Measurement of Outgassing Rates of Steels

Summary

A protocol for the measurement of outgassing rates of hydrogen from ordinary steel vacuum chambers using the rate-of-pressure rise method is presented.

Abstract

Steels are commonly used materials in the fabrication of vacuum systems because of their good mechanical, corrosion, and vacuum properties. A variety of steels meet the criterion of low outgassing required for high or ultrahigh vacuum applications. However, a given material can present different outgassing rates depending on its manufacturing process or the various pretreatment processes involved during the fabrication. Thus, the measurement of outgassing rates is highly desirable for a specific vacuum application. For this reason, the rate-of-pressure rise (RoR) method is often used to measure the outgassing of hydrogen after bakeout. In this article, a detailed description of the design and execution of the experimental protocol involved in the RoR method is provided. The RoR method uses a spinning rotor gauge to minimize errors that stem from outgassing or the pumping action of a vacuum gauge. The outgassing rates of two ordinary steels (stainless steel and mild steel) were measured. The measurements were made before and after the heat pretreatment of the steels. The heat pretreatment of steels was performed to reduce the outgassing. Extremely low rates of outgassing (on the order of 10−11 Pa m3 sec−1 m−2) can be routinely measured using relatively small samples.

Introduction

Steels are routinely used in construction because of their good mechanical properties. Certain steels (ferrous steels, in particular) are preferred materials for applications involving vacuum. Depending on the type and grade, these steels have sufficiently low outgassing rates essential for high vacuum (HV, 10−7 < p < 10−5 Pa) or ultrahigh vacuum (UHV, 10−10 < p < 10−7 Pa) systems. Further, extensive research has been conducted toward the development of special pretreatment procedures that reduce outgassing1-3. The pretreatment measures are designed to minimize the pumping investment or to improve the vacuum from HV to UHV or from UHV to extreme-high vacuum (p < 10−10 Pa).

Although many practical methods have been proposed to reduce the outgassing rate of ferrous steels, recent methods are focused on reducing the time and temperature required to obtain a lower outgassing rate. Heat treatment at 350 °C-450 °C rather than vacuum firing at 800 °C-950 °C, is a good example of this approach.1,4,5 Furthermore, choosing the ideal material for a specific vacuum application is critical; for example, selecting a ferritic material with a very low outgassing rate for use in magnetic field shielding.6,7

During such investigations, precise measurement of the outgassing rate is a prerequisite for the screening of candidate materials or verifying the effectiveness of various pretreatment procedures.8,9 The most common experimental techniques used for the measurement of outgassing are the throughput and rate-of-pressure rise methods.10 Recently, various experiments have been conducted to measure the hydrogen outgassing rate based on the RoR method using spinning rotor gauge (SRG).1, 11-13 The RoR method using SRG is highly suitable for measuring very low hydrogen outgassing rates that often limit the lowest pressure achievable in a vacuum system made of steel. This is because the SRG has negligible pumping or outgassing action. Further, the SRG also has excellent accuracy and good linearity in high vacuum and ultra-high vacuum range.14

Given that the published literature on RoR experiments is limited, it is worthwhile to describe the experimental details to develop a deeper understanding of the method. In this video article, we describe in detail the process of setting up the experiment and provide detailed instructions to perform outgassing measurements using the RoR method. To demonstrate the efficacy of the method, the outgassing rates of two commonly used steels (stainless steel 304 and mild steel S20C) were measured before and after a preheat treatment to reduce the hydrogen outgassing rate. The pre- and post-treatment values were compared. Typical experimental results using a rather simple setup are presented to demonstrate the efficacy of the method optimized for evaluating low hydrogen degassing rates.

Protocol

Caution: Please follow all appropriate safety practices while assembling the equipment and sample chambers. Please wear personal protective equipment (safety glasses, gloves, safety shoes, etc.).

1. Fabrication of a Sample Vacuum Chamber

- Design and fabrication of the vacuum chamber

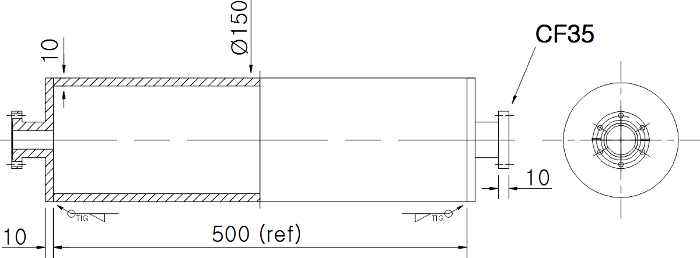

- Prepare and submit design drawings to a commercial vendor or an in-house machine shop for manufacturing the sample vacuum chamber. A representative example of the design drawing for a vacuum chamber made of S20C steel is shown in Figure 1. The chamber designed in this experiment is very basic and is commonly employed by vacuum companies.

