无约束和封闭表面活性剂中球形粒子沉降速度的实验测量 剪切变薄粘性流体

Summary

本文演示了测量表面活性切变粘液中球形粒子终端沉降速度的实验过程。准备了各种风湿特性的流体,并测量了平行壁之间无边界流体和流体中一系列粒子大小的沉降速度。

Abstract

进行了一项实验性研究,以测量基于表面活性剂的剪切变薄粘性 (VES) 流体中球形粒子的终端沉降速度。测量是针对在平行墙体和平行墙之间的无边界流体和流体中沉淀的粒子进行测量的。VES 流体具有广泛的风湿特性,具有风湿学特征。风湿特征包括稳定的剪切粘度和动态振荡切变测量,分别量化粘度和弹性特性。在无限制条件下的沉降速度以直径至少是颗粒直径25倍的烧嘴来测量。为了测量平行墙之间的沉降速度,构建了两个具有不同墙间距的实验单元。不同大小的球形粒子被轻轻地掉入流体中,并允许沉降。该过程使用高分辨率摄像机进行记录,粒子轨迹使用图像分析软件进行记录。终端沉降速度是根据数据计算的。

通过比较实验沉降速度与 Renaud 等人的无弹性阻力预测计算的沉降速度,可以量化弹性对无边界流体沉降速度的影响 。1结果表明,流体的弹性可以增加或降低沉降速度。减少/增加的幅度是流体的流变特性和粒子特性的函数。观察到封闭壁对沉降造成延缓效应,并根据墙体因素测量阻滞。

Introduction

在药物制造、废水处理、空间推进剂再注入、半导体加工和液体洗涤剂制造等应用中,液体颗粒的悬浮。在石油工业中,粘性压裂液用于在液压断裂中运输质子(通常是砂)。停止抽水后,前体保持断裂打开,并为碳氢化合物回流提供导电途径。

粒子的沉降受流体的流变学和密度、颗粒的大小、形状和密度以及密闭壁的影响的制约。对于在蠕变流系中沉淀在牛顿流体中的球形粒子,沉降速度由斯托克斯方程给出,斯托克斯于 1851 年得出。在随后的研究人员2-6中提出了计算高雷诺兹数字阻力的表达方式。封闭壁通过对粒子施加阻滞作用来降低沉降速度。墙体因子 ,Fw,被定义为在无限制条件下将墙限制在沉降速度的终端沉降速度比率。墙系数量化了密闭墙的阻滞效应。文献7-13提供了许多理论和实验研究,以确定在不同断面管中以不同断面管中沉淀的球体的壁因子。总之,有大量的信息可用于确定牛顿流体中球体的阻力。

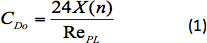

过去关于确定非内托输液中颗粒的沉降速度的工作,特别是粘性流体,并不完整。各种数值预测14-18和实验研究19-24可用于文献,以确定在无弹性功率定律流体的球体上的阻力。使用特里帕蒂等人的理论预测。15和特里帕蒂和查布拉17日,雷纳德等人。1开发以下表达式以计算无弹性功率定律流体中的阻力系数(CD)。

对于重新pl<0.1 (爬行流系统)

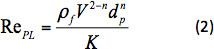

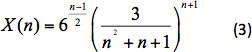

其中 X(n) 是拖动校正因子13。RePL是属于权力法液体中的球体的雷诺兹数字,定义为:

其中ρ f是液体的密度。拖动校正因子安装下列方程1:

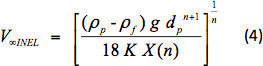

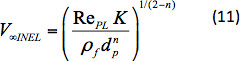

使用拖动系数的定义,将沉降速度计算为:

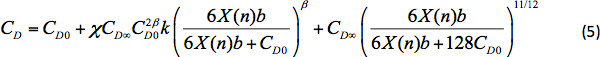

对于 0.1<RePL<100

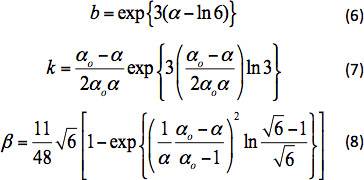

其中 X是表面积与粒子预测面积的比率,球体等于 4。CD0是方程 1给出的斯托克斯区域(rePL < 0.1)的阻力系数,C D∞是牛顿区域的拖动系数值(rePL > 5 x 102),等于 0.44。参数β,b,k表示为:

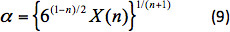

αo = 3 和 α 是与 X(n) 相关的平均剪切率的修正如下:

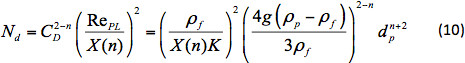

要计算沉降速度,使用无维组Nd 25:

Nd 独立于沉降速度,可以明确计算。使用这个值和 方程5中的阻力系数表达,可以反复解决RePL。 然后,可以使用:

方程1-9中的表达基于对值1≥n≥0.4的理论预测。 查布拉13日将上述表述的预测与沙阿26-27(n变化为0.281-0.762)和福特等人的实验结果进行了比较。 28 (n变化从 0.06-0.29).这些表达式被证明能够准确预测阻力系数。基于这些分析,上述配方可用于计算无弹性功率定律流体中球形粒子的沉降速度为 1 ≥ n ≥ 0.06。将无弹性功率定律流体的沉降速度与功率定粘液中的实验速度进行比较,以确定流体弹性对沉降速度的影响。下一节中提到了详细的步骤。

测定粘胶液中颗粒的沉降速度也是不同研究人员不同观测的课题:(一) 在爬行流系中,剪切变薄效应完全掩盖粘性效应和沉降速度与纯粘性理论29-32非常一致,(ii) 粒子在爬行流系内外经历阻力减少,由于弹性30,33,34而沉降速度增加,(iii) 沉降速度因流体弹性35而降低。沃尔特斯和坦纳36 总结说,对于博格流体(恒定粘度弹性流体)弹性导致低威森博格数字的阻力减少,其次是在较高的魏森博格数字的阻力增强。麦金利37 强调,球体后的延伸效应导致威森伯格数字的阻力增加。Chhabra13 在对先前在无限制和密闭粘性流体中沉降粒子的工作进行了全面回顾后,强调了在理论发展中结合切变率依赖粘度和流体弹性的现实描述的挑战。在过去几年中,对球形粒子沉降的壁效应的研究也是研究的一个领域。然而,所有的工作都完成了球形粒子在圆柱形管中的沉降。没有关于球形粒子在平行墙体之间沉淀在粘性流体中的数据。

这项工作试图实验研究球体在剪切稀释粘性液体中的沉降。这项实验研究的目的是了解流体弹性、剪切变薄和墙体密闭对剪切稀释粘液中球形粒子沉降速度的影响。本文重点介绍了本研究的实验方法以及一些具有代表性的结果。详细的结果,连同分析,可以在较早的出版物43中找到。

Protocol

Representative Results

Discussion

实验研究的重点是在未受约束和封闭的条件下,测量剪切稀释粘性流体中球形粒子的沉降速度。介绍了详细的实验程序,以获得可重复测量的沉降速度。结果表明,流体弹性可以增加或降低沉降速度。墙体对沉降产生延缓效应,这种效应是用墙体因素来衡量的。

在实验之前,应确保粒子接近表面光滑的完美球体。球体的直径应准确测量。实验过程,包括图像分析,应该通过?…

Disclosures

The authors have nothing to disclose.

Acknowledgements

作者感谢美国能源部和RPSEA的财政支持,以及赞助德克萨斯大学奥斯汀分校水力压裂和防沙的JIP的公司(液体空气、空气产品、阿纳达科、阿帕奇、贝克休斯、必和必拓、英国石油公司美国公司、雪佛龙公司、康菲石油公司、埃克森美孚公司、费鲁斯公司、哈里伯顿公司、赫斯公司、林德集团公司、佩梅克斯公司、先锋自然资源公司),普拉克斯尔,沙特阿美,斯伦贝谢,壳牌,西南能源,挪威国家石油公司,韦瑟福德和YPF)。

Materials

| Name of the reagent / equipment | Company | Catalogue number | Comments |

| Glass Microspheres | Whitehouse Scientific | #GP1750 | Available in different sieve fractions. |

| Rheometer | TA Instruments | ARES | Any standard rheometer capable of taking dynamic and static measurements |

| Anionic Surfactant (Component A) | Proprietary fluid | Used in oil field services for hydraulic fracturing. Sodium Xylene Sulfonate can be used as a substitute. | |

| Cationic Surfactant (Component B) | Proprietary fluid | Used in oil field services for hydraulic fractuing. N,N,N-Trimethyl-1-Octadecamonium Chloride can be used as a substitute. |

References

- Renaud, M., Mauret, E., Chhabra, R. P. Power-law fluid flow over a sphere: average shear rate and drag. 82, 1066-1070 (2004).

