Testes de compressão em concreto endurecido

English

Share

Overview

Fonte: Roberto Leon, Departamento de Engenharia Civil e Ambiental, Virginia Tech, Blacksburg, VA

Há duas etapas distintas em um projeto de construção envolvendo concreto. A primeira etapa envolve loteamento, transporte e fundição de concreto fresco. Nesta fase, o material é viscoso, e a capacidade de trabalho e acabamento são os principais critérios de desempenho. A segunda etapa ocorre quando o processo de hidratação começa logo após o concreto ser colocado na forma, e o concreto vai definir e começar a endurecer. Esse processo é muito complexo, e nem todas as suas fases são bem compreendidas e caracterizadas. No entanto, o concreto deve alcançar sua força de projeto pretendida e rigidez em cerca de 14 a 28 dias após o fundamento. Neste ponto, uma série de testes serão realizados em cilindros de concreto moldado no momento da colocação para determinar as forças compressivas e de tração do concreto, bem como, ocasionalmente, sua rigidez.

Os objetivos deste experimento são três vezes: (1) realizar testes de cilindro compressivo para determinar a força de concreto de 7, 14 e 28 dias, (2) determinar o módulo de elasticidade aos 28 dias, e (3) demonstrar o uso de um simples teste não destrutivo para determinar a força concreta in situ.

Principles

Procedure

Results

The cylinders in compression tended to fail along an inclined plane, at roughly 45 degrees. This feature indicates that the failure was not driven by pure compression (crushing of the cylinder) but rather by shear forces, or more precisely by splitting tension stresses.

The compressive test results are computed by dividing the maximum measured load (Pmax) by the measured area. The compressive strength value is taken as the average of three cylinder tests, provided that none of them resulted in a value of less than 500 psi from the average.

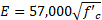

The Young's modulus and Poisson's ratio are obtained from the initial slope of the stress-strain curve and the ratio of longitudinal to transverse strains. The value of Young's modulus is often taken as  , while Poisson's ratio varies between 0.12 and 0.2.

, while Poisson's ratio varies between 0.12 and 0.2.

The average of the Schmidt hammer readings was 32.4 with a standard deviation of 1.3. These results are considered acceptable, and the concrete in situ strength was determined to be 4650 psi based on calibration to parallel laboratory cylinder tests.

Applications and Summary

Compression tests on concrete cylinders were performed, as well as measurements of Young’s modulus, Poisson’s ratio, and a demonstration of NDT measurements in concrete. Compression test results from the cylinder tests, like those carried out in this laboratory exercise, are relatively simple to conduct and produce results with acceptable variability. Measurements of Poisson’s ratio and Young’s modulus are difficult to make, and these properties are often calculated by empirical formulae from the compression strength rather than by experimental methodology.

Compression tests of the type described herein are used to monitor the strength gain in concrete structures. The results at 28 days have to meet discrete specifications, but in general, the test is not run with only the specific purpose of meeting specifications, or checking the strength of a particular member. The main idea of these tests is to monitor the quality of all of the concrete delivered over the lifespan of the entire project.

Another common application of cylinder testing is to test cores extracted from existing structures. In these cases, the intent is to determine if the structure can carry loads higher than initially designed for. One example is in older bridges, where the increased truck loads require that bridges be rated for new load combinations (weight per axle and axle spacing, for example) or in forensic investigations where after a failure has occurred, it is necessary to rule out certain failure modes.

Transcript

The strength of concrete used in structures is evaluated using compression tests to meet specific requirements after installation and also to monitor the quality over the lifespan of the project.

When concrete is poured into a form, it will begin to set and harden. The concrete will achieve its design strength and stiffness 14 to 28 days after casting. Concrete test cylinders are cast at the same time that the concrete is put in place. These samples are tested to determine the concrete strength and stiffness.

In this experiment, we will test the 28-day compressive strength of concrete. And use a simple non-destructive test of in-situ concrete strength.

As soon as concrete is put in place, the hydration process starts with the dissolution of cement in water. Which leads to a saturation of ions in the solution. Within a few hours crystals form and the space is occupied by the cement, which will give the material its final structure. The strength of the cured concrete is affected by the mixed design, the curing temperature and humidity, and the uniformity of the product. To measure this strength a hydraulic testing machine is used.