NOTE: The manufacturer should have a basic knowledge of UHV systems. - Inspect all dimensions to ensure compliance with the drawing.

- After shaping (machining) the vacuum chamber, cover the end CF flanges with plastic to prevent damage during transportation.

- Prepare and submit design drawings to a commercial vendor or an in-house machine shop for manufacturing the sample vacuum chamber. A representative example of the design drawing for a vacuum chamber made of S20C steel is shown in Figure 1. The chamber designed in this experiment is very basic and is commonly employed by vacuum companies.

- Cleaning

NOTE: Follow local environment, health, and safety regulations during chemical cleaning. Wear personal protective equipment. Handle the parts using vinyl gloves. Do not touch the parts with bare hands.- Clean the steel parts following the UHV cleaning procedure for steels. A typical cleaning procedure is described below.

- Degrease the parts using a solvent, such as acetone, at room temperature for 5 min.

- Clean the parts in an ultrasonic bath for 20 min using a BN cleaner (pH 13).

- Rinse the parts with tap water for 10 min, followed by a thorough rinse with deionized water for 20 min.

- Rinse thoroughly with alcohol and blow dry using dry nitrogen gas.

- Wrap the parts in clean, lint-free paper and allow the parts to air-dry for one day.

- Welding

NOTE: Do not touch the parts with bare hands. The welder should be trained in UHV welding.- Place the parts on a welding bench.

- Preassemble the parts and align the parts as per the design drawing.

- Back-purge with argon gas (5 L/min) to prevent corrosion during welding.

- Tack weld the end flanges using the Tungsten inert gas (TIG) weld technique (argon flow rate: 8-9 L/min).15

- Weld the end flanges completely using the TIG technique and a turning jig. Allow the heat-affected zone to cool down to room temperature. Stop the argon gas flow.

- Leak test

- Seal one end of the chamber with a CF blank flange.

- Connect the other end to a helium leak detector (HLD).

- Pump down the sample vacuum chamber using the HLD.

- Place the heat-welded seam in a vinyl bag and fill the bag with helium gas.

- Measure any change in the helium level. Ensure that the chamber is leak-proof. The helium leak rate should be <1 × 10−11 Pa m3 sec−1 (1 × 10−10 mbar L sec−1).

- If no leak is observed, vent the chamber. Otherwise, reweld the vacuum chamber after venting (repeat steps 1.3.3 through 1.4.5).

2. Fabrication of the Oven

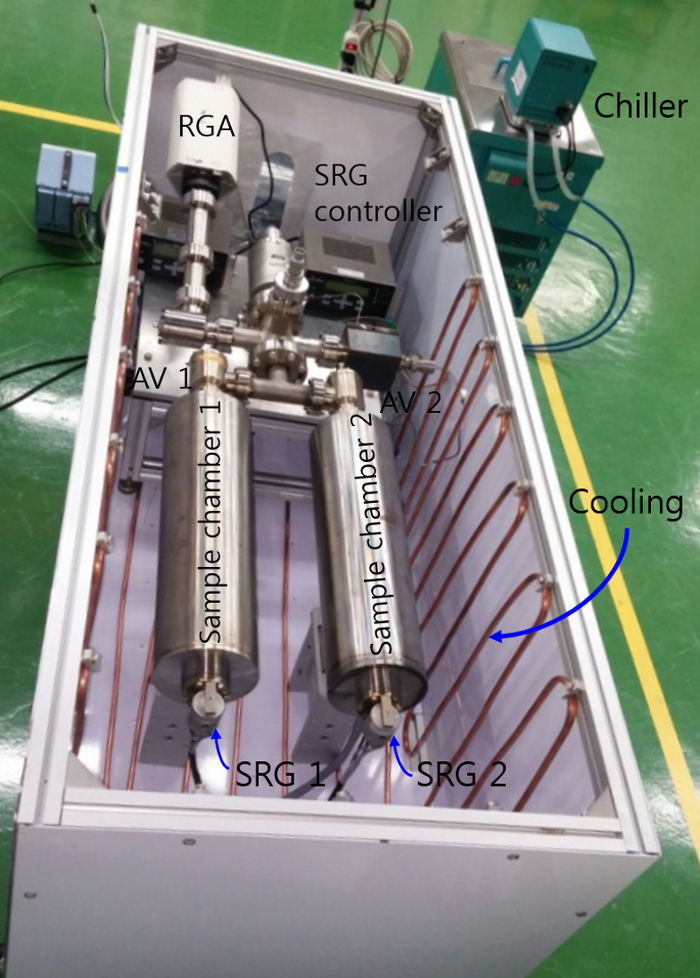

- Prepare and submit the design drawings to a vendor or an in-house machine shop for manufacturing the oven. Refer to the picture shown in Figure 2.

