Manufacturing Process for Non-Adhesive Super-Soft Vocal Fold Models

Summary

This study demonstrates the manufacturing of non-sticky and super-soft vocal fold models by introducing a specific way to create the vocal fold layers, providing a detailed description of the manufacturing procedure, and characterizing the properties of the models.

Abstract

This study aims to develop super-soft, non-sticky vocal fold models for voice research. The conventional manufacturing process of silicone-based vocal fold models results in models with undesirable properties, such as stickiness and reproducibility issues. Those vocal fold models are prone to rapid aging, leading to poor comparability across different measurements. In this study, we propose a modification to the manufacturing process by changing the order of layering the silicone material, which leads to the production of non-sticky and highly consistent vocal fold models. We also compare a model produced using this method with a conventionally manufactured vocal fold model that is adversely affected by its sticky surface. We detail the manufacturing process and characterize the properties of the models for potential applications. The outcomes of the study demonstrate the efficacy of the modified fabrication method, highlighting the superior qualities of our non-sticky vocal fold models. The findings contribute to the development of realistic and reliable vocal fold models for research and clinical applications.

Introduction

Vocal fold models are used to simulate and investigate human voice production under normal and pathological conditions1,2. One of the biggest challenges in creating vocal fold models is to achieve a realistic softness and flexibility that closely approximates those of humans. To achieve these properties, silicone elastomers are often used, which are diluted with high amounts of silicone oil to achieve the corresponding elasticity moduli3,4. Another crucial factor in creating realistic vocal fold models is layering, as vocal folds consist of multiple layers of varying softness, which determine the pattern of flow-induced vibration and the frequency at which vibration is possible.

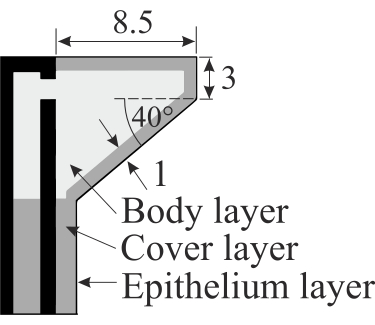

In this study, we created a typical vocal fold model. We used the common geometry provided by Scherer5, which represents typical dimensions for male vocal folds with 17 mm length according to Zhang6 and consists of three layers: one layer for the vocalis muscle (body layer), one for the entire mucosal layer (cover layer), and one for the epithelium. This structure can be seen in the coronal cross-section view in Figure 1.

Figure 1: Coronal cross-section of the larynx modules. Coronal cross-section of the larynx modules illustrating the widest width of the vocal folds (8.5 mm). Each vocal fold comprises a body layer, a cover layer, and an epithelium layer. This figure has been modified from13. Reproduced from Häsner, P., Prescher, A., Birkholz, P. Effect of wavy trachea walls on the oscillation onset pressure of silicone vocal folds. J Acoust Soc Am.149 (1), 466-475 (2021) with the permission of the Acoustical Society of America. Please click here to view a larger version of this figure.

Other publications use partially only one layer7, two layers without epithelium layer2 or model the mucosa with multiple layers3. Usually, the layers are cast from the inside out, i.e., starting with the deepest layer. The epithelium, which is very thin with 30 µm thickness, is cast at the end over the entire body to envelop it with a sturdy skin8.

The cover layer in the model is the softest part, with Young's modulus of about 1.1 kPa9. For the body layer, the approximate Young's modulus in the transverse direction using in vitro measurements10 is 2 kPa. In vivo, the Young's modulus of the thyroarytenoid muscle may be higher due to the presence of fibers in the longitudinal direction as well as the possible tensing of the muscle. To achieve this extremely low Young's modulus, it is necessary to add a high amount of silicone oil to the silicone mixture (approximately 72%). However, the manufacturer strongly advises against using an oil proportion greater than 5%. In general, the addition of silicone oil to the elastomer is intended to increase flow and drip time, as well as reduce the shrinkage of the cured silicone polymer. It helps the silicone to cure more uniformly, thereby reducing stress in the material. Its purpose is to optimize the moldability and properties of the cured material, rather than to increase its softness, although this is also a consequence. This is because silicone oil is chemically inert, meaning that it cannot polymerize itself and is not integrated into the network of the silicone polymer11. Instead, it remains as a liquid phase in the polymer matrix, weakening the polymer structure at higher levels and potentially causing it to dissolve out of the cured material and adhere to the surface. As a result, other negative properties such as curing disorders, uneven vulcanization, chemical shrinkage, and brittleness are possible. Vocal fold models with high silicone oil contents were investigated with regard to aging and reproducibility, and it was found that there is a high variability in the properties of different models and a change in their properties over time11.

When producing vocal fold models in the conventional way7,12, the stickiness of the epithelial layer can be a problem as it can affect the homogeneity of vibration and lead to rupture of the epithelium. Although the silicone used to make the epithelium is undiluted, it can be assumed that the oil that leaks from the neighboring mucosa layer has similar effects on the silicone as if it had been diluted. The problem of stickiness was addressed by adding various powders such as talcum or carbon powder as an intermediate layer between the mucosa and the epithelial layer12. This approach may have been successful because the oil was partially absorbed by the powder and, as a result, the stickiness of the epithelial surface could be reduced.

