Préparation du liquide-exfoliée métal de transition dichalcogénure nanofeuillets avec Controlled Taille et Epaisseur: Un État du Protocole d'Art

Summary

A protocol for the liquid exfoliation of layered materials to nanosheets, their size selection and size measurement by microscopic and spectroscopic techniques is presented.

Abstract

We summarize recent advances in the production of liquid-exfoliated transition metal dichalcogenide (TMD) nanosheets with controlled size and thickness. Layered crystals of molybdenum disulphide (MoS2) and tungsten disulphide (WS2) are exfoliated in aqueous surfactant solution by sonication. This yields highly polydisperse mixtures containing nanosheets with broad size and thickness distributions. However, for most purposes, specific sizes (in terms of both lateral dimension and thickness) are required. For example, large and thin nanosheets are desired for (opto) electronic applications, while laterally small nanosheets are interesting for catalytic applications. Therefore, post-exfoliation size selection is an important step that we address here. We provide a detailed protocol on the efficient size selection in large quantities by liquid cascade centrifugation and the size and thickness quantification by statistical microscopic analysis (atomic force microscopy and transmission electron microscopy). The comparison of MoS2 and WS2 shows that both materials are size-selected in a similar way by the same procedure. Importantly, the dispersions of size-selected nanosheets show systematic changes in their optical extinction spectra with size due to edge and confinement effects. We show how these optical changes are related quantitatively to the nanosheets dimensions and describe how mean nanosheets length and layer number can be extracted reliably from the extinction spectra. The exfoliation and size selection protocol can be applied to a broad range of layered crystals as we have previously demonstrated for graphene, gallium sulphide (GaS) and black phosphorus.

Introduction

The possibility to produce and process graphene, related two-dimensional (2D) crystals in the liquid phase makes them promising materials for an ever growing range of applications as composite materials, sensors, in energy storage and conversion and flexible (opto) electronics.1-6 To exploit 2D nanomaterials within applications such as these will require inexpensive and reliable functional inks with on-demand lateral size and thickness of the nanoscale constituents, as well as controlled rheological and morphological properties amenable to industrial-scale printing/coating processes.7 In this regard, liquid phase exfoliation has become an important production technique giving access to a whole host of nanostructures in large quantities.6,8,9 This method involves the sonication or shearing of layered crystals in liquids. If the liquid is appropriately chosen (i.e., suitable solvents or surfactant) the nanosheets will be stabilized against reaggregation. Numerous applications and proof-of-principle devices have been demonstrated by such techniques.6 Probably the greatest strength of this strategy is its versatility, as numerous layered parent crystals can be exfoliated and processed in a similar way, providing access to a broad palette of materials which can be tailored to the desired application.

However, despite this recent progress, the resultant polydispersity that arises due to these liquid-phase production methods (in terms of nanosheet length and thickness) still presents a bottleneck in the realization of high performance devices. This is mostly because the development of novel and innovative size selection techniques has thus far required nanosheets length and thickness characterization using tedious statistical microscopy (atomic force microscopy, AFM and/or transmission electron microscopy, TEM).

Despite these challenges, several centrifugation techniques have been reported to achieve length and thickness sorting.6,10-13 The simplest scenario is homogeneous centrifugation, where the dispersion is centrifuged at a given centrifugal acceleration and the supernatant is decanted for analysis. The centrifugation speed sets the size cut-off, whereby the higher the speed, the smaller are the nanosheets in the supernatant. However, this technique suffers from two major disadvantages; firstly, when larger nanosheets are to be selected (i.e., the dispersion is centrifuged at low speeds and the supernatant is decanted) all smaller nanosheets will also remain in the sample. Secondly, regardless of the centrifugation speed, a significant proportion of the material tends to be wasted in the sediment.

