Microtensiometer for Confocal Microscopy Visualization of Dynamic Interfaces

Summary

This manuscript describes the design and operation of a microtensiometer/confocal microscope to do simultaneous measurements of interfacial tension and surface dilatational rheology while visualizing the interfacial morphology. This provides the real-time construction of structure-property relationships of interfaces important in technology and physiology.

Abstract

Adsorption of surface-active molecules to fluid-fluid interfaces is ubiquitous in nature. Characterizing these interfaces requires measuring surfactant adsorption rates, evaluating equilibrium surface tensions as a function of bulk surfactant concentration, and relating how surface tension changes with changes in the interfacial area following equilibration. Simultaneous visualization of the interface using fluorescence imaging with a high-speed confocal microscope allows the direct evaluation of structure-function relationships. In the capillary pressure microtensiometer (CPM), a hemispherical air bubble is pinned at the end of the capillary in a 1 mL volume liquid reservoir. The capillary pressure across the bubble interface is controlled via a commercial microfluidic flow controller that allows for model-based pressure, bubble curvature, or bubble area control based on the Laplace equation. Compared to previous techniques such as the Langmuir trough and pendant drop, the measurement and control precision and response time are greatly enhanced; capillary pressure variations can be applied and controlled in milliseconds. The dynamic response of the bubble interface is visualized via a second optical lens as the bubble expands and contracts. The bubble contour is fit to a circular profile to determine the bubble curvature radius, R, as well as any deviations from circularity that would invalidate the results. The Laplace equation is used to determine the dynamic surface tension of the interface. Following equilibration, small pressure oscillations can be imposed by the computer-controlled microfluidic pump to oscillate the bubble radius (frequencies of 0.001-100 cycles/min) to determine the dilatational modulus The overall dimensions of the system are sufficiently small that the microtensiometer fits under the lens of a high-speed confocal microscope allowing fluorescently tagged chemical species to be quantitatively tracked with submicron lateral resolution.

Introduction

Air-water interfaces covered by surfactant films are ubiquitous in daily life. Surfactant-water injections are used to enhance oil recovery from depleted fields and are used as hydraulic fracturing solutions for shale gas and oil. Gas-liquid foams and liquid-liquid emulsions are common to many industrial and scientific processes as lubricants and cleaning agents and are common in food. Surfactants and proteins at interfaces stabilize antibody conformations during packaging, storage, and administration1,2,3,4,5, tear film stability in the eye6,7,8, and pulmonary mechanics9,10,11,12,13,14,15.

The study of surface-active agents or surfactants adsorbing to interfaces and their properties has a long history with many different experimental techniques16,17,18,19,20,21,22,23,24,25,26,27. A recent development is the capillary pressure microtensiometer (CPM), which allows the examination of interfacial properties on highly curved interfaces, at much smaller length scales, while using significantly fewer materials than other common methods9,23,24,25. Confocal fluorescence microscopy (CFM) can be used to study the morphology of lipids and proteins at the air-water interfaces in the CPM22 or on Langmuir troughs20,26,27,28,29. Here a CPM and CFM have been combined to connect morphological phenomena to dynamic and equilibrium interfacial properties to develop structure-function relationships for biological and technological interfaces.

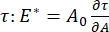

There are numerous parameters of importance in interfacial surfactant systems accessible to the CPM-CFM. In the CPM, a 30-200 µm diameter air bubble is pinned to the tip of a glass capillary tube. In earlier versions of the CPM, the capillary pressure difference between the inside and outside of the bubble was controlled via a water column and oscillatory syringe pump9,30 ; the new version described here replaces these with a higher precision, computer-controlled microfluidic pump. The surface tension (γ) is determined via the Laplace equation, ΔP = 2γ/R, from the pressure drop across the interface set by the pump, ΔP, and optical analysis of the radius of curvature of the bubble, R. The dynamic surface tension of the interface can be determined with 10 ms time resolution following the generation of a new bubble in contact with a bulk liquid containing a soluble surfactant. The surfactant adsorption dynamics can be described by the classic Ward-Tordai equation10,31 to determine essential properties of the surfactant, including the diffusivity, surface coverage, and the relationship between bulk concentration and equilibrium surface tension. Once an equilibrium surface tension is achieved, the interfacial area can be oscillated to measure the dilatational modulus,  , by recording the changes in surface tension, induced by small changes in the bubble surface area, A32. For more complex interfaces that develop their own internal structures such as entangled polymers or proteins, the surface tension, , is replaced by a more general surface stress4,33,

, by recording the changes in surface tension, induced by small changes in the bubble surface area, A32. For more complex interfaces that develop their own internal structures such as entangled polymers or proteins, the surface tension, , is replaced by a more general surface stress4,33,  .

.

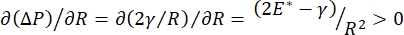

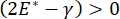

Lung stability during breathing may be directly tied to maintaining both a low surface tension and a high dilatational modulus at the alveolar air-liquid interface9,10. All internal lung surfaces are lined with a continuous, microns-thick film of epithelial lining fluid to maintain tissue hydration34. This epithelial lining fluid is primarily water, with salts and various other proteins, enzymes, sugars, and lung surfactant. As is the case for any curved liquid-vapor interface, a capillary pressure is induced with the pressure higher on the inside of the alveolus (or bubble). However, if the surface tension was constant everywhere within the lungs, the Laplace equation, ΔP = 2γ/R, shows that smaller alveoli would have a higher internal pressure relative to larger alveoli, forcing the gas contents of the smaller alveoli to flow to larger, lower pressure alveoli. This is known as "Laplace Instability"9,35. The net result is that the smallest alveoli would collapse and be filled with liquid and become difficult to re-inflate causing part of the lung to collapse, and other parts would over-inflate, both of which are typical symptoms of acute respiratory distress syndrome (ARDS). However, in a properly functioning lung, the surface tension changes dynamically as the air-epithelial fluid interface in the alveolus interfacial area expands and contracts during breathing. If  , or

, or  , the Laplace pressure decreases with decreasing radius and increases with increasing radius so as to eliminate the Laplace instability, thereby stabilizing the lung9. Hence,

, the Laplace pressure decreases with decreasing radius and increases with increasing radius so as to eliminate the Laplace instability, thereby stabilizing the lung9. Hence,  , and how it depends on frequency, monolayer morphology and composition, and alveolar fluid composition may be essential for lung stability. The CPM-CFM has also provided the first demonstrations of the effects of interfacial curvature on surfactant adsorption25, monolayer morphology22 and dilatational modulus9. The small volume (~1 mL) of the reservoir in the CPM allows for the quick introduction, removal, or exchange of the liquid phase and minimizes the required quantity of expensive proteins or surfactants10.

, and how it depends on frequency, monolayer morphology and composition, and alveolar fluid composition may be essential for lung stability. The CPM-CFM has also provided the first demonstrations of the effects of interfacial curvature on surfactant adsorption25, monolayer morphology22 and dilatational modulus9. The small volume (~1 mL) of the reservoir in the CPM allows for the quick introduction, removal, or exchange of the liquid phase and minimizes the required quantity of expensive proteins or surfactants10.

Contrast in a CPM-CFM image is due to the distribution of small fractions of fluorescently tagged lipids or proteins at the interface16,27. Two-dimensional surfactant monolayers often exhibit lateral phase separation as a function of surface tension or surface pressure,  π is the difference between the surface tension of a clean fluid-fluid interface, γ0, and a surfactant-covered interface, γ. π can be thought as the 2-D "pressure" caused by the interactions of surfactant molecules at the interface that acts to lower the pure fluid surface tension. At low surface pressures, lipid monolayers are in a liquid-like disorganized state; this is known as the liquid expanded (LE) phase. As the surface pressure increases and the area per lipid molecule decreases, the lipids orient with each other and can undergo a first order phase transition to the long-range ordered liquid condensed (LC) phase16,20,27. The LE and LC phases can coexist at various surface pressures and can be visualized as fluorescently tagged lipids are excluded from the LC phase and segregate to the LE phase. Thus, the LE phase is bright and the LC phase is dark when imaged with CFM16.

π is the difference between the surface tension of a clean fluid-fluid interface, γ0, and a surfactant-covered interface, γ. π can be thought as the 2-D "pressure" caused by the interactions of surfactant molecules at the interface that acts to lower the pure fluid surface tension. At low surface pressures, lipid monolayers are in a liquid-like disorganized state; this is known as the liquid expanded (LE) phase. As the surface pressure increases and the area per lipid molecule decreases, the lipids orient with each other and can undergo a first order phase transition to the long-range ordered liquid condensed (LC) phase16,20,27. The LE and LC phases can coexist at various surface pressures and can be visualized as fluorescently tagged lipids are excluded from the LC phase and segregate to the LE phase. Thus, the LE phase is bright and the LC phase is dark when imaged with CFM16.

