Formulation and Characterization of Bioactive Agent Containing Nanodisks

Summary

Here, we describe the production and characterization of bioactive agents containing nanodisks. Amphotericin B nanodisks are taken as an example to describe the protocol in a stepwise manner.

Abstract

The term nanodisk refers to a discrete type of nanoparticle comprised of a bilayer forming lipid, a scaffold protein, and an integrated bioactive agent. Nanodisks are organized as a disk-shaped lipid bilayer whose perimeter is circumscribed by the scaffold protein, usually a member of the exchangeable apolipoprotein family. Numerous hydrophobic bioactive agents have been efficiently solubilized in nanodisks by their integration into the hydrophobic milieu of the particle's lipid bilayer, yielding a largely homogenous population of particles in the range of 10-20 nm in diameter. The formulation of nanodisks requires a precise ratio of individual components, an appropriate sequential addition of each component, followed by bath sonication of the formulation mixture. The amphipathic scaffold protein spontaneously contacts and reorganizes the dispersed bilayer forming lipid/bioactive agent mixture to form a discrete, homogeneous population of nanodisk particles. During this process, the reaction mixture transitions from an opaque, turbid appearance to a clarified sample that, when fully optimized, yields no precipitate upon centrifugation. Characterization studies involve the determination of bioactive agent solubilization efficiency, electron microscopy, gel filtration chromatography, ultraviolet visible (UV/Vis) absorbance spectroscopy, and/or fluorescence spectroscopy. This is normally followed by an investigation of biological activity using cultured cells or mice. In the case of nanodisks harboring an antibiotic (i.e., the macrolide polyene antibiotic amphotericin B), their ability to inhibit the growth of yeast or fungi as a function of concentration or time can be measured. The relative ease of formulation, versatility with respect to component parts, nanoscale particle size, inherent stability, and aqueous solubility permits myriad in vitro and in vivo applications of nanodisk technology. In the present article, we describe a general methodology to formulate and characterize nanodisks containing amphotericin B as the hydrophobic bioactive agent.

Introduction

Nascent discoidal high density lipoproteins (HDLs) are naturally occurring progenitors of the far more abundant spherical HDL present in the human circulatory system. These nascent particles, also referred to as pre-ß HDL, possess unique and distinctive structural properties1. Indeed, rather than existing as a spheroidal particle, nascent HDLs are disk-shaped. Extensive structural characterization studies on natural and reconstituted discoidal HDLs have revealed that they are comprised of a phospholipid bilayer whose perimeter is circumscribed by an amphipathic exchangeable apolipoprotein (apo), such as apoA-I. In human lipoprotein metabolism, circulating nascent HDLs accrue lipids from peripheral cells and mature into spherical HDLs in a process that is dependent upon key protein mediators, including the ATP binding cassette transporter A1 and lecithin:cholesterol acyltransferse2. This process represents a critical component of the reverse cholesterol transport pathway that is considered to be protective against heart disease. Armed with this knowledge and the ability to reconstitute discoidal HDLs, researchers have employed these particles as a therapeutic intervention to treat atherosclerosis3. In essence, the infusion of reconstituted HDL (rHDL) into patients promotes cholesterol efflux from plaque deposits and returns it to the liver for conversion to bile acids and excretion from the body. Several biotechnology/pharmaceutical companies are pursuing this treatment strategy4.

At the same time, the ability to generate these particles in the laboratory has sparked a flurry of research activities that has led to novel applications and new technologies. One prominent application involves the use of rHDL particles as a miniature membrane to house transmembrane proteins in a native-like environment5. To date, hundreds of proteins have been successfully incorporated into discoidal rHDL, and research has demonstrated that these proteins retain both native conformation and biological activity as receptors, enzymes, transporters, etc. These particles, referred to as "nanodiscs", have also been shown to be amenable to structural characterization, often at high resolution6. This approach to investigations of transmembrane proteins is recognized as superior to studies with detergent micelles or liposomes and, as a result, is rapidly advancing. It is important to recognize that two distinct methods have been reported that are capable of forming an rHDL. The "cholate dialysis" method13 is popular for applications related to the incorporation of transmembrane proteins in the rHDL bilayer5. Essentially, this method of formulation involves mixing a bilayer forming phospholipid, a scaffold protein, and the transmembrane protein of interest in a buffer containing the detergent sodium cholate (or sodium deoxycholate; micelle molecular weight [MW] of 4,200 Da). The detergent effectively solubilizes the different reaction components, permitting the sample to be dialyzed against buffer lacking detergent. During the dialysis step, as the detergent is removed from the sample, an rHDL spontaneously forms. When this approach is used to entrap a transmembrane protein of interest, the product particles have been termed nanodiscs5. Attempts to use this method to incorporate small molecule hydrophobic bioactive agents (MW <1,000 Da), however, have been largely unsuccessful. Unlike transmembrane proteins, small molecule bioactive agents are able to escape from the dialysis bag along with the detergent, greatly decreasing their incorporation efficiency into rHDLs. This problem was solved by omitting detergents from the formulation mixture14. Instead, the components are added to an aqueous buffer sequentially, beginning with the bilayer forming lipid, forming a stable bioactive agent containing rHDL, referred to as a nanodisk. Others have used rHDL for the incorporation and transport of in vivo imaging agents7. More recently, specialized rHDL comprised of an apolipoprotein scaffold and the anionic glycerophospholipid, cardiolipin, have been employed in ligand binding studies. These particles provide a platform for studies of the interaction of cardiolipin with various water soluble ligands, including calcium, cytochrome c, and the anticancer agent doxorubicin8.

The focus of the present study is on the formulation of rHDL that possess a stably incorporated hydrophobic bioactive agent (i.e. nanodisk). The ability of these agents to integrate into the lipid milieu of discoidal rHDL particles effectively confers them with aqueous solubility. As such, nanodisks have the potential for in vivo therapeutic applications. When formulating nanodisks, specific incubation/reaction conditions are required to successfully incorporate discrete hydrophobic bioactive agents into the product particle, and the goal of this report is to provide detailed practical information that can be used as a foundational template for creating novel nanodisk particles for specific applications. Thus, in the context of this manuscript the terms nanodisc and nanodisk are not interchangeable. Whereas nanodisc refers to an rHDL formulated to contain a transmembrane protein embedded in its lipid bilayer5, the term nanodisk refers to an rHDL formulated to incorporate low molecular weight (< 1,000 Da) hydrophobic bioactive agents, such as amphotericin B14.