An alternative strategy for size selection is density gradient (or isopycnic) centrifugation.11,14 In this case, the dispersion is injected into a centrifuge tube containing a density gradient medium. During ultracentrifugation (typically > 200,000 x g), a density gradient is formed and the nanosheets move to the point in the centrifuge where their buoyant density (density including the stabilizer and solvent shell) matches the density of the gradient. Note that the nanomaterial can also move upward during this process (depending on where it was injected). In such a way, the nanosheets are effectively sorted by thickness rather than mass (opposed to homogeneous centrifugation). While this procedure offers a unique opportunity to sort nanosheets by thickness, it suffers from notable disadvantages. For example, the yields are very low and at present do not allow for the mass production of separated nanosheets. This is partly related to low contents of monolayers in stock dispersions after liquid-exfoliation and can potentially be improved by optimizing exfoliation procedures in the future. In addition, it is typically a time-consuming multi-step ultracentrifugation process involving multiple iterations to achieve efficient size selection. Furthermore, in the case of inorganic nanomaterials, it is restricted to polymer-stabilized dispersions to obtain the required buoyant densities and the gradient medium in the dispersion may interfere with further processing.

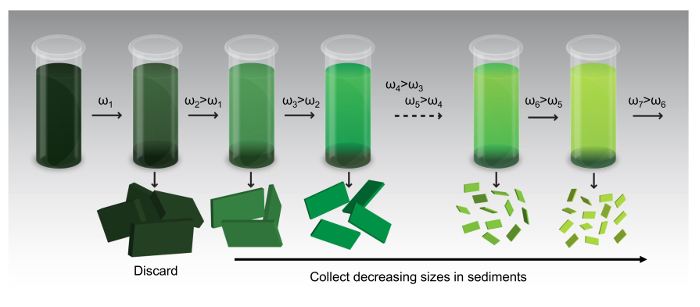

We have recently shown that a procedure we term liquid cascade centrifugation (LCC) offers an exciting alternative,13 as we will also detail in this manuscript. This is a multi-step procedure which is extremely versatile allowing various cascades to be designed according to the desired outcome. To demonstrate this process, a standard cascade is portrayed in Figure 1 and involves multiple centrifugation steps whereby each features a higher speed than the last. After each step, the sediment is retained and the supernatant is then used in the proceeding stage. As a result, each sediment contains nanosheets in a given size range which have been "trapped" between two centrifugations with different speeds; the lower one removing larger nanosheets into the previous sediment while the higher speed removes the smaller nanosheets into the supernatant. Critical to LCC, the resulting sediment can be redispersed completely by mild sonication in the respective medium, which in this case is aqueous sodium cholate H2O-SC (at SC concentrations as low as 0.1 g L-1). The result is dispersions with virtually any chosen concentration. Importantly, virtually no material is wasted in LCC, resulting in the collection of relatively large masses of size-selected nanosheets. As shown here, we have applied this procedure to a number of liquid-exfoliated nanosheets including MoS2 and WS2 as well as GaS,15 black phosphorus16 and graphene17 in both solvent and surfactant systems.

This unique centrifugation procedure enables the efficient size-selection of liquid exfoliated nanosheets and has subsequently enabled a significant advancement in terms of their size and thickness determination. In particular, through this approach we demonstrated previously that optical extinction (and absorbance) spectra of the nanosheets change systematically as function of both nanosheets lateral dimensions and nanosheets thickness. As we summarize here, this has allowed us to link the nanosheet spectral profile (specifically the intensity ratio at two positions of the extinction spectrum) to the mean nanosheet length as a result of nanosheet edge effects.12,13 Importantly, the same equation can be used to quantify the size of MoS2 and WS2. Furthermore, we show that the A-exciton position shifts towards lower wavelengths as a function of mean nanosheet thickness due to confinement effects. Even though exfoliation, as well as size selection and determination are in general rather robust procedures, the quantitative outcome depends on subtleties in the protocol. However, especially for newcomers to the field, it is difficult to judge which process parameters are most relevant. This comes down to the fact that experimental sections of research papers only provide a rough protocol, without discussing what outcome is to be expected when modifying the procedure or giving a rational behind the protocol. In this contribution, we intend to address this as well as provide a detailed guide and discussion to the production of liquid-exfoliated nanosheets of controlled size and to the accurate determination of size by either statistical microscopy or analysis of the extinction spectra. We are convinced that this will help to improve reproducibility and hope it will be a useful guide for other experimentalists in this research area.