- Procure the required parts and equipment described in Temperature Control of List of Specific Materials/Equipment.

- Connect the cooling line.

- Supply cooling water to a chiller. Run the chiller and check for water leaks. Stop the chiller.

3. Experimental Setup for RoR Measurements

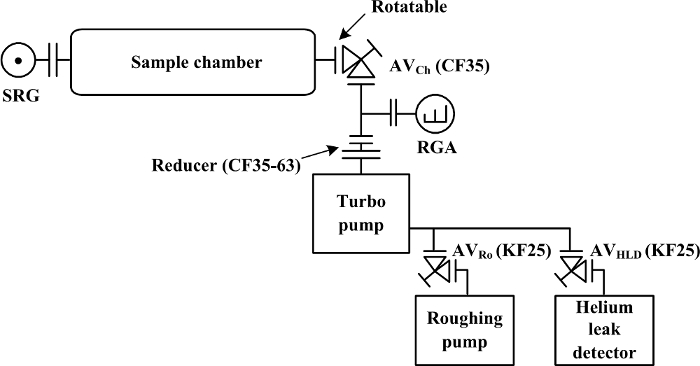

- Collect the required vacuum equipment/hardware specified in the List of Specific Materials/Equipment. The test setup primarily consists of a SRG, a residual gas analyzer (RGA), a turbomolecular pump (TMP) equipped with a roughing pump (RP), an all-metal angle valve (AVCh), a tee (CF35), and a reducer (CF35 to CF63). Additional items may include a helium leak detector and an UHV gauge, as listed in the List of Specific Materials/Equipment. The AVCh should have a rotatable flange on the seat (sealing) side to level off the SRG.

- Collect the wrenches (M6 and M8), copper gaskets (CF35 and CF63), and bolts/nuts (M6 and M8) required for the assembly.

- Use an industrial level meter to assemble the SRG.

- Handle the parts using vinyl gloves. Do not touch the surface that is exposed to vacuum with bare hands. Wear safety shoes.

- Assembly of the experimental apparatus

- Assemble the vacuum components sequentially using copper gaskets from the pump side to the sample side, as shown in Figure 3. Always place the valve seat side facing the sample chamber. Tighten all flange joints face-to-face with a copper gasket (CF35) using a wrench (M6), except the joint between the sample chamber and the chamber isolation valve (AVCh).

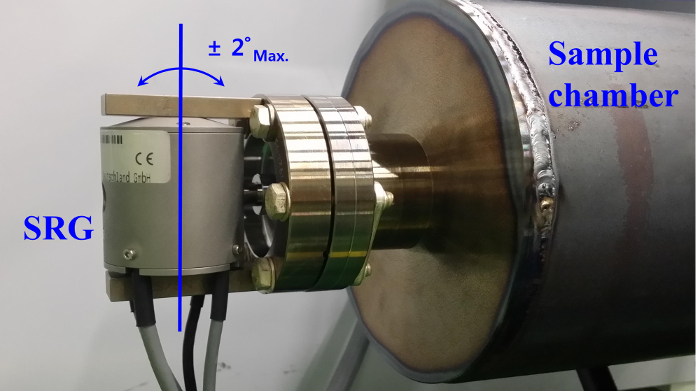

- Adjust the SRG flange assembly and the sample chamber so that the axis of the SRG head is vertical using the level meter; within ±2° (max) (Figure 4). Tighten the flange joint between the sample chamber and the AVCh, face-to-face, while maintaining the SRG flange's level. Refer to the SRG user's manual for detailed instructions.

- Connect the RP and the HLD with isolating valves (AVRo, AVHLD) to the clamp flange (KF) port of the exhaust end of the TMP.

Caution: Ensure that there is no mechanical shock to the SRG flange assembly or rotor.

- Leak test

- Turn on the HLD and wait until the detector is ready. Open the AVHLD and close the AVRo.

- Pump down the setup using the HLD. Refer to the HLD manual for the correct operating procedure. Wait for ~30 min to pump out the residual helium gas from the setup. Ensure that the helium level is within the minimum detectable limit of the HLD.

- Spray helium gas through the leak-test groove on the flanges.