The goal of this manuscript is to describe the steps necessary to build and operate the combined confocal microscope microtensiometer. This will allow the reader to perform adsorption studies, measure surface tension, rheological behavior, and examine interfacial morphology simultaneously on a micron-scale air/water or oil/water interface. This includes a discussion of how to pull, cut and hydrophobize the required capillaries, instructions for using pressure, curvature, and surface area control modes, and interfacial transfer of insoluble surfactant to the microtensiometer curved interface.

Protocol

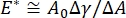

1. Preparation of capillary tubes

- Place the capillary into a capillary puller and run the desired pulling program to make two tapered capillaries with an outside diameter (OD) of ~1 µm at the tip.

NOTE: The OD of the capillary before pulling must be the OD specified to fit in the capillary holder in the microtensiometer cell. The inner diameter (ID) of the capillary can vary, but will affect the critical radius of the capillary following pulling. A pulling program is chosen so that the resulting taper initially reduces the capillary OD and ID quickly, then reaches a radius near the desired capillary OD and ID, and then reduces in diameter more slowly. This will create a greater capillary length that can be scored to yield a usable capillary of 30-100 µm in ID. - Score the tip of the capillary at the desired spot to obtain an ID of 30-100 µm and break off the tip. The capillary will now have an OD and ID of the desired radius at the tip (Figure 1A). The capillaries can be stored until step 2.

NOTE: The cut edge of the capillary must be a 90° clean break. Any defect in the cut edge will lead to bad pinning of the bubble to the capillary and poor surface property measurements. Tapered capillary tips are very delicate. They will be destroyed if they come into contact with anything other than the solutions (e.g., vial walls, air nozzle).

2. Hydrophobization of capillaries

- Gather pulled glass capillaries, acid cleaning solution, plastic tweezers, deionized (DI) water, hydrophobization solution (2% silane in ethanol), vacuum pump, and ethanol solution. See Table of Materials for details.

CAUTION: Acid cleaning solution is acutly toxic, causes skin and eye corrosion/irritation, is oxidizing. Hydrophobization solution is a skin/eye/respiratory irritant. Wear eye protection, lab coats, and gloves and work with solutions in a fume hood. - Acid-clean the capillary

NOTE: Acid-cleaning the capillary removes any organic residues inside the capillary and prepares the glass surface for the silanization reaction that renders the capillary hydrophobic.- Grab a capillary firmly near its wide end with the tweezers.

- Dip the tapered tip into the acid cleaning solution while attaching the hose from the vacuum pump to the wide end of the capillary. This will suck the solution into the capillary.

NOTE: A pipette tip may be attached to the end of the capillary hose to allow for a better fit with the capillary end. - Stop when the acid cleaning solution has filled about half of the capillary.

NOTE: After removal of the capillary tip from the acid cleaning solution, the solution on the exterior of the capillary often forms a bead near the capillary tip. Gently touch the capillary to the neck of the solution vial to remove excess solution. - Allow the acid cleaning solution to remain in the capillaries for at least 30 min, ensuring that the plug of the liquid remains at the tapered end of the capillary.

- Remove the acid cleaning solution from the capillary by firmly holding the capillary with the tweezers and using the vacuum hose to pull out the liquid from the large end of the capillary.

- Rinse the capillary

- Submerge the tapered end of the capillary into DI water ensuring it is submerged deep enough to cover any exterior that was submerged in the acid cleaning solution. While the tip is submerged, use the vacuum hose to pull DI water through the capillary. Remove the capillary from the water and remove the remaining water with the vacuum hose.

- Repeat the above step at least 4x.

- Perform step 2.3 again substituting ethanol for DI water.

- Apply suction continuously until the ethanol completely evaporates from the interior of the capillary. The capillary will become cloudy and cool to touch as the ethanol begins to evaporate but will clear after 30 to 45 s.

- Coat the capillary with the hydrophobization solution

- Briefly dip the wide end of the capillary into the ~2% silane in ethanol solution. Capillary action will cause the coating solution to rise within the capillary. Remove the capillary from the solution once a ~1 cm size plug has risen within the capillary.

- Orient the capillary so that the tapered tip faces downward, allowing the coating solution to fall with gravity toward the tapered tip.

- Allow the coating solution to remain in the capillary for at least 3 min.

NOTE: There must be no air bubbles in the plug of the coating solution that is in contact with the interior of the tapered tip. If there is an air bubble, then the capillary interior was likely not sufficiently dried in step 2.5. To remedy this, repeat steps 2.4-2.6 as needed.

- Rinse the capillaries with ethanol 1x in the same manner as step 2.3.

- Set the hydrophobic coating on the capillary

- Place clean and dry scintillation vials into a vacuum oven set to 120 °C. Place coated capillaries into the vials (ideally one capillary per vial) with wide ends resting on the base of the vial. Allow capillaries to remain in the oven for at least 6 h (overnight preferred) to achieve permanent bonding of the hydrophobic silane layer to the capillaries. The capillaries can be stored until step 4.

3. Sample preparation and storage

- Mix and store surfactant and fluorophore solutions in clean acid-washed vials to avoid contamination.

NOTE: Commercially available lipids must be of the highest purity and stored between use at – 20 °C. Old or contaminated lipids often cause results to be difficult to reproduce.

4. Setting up the microtensiometer

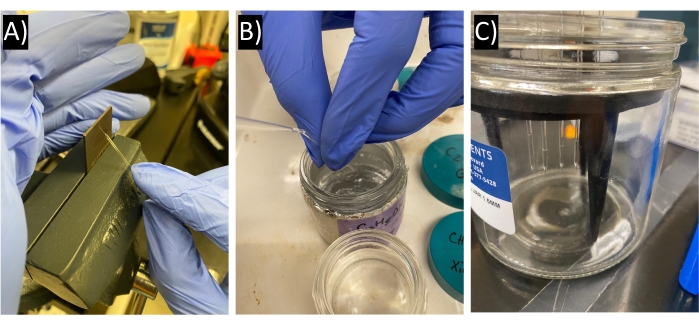

- Assemble the CPM cell as described in Figure 2.

- Place the large side of the capillary into the top of the CPM cell until it pushes through to the underside of the cell.

- Gently tighten the PEEK plug to secure the capillary, and then attach the tube from the microfluidic pump to the large side of the capillary. Be careful not to touch the tapered capillary tip.

- As necessary, attach the reservoir exchange and/or temperature control hoses to the respective inlets and outlets on the CPM cell (Figure 2); otherwise, plug the unused inlets and outlets.

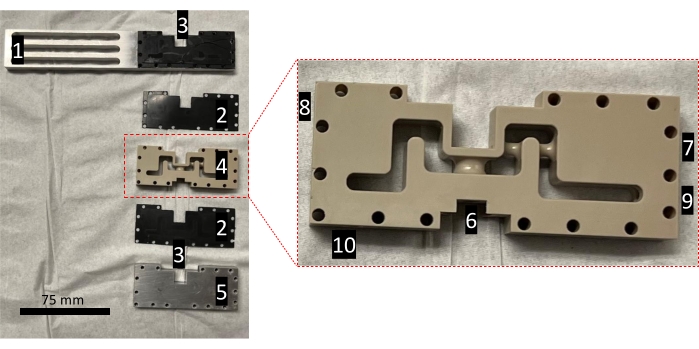

- Attach the CPM cell to the confocal microscope stage, roughly aligning it with the CFM objective, CPM camera, and CPM light source (Figure 3).

- Open the gas flow to the microfluidic pump at the recommended operating pressure of the pump (150 mbar for the microfluidic pump used here) and ensure the flow to the capillary is open.