A variety of methods are available for the acquisition of suitable scaffold proteins. It is possible to purchase scaffold proteins from manufacturers [e.g. apoA-I (SRP4693) or apoE4 (A3234)], however, the cost may be a limiting factor. A preferred approach is to express recombinant scaffold proteins in Escherichia coli. Protocols are published for human apoA-I9, apoE410, as well as the insect hemolymph protein apolipophorin-III11. For the purpose of the experiments described herein, recombinant human apoE4 N-terminal (NT) domain (amino acids 1-183) was used. The nucleotide sequence encoding human apoE4-NT was synthesized and inserted into a pET-22b (+) expression vector directly adjacent to the vector-encoded pelB leader sequence. This construct leads to the expression of a pelB leader sequence-apoE4-NT fusion protein. Following protein synthesis, the bacterial pelB leader sequence directs the newly synthesized protein to the periplasmic space where leader peptidase cleaves the pelB sequence. The resultant apoE4-NT protein, with no sequence tags or tails, subsequently escapes the bacteria and accumulates in the culture medium11,12, simplifying downstream processing.

Protocol

1. Transformation, expression, and purification of scaffold protein component

- BL21 bacterial transformation with apoE4-NT containing plasmid

- Thaw a tube of BL21 (DE3) competent cells on ice for 10 min.

- Once all the ice has melted, mix gently and carefully pipette 50 µL of the cells into a transformation tube on ice.

- Add 5 µL containing 50 ng of plasmid DNA (for sequence, see Supplemental Table 1) to the cell mixture. Carefully flick the tube four or five times to mix. Do not vortex.

- Place the mixture on ice for 30 min.

- Heat shock the mixture at exactly 42 °C for 10 s.

- Place on ice for 5 min.

- Pipette 950 µL of S.O.C. medium into the tube at room temperature.

- Place the tube in a 37 °C shaking incubator for 60 min with oscillation set to 250 rpm.

- Mix the cells thoroughly by flicking and inverting, then spread 100 µL of cell solution onto a 20 mL Luria Broth + Agar selection plate treated with ampicillin at a concentration of 0.1 mg/mL.

- Incubate overnight at 37 °C, or until visible colonies have grown.

- Using an electronic pipettor, transfer 25 mL of sterile, NZCYM medium into a sterile 250 mL conical flask at room temperature and add ampicillin to a final working concentration of 0.1 mg/mL.

- Using a sterile inoculation loop, transfer one individual colony from the selection plate containing the appropriately transformed bacterial strain and add directly to the flask containing 25 mL of NZCYM media + ampicillin.

- Place the 25 mL of NZCYM seed culture flask into a 37 °C shaking incubator with orbital oscillation set to 250 rpm.

NOTE: It is recommended that this seed culture be grown overnight to reach a suitable bacterial concentration (~1.5-2.0 optical density units), as measured using a spectrophotometer set to wavelength = 600 nm. - Transfer 250 mL of sterile NZCYM medium into four 1 L baffled flasks and add ampicillin antibiotic to a working concentration of 0.1 mg/mL.

- Under sterile conditions, transfer 5 mL of saturated seed culture into each of the four 250 mL culture containing flasks and place in a 37 ˚C shaking incubator with orbital oscillation set to 250 rpm.

NOTE: At this point, the culture will be referred to as an expansion culture and exponential growth will be monitored using a UV1800 spectrophotometer. Growth is allowed to proceed until the culture optical density at 600 nm (OD600) reaches a value between 0.6-0.8. - Once the expansion culture has reached the desired OD600 value of 0.6-0.8, add 59.6 mg of isopropyl β-D-1-thiogalactopyranoside (IPTG) to each 250 ml culture containing flask for a final concentration of 1 mM to induce protein expression. At this point, the expansion culture is referred to as the expression culture. Commence expression for a period of 5 h.

- At the end of the 5 h expression period, remove the four flasks from the shaking incubator and pipette 125 mL into six 250 ml centrifuge bottles (750 mL total).

- Balance each centrifuge bottle to ensure the total mass is within ±0.5 mg of one another.

NOTE: This step is essential to ensure safe operation of the centrifuge device. - Prepare the centrifuge device by first flipping the power switch to the on position. Click the button labeled "Set/Actual" and adjust the parameters to "JA-14", "9,400 x g", 20.00 min, and 4 °C using the corresponding dials.

- Load the six balanced centrifuge bottles into an appropriately sized centrifuge rotor and place into the centrifuge ensuring any specific safety parameters are followed.

NOTE: Continue this step until all bacterial cell culture has been centrifuged and supernatants collected. - Filter the isolated bacterial supernatant through a vacuum filtration or equivalent apparatus fitted with a 0.45 micron filter to remove any residual debris.

- Heparin purification of the recombinant apoE4-NT scaffold protein

NOTE: The column purification procedure is conducted at room temperature.- Equilibrate the Hi-trap Heparin column by applying 10 column volumes (50 mL) of 10 mM sodium phosphate buffer, pH 7.2, and eluting at a rate of 5 mL/min.

- Apply apoE4-NT enriched medium to the column at a rate of 2.5 mL/min until the entire 1 L volume of medium has been applied and discard the flowthrough.

- Wash the column with 10 column volumes (50 mL) of 10 mM sodium phosphate buffer, pH 7.2, and discard the flowthrough.

- Elute the desired apoE4-NT protein by applying three column volumes (15 mL) of elution buffer (10 mM sodium phosphate buffer + 1.5 M NaCl, pH 7.2) to the column and collect the eluate.

- Dialysis of apoE4-NT eluate

- Prepare a section of dialysis tubing (dimensions of dialysis tubing used were 22 cm in length, 12 mm internal diameter, and 10,000 MWCO) by thoroughly soaking in distilled deionized (ddi) water for 10 min.

- Prepare 1 L of phosphate buffered saline (PBS) (10 mM sodium phosphate + 150 mM NaCl, pH 7.2) in a 1 L plastic beaker or equivalent.

- Using a dialysis tubing clamp, clamp one end of the soaked dialysis tubing, ensuring the clamp is secured and no liquid can escape.

