.

- Click on the "Scan" toolbar button.

Note: The scanner will start to scan the particles. It will take between 2-3 min. The tabulated results and optically scanned image are displayed on the screen.

- Aspect Ratio Analysis

- Examine the scanned results and ensure that all legit particles are included in the scan.

Note: Legit particles have and L/D > 1, rest in a natural position for the scan and do not touch other extrudates. - Review each particle suspected of touching a neighboring particle as the computation algorithm is not perfect.

- Eliminate particles that rest improperly due to crowding (touching or lying on top of each other) with eliminated with the software. Alternatively, adjust the particle's position with tweezers and the entire sample can be re-scanned.

- Save the results and record the following information: average diameter, average length, and the particle number.

- Examine the scanned results and ensure that all legit particles are included in the scan.

4. Bulk Crush testing

- Bulk Crush Sample Preparation

- The catalyst extrudate sample of interest should be riffled so as to obtain a suitable representative of the total amount.

- Heat-treat the catalyst sample at 538 °C for minimum 1 h in a muffle oven or similar and place it hot in a desiccator and allow it to cool to ambient conditions.

- Bulk Crush Procedure

- Tare the catalyst sample container (cup) and fill it to overflowing with the catalyst so that there is an excess catalyst in the container.

- Carefully level the cup with a metal straight edge without over-packing the bed.

- Reweigh the container with a leveled catalyst to obtain the weight of the sample.

- Carefully place the sample in the load block and piston assembly. Place the load block on top of the sample without crushing the catalyst.

- Place the ball bearing in the center of the load block and adjust the lock arm to the proper height evenly over the ball bearing using a small carpenter's level. Lock the arm in place.

- Check that the pressure regulator is set at the pressure specified by the user to be applied to the catalyst sample.

Note: Typically, it is in the 5-1,000 kPa range and it is normally found by trial and error for the particular application. - Check that the load control valve and pressure valve are open and then close the bleed valve.

Note: The load block will rise to its set pressure. - Wait for 60 s for the sample to equilibrate.

- Release the pressure by opening the bleed valve and closing the pressure valve. Watch the load block coming back to its original position.

- Unlock the adjustable lock arm and take the bearing ball and load block out carefully.

- Measure and record the indentation of the sample after the crush test.

- Sieve out the fines. Record the fines collected and measure the aspect ratio of the sample according to protocol section 3.

Representative Results

Breakage by Collision:

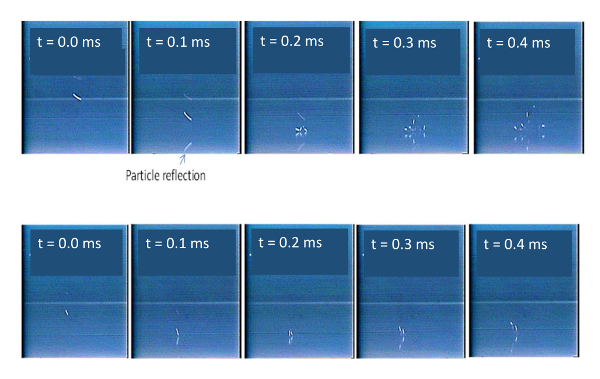

To give the reader an idea of the complexity of an impact of an extrudate onto a surface, it was thought to be beneficial to supply a few snapshot pictures at the highest frame speed we had available at the time (10,000 frames/s). Figure 2 shows such high-speed photography and captures the breakage of individual extrudates as they impact a polycarbonate surface. This surface has the added advantage that it shows the approach of the extrudate prior to impact by reflectance off the surface and allows to clearly define the instance of contact. The duration of the breakage by impact appears to be less than 10-4 s while the full impact history shows to be very complex. The forces experienced by the extrudate as a function of time during the collision are very spiked and irregular. The average deceleration defined as the impact speed over the contact time is only a rough estimate of what happens. When multiplied by the mass of the extrudate it is again only a rough estimate of the force.

The asymptotic aspect ratio Φ∞ has been determined on 25 different kinds of catalysts and their properties are given in Beeckman16. The model parameter Φ∞ for each catalyst has been obtained by non-linear regression using Eq. (2) shown in the introduction.