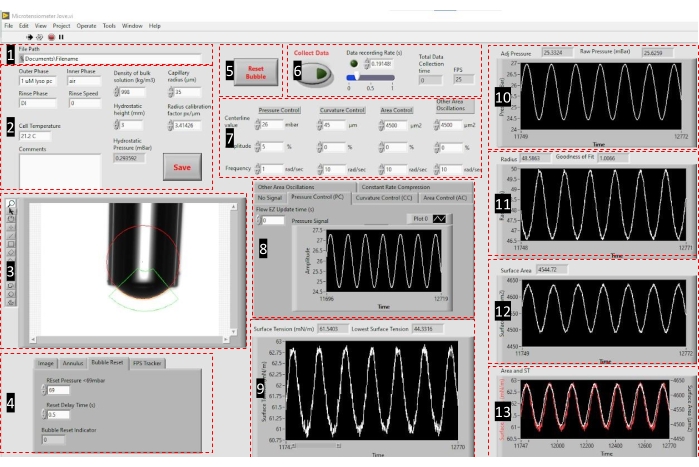

- Start running the CPM virtual interface (Supplemental Coding File 1: Microtensiometer Virtual Interface.vi) in Pressure Control mode with the capillary pressure oscillation frequency and amplitude set to zero (Figure 4–7). Figure 4 shows a screenshot of the virtual interface. For DI water and a capillary radius of ~35 µm, a pressure of ~20 mbar ensures that no water enters the capillary.

- Fill the CPM cell with water using a pipette.

- Focus on the capillary tip using the microtensiometer camera.

- Focus on the capillary tip with the CFM. If there is difficulty finding the capillary, use the CPM camera to find the CFM objective. This will help approximate the distance between the CFM objective and the bubble, achieving the correct working distance.

- After the annulus (green sector projection) is centered on the bubble, manually adjust the focus so that the bubble edge can be seen clearly (Figure 4-3).

NOTE: The position, start and end angle, and inner and outer radii of the annulus can be adjusted via the menu below the view window. - Click on Reset Bubble, and make sure that a new bubble is formed (one will be able to hear the old bubble pop, and the new bubble will be observable from the control panel viewing window; Figure 4-3). If the bubble does not pop, increase the Reset Pressure or increase the Reset Delay Time in the Bubble Reset tab below the viewing window. Check whether the surface tension is around 73 mN/m (for saline or water/air bubbles) (Figure 4-9).

- Take out the water via the direct-to-cell syringe (Figure 3-13), empty it, and reattach it. The sample is ready for loading to run the experiment.

5. Adsorption study

- Fill the cell with the desired sample using an autoclaved pipette keeping the CPM software in Pressure Control mode. Make sure the initial surface tension is around 73 mN/m when a new bubble interface is created.

- Determine the radius of the newly formed bubble and input that value into the centerline area control (Figure 4-7) and change the control type to area control by clicking on the Area Control tab (Figure 4-8).

NOTE: Constant pressure control can also be used, but this causes the bubble radius to change continuously as the surface tension of the interface changes. This changing area can complicate the analysis of surfactant adsorption rates and cause the bubble to pop during the study. - Start recording the confocal video.

- Click on Reset Bubble (Figure 4-5), and immediately click on Collect Data (Figure 4-6). The signaling light on the button will turn green.

- Adjust the data recording rate according to the concentration of the sample by sliding the bar shown in Figure 4-6. For slower adsorptions, use a slower recording rate. This can be adjusted in the middle of a run if a higher recording rate is desired early on, but a slower rate is preferable for long studies in order to reduce file size.

- After the end of the experiment (when a final surface tension plateau has been reached), save the file by choosing the correct file path (Figure 4-1) and clicking on the Save button (Figure 4-2).

- Stop and save the recording on the CFM as well.

6. Oscillation/relaxation study

- Fill the cell with the sample using an autoclaved pipette keeping the CPM software in Pressure Control mode. Make sure the surface tension is around 73 mN/m when a new bubble interface is created.

- Wait until the sample is fully adsorbed to the interface. This can be performed directly after an adsorption study instead of starting over with a new bubble interface.

- Decide whether oscillation will be a pressure oscillation, area oscillation, or curvature oscillation by selecting the appropriate tab (Figure 4-8) and entering the desired baseline value, oscillation% and oscillation frequency (Figure 4-7).

NOTE: Sawtooth, square, and triangular wave area oscillations are also accessible from the drop-down menu in the Other Area Oscillation tab. - Start the recording of the confocal video and click on Collect Data (Figure 4-6) on the CPM software.

- Start the oscillation. Be sure to record at least seven cycles for best results. Choose a data acquisition rate (Figure 4-6) to give an adequate number of data points for each oscillation cycle.

- If other oscillation amplitudes or frequencies are desired, change the values during the experiment.

- Save the results as in steps 5.6 and 5.7.

7. Solvent exchange study

- Fill the cell with the sample using an autoclaved pipette keeping the CPM software in pressure control mode. Make sure the surface tension is around 73 mN/m, when a new bubble interface is created.

NOTE: Adsorption and/or oscillation studies can be performed prior to the solvent exchange study. - Connect the inlet tube with the bottle of desired exchange solution (Figure 3-11) to the peristaltic pump (Figure 3-10).

- Start the recording of the video in confocal software and click on Collect Data (Figure 4-6) on the CPM software.

- Set the peristaltic pump speed. This will control the rate of fluid exchange and must be chosen based on the requirements for the experiment, i.e., how fast the solvent needs to be exchanged.

- If multiple fluids need to be exchanged, stop the peristaltic pump, and connect the inlet to another exchange solution.

- After the exchange has finished (~20 min), save the results as in step 5.6 and 5.7.

8. Insoluble surfactant adsorption

NOTE: If the surfactant to be adsorbed is not soluble in the reservoir liquid, this method can be used to transfer a monolayer from the air/water interface of the cell to the bubble surface. Many bilayer forming lipids are almost insoluble in saline solution and do not spontaneously absorb to the bubble when suspended in the reservoir solution.

- Fill the cell with the sample using an autoclaved pipette keeping the CPM software in Pressure Control mode. Make sure the surface tension is around 73 mN/m, when a new bubble interface is created.

- Deposit a monolayer of insoluble surfactant on air-water interface of the cell from a solution in a volatile organic solution. Using a syringe, deposit small droplets at the interface and allow the solvent to evaporate leaving the lipid behind as a thin film.

CAUTION: Chloroform is used as a solvent for phospholipids such as phosphatidylcholines and fatty acids. Spreading solutions are usually 0.01-0.02 mg of lipid per mL of the solvent. Chloroform is acutely toxic, can cause skin and eye irritation, and is carcinogenic. Wear appropriate eye protection, lab coat, and gloves and make the solution in a fume hood. - Decrease the surface area via the centerline pressure control (Figure 4-7) of the bubble until it is nearly flat. This prevents the bubble from popping after the surfactant has adsorbed.

- Remove the reservoir liquid from the cell via the direct-to-cell syringe until the air/water interface moves past the tip of the capillary. While a syringe pump can be used, this step can be achieved by manually using the syringe.

- Increase the reservoir liquid height to its initial level.

NOTE: After the tip is resubmerged, the bubble will be larger due to the surfactant that is now adsorbed on the interface. The monolayer will now be ready for oscillation or solvent exchange experiments.

9. Clean up

- Turn off the CFM.

- Change to the Pressure Control mode.

- Remove the sample from the cell using a pipette. Load the cell with DI water and turn up the pressure to ~50 mbar to cause bubbles to constantly escape the capillary and clean the capillary tip. Repeat this process 2x.

- Close the safety valve and turn off the CPM by clicking on the red button in the upper-left corner, turn off the light and blue pressure control panel, and close off the pressure source.

- Remove the cell from the confocal microscope stage. Rinse the cell out with ethanol and DI water. Remove the capillary tube from the CPM cell.

10. Cleaning the cell

- Disassemble the cell. Brush the inside wall with a toothbrush while rinsing under DI water. Submerge the parts in ethanol and sonicate it for ~30 min.

- Rinse all the parts with DI water a few times. Dry the parts by either blowing them with nitrogen gas or drying them inside a vacuum oven.

11. Oscillation analysis

- Run the Dilatational_Rheology_Analysis.m code (Supplemental Coding File 2), choosing the desired file saved from the CPM virtual interface. Sample data is included in the supplemental files.

- The pressure vs. time plot will appear as shown in Supplementary Figure 1. Left-click the point where the oscillation starts and left-click again where the oscillation ends. If the data contains multiple oscillations, repeat this process for all oscillations.

- When all start and end points have been left-clicked, right-click the mouse anywhere. For example, as shown in Supplementary Figure 1, one can left click at points 1, 2, 3, and 4, followed by a right-click.

NOTE: The code will calculate the dilatational modulus and phase angle and the results will be written to a new .csv file in the original file location. The results for the sample data can be seen in the code results given in the Supplemental Coding File 2. MATLAB will also generate several graphical representations of the data as shown in Supplementary Figure 2.