- Measure any change in the helium level. Ensure that the chamber is leak tight. The helium leak rate should be <1 × 10−11 Pa m3 sec−1 (1 × 10−10 mbar L sec−1).

- In case of leakage from the flanges, retorque the flanges.

- If no leaks are found, stop the leak testing and vent the vacuum system. Open the AVRo and close the AVHLD.

4. Measurement of Outgassing Rates

- Pump down procedure

- Pump down the vacuum system by switching on the TMP and the RP at the same time.

- While the pumping process is on, collect the necessary items for bakeout; electrical heater tapes, heater controllers, handheld multimeter, Al foil, and temperature sensors/cables.

- Bakeout procedure

- Remove the SRG head from the flange assembly. Wrap vacuum components (between the SRG flange assembly and the inlet flange of the TMP) in band heaters.

- Check and ensure that there is no electrical short circuit between the heaters and the vacuum parts using handheld multimeter.

- Connect the heaters to the respective controllers and wrap the chamber in Al foil.

- Raise the temperature to 150 °C at a ramp rate of 1 °C-2 °C/min.

- Hold the chamber at 150 °C for 24-48 hr using bakeout program controller. Maintain the temperature of the RGA electronics under 50 °C using cooling fan.

- Degas each of the RGA filaments by electron bombardment for at least 5 min.

- Measure the RGA spectrum from 1 to 50 m/e to ensure that the H2O peak (m/e = 18) is less than one-half of the H2 peak (m/e = 2). If not, continue the bakeout.

- Allow the system to cool down to room temperature at a ramp rate of 1 °C-2 °C/min. Check for leaks referring to the RGA spectrum measured during the cool down.

- Analyze the residual gas in the sample chamber. Measure the RGA spectrum. Close the AVCh and measure the RGA spectrum again. The RGA spectrum of the sample chamber corresponds to the difference between the spectra acquired before and after closing the AVCh.

- Verify that the sum of all impurity gases, such as H2O, CO, and CO2, is below 5%; otherwise, repeat the bakeout again.

- Operating the SRG

NOTE: Proper operation of the SRG is very important. Refer to the SRG operating manual for instructions.- Assemble the SRG head on the SRG flange assembly.

- Ensure that the axis of the SRG head is within ±2° (max) (Figure 4). Use a level meter for reference.

- Start the SRG and wait for stabilization of the residual drag, a pressure-independent signal of the SRG, which usually takes a few hours.

- Enter the proper input parameters, such as gas (H2), temperature (24 °C), and measurement interval (10 sec).

- Procedure for initiating temperature control

- While waiting for the signal to stabilize, stabilize the temperature of the sample. Switch on the chiller to run cooling water through the system. Set the fluid temperature to 15 °C.

- Start the heater controller for the sample. Set the target temperature to 24 °C. Wait for the temperature to stabilize within ±0.1 °C after closing the door of the oven.

- Procedure for acquiring the SRG signal

- Verify that the variation of the offset value of the signal is within ±1 × 10−9 Pa/sec; otherwise, disassemble the SRG from the system and change the rotor or flange assembly, then repeat 3.5-4.4. (If this is not possible, acquire the slope of the offset for 8-24 hr. This will be subtracted from the measured outgassing rate data.)

- Check the signal level provided by SRG controller; it should be at least −10 dB. Ideally, it should be between 0 and 6 dB. However, values of up to 12 dB are acceptable. If the signal is >14 dB, stop the SRG operation. Detach the head and heat the thimble to 200 °C. Repeat the entire operation starting from step 4.5.1.

- Check the damping level provided by SRG controller; the optimum value is between −35 and −60 dB, which is normally satisfied in the system using TMP and scroll pump which is laid on a rubber pad. Otherwise, stop all running equipment and remove sources of any mechanical vibration.

- Acquiring the RoR data

- Gently close the AV to start the pressure buildup. Be careful not to subject the SRG to a mechanical shock.

- Close the door of the oven and acquire pressure data for 8-24 hr using a computer.

- Precheck the measured data to verify that the variation in temperature is within ±0.1 °C after stabilization and that the pressure rise is linear within 10% error. If these criteria are met, stop the measurement. Otherwise, continue to measure until the pressure rise becomes linear within 10% error for at least 16 hr.

- Turn off all equipment.

- Calculation of the outgassing rate

- Select the pressure set after the temperature stabilization.

- Fit the pressure rise data using linear least squares fitting and calculate the slope. The slope dP/dt is the measured rate of pressure rise after the valve is closed.