Figure 1: Schematic of the size selection by liquid cascade centrifugation. Size-selected nanosheets are collected as sediments. Each sediment is collected or "trapped" between two centrifugation speeds (ω) starting from low speeds and going to higher ones from step to step. The sediment discarded after the first centrifugation contains unexfoliated layered crystallites while the supernatant discarded after the last centrifugation step contains extremely small nanosheets. Size-selected dispersions are prepared by re-dispersing the collected sediments in the same medium (here aqueous surfactant solution) at reduced volumes. Adapted with permission from 13. Please click here to view a larger version of this figure.

Protocol

Representative Results

Discussion

Sample preparation

The samples described here are produced by tip sonication. Alternative exfoliation procedures can be used, but will lead to different concentrations, lateral sizes and degrees of exfoliation. Higher amplitudes and longer on pulses during the sonication should be avoided to prevent damaging of the sonicator. Similar results were obtained using 500 W processors. However, sonication time and amplitude has an impact on the nanosheet exfoliation and variations from this protocol may…

Disclosures

The authors have nothing to disclose.

Acknowledgements

The research leading to these results has received funding from the European Union Seventh Framework Program under grant agreement n°604391 Graphene Flagship. C.B. acknowledges the German Research Foundation, DFG, under grant BA 4856/2-1.

Materials

| Sodium cholate hydrate, from ox and/or sheep bile | Sigma Aldrich | C1254-100G | Surfactant used as stabilizer in the form of an aqueous solution (i.e. after dissolving the powder in millipore water) |

| MoS2 powder | Sigma Aldrich | 69860-100G | Other distributors available, but exfoliation and outcome of size selection can vary |

| WS2, powder 2 um | Sigma Aldrich | 243639-50G | Other distributors available, but exfoliation and outcome of size selection can vary |

| ImageJ Software | Developer: National Insitutes of Health | 64-bit Java version 2.45 1.6.0_24 | Image processing software used for TEM analysis, free download |

| Gwyddion Software | Developer: Czech Metrology Institute | 64-bit Java version 2.45 | Image processing software used for AFM analysis, free download |

| Origin Pro Software | OriginLab | Version 2016 | Software used for data analysis such as differntiation and fitting of the extinction spectra |

| Centrifuge | HettichLab | Mikro 220R | any other benchtop centrifuge is suitable |

| Rotor 1 | Hettich | Rotor 1016 | for centrifugation < 5000 x g |

| Rotor 2 | Hettich | Rotor 1195-A | for centrifugation > 5000 x g |

References

- Zhang, H. Ultrathin Two-Dimensional Nanomaterials. ACS Nano. 9, 9451-9469 (2015).

- Yi, M., Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mat. Chem. A. 3, 11700-11715 (2015).

- Jariwala, D., Sangwan, V. K., Lauhon, L. J., Marks, T. J., Hersam, M. C. Emerging Device Applications for Semiconducting Two-Dimensional Transition Metal Dichalcogenides. ACS Nano. 8, 1102-1120 (2014).

- Nicolosi, V., Chhowalla, M., Kanatzidis, M. G., Strano, M. S., Coleman, J. N. Liquid Exfoliation of Layered Materials. Science. 340, 1420 (2013).

- Butler, S. Z., et al. Progress, Challenges, and Opportunities in Two-Dimensional Materials Beyond Graphene. ACS Nano. 7, 2898-2926 (2013).