- When all start and end points have been left-clicked, right-click the mouse anywhere. For example, as shown in Supplementary Figure 1, one can left click at points 1, 2, 3, and 4, followed by a right-click.

Representative Results

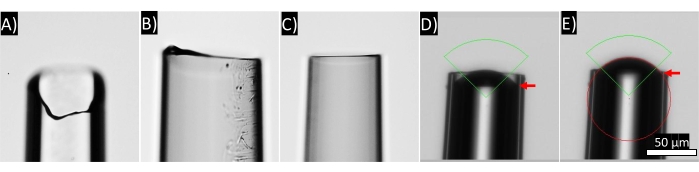

A major source of measurement error arises from the capillaries that have defects either from the cutting process (Figure 5A,B) or the coating process (Figure 5D). Both types of defects lead to errors in determining the bubble shape and size by the optical image analysis system, leading to inaccurate surface tension values. It is important to carefully examine each new capillary after it is pulled and coated under the optical microscope before inserting the capillary into the CPM. A miscut capillary must be discarded, but a poorly coated capillary can be acid-cleaned and re-coated to improve the bubble pinning at the end of the capillary (step 2 of the Protocol). Capillaries work best if the end cut is perfectly perpendicular to the capillary (Figure 5C) and the bubble pins directly at the end of the capillary (Figure 5E). The hydrophobic coating on the capillary will become less effective at pinning with use, requiring the capillary to be re-cleaned and re-coated.

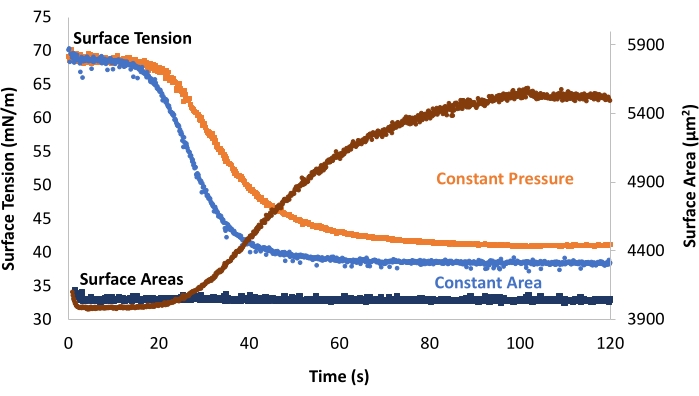

Representative data for surfactant adsorption vs. time is presented in Figure 6. Previous experimental techniques such as a pendant or sessile drops used to measure surfactant adsorption did not have a mechanism to dynamically adjust the capillary pressure as the change in surface tension causes the bubble area to change during adsorption30,36,37. In fact, for larger bubbles and drops, changes in the bubble or drop shape (and hence surface area) are required to determine the surface tension from the analysis of the interface shape as the capillary pressure is not measured independently and the capillary pressure varies over the drop or bubble surface37. This also complicates the analysis of the adsorption because as surfactant adsorbs to the interface, the surface tension decreases, and to satisfy the Laplace equation the surface area of the bubble must increase, requiring additional surfactant to adsorb to reach equilibrium. In the CPM, a fixed capillary pressure requires that the initial bubble radius must be within a small range prior to surfactant adsorption to prevent the bubble from ejecting from the capillary if the surface tension decreases too much. Surfactant adsorption dynamics are often modeled by the classic Ward-Tordai equation31, which describes the adsorption of surfactant molecules to a clean interface of constant interfacial area. While the Ward-Tordai equation can be modified to account for the changing surface area, this introduces additional parameters and greatly complicates the analysis38,39.

To overcome these issues, a model-based feedback loop was developed using the Laplace equation that holds the curvature (and surface area) of the bubble constant throughout the adsorption process by dynamically adjusting the capillary pressure. There are significant differences in the rate of change of the surface tension because the area of the bubble is not constantly increasing. The changes in the bubble area during adsorption are not constant with time as the surface tension changes slowly at first, and then rapidly accelerates prior to equilibration. An additional complication is that the fractional change in the area depends on the initial bubble radius. An additional benefit of constant bubble radius is that imaging the interface is simplified as the bubble surface remains fixed, which simplifies focusing the CFM. During the adsorption process, as surfactant adsorbs to the interface (Video 1), the fluorescent signal from the interface increases. If the surfactant forms surface domains, these domains can be observed forming and growing22.

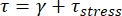

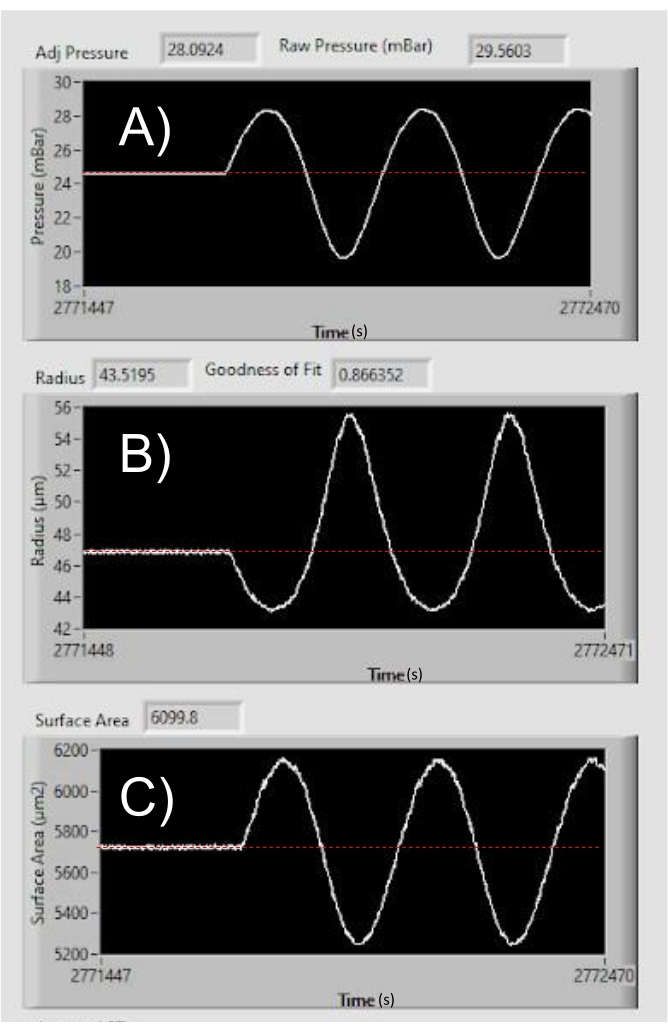

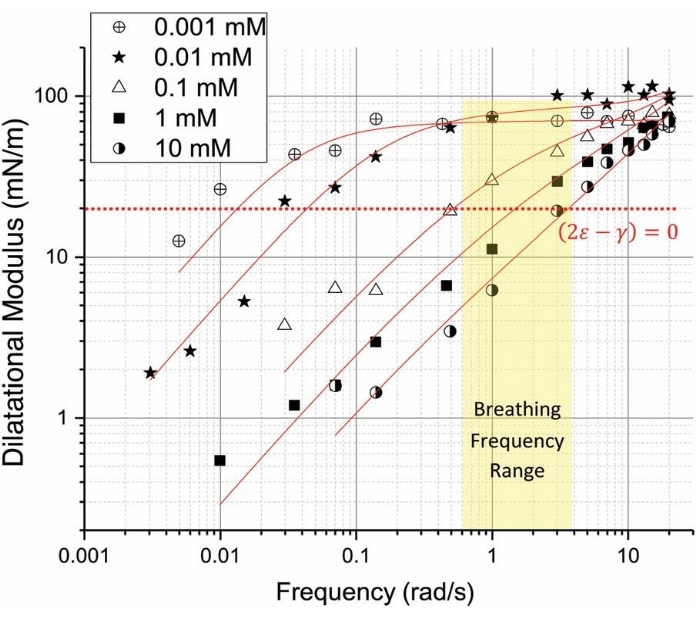

The changes in surface tension during area oscillations are shown in Figure 7. In previous versions of the CPM, oscillations were made in the bubble capillary pressure; however, generating a sine wave in capillary pressure does not translate directly into a sine wave in surface area as the two are related via the Laplace equation. By taking advantage of a model-based feedback loop using the Laplace equation, oscillations are created in the area rather than in capillary pressure, leading to data that is easier to analyze and collect over a larger range of amplitudes. As a result, the surface tension vs. area data collected from this method can be used to directly calculate the interfacial dilatational modulus of the surfactant layer:  (Figure 8), where

(Figure 8), where  is the total stress of the system and τstress is non-isotropic deviatoric stress often absent in simple surfactant solutions4,33. Thus, for a simple surfactant system,

is the total stress of the system and τstress is non-isotropic deviatoric stress often absent in simple surfactant solutions4,33. Thus, for a simple surfactant system,  . For interfaces where elastic networks can be formed, such as surface-active proteins, extra stresses are often present and thus must be accounted for when defining the dilatational modulus. Video 2 shows a CFM video of the motion of black LC domains in a continuous colored LE phase matrix in phospholipid monolayers. The distinct LC domains on the interface reorganize into a branching network that covers the interface when oscillations take place on the curved bubble22,40. The Other Area Oscillations tab can be used to create sawtooth, square, and triangular waves as seen in Supplemental Figure 3 and the Compression tab allows for constant rate area compression and expansion.