- Calculate the outgassing rate, q (H2 equivalent), using the equation

q = (V/A) (dP/dt) [Pa m3 sec−1 m−2],

where V is the volume of the sample chamber (m3) and A is the geometrical surface area of the chamber (m2).

Representative Results

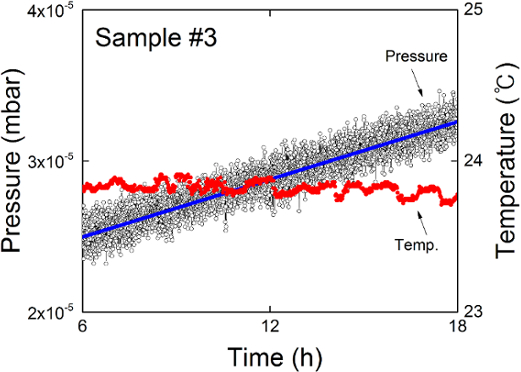

As expected, the residual gas after the bakeout was mostly hydrogen.7 The pressure rise measured using the SRG was linear over a long period of time (Figure 5). Thus, the readsorption effect might be negligible and the intrinsic outgassing rate (q) for the steels tested in this study can be evaluated using the RoR method.10 The measured pressure rise data was analyzed using the linear least squares fitting method. The outgassing rates of the sample chambers were determined from the slope (Figure 5).

The measured outgassing rate for untreated STS304 steel (sample 1) was 5.1 × 10−9 Pa m3 sec−1 m-2, which is consistent with the reported values.1-7 A ~22-fold reduction in outgassing was achieved with a medium-temperature heat pretreatment in vacuum furnace for 36 hr at 450 °C (Table 1). This demonstrates the effectiveness of heat pretreatment in reducing the hydrogen outgassing rate of stainless steel, further indicating that the degassing of hydrogen during the heat treatment is governed by a bulk diffusion mechanism. While the outgassing rates for untreated mild steels were very low (<~4 × 10−10 Pa m3 sec−1 m−2 (samples 2 and 3), the outgassing rates were second to the rates of stainless steels after intensive heat treatment.1,3,4 In addition, the outgassing rate for mild steel (sample 2) decreased by only 66% following heat treatment at 850 °C for 12 hr in vacuum furnace (Table 1), and no significant reduction in outgassing was observed.

The findings from these measurements strongly suggest that the difference in outgassing between stainless steels and mild steels can be attributed to the differences in the steel making processes, and in particular, the secondary metallurgy processes, during which impurity gases are extracted.16 A vacuum degassing process, such as the Ruhrstahl-Hausen process, is generally employed during the production of mild steels. Thus, mobile hydrogen is completely degassed during the steel-making process. In contrast, mixed-gas refining, such as argon-oxygen decarburization at atmospheric pressure, is primarily used during the production of stainless steels. This provides a reasonable explanation for the observed lower hydrogen outgassing rate of untreated mild steel compared to untreated stainless steel.7

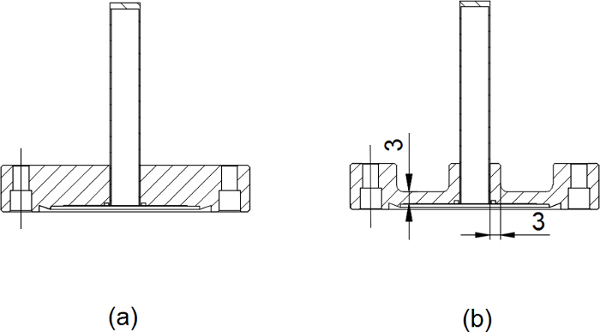

Figure 1. Sample chamber. An example of a vacuum chamber made of steel. A steel cylinder and two end plates with flanges (CF35) were directly welded. The area of the inner surface is ~2,400 cm2 and the volume is ~7 L. Please click here to view a larger version of this figure.

Figure 2. Oven. A bird-eye view of the oven, together with the experimental setup and the sample vacuum chamber. A simple, box-shaped oven is adequate for this experiment. Please click here to view a larger version of this figure.

Figure 3. Experimental setup. A schematic of the experimental setup for the measurement of outgassing rates using the RoR method. A cylindrical sample chamber is placed inside a simple oven and pumped through an all-metal angle valve (AV). After bakeout, the SRG pickup head is attached and is switched on. The active temperature control is then initiated. CF: flange, KF: clamp flange, RGA: residual gas analyzer, and TMP: turbomolecular pump. Please click here to view a larger version of this figure.

Figure 4. Mounting of the SRG head on the vacuum chamber. The axis of the SRG head should be vertical within ±2° (max) as shown. A level meter should be used to align the head. Please click here to view a larger version of this figure.