- Clift, R., Grace, J. R., Weber, M. E. . Bubbles, Drops and Particles. , (1978).

- Khan, A. R., Richardson, J. F. The resistance to motion of a solid sphere in a fluid. Chem. Eng. Sci. 62, 135-150 (1987).

- Zapryanov, Z., Tabakova, S. . Dynamics of Bubbles, Drops and Rigid Particles. , (1999).

- Michaelides, E. E., DeKee, D., Chhabra, R. P. Chapter 2. Analytical expressions for the motion of particles. Transport Processes in Bubbles Drops and Particles. , (2002).

- Michaelides, E. E. Hydrodynamic force and heat/mass transfer from particles, bubbles and drops – the Freeman Scholar Lecture. Journal of Fluids Engineering (AMSE. 125, 209-238 (2003).

- Der Faxen, H. Widerstand gegen die Bewegung einer starren Kugel in einer zähen Flüssigkeit, die zwischen zwei parallelen ebenen Wänden eingeschlossen ist). Annalen der Physics. 68, 89-119 (1922).

- Bohlin, T. On the drag on a sphere moving in a viscous fluid inside a cylindrical tube. Trans Royal Insitute of Technology Stockholm. 155, (1960).

- Miyamura, A., Iwasaki, S., Ishii, T. Experimental wall correction factors of single solid spheres in triangular and square cylinders, and parallel plates. International Journal of Multiphase Flow. 7, 41-46 (1981).

- Tullock, D. L., Phan-Thien, N., Graham, A. L. Boundary element simulations of spheres settling in circular, square and triangular ducts. Rheol. Acta. 31, 139-150 (1992).

- Chhabra, R. P. Wall effects on terminal velocity of non-spherical particles in non-Newtonian polymer solutions. Powder Technology. 88, 39-44 (1996).

- Chhabra, R. P., Dekes, D., Chhabra, R. P. Chapter 2. Wall effects on spheres falling axially in cylindrical tubes. Transport Processes in Bubbles Drops and Particles. , (2002).

- Chhabra, R. P., Francis, S. e. c. o. n. d. e. d. .. ,. T. a. y. l. o. r. &. a. m. p. ;. . Bubbles, Drops, and Particles in Non-Newtonian Fluids. , (2007).

- Dazhi, G., Tanner, R. I. The drag on a sphere in a power law fluid. Journal of Non-Newtonian Fluid Mechanics. 17, 1-12 (1984).

- Tripathi, A., Chhabra, R. P., Sundararajan, T. Power-law fluid over spheroidal particles. Industrial & Engineering Chemistry Research. 33, 403-410 (1994).

- Graham, D. I., Jones, T. E. R. Settling and transport of spherical particles in power-law fluids at finite Reynolds number. Journal of Non-Newtonian Fluid Mechanics. 54, 465-488 (1994).

- Tripathi, A., Chhabra, R. P. Drag on spheroidal particles in dilatant fluids. AIChE. 41 (3), 728-731 (1995).

- Missirlis, K. A., Assimacopoulos, D., Mitsoulis, E., Chhabra, R. P. Wall effects for motion of spheres in power-law fluids. Journal of Non-Newtonian Fluid Mechanics. 96 (3), 459-471 (2001).

- Dallon, D. S. . A drag coefficient correlation for spheres settling in Ellis fluids [Ph.D. Dissertation]. , (1967).

- Uhlherr, P. H. T., Le, T. N., Tiu, C. Characterization of inelastic power-law fluids using falling sphere data. Canadian Journal of Chemical Engineering. 54, 497-502 (1976).

- Machac, I., Lecjaks, Z. Wall Effect for a Sphere Falling Through a Non-Newtonian Fluid in a Rectangular Duct. Chemical Engineering Science. 50 (1), 143-148 (1995).

- Kelessidis, V. C., Mpandelis, G. Measurements and prediction of terminal velocity of solid particles falling through stagnant pseudoplastic liquids. Powder Technology. 147, 117-125 (2004).

- Shah, S. N., Fadili, Y. E., Chhabra, R. P. New model for single spherical particle settling velocity in power law (visco-inelastic) fluids. International Journal of Multiphase Flow. 33, 51-66 (2007).

- Rodrigue, D., DeKee, D., Chan Man Fong, C. F. The slow motion of a spherical particle in a Carreau fluid. Chemical Engineering Communications. 154, 203-215 (1996).