- Insert a narrow neck funnel into the open end of the dialysis tubing and pour the 15 mL of apoE4-NT eluate into the dialysis tubing.

NOTE: It is imperative to check for any leaks at this step. - Remove the funnel and clamp the end of the dialysis tubing with another dialysis tube clamp.

- Place a foam dialysis float onto one of the sealed ends of the dialysis tubing and place the assembled dialysis tubing into the beaker containing 1 L of PBS buffer.

- Place a magnetic stir bar into the bottom of the beaker and adjust the stirring control to "low", ensuring a vortex is not formed.

- After dialysis has concluded, decant the retentate into a 50 mL conical tube and store at -20 °C.

NOTE: It is recommended that this dialysis be conducted at 4 °C overnight.

2. Formulation of bioactive agent containing nanodisks

- Preparation of phospholipid aliquot

- Weigh 5 mg of an appropriate phospholipid (e.g., dimyristoylphosphatidylcholine [DMPC]) and transfer to a glass test tube.

- Dissolve the 5 mg of phospholipid by adding 300 µL of CHCl3 and 100 µL of CH3OH for a total ratio of 3:1 v/v.

- Evaporate the organic solvent by placing the glass test tube under a gentle stream of N2 gas for 10-15 min, such that a thin film of dried phospholipid forms along the walls of the bottom portion of the tube.

- Lyophilization of phospholipid aliquots

- Prepare phospholipid aliquots for lyophilization by covering the glass test tube opening with parafilm.

- Perforate the parafilm using a 24 G needle approximately 10-15 times.

- Place the perforated aliquots into an appropriate lyophilization container and ensure the rubber lid is sealed correctly.

- Attach the lyophilization container to the vacuum manifold located at the top of the lyophilization machine and ensure all the other valves are closed tightly.

- Turn on the lyophilization machine by flipping the power switch and pressing the vacuum initialization button.

- After the system has reached total vacuum, click the refrigeration initialization button to begin the freeze drying process.

NOTE: It is recommended that samples be allowed to lyophilize overnight.

- Formulation of amphotericin-B (amp-B) nanodisks

- Pipette 0.45 mL of PBS to the lyophilized phospholipid aliquot and vortex for ~30 s to disperse the lipid.

NOTE: The resulting sample will appear opaque and turbid. - Pipette 50 µL of a 20 mg/mL stock ampB solution (20 mg of ampB dissolved in 1 mL of dimethyl sulfoxide [DMSO], stored at -20 °C in a closed amber vessel) into the dispersed phospholipid sample and vortex.

NOTE: When selecting a solvent to use in preparing a stock solution of the hydrophobic bioactive agent, the two overarching considerations are 1) the solubility of the bioactive agent and 2) the miscibility of the solvent with the aqueous buffer used in the formulation. While DMSO is often used15,16,17,18,19, dimethylformamide20,21 or tetrahydrofuran22 have also been successfully employed23. - Pipette 0.5 mL of apoE4-NT scaffold protein (concentration of ~4 mg/mL) to the glass test tube containing the dispersed phospholipid and ampB. The final volume of the sample should be approximately 1 mL.

- Bath sonicate the sample at 24 °C until the solution clarifies (generally 10-15 min).

- Pipette 0.45 mL of PBS to the lyophilized phospholipid aliquot and vortex for ~30 s to disperse the lipid.

- Nanodisk centrifugation

- Transfer the clarified ampB-nanodisk solution to a sterile 1.7 mL micro-centrifuge tube.

- Place the tube into a tabletop micro-centrifuge rotor with the addition of a balance tube placed directly opposite.

- Tighten the rotor cap and close the centrifuge lid.

- Program the centrifuge to spin for 10 min at ~11,000 x g using the corresponding dials located on the front of the micro-centrifuge unit.

NOTE: At this point, a pellet may be visible. This pellet consists of unincorporated phospholipid and/or ampB. - Remove the supernatant and transfer it to another clean 1.7 mL micro-centrifuge tube.

- Dialysis of ampB-nanodisk sample

- Prepare a section of dialysis tubing (dimensions of dialysis tubing used were 3 cm in length, 16 mm internal diameter, and 10,000 MWCO) by thoroughly soaking in ddi water for 10 min.

- Prepare a 1 L PBS buffer solution (10 mM sodium phosphate + 150 mM NaCl, pH 7.2) in a 1 L plastic beaker or equivalent.

- Using a dialysis tubing clamp, clamp one end of the soaked dialysis tubing, ensuring the clamp is secured and no liquid can escape.

- Insert a narrow neck funnel into the open end of the dialysis tubing and transfer the ampB-nanodisk sample into the dialysis tubing.

- Remove the funnel and clamp the end of the dialysis tubing with another dialysis tube clamp.

- Place a foam dialysis float onto one of the sealed ends of the dialysis tubing and place the assembled dialysis tubing into the beaker containing the 1 L of PBS buffer.

- Place a magnetic stir bar into the bottom of the beaker and adjust the stirring control to "low", ensuring a vortex is not formed. Allow dialysis to continue overnight at 4 °C.

3. Spectral analysis of ampB-nanodisk samples

- Spectrophotometer initialization followed by auto blank

- Turn on the spectrophotometer by flipping the power switch and connect to a corresponding support computer by pressing the button labeled "PC Control".

- On the support computer, open the software labeled "UVProbe 2.61" and connect to the spectrophotometer by clicking the button labeled "Connect" in the bottom left corner.

- Click the button labeled Spectrum on the top toolbar within the UVProbe software.

- Click the button labeled Method on the top toolbar.

- Click on the Measurement tab and input "500" into the Start textbox located under "Wavelength Range (nm)" and "300" into the "End" textbox.

- Click the drop-down menu next to the tab labeled Scan Speed and set it to Medium.

- Prepare a sample blank by transferring 1 ml of DMSO into two quartz cuvettes (QS 1.000).

- Load both cuvettes into the respective sample ports of the spectrophotometer, click Autoblank, and record a spectrum from 300-500 nm by clicking Start in the bottom left corner.

- Preparation and spectral analysis of ampB standard

- Prepare 20 µg/mL ampB standard by removing the cuvette from the front sample port and adding 20 µL of a 1 mg/mL ampB stock solution (20 µg of ampB total).