A device called a compressometer is attached to the test specimen to allow for calculations of Young’s modulus and Poisson’s ratio. Temperature and humidity during storage, the condition of the test specimen during the test, and the way in which the test is performed are all factors that affect test results and must be controlled. While cylinder tests are useful to determine the strength of concrete delivered to the site, in-situ testing is utilized to evaluate the quality in place over the life of the structure.

For this, the Schmidt hammer test shoots a steel weight at the surface of the concrete. The distance that the steel rebounds is measured and related to the strength of the material. Measurements can be made across one surface or many surfaces to evaluate the consistency of the concrete.

In the next section, we will measure the compression strength of test specimens and observe their mode of failure. We will also demonstrate the use of the Schmidt hammer test to indicate material strength.

Compression tests will be carried out using a hydraulic testing machine. For these tests the load capacity must be very high to test high-strength concretes. Remove the concrete cylinder from the mold and dry its surface to prepare the specimen for testing.

Then, inspect the concrete cylinder and remove any major surface imperfections from its ends using a file. After each end is prepared, apply a neoprene cap to ensure that the ends are as flat and level as possible. Center the specimen in the hydraulic testing machine and then apply the compressive load slowly and continuously at a rate between 20 to 50 psi per second. Allow the load to increase until the maximum is reached and the cylinder is crushed.

Failure is imminent when the load indicator slows down and finally stops. When the test is complete, record the maximum load and then closely examine the type of failure in the concrete cylinder. Determine the compressive strength of the specimen and record the fracture mode. Repeat this test for four of the five remaining specimens. For the final specimen install a compressometer so that Young’s modulus and Poisson’s ratio can be determined for this concrete mix.

First, unscrew all seven contact screws until the points are flush with the inner surface of the rings. Now, place the compressometer over the concrete cylinder and prop it up with three equal height spacers to center it vertically with the specimen. Hand-tighten the three contact screws on the lower ring and the two on the upper ring to secure the specimen concentrically in the compressometer.

When the specimen is secured, hand-tighten the final two contacts screws in the middle ring. Check that the vertical stem of the axial strain dial indicator is midway between the two portions of the middle ring. Confirm that the stem of the axial dial indicator is close to fully extended, and the stem of the diametrical dial indicator is close to fully retracted.

Finally, remove both spacer rods from the sides and the third rod located on the center ring. Lift the assembly by holding the specimen and carefully place it in the hydraulic testing machine and then zero both dial indicators. Apply a series of loads in steps of 10,000 pounds up to a maximum of 60,000 pounds. At each load, record longitudinal and hoop deformations as indicated on the dial indicators.

Find a concrete surface that is smooth, dry and at least four inches thick, and mark a 2 foot by 2 foot grid, covering a total area of 10 feet by 10 feet. If the piston of the Schmidt hammer is not extended place the end against a stiff surface and gently press down until a click is heard. The piston will extend as you pull the hammer away from the surface.

Now, gently press the hammer against the first grid point marked on the concrete surface. Continue to push until a rattling sound is heard. Read the rebound number on the scale and then pull the hammer away from the surface. Repeat this measurement at each grid point marked on the surface and then compute the average and standard deviation for the whole set of measurements.

The cylinders in compression tended to fail along an inclined plane at roughly 45 degrees. This feature indicates that the failure was not driven by pure compression crushing of the cylinder, but rather by shear forces or more precisely by splitting tension stresses.

The average of the Schmidt hammer readings was 32.4 with a standard deviation of 1.3, which correlates to an in-situ strength of 4,650 psi based on calibration to parallel laboratory cylinder tests.

Now that you appreciate the strength testing methods for concrete structures, let’s take a look at how it is applied to assure the quality of structures in our world.

In older bridges increased loading requirements can call for concrete strength testing. In these cases, cores are extracted from existing structures and tested in the laboratory to determine if the structure can carry loads higher than initially designed for.

In between the more destructive but very accurate in-situ core testing and the non-destructive but less accurate Schmidt hammer test, is the Windsor probe. In this test, probes are shot into the concrete surface and the penetration depth is measured to determine concrete strength.

You’ve just watched JoVE’s introduction to compression tests on hardened concrete. You should now understand core testing and Schmidt hammer testing of concrete.

Thanks for watching!