- Darby, R. . Chemical Engineering Fluid Mechanics. , (2001).

- Shah, S. N. Proppant settling correlations for non-Newtonian fluids. Society of Petroleum Engineers Journal. 22 (2), 164-170 (1982).

- Shah, S. N. Proppant-settling correlations for non-Newtonian Fluids. Society of Petroleum Engineers Production Engineering Journal. 1 (6), 446-448 (1986).

- Ford, J. T., Oyeneyin, M. B., et al. The formulation of milling fluids for efficient hole cleaning: an experimental investigation. Paper SPE 38819. , (1994).

- Acharya, A., Mashelkar, R. A., Ulbrecht, J. Flow of inelastic and viscoelastic fluids past a sphere, Part II: Anomalous separation in the viscoelastic fluid flow. Rheological Acta. 15, 471-478 (1976).

- Acharya, A. R. Viscoelasticity of crosslinked fracturing fluids and proppant transport. SPE Production Engineering. 3, 483-488 (1988).

- Chhabra, R. P., Uhlherr, P. H. T. Creeping motion of spheres through shear-thinning elastic fluids described by the Carreau viscosity equation. Rheological Acta. 19 (2), 187-195 (1980).

- Bush, M. B., Phan-Thien, N. Drag force on a sphere in creeping motion through a Carreau model fluid. Journal of Non-Newtonian Fluid Mechanics. 16 (3), 303-313 (1984).

- Broadbent, J. M., Mena, B. Slow flow of an elastico-viscous fluid past cylinders and spheres. Chemical Engineering Journal. 8, 11-19 (1974).

- Sigli, D., Coutanceau, M. Effect of finite boundaries on the slow laminar isothermal flow of a viscoelastic fluid around a spherical obstacle. Journal of Non-Newtonian Fluid Mechanics. 2, 1-21 (1977).

- Brule, B. H. A. A. V. D., Gheissary, G. Effects of fluid elasticity on the static and dynamic settling of a spherical particle. Journal of Non-Newtonian Fluid Mechanics. 49, 123-132 (1993).

- Walters, K., Tanner, R. I., Chhabra, R. P. . D. e. K. e. e. ,. D. .. ,., DeKee, D. Chapter 3. The Motion of a Sphere through an Elastic Fluid.. Transport Processes in Bubbles, Drops and Particles. , (1992).

- McKinley, G. H., DeKee, D., Chhabra, R. P. Chapter 14. Steady and transient motion of spherical particles in viscoelastic liquids. Transport Processes in Bubbles, Drops and Particles. , (2002).

- Chhabra, R. P., Tiu, C., Uhlherr, P. H. T. A study of wall effects on the motion of a sphere in viscoelastic fluids. Canadian Journal of Chemical Engineering. 59, 771-775 (1981).

- Jones, W. M., Price, A. H., Walters, K. The motion of a sphere falling under gravity in a constant viscosity elastic liquid. Journal of Non-Newtonian Fluid Mechanics. 53, 175-196 (1994).

- Navez, V., Walters, K. A note on settling in shear-thinning polymer solutions. Journal of Non-Newtonian Fluid Mechanics. 67, 325-334 (1996).

- Huang, P. Y., Wall Feng, J. effects on the flow of viscoelastic fluids around a circular cylinder. Journal of Non-Newtonian Fluid Mechanics. 60, 179-198 (1995).

- Sugeng, F., Tanner, R. I. The drag on spheres in viscoelastic fluids with significant wall effects. Journal of Non-Newtonian Fluid Mechanics. 20, 281-292 (1986).

- Malhotra, S., Sharma, M. M. Settling of Spherical Particles in Unbounded and Confined Surfactant-Based Shear Thinning Viscoelastic Fluids: An Experimental Study. Chemical Engineering Science. 84, 646-655 (2012).

- Zhang, K. Fluids for Fracturing Subterranean Formations.U.S. US patent. , (2002).

- Gupta, D. V. S., Leshchyshyn, T. T., Hlidek, B. T. Surfactant gel foam/emulsions: History and field application in the western Canadian sedimentary basin. , (2005).

- Ferry, J. D. . Viscoelastic Properties of Polymers. , (1970).

- Yesilata, B., Clasen, C., McKinley, G. H. Nonlinear shear and extensional Flow dynamics of wormlike surfactant solutions. Journal of Non-Newtonian Fluid Mechanics. 133, 73-90 (2006).