Figure 5. Representative raw RoR data (dotted line) measured using the SRG after bakeout. The solid line (in blue) is the least-squares fit of the data. The slope of the curve corresponds to an outgassing rate of 4 × 10−10 Pa m3 sec−1 (H2 equivalent). The solid line at the bottom (in red) shows the measured temperature variation, which is within ±0.1 °C. Please click here to view a larger version of this figure.

Figure 6. Modification of a commercial SRG flange. The flange is thinned as per the design drawing and heat treated at 400 °C for 72 hr (Fo ~6.4) to reduce outgassing. The measured gas load on the SRG flange, together with the angle valve (from the surface exposed to the SRG side), was 8.3 (± 0.1) × 10−12 Pa m3 sec−1, which amounts to 15%-28% of the outgassing from the samples after heat treatment (Table 1). This background gas load must be subtracted from the total gas load on the sample vacuum chamber. Please click here to view a larger version of this figure.

| Material | Sample no. | d (mm) | D (cm2/sec) | Heat treatment | Fo | q (Pa m3 sec-1 m-2) |

| Stainless steel (304) | 1 | 3.3 | – | 5.1×10-9 | ||

| 5×10-7 | 450 °C, 36 hr | 2.4 | 2.3×10-10 | |||

| Mild steel (S20C) | 2 | 10 | – | 2.6×10-10 | ||

| 1×10-4 | 850 °C, 12 hr | 17 | 8.8×10-11 | |||

| 3 | 10 | – | 4.0×10-10 |

Table 1: Measured outgassing rates. The rates (q) are total outgassing rates, in hydrogen equivalent units, and measured after an in situ bakeout at 150 °C for 48 hr. Fo represents the intensity of heat treatment (dimensionless); Fo = 4Dt/d2, where D is the diffusion constant at the heat pretreatment temperature and d is the thickness of the chamber.12,13

Discussion

Numerous methods for the measurement of outgassing rates have been reported in the literature. Experimental methods include the throughput, conductance modulation, two-path, RoR, and variations of these methods. However, no one method is ideal for obtaining the necessary outgassing data.10 The RoR method using SRG, however, became the method of choice for measurement of low outgassing materials.11-13 SRG17 is often used as a secondary standard in high vacuum systems without erroneous pumping or outgassing action. The RoR method using SRG is particularly suitable for measuring hydrogen outgassing at room temperature after bakeout. In contrast, other UHV gauges can cause significant errors generated by the gauges themselves. An extractor gauge, for instance, is a type of UHV ion gauge with low outgassing. However, the gauge itself and the surrounding walls generate a gas load as large as 1 × 10−11 Pa m3 sec−1.18 This amounts to 14%-30% of the gas load from the samples following the heat treatment (Table 1).

The outgassing from SRG flange (CF35) must be taken into account when measuring samples with a small area. Though small in size, the hydrogen outgas from the flange is as large as 7.5 × 10−12 Pa m3 sec−1 and the flange is too thick to degas hydrogen without firing. This amounts to approximately 12%-26% of the outgassing from the samples after heat treatment (Table 1). Thus, this systematic error in the measured gas load must be corrected. Thinning the commercial SRG flange (Figure 6) and performing an appropriate heat treatment in vacuum will help minimize the outgassing. However, in a real situation, the combined background gas loads from the SRG flange assembly and the angle valve must be measured and corrected before the main measurements. Furthermore, using a thimble without a flange that is directly welded on the sample chamber is another good technique for measuring outgassing from very small samples (surface area <500 cm2) using a pinch-off copper tube instead of an angle valve.12,13

In addition, proper operation of the SRG is crucial to ensure the precise measurement of extremely low outgassing rates. The pressure range that the measurement is taken over is from 10−8 Pa to 10−3 Pa. The temperature control is especially important. A slow, constant temperature change of 0.14 °C/hr causes a 10% error in the measured values.

Thus, the active temperature control unit, comprising a copper cooling coil at a constant temperature of 15 °C and a proportional-integral-derivative controlled heater, was deployed in this study. The temperature was stabilized to within ±0.1 °C during the measurements (Figure 5). At this temperature stability, RoR measurements as low as 1 × 10−3 Pa/day could be made in a single day.

Fabrication of individual parts of the sample chamber with the same thickness is another important factor affecting the outgassing rate following heat treatment (Figure 1). As stated earlier, bulk diffusion governs the degassing of mobile hydrogen, at least in the initial stage of heat treatment. In the RoR method, the outgassing rate depends not only on the duration of the heat treatment but also strongly on the sample thickness.19 Thus, reporting the outgassing rate with respect to the intensity of heat treatment (for example, Fo = 4Dt/d2, Table 1)12,13 is recommended; simply reporting the duration of the heat treatment is misleading with respect to the intensity of heat treatment.