- Load the cuvette back into the sample port of the spectrophotometer and click Start to record the sample absorbance.

- Remove the cuvette from the sample port and decant the liquid contents into an appropriately labeled waste container.

- Thoroughly rinse the cuvette with three washes of deionized water followed by three washes with 70% ethanol.

- Preparation and spectral analysis of disrupted ampB-nanodisk sample

- Prepare a disrupted ampB-nanodisk sample (containing 20 µg/mL as ampB) by pipetting 20 µL of a 1 mg/mL ampB-nanodisk stock into 1 mL of DMSO. Incubate for at least 1 min prior to recording the spectrum.

- Load the cuvette into the front sample port of the spectrophotometer and click Start to record the sample absorbance.

- Preparation and spectral analysis of a PBS buffer blank

- Prepare a PBS buffer blank by transferring 1 mL of PBS buffer into two quartz cuvettes (QS 1.000).

- Load the cuvettes into the respective sample ports of the spectrophotometer, click Autoblank, and record the spectrum from 300-500 nm.

- Preparation and spectral analysis of a non-disrupted ampB-nanodisk sample

- Prepare a non-disrupted ampB-nanodisk sample (containing 20 µg/mL as ampB) by removing the cuvette from the front sample port and introducing 20 µL of a 1 mg/mL ampB-nanodisk sample into the PBS buffer.

- Load the cuvette back into the sample port of the spectrophotometer, click Start, and record the sample spectrum.

NOTE: All chemical waste should be disposed of in an appropriately labeled waste container following accepted guidelines.

4. Yeast viability assay analysis

NOTE: Yeast viability assays were performed in order to evaluate the biological activity of ampB and determine whether the process of formulation or incorporation into nanodisks, affected its yeast growth inhibition activity.

- Formulate two ampB-nanodisk samples (final volume = 1 mL) to contain 1 mg of ampB per 5 mg of DMPC and 0.1 mg of ampB per 5 mg of DMPC following the previously described method (2.3-2.4.1).

NOTE: To make a 1 mg/mL and 0.1 mg/mL ampB per 5 mg of DMPC, pipette 50 µL and 5 µL, respectively, of a 20 mg/mL ampB in DMSO stock into each sample vial. - Preparation of a saturated yeast culture

- Transfer 25 mL of sterile Yeast Extract-Peptone-Dextrose (YPD) medium into a sterile 50 mL conical tube.

- Use a sterile inoculation loop to transfer a single Saccharomyces cerevisiae (BY4741) colony into the 25 mL of YPD medium.

- Culture the yeast in a shaking incubator set at 30 °C, with oscillation set to 200 rpm for 18 h.

- Preparation of individual growth inhibition assay samples

- Transfer 5 mL of sterile YPD medium into 30 sterile 13 mL culture tubes.

- Treat three sets of culture tubes by adding 20, 10, and 5 µL of the 1 mg/mL ampB-nanodisk sample, representing 20, 10, and 5 µg of ampB, respectively.

- Treat three sets of culture tubes by adding 20, 10, and 5 µl of the 0.1 mg/mL ampB-nanodisk sample, representing 2, 1, and 0.5 µg of ampB, respectively.

- Treat four sets of culture tubes by adding 20 µL of PBS, DMSO, control rHDL (no ampB), or 20 µg of ampB in DMSO.

NOTE: Each set of culture tubes represents an independent replicate. Therefore, following this methods results in an overall n value of n = 3.

- Yeast viability assay initialization

- Initiate the experiment by inoculating each sample with 100 µL (2% vol/vol) of the saturated yeast culture

- Culture the yeast using a shaking incubator set to 30 °C, with oscillation set to 200 rpm for a maximum of 18 h.

- Yeast viability measurements

- Turn on the spectrophotometer by flipping the power switch, then click the button labeled Go To WL and set the value to 600 nm.

- Transfer 1 mL of sterile YPD medium into two plastic cuvettes, load into the respective sample ports on the spectrophotometer, and click Autoblank.

- Transfer 1 mL of each sample into a plastic cuvette, making sure to change cuvettes each time and load the cuvette into the front sample port of the spectrophotometer.

- Measure and record each sample's optical density at 600 nm and dispose of each expended cuvette into a properly labeled biohazard waste container.

Representative Results

Bioactive agent nanodisk formulation process

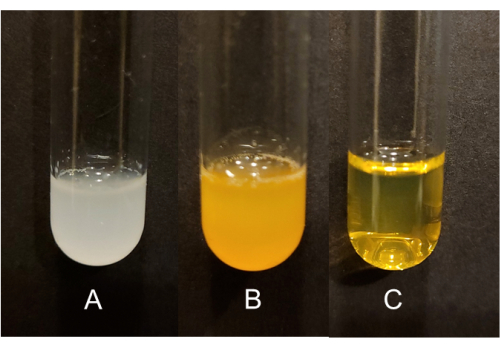

In the ampB-nanodisk formulation procedure described, the reaction is considered complete when the sample appearance transitions from turbid to clear (Figure 1). This change indicates that nanodisks have formed and that the bioactive agent has been solubilized. Oftentimes, bioactive agents absorb light in the visible wavelength region (e.g., ampB, curcumin, lutein, coenzyme Q10) and, in these cases, the sample adopts the color of the bioactive agent. Once sample clarification is complete (usually 5-20 min of bath sonication), the sample is transferred to a 1.7 ml micro-centrifuge tube and centrifuged at 11,000 x g for 5 min to pellet insoluble material. The absence of a visible pellet can be considered strong evidence that the bioactive agent has been incorporated in the nanodisks. On the other hand, the appearance of a pellet indicates that partial or no bioactive agent incorporation has occurred. If necessary or useful, control formulations containing the bilayer forming lipid and scaffold protein only can be performed in parallel, and the extent of clarification of both samples compared visually and quantitatively using a spectrophotometer. In any case, following centrifugation of a bioactive agent containing nanodisks, the sample is dialyzed against PBS, or another appropriate buffer, to remove traces of solvent.