. For interfaces where elastic networks can be formed, such as surface-active proteins, extra stresses are often present and thus must be accounted for when defining the dilatational modulus. Video 2 shows a CFM video of the motion of black LC domains in a continuous colored LE phase matrix in phospholipid monolayers. The distinct LC domains on the interface reorganize into a branching network that covers the interface when oscillations take place on the curved bubble22,40. The Other Area Oscillations tab can be used to create sawtooth, square, and triangular waves as seen in Supplemental Figure 3 and the Compression tab allows for constant rate area compression and expansion.

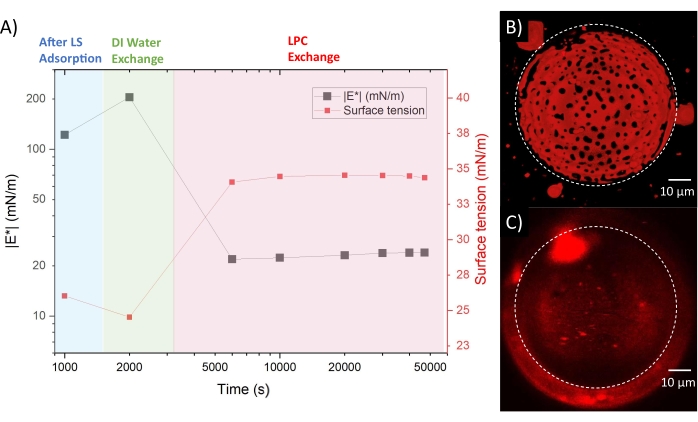

For solvent exchange studies, a surfactant is first allowed to adsorb to the interface, and then the reservoir liquid is exchanged to allow a second surface-active species to contact that interface. It is possible to examine the change in surface tension as the second surfactant competes with the original surfactant at the interface. The surface dilatational modulus is often a more sensitive probe of the surfactant exchange along with the surface morphology via CFM. Figure 9 shows the change in surface tension, surface dilatational modulus, and surface morphology as one such solvent exchange takes place. While the specifics of such an exchange can vary, a change to any of the three properties could indicate integration of the second component into the monolayer or solvation of the primary component into the bulk. A second fluorescent tag could be attached to the secondary species to observe its interaction with the interface from the CFM images.

Figure 1: Capillary Treatment. (A) Image showing the scoring of the capillary. The glass scoring ceramic is held in a clamp to hold it steady. (B) Acid-cleaning of the capillary. The acid cleaning solution is pulled into the capillary with the vacuum pump. (C) Hydrophobization of the capillary. Silane solution plug held inside the capillary Please click here to view a larger version of this figure.

Figure 2: Cell construction. (1) Large aluminum cell holder, (2) Fluoroelastomer gasket (four in total), (3) glass slide (two in total), (4) PEEK cell, and (5) small aluminum cell holder. When assembled, a fluoroelastomer gasket is placed on either side of each glass slide. The cell is held together with screws and bolts. The zoomed-in image of the PEEK cell shows the locations of the various ports: (6) capillary port, (7) solvent exchange inlet, (8) solvent exchange outlet, and (9,10) temperature control jacket inlet and outlet. A PEEK plug can be used to attach the tubing or capillary to the cell. Ports that are not being used can be completely closed by plugs without channels. Please click here to view a larger version of this figure.

Figure 3: Schematic of CPM/CFM, not to scale. (1) the CPM cell, (2) the capillary tube with a bubble at the tip, (3) confocal microscope objective, (4) microscope camera objective with filter, (5) CPM light source, (6) microfluidic pump, (7) safety valve, (8) fluid exchange inlet, (9) fluid exchange outlet, (10) peristaltic pump, (11) exchange fluid reservoir, (12) fluid exchange waste, (13) direct to cell syringe, (14) temperature control jacket inlet and outlet, and (15) temperature-controlled reservoir and pump. Please click here to view a larger version of this figure.

Figure 4: CPM virtual interface. (1) the file path where the data will be saved; (2) system parameters, comments, and the Save button. All fields in this area are saved to the final data file; (3) the CPM camera image; (4) settings controlling the image analysis, annulus measurement, bubble reset, and frames per second tracking; (5) the Bubble Reset button; (6) the Collect Data button, data recording rate control, and data collection indicators; (7) controls for all operating mode centerline values, oscillation amplitude, and oscillation frequency; (8) operating mode switch: clicking each tab changes to that control mode. Each mode shows the pressure signal being sent to the pump in the "Pressure Signal" graph as well as some additional controls; (9) live surface tension data; (10) live pressure data; (11) live radius of curvature data; (12) live surface area data; and (13) live surface tension and surface area data, which can be used to roughly determine the phase angle during an oscillation study. Please click here to view a larger version of this figure.

Figure 5: Capillary Defects. (A) and (B) Miscut capillaries; (C) correctly cut capillary, (D) capillary with bad pinning due to poor or degraded coating, and (E) properly pinned capillary. The red arrows in D and E indicate where the bubbles are pinned. For the best results, the bubble will pin at the capillary tip. Please click here to view a larger version of this figure.

Figure 6: Adsorption study microtensiometer results for both constant pressure (orange) and constant area (blue) adsorptions. The bubble surface area for the constant area adsorption increases significantly throughout the study and causes the adsorption to take longer to reach the same surface tension. Please click here to view a larger version of this figure.

Figure 7: Typical surface area control oscillation. (A) Pressure, (B) curvature, and (C) surface area data. The surface area data is a sinusoid while the pressure and curvature data are not, as evidenced by the centerline values not being at the midpoint of the oscillation. The mathematical relationship between the three values means only one can be a true sinusoid. Please click here to view a larger version of this figure.

Figure 8: Sample rheological results after analysis. Dilatational modulus of Lyso PC (1-palmitoyl-2-hydroxy-sn-glycero-3-phosphocholine) as a function of frequency for increasing concentrations of Lyso PC for ~45 µm radius bubbles. Concentrations >0.1 mM of Lyso PC that accompany inflammation decrease the dilatational modulus over the range of normal ventilation/ breathing rates (yellow) to make 2ε−γ < 0, which is the crossover value for inducing the Laplace instability (dotted red line). Low concentrations of Lyso PC ≤0.01 mM, that may occur in normal lungs do not induce instability. At frequencies >10 rad/sec, all Lyso PC concentrations are above the crossover, and would not be susceptible to the Laplace instability. Solid red lines are fits of theory to the data. Figure reproduced from reference9. Please click here to view a larger version of this figure.

Figure 9: CFM and CPM results for a solvent exchange study for lung surfactant exchanged with DI water and then Lyso PC. (A) shows how surface tension and surface dilatational modulus change throughout the study. The graph is separated into four regions: when the lung surfactant is adsorbed to the interface (blue), when the LS is exchanged with DI water (green), when the exchange solution is switched to a Lyso PC solution (red), and when the cell is filled with the Lyso PC solution (orange). The properties can be seen to change throughout the various exchanges indicating the interface is changing. (B) shows a confocal image of the lung surfactant adsorbed to the interface before exchange and (C) shows the same surface after the exchange with the Lyso PC solution is complete. In both cases, the white dashed circle indicates the inner edge of the capillary. The structure of the domains on the monolayer changes drastically after the solvent exchange, corroborating the CPM results. Please click here to view a larger version of this figure.