Using the protocol reported in this study that uses commercial parts to the extent possible, an outgassing rate lower than 1 × 10−10 Pa m3 sec−1 m−2 can be routinely measured from vacuum chambers made of steel. With careful design and under optimum experimental conditions, such a low rate can be measured from samples with a relatively small area. The surface area of the vacuum chamber used in this study is only 2,400 cm2, which is one-third of the surface area of the chambers (7,600 cm2) used in previous experiments for making similar measurements.5 The equipment identified in this protocol is specific to the most suitable commercial ones. It should be noted that with a proper, carefully designed experimental setup and protocol, other equipment or methods can be used for the same purpose.

Furthermore, although ferrous steels were used in this video protocol, the same techniques are applicable to the measurement of outgassing rates from numerous other materials that can be used for the fabrication of vacuum chambers.

Offenlegungen

The authors have nothing to disclose.

Acknowledgements

This work was supported jointly by the Converging Research Center Program through the Ministry of Science, ICT and Future Planning, Korea (NRF-2014M3C1A8048817) and R&D Convergence Program of NST (National Research Council of Science and Technology) of Republic of Korea (CAP-14-3-KRISS).

Materials

| Sample chamber | |||

| Stainless steel, 304 | POSCO (www.posco.co.kr) | ||

| Mild steel, D3752 | Xiangtan Iron&Steel co.,LTD (http://www.hnxg.com) | ||

| Mild steel, D3752 | SeAh Besteel (www.seahbesteel.co.kr) | ||

| Name | Company | Catalog Number | Comments |

| Cleaning | |||

| Cleaning bath | Samill IDS | Ultrasonic cleaning, heating, timer, concentration control | |

| Acetone | Samchun Chemical (www.samchun.com) | A1759 | HPLC GRADE (99.7%) |

| Tekusolv | NCH Co. (www.nch.com) | 0368-0058J | Solvents |

| BN cleaner | Henkel surface technologies (na.henkel-adhesives.com) | 6610263775 | Akkaline, pH 13 |

| Ethanol | Fisher Scientific (www.fishersci.com) | A995-4 | HPLC Reagent(99.9%) |

| Deionized water (Electro deionizer SYSTEM) | A.T.A (www.atagroup.co) | EDI SYSTEM | |

| Liquid N2 gas | Hanyoung (www.gasmaster.co.kr) | B/T 176 L | LN2 dewar, purity 99.999% |

| Name | Company | Catalog Number | Comments |

| Welding | |||

| Tungsten Inert Gas wedling machine | Thermal Arc (www.victortechnologies.com/thermalarc) | 400GTSW | Ar gas prefllow&postflow 8 liter/min, backflow 5 liter/min |

| turning jig | Vactron (www.vactron.co.kr) | Made to order | Made to order |

| Ar gas | Lindekorea (www.lindekorea.com) | Purity 99.999% | |

| Name | Company | Catalog Number | Comments |

| Leak test | |||

| Leak detector | Adixen (www.adixen.fr/en/) | ASM380 | Pumping Speed(air): 9.7 l/s |

| He gas | Lindekorea (www.lindekorea.com) | Purity 99.999% | |

| Name | Company | Catalog Number | Comments |

| Vacuum equipment | |||

| Spinning rotor gauge | MKS Instruments (www.mks.com) | SRG-3 | Controller, head, and thimble set |

| Industrial level meter | MKS Instruments (www.mks.com) | SRG-3 | For SRG assemble ± 1˚ |

| Oscilloscope | Tektronix (www.tek.com) | TDS2012B | |

| Residulal gas analyser | Balzers | QMA200 | m/e 0-100 |

| TMP(HiPace 80) | Pfeiffer Vacuum (www.pfeiffer-vacuum.com) | PMP03941 | Pumping Speed(N2): 67 l/s |

| Scroll pump | Anest Iwata (www.anest-iwata.co.jp) | ISP 90 | Pumping Speed(Air): 1.8 l/s |

| All-metall easy close angle valve(CF35) | VAT Inc. (www.vatvalve.com) | 54032-GE02-0002 | Rotatable flange |

| Angle valve(KF25) | MDC Vacuum Inc. (www.mdcvacuum.com) | KAV-100 | |

| Five-Way Crosses | MDC | Made to order | CF4-1/2 Spool-rotatable 1-way to CF2-3/4 Nipple 3ea, Vacuum degassed at 400℃ for 3 days |