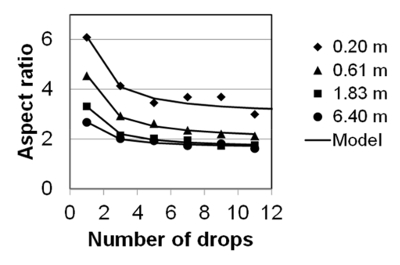

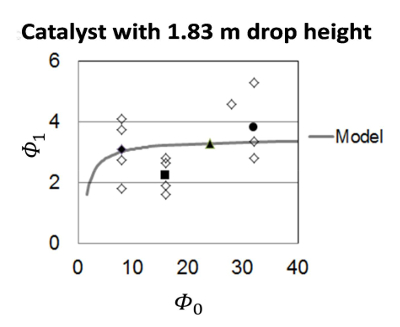

Figure 3 shows the reduction in the aspect ratio of a typical fresh catalyst of the same catalyst batch dropped repeatedly from different heights. This sequence clearly shows the line-out towards the asymptotic aspect ratio, Φ∞ for different drop heights i.e. different severities. Beeckman16 shows that the difference in aspect ratio for large drop heights becomes smaller and smaller due to the drag by ambient air during the fall which slows the acceleration of the extrudates and finally reaches the terminal velocity for large drop heights. It was also shown that the extrudates follow a second order break law which explains the shape of the trend curve of the aspect ratio with the number of consecutive drops. Figure 4 shows the aspect ratio of the same catalyst as in figure 3 but now starting with very long select catalyst strands after a single impact (each data-point is generated from a single extrudate). The solid symbols represent averages of the aspect ratio for each group of sizes. This shows the presence of the second asymptote Φα and also an appreciation for the error bar that is involved when the length to diameter ratio is obtained from a very limited number of extrudates.

The impulsive force that acts on the extrudate during the collision can be found by applying Newton's second law. It is shown that at the asymptotic aspect ratio Φ∞, equating the rupture force to the impulsive force leads to the following correlation:

(3)

(3)

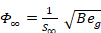

With the normalized dimensionless group given by:

(4)

(4)

Where σ, Ψ, p, D and g are respectively the catalyst modulus of rupture, the catalyst shape factor, the catalyst density, the catalyst diameter and the gravitational acceleration. The normalized dimensionless severity of the impact S∞ can be expressed as:

(5)

(5)

Where is v the impact velocity, Δt is the duration of the collision and C is a collision interaction factor. It is further shown that for a total of 25 catalysts of different size, shape and chemical make-up that were tested in the drop test that in first approximation, the group  is essentially a constant.

is essentially a constant.

Breakage by stress in a fixed bed:

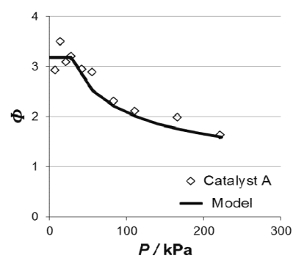

Five catalysts shown in Table 1 are investigated with the bulk crush test for various pressures. Below a certain pressure, here called the critical pressure, no essential change occurs in the catalyst aspect ratio of the bed. Once the pressure increases above this critical value, the catalyst extrudate starts to break down and the aspect ratio in the bed adjusts naturally until the flexural strength of the bed is again able to withstand the applied stress. An example of the comparison of the experimental results and the predicted results are shown in Figure 5. Predicted values are shown as the solid curve and is obtained by beginning from the starting aspect ratio Φ0 of the catalyst extrudates and remaining at that value until the critical pressure Pc is reached. Thereafter, the value of the aspect ratio diminishes with the negative one third power of the load pressure.

The methodology to find the maximum allowable load for a bed to withstand catalyst breakage utilizes a balance of the load force to the strength of the catalyst bed at rupture.

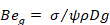

Beeckman18 shows that the aspect ratio of the catalyst in balance with the load force can be described by:

(6)

(6)

Wherein Φ is the extrudate aspect ratio while Ber is a dimensionless group given by:

(7)

(7)

Where σ, is the modulus of rupture, s is the same extrudate shape factor as for collision, and P is the stress. The value for Ψ is determined by the bed packing and by the bed particle to particle force interactions and the authors give a theoretical value of 61/6 or about 1.35 for Ψ.