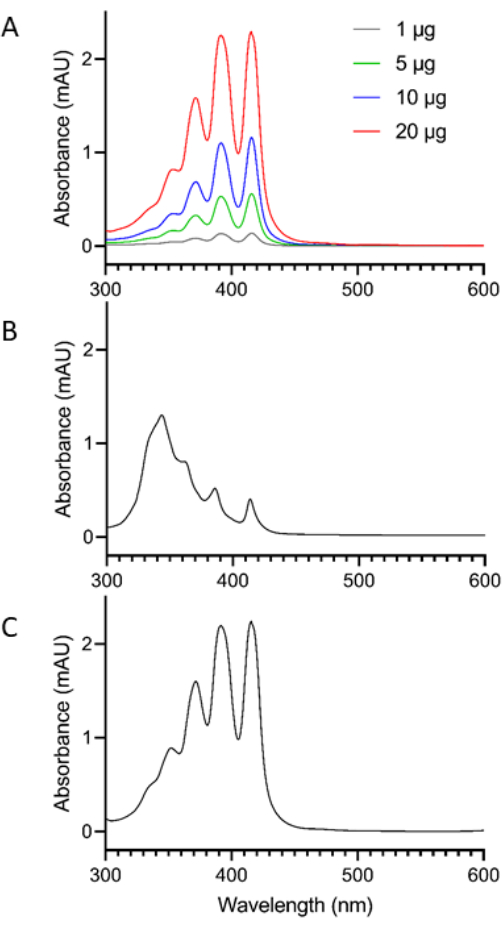

Analysis of bioactive agent solubilization efficiency

To illustrate how sample absorbance can be used to determine the solubilization efficiency, ampB-nanodisks may be used. Initially, a spectrum of ampB is collected in DMSO. This is achieved by adding 20 µL from a 1 mg/mL stock solution of ampB (in DMSO) to a cuvette containing 980 µl of DMSO. The spectrum is then recorded in the visible wavelength range from 300-500 nm on a UV/Vis spectrophotometer (Figure 2). This spectrum, obtained in DMSO solvent, yields three distinctive absorbance maxima at 372 nm, 392 nm, and 415 nm, peaks indicative of ampB. Subsequently, an absorbance spectrum of ampB-nanodisks in PBS is collected. To obtain this spectrum, 20 µL of ampB-nanodisks in PBS is added to 980 µL of PBS, and the spectrum recorded. This spectrum is expected to be quite different, with a single major absorbance peak at a shorter wavelength, from the spectrum observed in DMSO25. This result is due to the fact that, in PBS, the ampB-nanodisk particle structure remains intact, with individual ampB molecules confined and constrained to the interior of the hydrophobic milieu of the nanodisk bilayer. Because ampB molecules in the sample are in close proximity to other ampB molecules, higher order complexes/structures can form, resulting in a dramatic change in the spectral properties of ampB. To directly compare the spectra of ampB formulated into nanodisks versus stock ampB, a 20 µL aliquot of dialyzed ampB-nanodisks (in PBS) is added to 980 µL of DMSO. In this case, the DMSO solvent leads to disruption of the nanodisk particle structure, such that ampB integrated into the lipid bilayer of the nanodisk sample is liberated and becomes freely soluble in the DMSO solvent. The absorbance spectrum of this sample should appear very similar, if not identical, to the spectrum of stock ampB described above. This result provides direct evidence that ampB is present and that its chemical properties have not been altered by the process of nanodisk formulation. In this case, it is anticipated that the same three absorbance maxima will be detected.

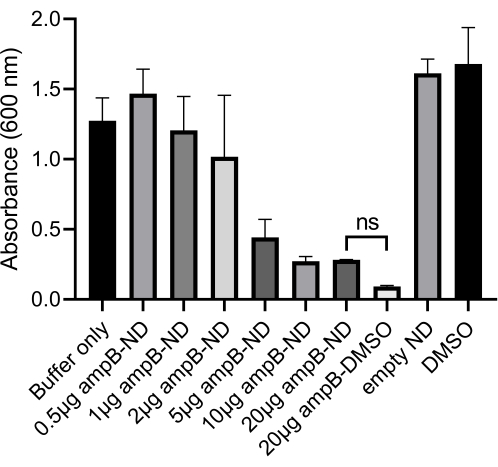

Biological activity of ampB-nanodisks

To assess the biological activity of ampB-nanodisks, yeast growth inhibition assays were performed. The yeast strain BY4741 (a descendent of S. cerevisiae S288C strain) was employed. Following treatment, the optical density of each yeast sample was measured at 600 nm on a UV-1800 UV/Vis spectrophotometer (Figure 3). The inclusion of three control samples (PBS, DMSO, and rHDL) demonstrated that nanodisk components other than ampB have no discernable effect on yeast growth. The positive control (20 µg of ampB in DMSO) confirmed that ampB is an efficient inhibitor of yeast growth. When ampB-nanodisks were tested, evidence of ampB concentration-dependent growth inhibition activity was obtained. Thus, sequestration of ampB in the lipid milieu of nanodisk particles allows for increased aqueous buffer solubility, with retention of potent biological activity.

Figure 1: Effect of bath sonication on nanodisk formulation and sample appearance. An ampB-nanodisk (ampB-ND) sample was prepared by dispersing 5 mg of DMPC in 0.75 mL of PBS, adding 1 mg of ampB to the sample from a 20 mg/mL stock solution in DMSO, followed by the addition of 2 mg of scaffold protein in 0.5 ml of PBS (from a 4 mg/ml stock solution). (A) DMPC dispersion in PBS. (B) DMPC dispersion in PBS following the addition of 1 mg of ampB. (C) nanodisk solution containing DMPC, ampB, and scaffold protein following bath sonication. Please click here to view a larger version of this figure.

Figure 2: UV/Vis absorbance spectroscopy of ampB samples. (A) ampB in DMSO. (B) ampB-nanodisks (ampB-ND) in PBS. (C) ampB-nanodisks in DMSO. Spectra were collected on a UV/Vis spectrometer. The ampB content of ampB-nanodisk samples may be determined by transferring a known aliquot to a solution of DMSO and measuring absorbance at 416 nm (ampB extinction coefficient at 416 nm = 1.24 x 105 M-1 cm-1). Please click here to view a larger version of this figure.