| Reducing Tees | MDC | Made to order | CF4-1/2 Flange to CF2-3/4 Tees(Half flange), Vacuum degassed at 400℃ for 3 days |

| Name | Company | Catalog Number | Comments |

| Temperature control | |||

| Chiller | JEIO Tech (www.jeiotech.com) | RW-2025G | |

| Cooling line | LS Metal (www.lsmetal.biz) | C1100 | Level Wound Coil, Diameter 10mm |

| Heater controllers | HMT | Made to order | Bakeout program controller |

| Electrical heater tapes | Brisk heat (www.briskheat.com) | BIH101080L | |

| Thermocouple(K type) | miraesensor (www.miraesensor.com) | MR-2290 | |

| Handheld multimeter | Saehan (www.saehan.co.kr) | 3234 | |

| Data recorder(Temp.) | Yokogawa (www.yokogawa.com) | GP10-1E1F-UC10 | |

Referenzen

- Mamun, M. A., Elmustafa, A. A., Stutzman, M. L., Adderley, P. A., Poelker, M. Effect of heat treatments and coatings on the outgassing rate of stainless steel chambers. J. Vac. Sci. Technol. A. 32 (2), 021604 (2014).

- Sasaki, Y. T. Reducing SS 304/316 hydrogen outgassing to 2×10−15 torr l /cm2 s. J. Vac. Sci. Technol. A. 25 (4), 1309-1311 (2007).

- He, P., Hseuh, H. C., Mapes, M., Todd, R., Weiss, D., Wilson, D. Outgassing properties of the spallation neutron source ring vacuum chambers coated with titanium nitride. J. Vac. Sci. Technol. A. 22 (3), 705-710 (2004).

- Bernardini, M., et al. Air bake-out to reduce hydrogen outgassing from stainless steel. J. Vac. Sci. Technol. A. 16 (1), 188-193 (1998).

- Park, C., Chung, S., Liu, X., Li, Y. Reduction in hydrogen outgassing from stainless steels by a medium-temperature heat treatment. J. Vac. Sci. Technol. A. 26 (5), 1166-1171 (2008).

- Kamiya, J., et al. Vacuum chamber made of soft magnetic material with high Permeability. Vacuum. 98, 12-17 (2013).

- Park, C., Ha, T., Cho, B. Thermal outgassing rates of low-carbon steels. J. Vac. Sci. Technol. A. 34 (2), 021601 (2016).

- Battes, K., Day, C., Hauer, V. Outgassing rate measurements of stainless steel and polymers using the difference Method. J. Vac. Sci. Technol. A. 33 (2), 021603 (2015).

- Jousten, K., Putzke, S., Buthig, J. Partial pressure measurement standard for characterizing partial pressure analyzers and measuring outgassing rates. J. Vac. Sci. Technol. A. 33 (6), 061603 (2015).

- Redhead, P. A. Recommended practices for measuring and reporting outgassing data. J. Vac. Sci. Technol. A. 20 (5), 1667-1675 (2002).

- Jousten, K. Calibration of total pressure gauges in the UHV and XHV regions. J. Vac. Soc. Jpn. 37 (9), 678-685 (1994).

- Nemanic, V., Setina, J. Outgassing in thin wall stainless steel cells. J. Vac. Sci. Technol. A. 17 (3), 1040-1046 (1999).

- Nemanic, V., Setina, J. A study of thermal treatment procedures to reduce hydrogen outgassing rate in thin wall stainless steel cells. Vacuum. 53, 277-280 (1999).

- Berg, R. F., Fedchak, J. A. NIST Calibration Services for Spinning Rotor Gauge Calibrations. Natl. Inst. Stand. Technol. Spec. Publ. , 250-293 (2015).

- Kou, S. . Welding Metallurgy. , 13-16 (2003).

- Fruehan, R. J. . Vacuum Degassing of Steel. , (1990).

- Fedchak, J. A., Scherschligt, J., Sefa, M. How to Build a Vacuum Spring-transport Package for Spinning Rotor Gauges. J. Vis. Exp. (110), e53937 (2016).

- Saitoh, M., Shimura, K., Iwata, T., Momose, T., Ishimaru, H. Influence of vacuum gauges on outgassing rate measurements. J. Vac. Sci. Technol. A. 11 (5), 2816-2821 (1993).

- Calder, R., Lewin, G. Reduction of stainless-steel outgassing in ultra-high vacuum. Brit. J. Appl. Phys. 18, 1459-1472 (1967).