To summarize, if a bed of extrudates is loaded in the bulk crush strength test and a stress P is applied, then the extrudates will break throughout the entire bed under the applied stress P to an average value given by Eq. (6). Hence a bed with a starting aspect ratio Φ0 has a critical pressure Pc it can withstand given by:

(8)

(8)

| Catalyst | Shape | D, diameter | Φ0 , initial aspect ratio | s, shape factor | ρ, density | σ MOR | Pc, critical stress |

| m | (-) | (-) | kgm-3 | MPa | kPa | ||

| A | QUADRULOBE | 1.43E-03 | 3.18 | 2.20 | 1250 | 0.81 | 27.9 |

| B | CYLINDER | 9.50E-04 | 5.92 | 2.55 | 750 | 1.38 | 6.4 |

| C | CYLINDER | 8.30E-04 | 7.48 | 2.55 | 1870 | 2.83 | 6.5 |

| D | TRILOBE | 2.89E-03 | 2.28 | 2.28 | 970 | 0.76 | 69.3 |

| E | CYLINDER | 1.55E-03 | 3.54 | 2.55 | NA | 1.37 | 39.7 |

Table 1: Catalysts and their properties employed in the bulk crushing study. Table 1 shows catalyst properties and derived stress properties that allow to calculate the reduction in aspect ratio during compression in the bulk crush strength measurement. Adapted from Beeckman et al. 201718

Figure 1: Three-Point Bending of a Catalyst Extrudate by an External Force F. Schematic representation of the catalyst and the position of the force applied in the middle of the two support points for the determination of the modulus of rupture. The amount of bending is highly exaggerated. According to elasticity theory, the axial stress is compressive at the top of the extrudate and the axial stress is tensile at the bottom of the extrudate. Hence there is an axis with zero stress and this is called the centroid. When the tensile stress at the bottom reaches the tensile strength of the material or modulus of rupture, the extrudate breaks at the extreme fiber located at the very bottom and propagates very fast to complete extrudate failure. Adapted from Beeckman et al. 2016 16. Please click here to view a larger version of this figure.

Figure 2: Impact of Extrudates on an Empty Polycarbonate Surface. High speed photography showing a sequence of two catalyst extrudate impingements against a polycarbonate surface. Shots are 0.1 ms apart from each other. Adapted from Beeckman et al. 2016 16. Please click here to view a larger version of this figure.

Figure 3: The aspect ratio as a function of the drop height and the number of impacts. Aspect ratio as a function of the drop height or severity and the number of impacts. For high drop heights, the asymptotic aspect ratio changes only little since the extrudates reach their terminal velocity. Adapted from Beeckman et al. 2016 15. Please click here to view a larger version of this figure.

Figure 4: Aspect ratio after 1 drop of catalyst A with a large initial aspect ratio. Aspect ratio after a single drop of extrudates that have a large aspect ratio prior to the drop. For such long extrudates, the second asymptote becomes plainly visible even in the presence of substantial experimental error due to the limited number of extrudates used. Adapted from Beeckman et al. 2016 15. Please click here to view a larger version of this figure.

Figure 5: Catalyst Aspect ratio versus load stress for catalyst A. Reduction of the aspect ratio as a function of the applied load stress in the bulk crush strength measurement according to method ASTM D7084-04. The aspect ratio remains constant until the critical pressure is reached whereafter the catalyst breaks to smaller and smaller values as the pressure increases. Each data-point is a separate measurement with fresh catalyst from the beginning. Adapted from Beeckman et al. 201718 Please click here to view a larger version of this figure.

Discussion

Breakage by Impulsive Forces due to Collision:

The reduction in extrudate aspect ratio due to collision against a surface can be measured in a laboratory drop test. In this test, the extrudates are released from a chute, fall and accelerate due to gravity and also experience drag with ambient air.

The method outlined above is so far only available in the literature as described in Beeckman15,16. Until recently, the high degree of tediousness to make manual measurements by caliper for a large number of extrudates is likely a contributing factor for this. The exposure time to ambient air and hence humidity should be minimized during and between measurements. If necessary, the protocol for the drop test may need to be performed with a N2 purge or a dry-air purge into the cylinder. One may also choose to let the catalyst equilibrate in ambient air overnight prior to taking any measurements to make moisture pick-up less of an issue. The protocol and method here employed has the benefit that it quickly yields the aspect ratio for over 100-300 extrudates and hence it takes most of the variability that can be observed with small samples out of contention.

It is important that extrudates with a length to diameter ratio less than unity be removed from the sample since the shape recognition software could assign length and diameter of such catalyst pieces erroneously. Hence it is also important to minimize and better yet to eliminate the number of such short extrudates. Therefore, it is recommended to work with extrudates that have a sufficiently large aspect ratio at the beginning of the test and to limit the impact severity of the test.