Video 1: Confocal video of constant pressure adsorption study for lung surfactant. The false-color shows the distance in the z-direction with the color bar on the left side of the video, with purple indicating the bubble near the capillary and green being the top of the bubble. The interface is initially dimly illuminated as only a little of the fluorescent surfactant is adsorbed. As more and more surfactant adsorbs, the bubble starts to grow as the color shifts more to green and the interface becomes populated by black LC domains that can move across the interface. Aggregates of surfactant in the solution can be seen floating in the solution as bright amorphous shapes and several settle onto the bubble interface, disintegrating and depositing their surfactant onto the interface. Please click here to download this Video.

Video 2: Confocal video of oscillation study for lung surfactant. The false-color shows the distance in the z-direction with the color bar on the left side of the video. The surface is subjected to several different oscillation frequencies and the dark LC domains on the interface can be seen to change throughout the oscillations. Please click here to download this Video.

Supplementary Figure 1: Example of an intermediate step in the code to determine the dilatational rheology. When this screen appears, the user should left-click at the left-most edge of the oscillation to analyze, and then left-click the right-most edge. Multiple oscillations can be analyzed so that the user could left-click on 1, 2, 3, and 4, and then right-click to analyze those two oscillations. The oscillations shown are of different amplitudes and frequencies. Please click here to download this File.

Supplementary Figure 2: Example of the graphical results produced by the dilatational rheology code. This shows the fits of sinusoids to the oscillations in pressure, radius, surface area, and surface tension as well as the Fourier transform of each oscillation. Ideally, the second harmonic in the Fourier transform should be less than 10% of the first harmonic for the surface area and surface tension. Please click here to download this File.

Supplementary Figure 3: Alternate operation modes. (A) Sine wave, (B) Sawtooth wave, (C) Square wave, (D) Triangular wave, (E) Constant rate expansion, and (F) Constant rate compression. The compression and expansive modes allow for Langmuir type isotherms to be created for insoluble surfactants. Please click here to download this File.

Supplemental Coding File 1: Microtensiometer Virtual Interface.vi. Please click here to download this File.

Supplemental Coding File 2: Dilatational_Rheology_Analysis.m. Please click here to download this File.

Discussion

The combined CPM/CFM is a powerful tool for examining interfacial dynamics, equilibria, and morphology. This protocol describes the steps necessary for obtaining data with CPM/CFM.

Figure 2 shows the cell design with channels for the capillary, solvent, and heat exchange indicated. The inlet for solvent exchange should be at the bottom of the cell while the outlet should be at the top, allowing for the cell to not overflow during the exchange. In practice, the inlet and outlet flow rates may be slightly different for the same peristaltic pump. One common problem with this cell design is leaking from the cell. This is most often caused by a poor connection between the cell and one of the connections, but if all connections are dry and not leaking, this may be due to a crack in the glass slide of the cell due to over-tightening of the bolts surrounding the cell.

Figure 3 shows the connections between the various pumps and the cell as well as the alignment of the cell with the CFM and CPM objectives. The CPM camera (4) is used to image the bubble shape during operation. The CPM camera must be outfitted with an optical filter that prevents the CFM exciting laser light from entering the CPM camera. Otherwise, the CFM laser makes images in the CPM camera exceedingly noisy and difficult to fit using image analysis. A safety valve connects the capillary and the microfluidic pump (7) and allows changes to be made to the pump and air pressure source, without the risk of backflow from the cell reaching the pump. A second valve (13) provides access to a syringe to allow direct injection of fluid into and out of the reservoir. Fluid may need to be added to the reservoir in the case of a leak and may need to be removed for step 8 of the protocol (insoluble surfactant adsorption) or to remove bubbles purged from the capillary if they have attached to the confocal objective.

During each experiment, several key steps must be performed carefully. Most of the problems that occur once the instrument is running, involve the capillary itself. As such, careful cutting and coating can minimize difficulties. Cutting the capillary to the desired diameter is a difficult and low-yield process. Any chip or unevenness in the tip of the capillary will lead to poor readings of the bubble radius. Additionally, if the hydrophobic coating is not applied correctly, or if it degrades over time and use, the bubble will not pin properly at the tip of the capillary. This can be indicated by the bubble appearing to be pinned inside the capillary or sliding along the inside of the capillary during an oscillatory study. A capillary that is cut well but not pinning properly can be recleaned and hydrophobically treated.

Another key step and possible source of error is cleaning the cell reservoir, tubing, and capillary between different materials or different concentrations of the same material. There are many small crevices in the reservoir and the surfactant can adsorb and alter measurements taken at later times if not cleaned properly. Complete disassembly and soaking of the cell are often required to ensure the removal of any excess surface-active material. It is better to start by using the lowest concentration if a series of concentrations of the same surfactant is to be studied.

At times, lining up the capillary tube with the confocal objective can be difficult. The microtensiometer camera can be used to help align the confocal objective, but for a large working distance of the CFM objective, this may not be helpful. If the confocal microscope is focused beyond the tip of the capillary, the capillary cross-section, a region devoid of any fluorescent material, can also be used to help orient the objective. If the capillary bubble does not eject, there may be a problem with the pressure being supplied to the capillary (which is supposed to be 150 mbar under normal operation). This can be checked by entering pressure control mode and setting the pressure to a high value. If the pressure does not reach the set pressure, there is likely a leak in the tubing from the microfluidic pump or the pump is not receiving sufficient gas pressure. As with many studies involving surface science, it is important to ensure that no contaminating materials are introduced to the solutions at any point. If readings are not as expected (surface tension starting too low or decreasing too quickly), making a new sample, or using a well-studied sample or pure liquid is also a good early step in troubleshooting.

Several modifications can be made to the apparatus to achieve other experimental goals. Oil or water can be added into the capillary allowing for the study of oil-water instead of air-water interfaces39. This increases the risk of backflow into the pump so additional care must be taken, potentially even adding an oil trap to the tubing between the pump and capillary may be necessary.

There are several limitations to the CPM/CFM. The CPM has a limited working range of capillary size, 20-300 µm for the capillary OD for the pump and optics in the system. While it is possible to add insoluble surfactant to the interface using solvent exchange41 or the method described here, the surface concentration can only be inferred from doing surface tension vs. area isotherms and comparing to those obtained from a Langmuir trough. CFM can only detect fluorescent materials, so any non-fluorescent or non-fluorescently tagged materials cannot be visualized. Many surfactants are small molecules, and tagging them can potentially change their properties, though this should be less of a problem for larger surface-active molecules such as proteins or polymers26,27.

This method has several key advantages over previous CPM and CFM analyses of surfactant-laden interfaces. The most important is that the hybrid instrument allows for visualization of the interface while various dynamic and equilibrium surface properties are being measured. Changes in the morphology of the interface can be directly linked to the interfacial dynamics and rheological properties. Previous CFM of surfactant-laden interfaces was done using a flat Langmuir trough16,20,28,29,42,43,44,45,46,47, while the method described here can be performed on highly curved interfaces22. Additionally, the entire interface can be imaged at once, showing a real-time trackable change of specific domains whereas surface flows on the Langmuir trough led to domains flowing in and out of the confocal visual window. Surface compressions on this apparatus are also isotropic, while the barriers on Langmuir troughs have particular compression directions. The CPM allows for much faster area oscillations than would be possible on a Langmuir trough.

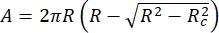

The new curvature and area-based control in this study has major advantages over previous versions of the CPM30. Typically, bubble size was controlled by setting a fixed capillary pressure; for dilatational moduli measurements, the capillary pressure was oscillated. When the capillary pressure is held constant, as surfactant adsorbs to the interface, the surface tension of the bubble decreases. To satisfy the Laplace equation, ΔP = 2γ/R, the radius of curvature must decrease as the surface tension decreases. For the hemispherical bubble in the CPM, decreasing the bubble radius of curvature increases the bubble area9,48:

in which Rc is the capillary radius and R is the bubble radius of curvature. The changing radius of the bubble changes the area of the interface during adsorption, which complicates the analysis of the adsorption using the Ward-Tordai equations10,38 Additionally, if the surface tension of the bubble is lowered enough, the bubble radius will become smaller than the capillary radius and the bubble will be ejected. The feedback loop in this newer CPM/CFM keeps the bubble area constant throughout adsorption, meaning that the original Ward-Tordai equation can be used, there is no risk of bubble ejection, and adsorption happens more quickly as the surface is not increasing in the area. For oscillatory studies, producing a sine wave in the pressure does not produce a sine wave in the surface area48. Previous CPM methods relied on keeping oscillations small in order for the area change caused by the pressure-driven oscillation to approximate a sine wave48. The described method directly controls the area of the bubble and can be used to create true sine wave oscillations in the interfacial area. It is possible to directly relate the stress (change in surface tension) to the interfacial strain (change in surface area) to calculate the dilatational modulus.