Figure 3: Effect of ampB on growth of S. cerevisiae. Yeast were cultured at 30 °C in the absence and presence of ampB. Control samples lacking ampB included PBS alone and rHDL. As a positive control, ampB was administered in DMSO. Test formulations included ampB-nanodisks (ampB-ND) at the indicated concentrations of ampB. Following incubation, individual sample optical density values were determined at 600 nm. Statistical significance was determined using a two-way ANOVA multiple comparison with a Tukey's post hoc test. Values reported are the mean ± standard error (n = 3), representative of three independent experiments. ns = not significant. Please click here to view a larger version of this figure.

| Bioactive agent | Molecular Weight (Da) | Solvent | Reference |

| Amphotericin B | 924.1 | DMSO | 15 |

| All-trans retinoic acid | 300.4 | DMSO | 16 |

| Curcumin | 368.4 | DMSO | 17 |

| Nutlin 3a | 581.5 | DMSO | 21 |

| Coenzyme Q10 | 863.3 | Dimethylformamide | 20 |

| Lutein | 568.9 | Tetrahydrofuran | 22 |

| Sphingadiene | 297.5 | DMSO | 19 |

| Docetaxel 1 | 807.9 | – | 23 |

| 10-hydroxycamptothecin | 364.4 | DMSO | 18 |

| Simvastatin1 | 418.5 | – | 24 |

| 1 Selected bioactive agent solvent was dried with phospholipid instead of being added to dispersed phospholipid in buffer. | |||

Table 1: Bioactive agents successfully incorporated into nanodisks.

Discussion

Formulation of a bioactive agent containing nanodisks provide a convenient method to solubilize otherwise insoluble hydrophobic compounds. Because the product bioactive agent nanodisks are fully soluble in aqueous media, they provide a useful delivery method for a wide range of hydrophobic molecules (Table 1). These include small molecules, natural and synthetic drugs, phytonutrients, hormones, etc. The formulation strategy usually follows a standard protocol that must take into consideration the solubility properties of the bioactive agent in organic solvents. In addition to selecting an appropriate organic solvent to dissolve the bioactive agent, two additional parameters, achieving an ~20 mg/ml stock solution and miscibility of the solvent with aqueous solutions, are required. This is necessary because it allows for a significant amount of bioactive agent to be added to the formulation mixture while not introducing excess organic solvent. Miscibility is important because phase separation will prevent bioactive agent incorporation into the product nanodisk.

Introducing the bioactive agent immediately following bilayer forming phospholipid dispersion in the buffer of choice allows these components to interact with one another prior to adding the scaffold protein. Prior to, and immediately following, scaffold protein addition, the sample appears as an opaque suspension. However, once the three components (phospholipid, bioactive agent, and scaffold protein, at a 5/1/2 w/w/w ratio) are added, and the sample is subjected to bath sonication at the correct temperature for a sufficient period, its appearance changes from turbid to clear. If the bioactive agent is colored, the clarified sample will take on that color. Thus, it is easy to detect nanodisk formation by visual inspection.

Although DMPC is convenient and often used as the phospholipid of choice for many applications, with certain bioactive agents, this phospholipid resists nanodisk formulation. For example, coenzyme Q10 nanodisks formed only when egg phosphatidylcholine (PC) was used19, and likewise for the xanthophyll, lutein22. Thus, whereas DMPC is oftentimes the phospholipid of choice, this is not universal. The reason why coenzyme Q10 and lutein prefer egg PC may be due to their extended hydrophobic regions, a preference for bilayers possessing unsaturated fatty acids or some other factor. When egg PC is employed, the temperature of sonication is raised to 45 °C during sonication to achieve full sample clarification. Once formulated, bioactive agent-containing nanodisks are centrifuged to remove insoluble material. It should be noted, however, that normally a precipitate does not form once optimal conditions are determined and followed. Subsequently, the sample is dialyzed against buffer overnight to remove the small amount of organic solvent that was added to the formulation mix along with the bioactive agent. Following dialysis, the product nanodisk can be stored at 4 °C for extended periods. If the incorporated bioactive agent is susceptible to oxidation, then the nanodisk sample should be stored in a closed vessel under N2 gas.

Various methods have been used to characterize and validate that nanodisks have actually formed. Perhaps the most precise method is electron microscopy26,27. This technique provides information about particle morphology, diameter, and population size heterogeneity. This method is considered definitive for nanodisk formation. A related method, atomic force microscopy, has also been used to investigate the properties of bioactive agent-containing nanodisks17,24,28. For practical purposes, however, fast protein liquid chromatography (FPLC) gel filtration chromatography is convenient and typically sufficient to characterize the size (~200,000 Da) and homogeneity of a given bioactive agent nanodisk sample20,22. Once it is determined that bioactive agent nanodisks have formed, it is also important and useful to determine the solubilization efficiency of the bioactive agent. If the bioactive agent has characteristic absorbance properties at a given wavelength, then UV/Vis absorbance spectroscopy represents a convenient method. One potentially complicating factor is scaffold protein absorbance at 280 nm. However, if a given bioactive agent absorbs at a different wavelength, then this is not a problem. If an extinction coefficient is known for the bioactive agent of interest, then it is possible to accurately determine the amount of bioactive agent solubilized in nanodisks. Otherwise, a standard curve derived from spectra of known amounts of the bioactive agent in an appropriate solvent can be used. Alternative methods include fluorescence spectroscopy17,22 or high-performance liquid chromatography (HPLC) analysis20,24.