In this publication, we show that the problem of stickiness can be circumvented by a slight modification of the process of vocal fold manufacturing. By changing the order of layering and starting with the undiluted epithelial silicone (so-called closed silicone), non-sticky super-soft vocal fold models can be produced. This change involves unusual types of molds and methods that are best presented and explained in the form of a video. In this paper, we describe our manufacturing process in detail and demonstrate how the properties of the vocal fold models can be characterized in an application.

Protocol

Representative Results

Discussion

The manufacturing process presented here involves critical steps that significantly impact its success. Firstly, it should be noted that the presented manufacturing process does not solve the problem of oil saturation in the vocal fold body material but rather circumvents certain negative side effects. The outgassing and the associated shrinkage and surface waviness still persist, albeit to a lesser extent. A solution to these problems would involve the use of an ultra-soft silicone or alternative material that combines …

Declarações

The authors have nothing to disclose.

Acknowledgements

This project has been supported by the German Research Foundation (DFG), grant no. BI 1639/9-1.

Materials

| 3D Printer | ULTIMAKER | Type S5 | |

| 3D Printing software | ULTIMAKER CURA | Version 5.2.2 | |

| CAD Software | Autodesk Inventor | Version 2023 | |

| High Speed Camera | XIMEA GmbH | MQ013CG-ON | |

| PLA+ 3D Printer Material | eSun | none | white |

| Primary silicone | KauPo Plankenhorn | 09301-005-000041 | EcoFlex 00-30 |

| Release Agent | KauPo Plankenhorn | 09291-006-000001 | UTS Universal |

| Secondary silicone | KauPo Plankenhorn | 09301-005-000181 | DragonSkin NV10 |

| Silicone Thinner | KauPo Plankenhorn | 09301-010-000002 | |

| Tougth PLA 3D Printer Material | BASF | black |

Referências

- Drechsel, J. S., Thomson, S. L. Influence of supraglottal structures on the glottal jet exiting a two-layer synthetic, self-oscillating vocal fold model. J Acoust Soc Am. 123 (6), 4434-4445 (2008).

- Stevens, K. A., Shimamura, R., Imagawa, H., Sakakibara, K. I., Tokuda, I. T. Validating Stereo-endoscopy with a synthetic vocal fold model. Acta Acustica United with Acustica. 102 (4), 745-751 (2016).

- Murray, P. R., Thomson, S. L. Synthetic, multi-layer, self-oscillating vocal fold model fabrication. J Vis Exp. (58), e3498 (2011).

- Spencer, M., Siegmund, T., Mongeau, L. Determination of superior surface strains and stresses, and vocal fold contact pressure in a synthetic larynx model using digital image correlation. J Acoust Soc Am. 123 (2), 1089-1103 (2008).

- Scherer, R. C., et al. Intraglottal pressure profiles for a symmetric and oblique glottis with a divergence angle of 10 degrees. J Acoust Soc Am. 109 (4), 1616-1630 (2001).

- Zhang, Z. Mechanics of human voice production and control. J Acoust Soc Am. 140 (4), 2614-2635 (2016).

- Birkholz, P., Wang, L. . Studientexte zur Sprachkommunikation: Elektronische Sprachsignalverarbeitung. , 58-66 (2017).

- Murray, P. R. . Flow-induced responses of normal, bowed, and augmented synthetic vocal fold models. , (2011).

- Alipour, F., Vigmostad, S. Measurement of vocal folds elastic properties for continuum modeling. J Voice. 26 (6), e21-29 (2012).

- Chhetri, D. K., Zhang, Z., Neubauer, J. Measurement of young’s modulus of vocal folds by indentation. J Voice. 25 (1), 1-7 (2011).

- Häsner, P., Birkholz, P. Reproducibility and aging of different silicone vocal folds models. J Voice. , (2023).

- Gabriel, F., Häsner, P., Dohmen, E., Borin, D., Birkholz, P. . Studientexte zur Sprachkommunikation: Elektronische Sprachsignalverarbeitung. , 221-230 (2019).

- Häsner, P., Prescher, A., Birkholz, P. Effect of wavy trachea walls on the oscillation onset pressure of silicone vocal folds. J Acoust Soc Am. 149 (1), 466-475 (2021).

- Birkholz, P. . Studientexte zur Sprachkommunikation: Elektronische Sprachsignalverarbeitung. , (2016).

- Boersma, P., Weenink, D. Praat, a system for doing phonetics by computer. Glot. Int. 5, 341-345 (2001).

- Fukui, K., Shintaku, E., Honda, M., Takanishi, A. Mechanical vocal cord model for anthropomorphic talking robot based on human biomechanical structure. Trans Japan Soc Mech Eng Ser C. 73 (734), 2750-2756 (2007).

- Syndergaard, K. L., Dushku, S., Thomson, S. L. Electrically conductive synthetic vocal fold replicas for voice production research. J Acoust Soc Am. 142 (1), 63 (2017).