To help with the implementation of this protocol, a brief description of the code controlling the microtensiometer is described here. The code consists of three segments in a loop: one issuing commands to the microfluidic pump, one controlling the reset mechanism of the bubble, and one measuring the radius of the bubble and saving the calculated values. The pump controller has three main operating modes: pressure control, curvature control, and area control. In pressure control, the user directly inputs a set point for the pressure created by the pump. This mode is important because it does not require a feedback loop, and as such is the most stable of the modes. Curvature control uses the previously measured surface pressure and the Laplace equation to calculate what pressure is required to create an interface of a given curvature. The surface area control mode builds on this by calculating what curvature is required to create a given surface area based on the geometry of the spherical cap, which also requires a precise measurement of the capillary radius. These two modes are especially useful for adsorption and oscillation studies but require a steady stream of consistent surface pressure data. As such, the feed into these two controllers may need to be smoothed from the raw data for better function. When the solution is not clear enough, often due to a highly turbid sample, this mode will not work properly as getting a good image of the bubble interface is not possible. The controls for the oscillation are also included in this section of the code. The middle segment of the code allows for the bubble to be cleared from the capillary. Here, the set pressure of the capillary is set to a high value and held there for a set amount of time allowing the bubble to pop and a new interface to be created. The last section of the code uses vision acquisition software to track the edge of the bubble and measure its radius. This radius is then used with the Laplace equation to calculate the surface tension, which is then fed to the initial part of the loop.

This hybrid CPM/CFM technique has proven to be greatly beneficial to our studies of model and clinical lung surfactants at air-water interfaces. The bubble dimensions approximate those in the alveoli in the human lung and the effects of interfacial curvature on the morphology and dynamics of lung surfactant monolayers can be observed9,10,22. The hybrid instrument will also be important to studies of other surface-active materials that are ubiquitous with applications ranging from petrochemical to household chemicals, from tear films to antibody stabilization. The combined CPM/CFM allows us to probe dynamic interfacial properties on the scale of phase-separated domains and visualize the morphologies on the surface as external conditions change. This method is particularly useful in applications where expensive materials require using minimal size samples. The simultaneous observation of the interfacial dynamics and monolayer morphology is almost impossible with any other technique, making it broadly applicable to the field of interfacial science.

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

All the confocal microscopy images were obtained using the Nikon A1RHD Multiphoton upright confocal microscope. We acknowledge the guidance and assistance of the support staff, especially Guillermo Marques, at the University Imaging Center at the University of Minnesota. This work was supported by NIH Grant HL51177. SI was supported by a Ruth L. Kirschstein NRSA Institutional Research Training Grant F32 HL151128.

Materials

| 1.5 O.D. Tygon tubing | Fischer Scientific | Tubing | |

| A1RHD Multiphoton upright confocal microscope | Nikon | Confocal Microscope | |

| Acid Cleaning Solution | Sulfuric acid and Alnochromix diluted with water 50% by volume, wait until clear befor diluting | ||

| Alnochromix | Alconox | 2510 | Mixed with sulfuric acid to package instructionand diluted to make acid cleaning solution |

| Ceramic glass cutter | Sutter Instruments | ||

| Chloroform | Sigma-Aldrich | 650471 | HPLC Plus |

| Curosurf | Chiesi | Lung Surfactant | |

| Di Water | 18.5 MΩ – cm | ||

| Ethanol | any | 200 proof used for hydrophobization, denatured used for cleaning | |

| Fiber-Lite Model 190 fiber optic illuminator | Dolan-Jenner Industries Inc. | 281900100 | Light source; other light sources should work as well |

| Flow EZ F69 mbar w/Link Module | Fluigent | LU-FEZ-0069 | Microfluidic Pump |

| Fluigent SDK VIs | Fluigent | Required for CPM virtual Interface | |

| Fluoroelastomer gaskets | Machined from 1 mm thick Viton sheet, See figure 3 | ||

| Gas filter | Norgren | F07-100-A3TG | Put between microfluidic pump and pressure regulator |

| Gas regulator | Norgren | 10R0400R | Steps down pressure from sorce to range of pump, connected to gas filter range 2-120 psi |

| Glass Capilary | Sutter Instruments | B150-86-10 | Borosilicate glass O.D. 1.5 mm I.D. 0.86 mm |

| Glass Slide | any | 75 mm x 25 mm | |

| Glass Syringe | Hamilton | 84878 | 25 μL glass syringe |

| Hydrophobizing Agent | Sigma-Aldrich | 667420 | 1H,1H,2H,2H-Perfluoro-octyltriethoxysilane 98%, other hydrophobic triethoxysilane can be substituted |

| Insoluble surfactant | Avanti | 850355C-200mg | 16:0 DPPC in chloroform |

| LabVIEW Software | National Instruments | 2017 | |

| Longpass Filter | ThorLabs | FEL0650 | 650 nm Longpass filter, wavelength must remove excitation lazer frequence |

| Lyso-PC | Avanti | 855675P | 16:0 Lyso PC 1-palmitoyl-2-hydroxy-sn-glycero-3-phosphocholine |

| Masterflex L/S variable speed analog consol pump system w/ Easy-Load II pump head | Masterflex | HV-77916-20 | Peristaltic Pump |

| MATLAB | Mathworks | R2019 | |

| Micropipette Puller P-1000 | Sutter Instruments | Capillary Puller | |

| Microtensiometer Cell and Holder | Cell machined from PEEK, holder machined from aluminum, See Figure 3 and 4 | ||

| Microtensiometer Objective | Nikon | Fluor 20x/0.50W DIC M/N2 ∞/0 WD 2.0 mm | |

| NI Vision Development Module | National Instruments | Required for CPM virtual Interface | |

| PEEK finger tight fittings | IDEX | F-120x | 10-32 Coned Ports |

| PEEK plug | IDEX | P-551 | 10-31 Coned Ports |

| pippette tips | Eppendorf | 22492225 | 100 μL – 1000 μL, Autoclaved |

| Plastic Forceps | Thermo Scientific | 6320-0010 | |

| Plastic Syringe | Fischer Scientific | 14-955-459 | 10 mL |

| Plumbing parts | Fischer Scientific | 3-way valves and other plumbing parts to connect tubing. | |

| Research Plus 1-channel 100 μL–1000 μL | Eppendorf | 3123000063 | Micro pipetter |

| Sulfuric Acid | any | Used for acid cleaning solution | |

| T Plan SLWD 20x/0.30 OFN25 WD 30 mm | Nikon | Confocal Microscope Objective | |

| Texas Red DHPE triethylammonim salt | Thermo Fischer Scientific | 1395MP | Fluorophore |

| Vaccum Pump | Gast | DOA-P704-AA |

Referencias

- Freer, E. M., Yim, K. S., Fuller, G. G., Radke, C. J. Interfacial rheology of globular and flexible proteins at the hexadecane/water interface: Comparison of shear and dilatation deformation. Journal of Physical Chemistry B. 108 (12), 3835-3844 (2004).

- Freer, E. M., Yim, K. S., Fuller, G. G., Radke, C. J. Shear and dilatational relaxation mechanisms of globular and flexible proteins at the hexadecane/water interface. Langmuir. 20 (23), 10159-10167 (2004).

- Kannan, A., Shieh, I. C., Fuller, G. G. Linking aggregation and interfacial properties in monoclonal antibody-surfactant formulations. Journal of Colloid and Interface Science. 550, 128-138 (2019).

- Kannan, A., Shieh, I. C., Leiske, D. L., Fuller, G. G. Monoclonal antibody interfaces: Dilatation mechanics and bubble coalescence. Langmuir. 34 (2), 630-638 (2018).

- Li, J. J., et al. Interfacial stress in the development of biologics: Fundamental understanding, current practice, and future perspective. The AAPS Journal. 21 (3), 44 (2019).

- Bhamla, M. S., Giacomin, C. E., Balemans, C., Fuller, G. G. Influence of interfacial rheology on drainage from curved surfaces. Soft Matter. 10 (36), 6917-6925 (2014).

- Fuller, G. G., Vermant, J. Complex fluid-fluid interfaces: Rheology and structure. Annual Review of Chemical and Biomolecular Engineering. 3, 519-543 (2012).