- Bonaccorso, F., Bartolotta, A., Coleman, J. N., Backes, C. Two-dimensional crystals-based functional inks. Adv. Mater. , (2016).

- Torrisi, F., Coleman, J. N. Electrifying inks with 2D materials. Nat. Nanotechnol. 9, 738-739 (2014).

- Coleman, J. N., et al. Two-Dimensional Nanosheets Produced by Liquid Exfoliation of Layered Materials. Science. 331, 568-571 (2011).

- Smith, R. J., et al. Large-Scale Exfoliation of Inorganic Layered Compounds in Aqueous Surfactant Solutions. Adv. Mater. 23, 3944-3948 (2011).

- Khan, U., O’Neill, A., Porwal, H., May, P., Nawaz, K., Coleman, J. N. Size selection of dispersed, exfoliated graphene flakes by controlled centrifugation. Carbon. 50, 470-475 (2012).

- Kang, J., Seo, J. -. W. T., Alducin, D., Ponce, A., Yacaman, M. J., Hersam, M. C. Thickness sorting of two-dimensional transition metal dichalcogenides via copolymer-assisted density gradient ultracentrifugation. Nat. Commun. 5, 5478 (2014).

- Backes, C., et al. Edge and Confinement Effects Allow in situ Measurement of Size and Thickness of Liquid-Exfoliated Nanosheets. Nat. Commun. 5, 4576 (2014).

- Backes, C., et al. Production of Highly Monolayer Enriched Dispersions of Liquid-Exfoliated Nanosheets by Liquid Cascade Centrifugation. ACS Nano. 10, 1589-1601 (2016).

- Green, A. A., Hersam, M. C. Solution Phase Production of Graphene with Controlled Thickness via Density Differentiation. Nano Lett. 9, 4031-4036 (2009).

- Harvey, A., et al. Preparation of Gallium Sulfide Nanosheets by Liquid Exfoliation and Their Application As Hydrogen Evolution Catalysts. Chem. Mater. 27, 3483-3493 (2015).

- Hanlon, D., et al. Liquid Exfoliation of Solvent-Stabilised Few-Layer Black Phosphorus for Applications Beyond Electronics. Nat. Commun. 6, 8563 (2015).

- Backes, C., et al. Spectroscopic metrics allow in-situ measurement of mean size and thickness of liquid-exfoliated few-layered graphene nanosheets. Nanoscale. 8, 4311-4323 (2016).

- Ridings, C., Warr, G. G., Andersson, G. G. Composition of the outermost layer and concentration depth profiles of ammonium nitrate ionic liquid surfaces. Phys. Chem. Chem. Phys. 14, 16088-16095 (2012).

- Nemes-Incze, P., Osváth, Z., Kamarás, K., Biró, L. P. Anomalies in thickness measurements of graphene and few layer graphite crystals by tapping mode atomic force microscopy. Carbon. 46, 1435-1442 (2008).

- Paton, K. R., et al. Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nat. Mater. 13, 624-630 (2014).

- Novoselov, K. S., et al. Two-dimensional atomic crystals. Proc. Nat. Ac. Sci. U. S. 102, 10451-10453 (2005).

- Kouroupis-Agalou, K., et al. . Nanoscale. 6, 5926-5933 (2014).

- Hanlon, D., et al. Production of Molybdenum Trioxide Nanosheets by Liquid Exfoliation and Their Application in High-Performance Supercapacitors. Chem. Mater. 26, 1751-1763 (2014).

- Yadgarov, L., et al. Dependence of the Absorption and Optical Surface Plasmon Scattering of MoS2 Nanoparticles on Aspect Ratio, Size, and Media. ACS Nano. 8, 3575-3583 (2014).

- Wilson, J. A., Yoffe, A. D. Transition metal dichalcogenides. Discussion and interpretation of the observed optical, electrical, and structural properties. Adv. Phys. 18, 193-335 (1969).