The basic formulation process described for bioactive agent containing nanodisks is amenable to a wide range of applications. For example, nanodisks harboring contrast agents have been used in medical imaging studies to diagnose and assess the progression of disease29. Another approach is to integrate lipid modified proteins into the bilayer of nanodisks. For example, Lalefar et al. successfully incorporated the "Wnt" protein into nanodisks via insertion of its covalently bound oleic acid moiety30. Wnt nanodisks were subsequently shown to constitute a water soluble Wnt transport vehicle capable of promoting ex vivo expansion of hematopoietic stem cells. In another study, Crosby et al. constructed a scaffold protein chimera comprised of apoA-I fused to a single chain variable antibody fragment (scFv) directed against the B cell surface antigen CD2031. Subsequent formulation of curcumin nanodisks with α-CD20 scFv·apoA-I as the scaffold component conferred targeting to B cells, thereby enhancing bioactive agent delivery. This strategy provides a novel approach to minimize toxicity associated with chemotherapeutic agents by directing them specifically to the target cell type. In another example, the synthetic cationic lipid 1,2-dimyristoyl-3-trimethylammonium-propane chloride (DMTAP) was incorporated into the bilayer of nanodisks32. This formulation strategy effectively conferred positive charge character to the nanodisk bilayer surface and, thereby, promoted a stable binding interaction with short interfering (si) RNA. siRNA-enriched DMTAP-nanodisks were then shown to possess biological activity in target gene knockdown studies. In yet another example, nanodisks have been formulated with cardiolipin as the sole phospholipid component. This unique anionic glycerophospholipid is known to bind various ligands, including the divalent mineral calcium, the hemoprotein cytochrome c, the anthracycline anti-cancer agent doxorubicin, and others33,34,35,36. Cardiolipin nanodisks have been used to characterize these binding interactions in detail by taking advantage of the solubility properties of nanodisks, their nanoscale size, and the presence of an accessible cardiolipin bilayer8. Based on these, and other applications, it is evident that nanodisk technology is a versatile platform for a multitude of applications.

Divulgazioni

The authors have nothing to disclose.

Acknowledgements

This work was supported by a grant from the National Institutes of Health (R37 HL-64159).

Materials

| Amphotericin B | Cayman Chemical Company | 11636 | ND Formulation & Standard Preparation |

| Ampicillin | Fisher Scientific | BP17925 | Transformation & Expansion |

| ApoE4-NT Plasmid | GenScript | N/A | Transformation |

| Baffled Flask | New Brunswick Scientific | N/A | Expansion & Expression |

| BL21 competent E coli | New England Biolabs | C2527I | Transformation |

| Centrifuge bottles | Nalgene | 3140-0250 | Expression |

| Chloroform | Fisher Scientific | G607-4 | ND Formulation |

| DMSO | Sigma Aldrich | 472301 | Standard Prepartation |

| Dymyristoylphosphatidylcholine | Avanti Lipids | 850345P | ND Formulation |

| Erlenmeyer flask | Bellco Biotechnology | N/A | Expansion & Expression |

| Falcon Tubes | Sarstedt Ag & Co | D51588 | Yeast Viability Assay |

| Glass borosilicate tubes | VWR | 47729-570 | ND Formulation |

| GraphPad (Software) | Dotmatics | N/A | Yeast Viability Assay |

| Heated Sonication Bath | VWR | N/A | ND Formulaton |

| Heating and Nitrogen module | Thermo Scientific | TS-18822 | ND Formulation |

| HiTrap Heparin HP (5 mL) | GE Healthcare | 17-0407-03 | Purification |

| Isopropyl β-D-1-thiogalactopyranoside | Fisher Scientific | BP1755 | Expression |

| J-25 Centrifuge | Beckman Coulter | J325-IM-2 | Expression |

| JA-14 Rotor | Beckman Coulter | 339247 | Expression |

| Lyophilizer | Labconco | 7755030 | ND Formulation |

| Methanol | Fisher Scientific | A452-4 | ND Formulation |

| Nitrogen gas | Praxair | UN1066 | ND Formulation |

| NZCYM media | RPI Research Products | N7200-1000.0 | Expansion & Expression |

| Pet-22B vector | GenScript | N/A | Transformation |

| Petri dish | Fisher Scientific | FB0875718 | Transformation & Expansion |

| Quartz Cuvettes | Fisher Brand | 14385 928A | Spectral Analysis |

| Shaking Incubator | New Brunswick Scientific | M1344-0004 | Transformation, Expansion, & Expression |

| Slide-A-Lyzer Buoys | Thermo Scientific | 66430 | Purification |

| SnakeSkin Dialysis Tubing | Thermo Scientific | 68100 | Purification |

| SnakeSkin Dialysis Tubing | Thermo Scientific | 88243 | Purification |

| Sodium Chloride | Fisher Scientific | S271 | Purification |

| Sodium Phosphate dibasic | Fisher Scientific | S374-500 | Purification |

| Sodium Phosphate monobasic | Fisher Scientific | BP329-500 | Purification |

| Spectra/POR Weighted Closures | Spectrum Medical Industries | 132736 | Purification |

| Spectrophotometer | Shimadzu UV-1800 | 220-92961-01 | spectral analysis |

| Tabletop Centrifuge | Beckman Coulter | 366816 | ND Formulation |

| UVProbe 2.61 (Software) | Shimadzu | N/A | Spectral Analysis |

| Vacuum filter | Millipore | 9004-70-0 | Expression & Purification |

| Vacuum pump | GAST Manufacturing Inc | DOA-P704-AA | Expression & Purification |

| Vortex | Fisher Scientific | 12-812 | ND Formulation |

| Yeast | N/A | BY4741 | Yeast Viability Assay |

| Yeast Extract-Peptone-Dextrose | BD | 242820 | Yeast Viability Assay |

Riferimenti

- Fox, C. A., Moschetti, A., Ryan, R. O. Reconstituted HDL as a therapeutic delivery device. Biochimica et Biophysica Acta. Molecular and Cell Biology of Lipids. 1866 (11), 159025 (2021).

- Ong, K. L., Cochran, B. J., Manandhar, B., Thomas, S., Rye, K. A. HDL maturation and remodelling. Biochimica et Biophysica Acta. Molecular and Cell Biology of Lipids. 1867 (4), 159119 (2022).

- Nicholls, S. J., et al. Effect of serial infusions of CER-001, a pre-β high-density lipoprotein mimetic, on coronary atherosclerosis in patients following acute coronary syndromes in the CER-001 Atherosclerosis Regression Acute Coronary Syndrome Trial: a randomized clinical trial. JAMA Cardiology. 3 (9), 815-822 (2018).

- Kingwell, B. A., Chapman, M. J., Kontush, A., Miller, N. E. HDL-targeted therapies: progress, failures and future. Nature Reviews Drug Discovery. 13 (6), 445-464 (2014).

- Denisov, I. G., Sligar, S. G. Nanodiscs for structural and functional studies of membrane proteins. Nature Structure & Molecular Biology. 23 (6), 481-486 (2016).

- Hoel, C. M., Zhang, L., Brohawn, S. G. Structure of the GOLD-domain seven-transmembrane helix protein family member TMEM87A. eLife. 11, e81704 (2022).