- Rosenfeld, L., et al. Structural and rheological properties of meibomian lipid. Investigative Ophthalmology & Visual Science. 54 (4), 2720-2732 (2013).

- Barman, S., Davidson, M. L., Walker, L. M., Anna, S. L., Zasadzinski, J. A. Inflammation product effects on dilatational mechanics can trigger the Laplace instability and acute respiratory distress syndrome. Soft Matter. 16 (29), 6890-6901 (2020).

- Barman, S., et al., Ramachadran, A., et al. . Recent Advances in Rheology: Theory, Biorheology, Suspension and Interfacial Rheology. , (2022).

- Alonso, C., Zasadzinski, J. A. A brief review of the relationship between monolayer viscosity, phase behavior, surface pressure and temperature using a simple monolayer viscometer. The Journal of Physical Chemistry B. 110 (44), 22185-22191 (2006).

- Alonso, C., et al. More than a monolayer: Relating lung surfactant structure and mechanics to composition. Biophysical Journal. 87 (6), 4188-4202 (2004).

- Alonso, C., Bringezu, F., Brezesinski, G., Waring, A. J., Zasadzinski, J. A. Modifying calf lung surfactant by hexadecanol. Langmuir. 21 (3), 1028-1035 (2005).

- Alonso, C., Waring, A. J., Zasadzinski, J. A. Keeping lung surfactant where it belongs: Protein regulation of two-dimensional viscosity. Biophysical Journal. 89 (1), 266-273 (2005).

- Zasadzinski, J. A., et al. Inhibition of pulmonary surfactant adsorption by serum and the mechanisms of reversal by hydrophilic polymers: Theory. Biophysical Journal. 89 (3), 1621-1629 (2005).

- McConnell, H. M. Structures and transitions in lipid monolayers at the air-water-interface. Annual Reviews of Physical Chemistry. 42, 171-195 (1991).

- McConnell, H. M., Moy, V. T. Shapes of finite two-dimensional lipid domains. Journal of Physical Chemistry. 92 (15), 4520-4525 (1988).

- Zasadzinski, J. A., Stenger, P., Shieh, I., Dhar, P. Overcoming rapid inactivation of lung surfactant: analogies between competitive adsorption and colloid stability. Biochemica et Biophysica Acta. 1798 (4), 801-828 (2010).

- Zasadzinski, J. A., Nag, K., et al. . Surfactant Progress. , (2008).

- Valtierrez-Gaytan, C., et al. Spontaneous evolution of equilibrium morphology in phospholipid-cholesterol monolayers. Science Advances. 8 (14), (2022).

- Williams, I., Zasadzinski, J. A., Squires, T. M. Interfacial rheology and direct imaging reveal domain-templated network formation in phospholipid monolayers penetrated by fibrinogen. Soft Matter. 15 (44), 9076-9084 (2019).

- Sachan, A. K., Zasadzinski, J. A. Interfacial curvature effects on the monolayer morphology and dynamics of a clinical lung surfactant. Proceedings of the National Academy of Sciences of the United States of America. 115 (2), 134-143 (2018).

- Alvarez, N. J., Anna, S. L., Saigal, T., Tilton, R. D., Walker, L. M. Intefacial dynamics and rheology of polymer grafter nanoparticles at air-water and xylene-water interfaces. Langmuir. 28 (21), 8052-8063 (2012).

- Alvarez, N. J., Vogus, D. R., Walker, L. M., Anna, S. L. Using bulk convection in a microtensiometer to approach kinetic-limited surfactant dynamics at fluid-fluid interfaces. Journal of Colloid and Interface Science. 372 (1), 183-191 (2012).

- Alvarez, N. J., Walker, L. M., Anna, S. L. Diffusion-limited adsorption to a spherical geometry: The impact of curvature and competitive time scales. Physical Review. E, Statistical, Nonlinear, and Soft Matter Physics. 82, 011604 (2010).

- Shieh, I., Waring, A. J., Zasadzinski, J. A. Visualizing the analogy between competitive adsorption and colloid stability to restore lung surfactant function. Biophysical Journal. 102 (4), 777-786 (2012).

- Shieh, I., Zasadzinski, J. A. Visualizing monolayers with a water-soluble fluorophore to quantify adsorption, desorption and the double-layer. Proceedings of the National Academy of Sciences of the United States of America. 112 (8), 826-835 (2015).

- Lipp, M. M., Lee, K. Y. C., Takamoto, D. Y., Zasadzinski, J. A., Waring, A. J. Coexistence of buckled and flat monolayers. Physical Review Letters. 81, 1650-1653 (1998).

- Lipp, M. M., Lee, K. Y. C., Waring, A., Zasadzinski, J. A. Fluorescence, polarized fluorescence, and Brewster angle microscopy of palmitic acid and lung surfactant protein B monolayers. Biophysical Journal. 72 (6), 2783-2804 (1997).

- Alvarez, N. J., Walker, L. M., Anna, S. L. A microtensiometer to probe the effect of radius of curvature on surfactant transport to a spherical interface. Langmuir. 26 (16), 13310-13319 (2010).

- Ward, A. F. H., Tordai, L. Time dependents of boundary tensions of solutions. 1. The role of diffusion in time-effects. Journal of Chemical Physics. 14, 453-461 (1946).

- Lucassen, J., Vanden Tempel, M. Dynamic measurements of dilatational properties of a liquid interface. Chemical Engineering Science. 27 (6), 1283-1291 (1972).

- Lin, G. L., et al. Interfacial dilatational deformation accelerates particle formation in monoclonal antibody solutions. Soft Matter. 12 (14), 3293-3302 (2016).

- Bastacky, J., et al. Alveolar lining layer is thin and continuous: low temperature scanning electron microscopy of rat lung. Journal of Applied Physiology. 79 (5), 1615-1628 (1995).

- Adamson, A. W., Gast, A. P. . Physical Chemistry of Surfaces, Sixth ed. , 784 (1997).

- del Rio, O. I., Kwok, D. Y., Wu, R., Alvarez, J. M., Neumann, A. W. Contact angle measurements by axisymmetric drop shape analysis and an automated polynomial fit program. Colloids and Surfaces A Physicochemical and Engineering Aspects. 143 (2-3), 197-210 (1998).

- Kanthe, A., et al. No ordinary proteins: Adsorption and molecular orientation of monoclonal antibodies. Science Advances. 7 (5), 14 (2021).

- Manikantan, H., Squires, T. M. Surfactant dynamics: hidden variables controlling fluid flows. Journal of Fluid Mechanics. 892, 115 (2020).

- Narayan, S., et al. Dilatational rheology of water-in-diesel fuel interfaces: effect of surfactant concentration and bulk-to-interface exchange. Soft Matter. 17 (18), 4751-4765 (2021).

- Meng, G. N., Paulose, J., Nelson, D. R., Manoharan, V. N. Elastic instability of a crystal growing on a curved surface. Science. 343 (6171), 634-637 (2014).

- Kotula, A. P., Anna, S. L. Insoluble layer deposition and dilatational rheology at a microscale spherical cap interface. Soft Matter. 12 (33), 7038-7055 (2016).

- Lipp, M. M., Lee, K. Y. C., Zasadzinski, J. A., Waring, A. J. Phase and morphology changes in lipid monolayers induced by SP-B protein and its amino-terminal peptide. Science. 273 (5279), 1196-1199 (1996).

- Pocivavsek, L., et al. Stress and fold localization in thin elastic membranes. Science. 320 (5878), 912-916 (2008).

- Pocivavsek, L., et al. Lateral stress relaxation and collapse in lipid monolayers. Soft Matter. 4 (10), 2019-2029 (2008).

- Kim, K., Choi, S. Q., Squires, T. M., Zasadzinski, J. A. Cholesterol nanodomains: their effect on monolayer morphology and dynamics. Proceedings of the National Academy of Sciences of the United States of America. 110 (33), 3054-3060 (2013).

- Kim, K., Choi, S. Q., Zasadzinski, J. A., Squires, T. M. Interfacial microrheology of DPPC monolayers at the air-water interface. Soft Matter. 7 (17), 7782-7789 (2011).

- Kim, K., Choi, S. Q., Zasadzinski, J. A., Squires, T. M. Nonlinear chiral rheology of phospholipid monolayers. Soft Matter. 14 (13), 2476-2483 (2018).

- Kotula, A. P., Anna, S. L. Regular perturbation analysis of small amplitude oscillatory dilatation of an interface in a capillary pressure tensiometer. Journal of Rheology. 59, 85-117 (2015).