For future work and from a fundamental perspective, it would be very interesting to study the collision of single extrudates as a function of their length, as a function of the drop height, as a function of the impact angle and as a function of angular momentum to mention just a few variables. Upon breakage, it will be interesting to determine the location of the rupture surface(s) along the length of the original extrudate. This methodology may also be applicable to materials that are not extruded but that are rather obtained by pressing or for spherical pellets and hence may have applications for the pharmaceutical industry and the food industry.

Breakage due to stress in a fixed bed

The method outlined above is so far only available in the literature as described in Beeckman18. For the bulk crush strength, it is important to follow the standard operating protocol as outlined in ASTM D7084-0417 for reason of repeatability.

The exposure time to ambient air and hence humidity should be minimized during and between measurements. If necessary, the protocol may need to be performed in a glove box for the application of the bulk crush strength.

As in the case of collision, this methodology may also find applicability to materials that are not extruded but rather obtained by pressing into pellet form or for spherical pellets obtained via dripping or granulation.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors acknowledge the help from Michael Pluchinsky with the high-speed photography work

Materials

| Modulus of rupture (MOR) | INSTRON | MODEL 5942 SINGLE COLUMN TABLE TOP | |

| Modulus of rupture (MOR) | INSTRON | 10 NEWTON LOAD CELL | |

| Modulus of rupture (MOR) | INSTRON | 50 NEWTON LOAD CELL | |

| Modulus of rupture (MOR) | INSTRON | BLEUHILL 3 SOFTWARE | |

| Filter | VWR | BUCHNER FILTER | |

| Aspect ratio (avg L/D) | EPSON | PERFECTION V700 PHOTO INSTRUMENT | |

| Software | CASCADE DATA SYSTEMS | ALIAS 3-4 SOFTWARE | |

| Riffling | HUMBOLDT MFG. Co | SPINNING RIFFLER | |

| Riffling | HUMBOLDT MFG. Co | RIFFLE -TYPE SAMPLE DIVIDER | |

| Sieve screen | VWR | US MESH SIEVE SCREEN, # 16 |

References

- Le Page, J. F. . Applied Heterogeneous Catalysis. , (1987).

- Woodcock, C. R., Mason, J. S. . Bulk Solids Handling: An Introduction to the Practice and Technology. , (1987).

- Bertolacini, R. J. Mechanical and Physical Testing of Catalysts. ACS Symposium series. , 380-383 (1989).

- Wu, D. F., Zhou, J. C., Li, Y. D. Distribution of the mechanical strength of solid catalysts. Chem Eng Res Des. 84 (12), 1152-1157 (2006).

- Li, Y., Wu, D., Chang, L., Shi, Y., Wu, D., Fang, Z. A model for bulk crushing strength of spherical catalysts. Ind Eng Chem Res. 38, 1911-1916 (1999).

- Li, Y., et al. Measurement and statistics of single pellet mechanical strength of differently shaped catalysts. Powder Technol. 113, 176-184 (2000).

- Staub, D., Meille, S., Le Corre, V., Chevalier, J., Rouleau, L. Revisiting the side crushing test using the three-point bending test for the strength measurement of catalyst supports. Oil Gas Sci Technol. 70, 475-486 (2015).

- Bridgwater, J. Chapter 3, Particle Breakage due to Bulk Shear. Handbook of Powder Technology, 1st ed. 12, (2007).

- Farsi, A., Xiang, J., Latham, J. P., Carlsson, M., Stitt, E. H., Marigo, M. Does Shape Matter? FEMDEM Estimations of Strength and Post Failure Behaviour of Catalyst Supports. 5th International Conference on Particle-Based methods. , (2017).

- Beeckman, J. W. L., Fassbender, N. A., Datz, T. E. Length to Diameter Ratio of Extrudates in Catalyst Technology, I. Modeling Catalyst Breakage by Impulsive Forces. AIChE J. 62, 639-647 (2016).

- Beeckman, J. W. L., Fassbender, N. A., Datz, T. E. Length to Diameter Ratio of Extrudates in Catalyst Technology, II. Bending strength versus Impulsive Forces. AIChE J. 62, 2658-2669 (2016).

- Beeckman, J. W. L., Cunningham, M., Fassbender, N. A., Datz, T. E. Length-to-Diameter Ratio of Extrudates in Catalyst Technology: III. Catalyst Breakage in a Fixed Bed. Chem. Eng. Technol. , 1844-1851 (2017).