- Pérez-Medina, C., et al. PET imaging of tumor-associated macrophages with 89Zr-labeled high-density lipoprotein nanoparticles. Journal of Nuclear Medicine. 56 (8), 1272-1277 (2015).

- Fox, C. A., Ryan, R. O. Studies of the cardiolipin interactome. Progress in Lipid Research. 88, 101195 (2022).

- Ryan, R. O., Forte, T. M., Oda, M. N. Optimized bacterial expression of human apolipoprotein A-I. Protein Expression and Purification. 27 (1), 98-103 (2003).

- Argyri, L., Skamnaki, V., Stratikos, E., Chroni, A. A simple approach for human recombinant apolipoprotein E4 expression and purification. Protein Expression and Purification. 79 (2), 251-257 (2011).

- Lethcoe, K., Fox, C. A., Ryan, R. O. Foam fractionation of a recombinant biosurfactant apolipoprotein. Journal of Biotechnology. 343, 25-31 (2022).

- Fisher, C. A., et al. Bacterial overexpression, isotope enrichment, and NMR analysis of the N-terminal domain of human apolipoprotein E. Biochemistry and Cell Biology. 75 (1), 45-53 (1997).

- Jonas, A. Reconstitution of high-density lipoproteins. Methods in Enzymology. 128, 553-582 (1986).

- Ryan, R. O. Nanodisks: hydrophobic drug delivery vehicles. Expert Opinion on Drug Delivery. 5 (3), 343-351 (2008).

- Oda, M. N., et al. Reconstituted high density lipoprotein enriched with the polyene antibiotic amphotericin B. Journal of Lipid Research. 47 (2), 260-267 (2006).

- Redmond, K. A., Nguyen, T. S., Ryan, R. O. All-trans-retinoic acid nanodisks. International Journal of Pharmaceutics. 339 (1-2), 246-250 (2007).

- Ghosh, M., et al. Curcumin nanodisks: formulation and characterization. Nanomedicine. 7 (2), 162-167 (2011).

- Yuan, Y., et al. Synthetic high-density lipoproteins for delivery of 10-hydroxycamptothecin. International Journal of Nanomedicine. 11, 6229-6238 (2016).

- Zhao, P., et al. Sphingadienes show therapeutic efficacy in neuroblastoma in vitro and in vivo by targeting the AKT signaling pathway. Investigational New Drugs. 36 (5), 743-754 (2018).

- Moschetti, A., et al. Assembly and characterization of biocompatible coenzyme Q10 enriched lipid nanoparticles. Lipids. 55 (2), 141-149 (2020).

- Krishnamoorthy, A., Witkowski, A., Ryan, R. O. Nutlin-3a nanodisks induce p53 stabilization and apoptosis in a subset of cultured glioblastoma cells. Journal of Nanomedicine and Nanotechnology. 8 (4), 454 (2017).

- Moschetti, A., Fox, C. A., McGowen, S., Ryan, R. O. Lutein nanodisks protect retinal pigment epithelial cells from UV light induced damage. Frontiers in Nanotechnology. 4, 955022 (2022).

- Scheetz, L. M., et al. Synthetic HDL nanoparticles delivering docetaxel and CpG for chemoimmunotherapy of colon adenocarcinoma. International Journal of Molecular Sciences. 21 (5), 1777 (2020).

- Duivenvoorden, R., et al. A statin-loaded reconstituted high-density lipoprotein nanoparticle inhibits atherosclerotic plaque inflammation. Nature Communications. 5, 3065 (2014).

- Hargreaves, P. L., Nguyen, T. S., Ryan, R. O. Spectroscopic studies of amphotericin B solubilized in nanoscale bilayer membranes. Biochimica et Biophysica Acta. 1758 (1), 38-44 (2006).

- Tufteland, M., Pesavento, J. B., Bermingham, R. L., Hoeprich Jr, P. D., Ryan, R. O. Peptide stabilized amphotericin B nanodisks. Peptides. 28 (4), 741-746 (2007).

- Tufteland, M., Ren, G., Ryan, R. O. Nanodisks derived from amphotericin B lipid complex. Journal of Pharmaceutical Sciences. 97 (10), 4425-4432 (2008).

- Nguyen, T. S., et al. Amphotericin B induces interdigitation of apolipoprotein stabilized nanodisk bilayers. Biochimica et Biophysica Acta. 1778 (1), 303-312 (2008).

- Ryan, R. O. Nanobiotechnology applications of reconstituted high density lipoprotein. Journal of Nanobiotechnology. 8, 28 (2010).

- Lalefar, N. R., Witkowski, A., Simonsen, J. B., Ryan, R. O. Wnt3a nanodisks promote ex vivo expansion of hematopoietic stem and progenitor cells. Journal of Nanobiotechnology. 14 (1), 66 (2016).

- Crosby, N. M., et al. Anti-CD20 single chain variable antibody fragment-apolipoprotein A-I chimera containing nanodisks promote targeted bioactive agent delivery to CD20-positive lymphomas. Biochemistry and Cell Biology. 93 (4), 343-350 (2015).

- Ghosh, M., Ren, G., Simonsen, J. B., Ryan, R. O. Cationic lipid nanodisks as an siRNA delivery vehicle. Biochemistry and Cell Biology. 92 (3), 200-205 (2014).

- Fox, C. A., Ellison, P., Ikon, N., Ryan, R. O. Calcium-induced transformation of cardiolipin nanodisks. Biochimica et Biophysica Acta. Biomembranes. 1861 (5), 1030-1036 (2019).

- Fox, C. A., Lethcoe, K., Ryan, R. O. Calcium-induced release of cytochrome c from cardiolipin nanodisks: Implications for apoptosis. Biochimica et Biophysica Acta Biomembranes. 1861 (12), 183722 (2021).

- Fox, C. A., Ryan, R. O. Dye binding assay reveals doxorubicin preference for DNA versus cardiolipin. Analytical Biochemistry. 594, 113617 (2020).

- Fox, C. A., Romenskaia, I., Dagda, R. K., Ryan, R. O. Cardiolipin nanodisks confer protection against doxorubicin-induced mitochondrial dysfunction. Biochimica et Biophysica Acta Biomembranes. 1864 (10), 183984 (2022).